Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Fiber degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for the development of ruminant feed formulations

ActiveUS20050000457A1Improve energy efficiencyDegree of rate and extent of digestionAnimal feeding devicesAnimal feeding stuffRuminant animalAgricultural science

A method that accounts for environmental factors by measuring the starch and fiber degradation characteristics of a variety of genetically different crop plants and grain from crop plants in real time to determine how the crop plants should be conserved, processed and blended into a feed formulation that results in optimum productivity of the ruminant animal. A method further including determining starch digestibility characteristics of a set of crop plant samples comprising grain of said crop plant; developing a prediction equation based on said starch digestibility characteristics, obtaining a grain sample from a crop plant, determining in real time starch digestibility characteristics by NIRS of said sample by inputting data from said NIRS into said equation, storing and / or milling said grain on an identity preserved basis, and determining the amount of said crop plant to incorporate into a feed formulation based on the starch digestibility characteristics.

Owner:LAND O'LAKES +1

Method of producing filamentous fungus culture product

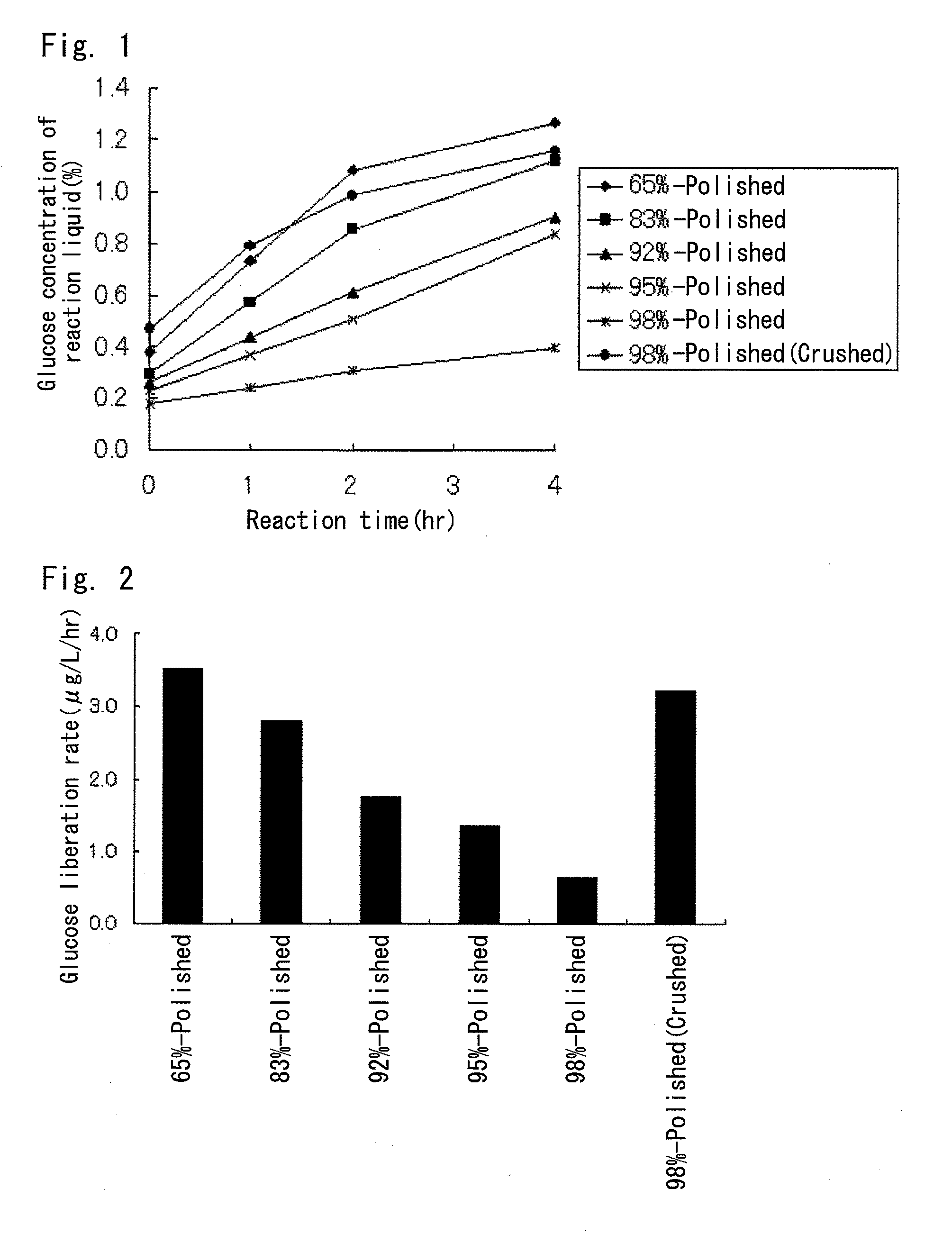

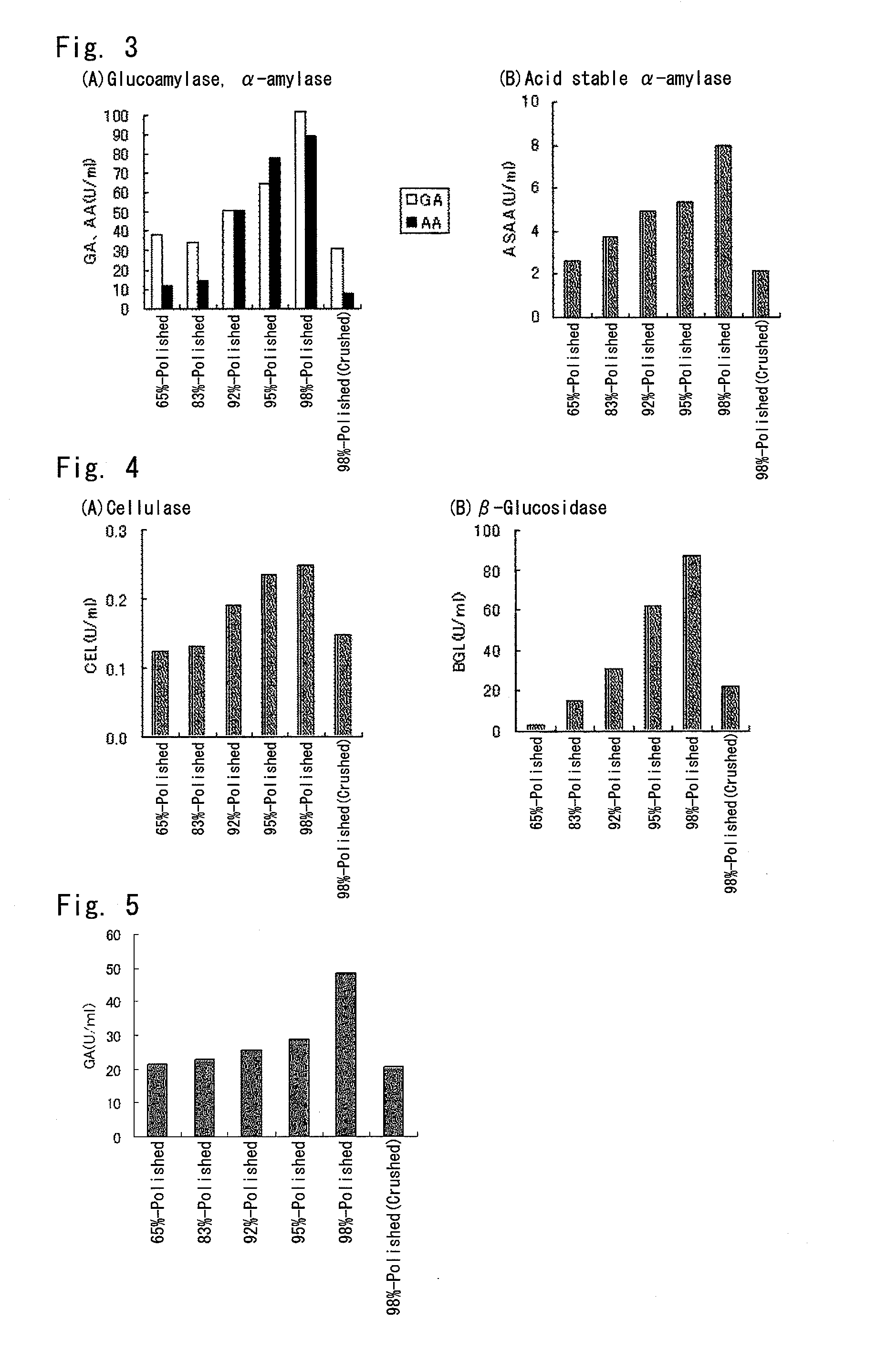

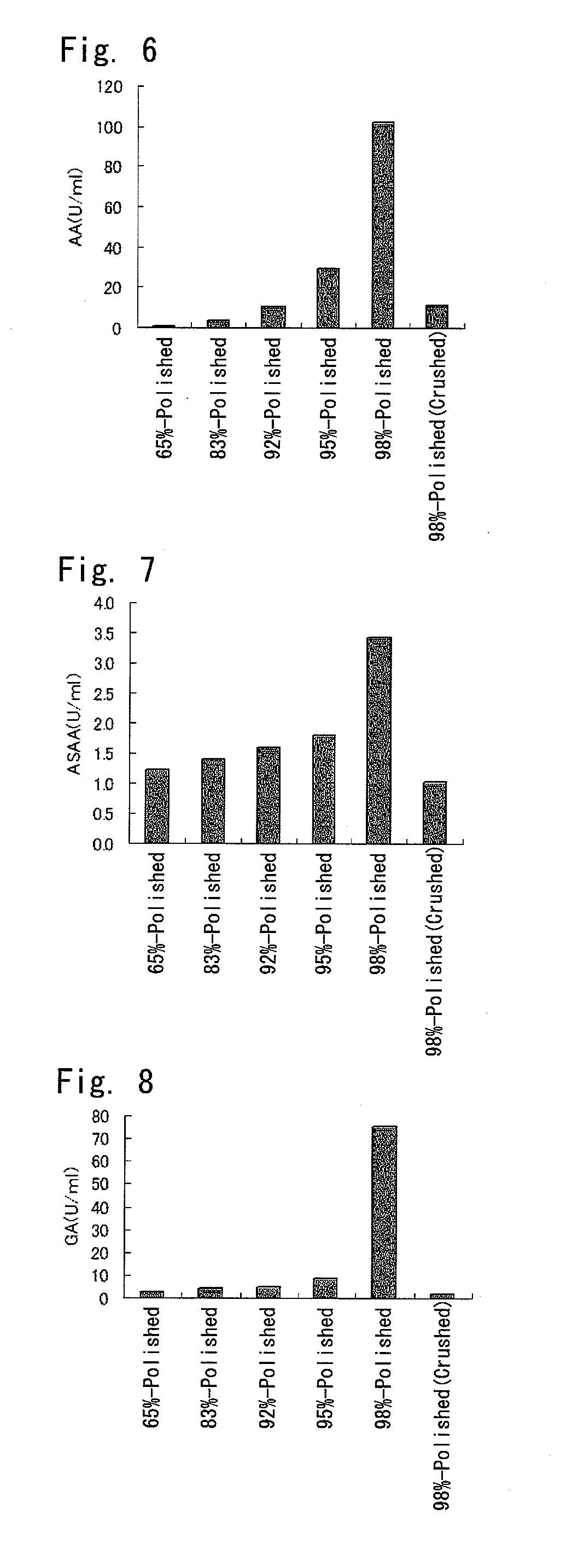

InactiveUS20090280212A1Lower levelEnzymatic productivity is adjustedMilk preparationFungiBiotechnologyLiquid medium

It is an object of the present invention to provide a method of adjusting productivity of enzymes, in particular, amylolytic enzymes, plant fiber degradation enzymes and proteolytic enzymes in a filamentous fungus culture product, by controlling releasing rate of nutrients from the culture raw material into the culture system when a filamentous fungus culture product is produced by culturing filamentous fungi in liquid medium containing as the culture raw material at least one selected from the group consisting of cereals, beans, tubers, amaranthus and quinoa. The present invention provides a method of producing filamentous fungus culture product by using liquid medium containing as culture raw material at least one selected from the group consisting of cereals, beans, tubers, amaranthus and quinoa comprising, culturing filamentous fungi while releasing rate of nutrients from the culture raw material into the culture system is controlled to adjust productivity of enzymes in the filamentous fungus culture product.

Owner:ASAHI BREWERIES LTD

Method for the development of ruminant feed formulations

ActiveUS7174672B2Improve energy efficiencyAnimal feeding stuffAnimal housingRuminant animalAgricultural science

A method that accounts for environmental factors by measuring the starch and fiber degradation characteristics of a variety of genetically different crop plants and grain from crop plants in real time to determine how the crop plants should be conserved, processed and blended into a feed formulation that results in optimum productivity of the ruminant animal. A method further including determining starch digestibility characteristics of a set of crop plant samples comprising grain of said crop plant; developing a prediction equation based on said starch digestibility characteristics, obtaining a grain sample from a crop plant, determining in real time starch digestibility characteristics by NIRS of said sample by inputting data from said NIRS into said equation, storing and / or milling said grain on an identity preserved basis, and determining the amount of said crop plant to incorporate into a feed formulation based on the starch digestibility characteristics.

Owner:LAND O'LAKES +1

Anti-adhesion biological membrane and preparation method thereof

ActiveCN103405811AGood biocompatibilityGood physical barrier anti-adhesion effectSurgeryLight whitePharmaceutical Substances

The invention provides an anti-adhesion biological membrane and a preparation method thereof. The anti-adhesion biological membrane is a dry membrane which is formed by SIS (styrene isoprene styrene block copolymer) as a support material, compound hyaluronic acid, functional proteins and anti-inflammotary medicines. The anti-adhesion biological membrane is semi-transparent from light white to faint yellow. The thickness of the anti-adhesion biological membrane is 0.01-0.5mm. Compared with the prior art, the anti-adhesion biological membrane has very good biocompatibility, good physical barrier anti-adhesion effect and the effects of resisting inflammatory, stopping bleeding and promoting fiber degradation. The effects of the anti-adhesion biological membrane are obviously superior to those of existing anti-adhesion biological membrane products. Animal experiments prove that the effective rate of the anti-adhesion biological membrane prepared by the method for preventing the adhesion after abdominal surgery reaches above 90%, the effective rate for preventing the adhesion after pelvic cavity surgery reaches above 80%, and the effective rate for preventing the adhesion after tendon surgery reaches above 70%.

Owner:XIAN TISSUE ENG & REGENERATIVE MEDICINE RES INST

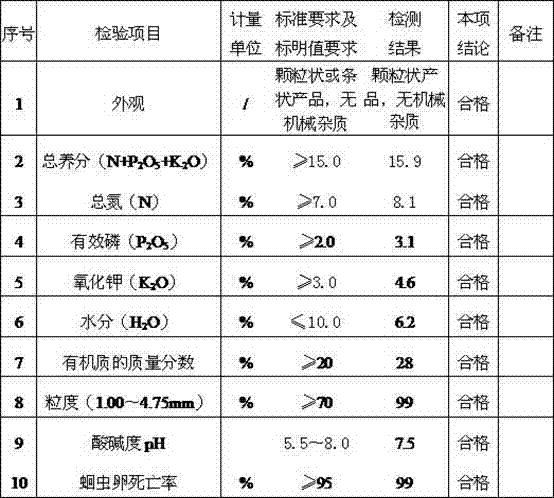

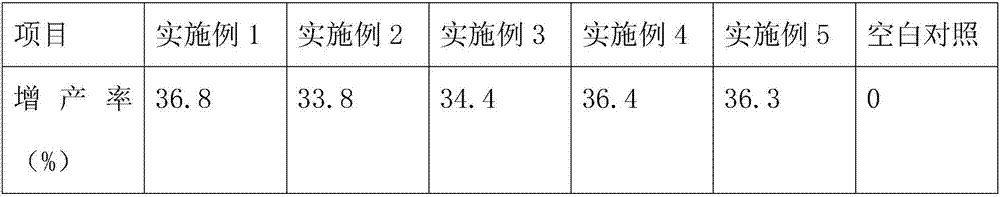

Organic-inorganic compound fertilizer produced by fermented material of traditional Chinese medicine decoction dregs and method thereof

InactiveCN102731195AMeet the design requirementsModernize operationsBio-organic fraction processingOrganic fertiliser preparationAdditive ingredientPhosphate

The invention relates to an organic-inorganic compound fertilizer which is produced by fermented material of traditional Chinese medicine decoction dregs and a method of the organic-inorganic compound fertilizer. The traditional Chinese medicine decoction dregs are taken as the main material; crude fiber degradation bacteria, turf or other plant fibers are added properly after drying and wetting processing for mixed retting fermentation to obtain semi-finished products of organic fertilizer of fermented material of traditional Chinese decoction dregs; monoammonium phosphate, ammonium sulfate, potassium chloride or potassium sulfate are added according to the needed content of nitrogen, phosphorus and potassium; and the materials are mixed evenly, pelleted and dried to obtain the finished product fertilizer. The fertilizer contains organic materials and inorganic materials of nitrogen, phosphorus and potassium and the content of the organic materials is more than 20%; nitrogen, phosphorus and potassium are rich in nutrient and the total nutrient content is more than 15%, so that the products are characterized by comprehensive nutritional ingredient, good effect, no pollution and the like. Fermented material of traditional Chinese medicine decoction dregs is adopted to produce the organic-inorganic compound fertilizer provided by the invention, so that the pollution to the environment by the decoction dregs is eliminated and the waste is recycled to realize the benefit of comprehensive development of environment friendliness, energy and fertilizer.

Owner:GUANGDONG FUERKANG CHEM TECH

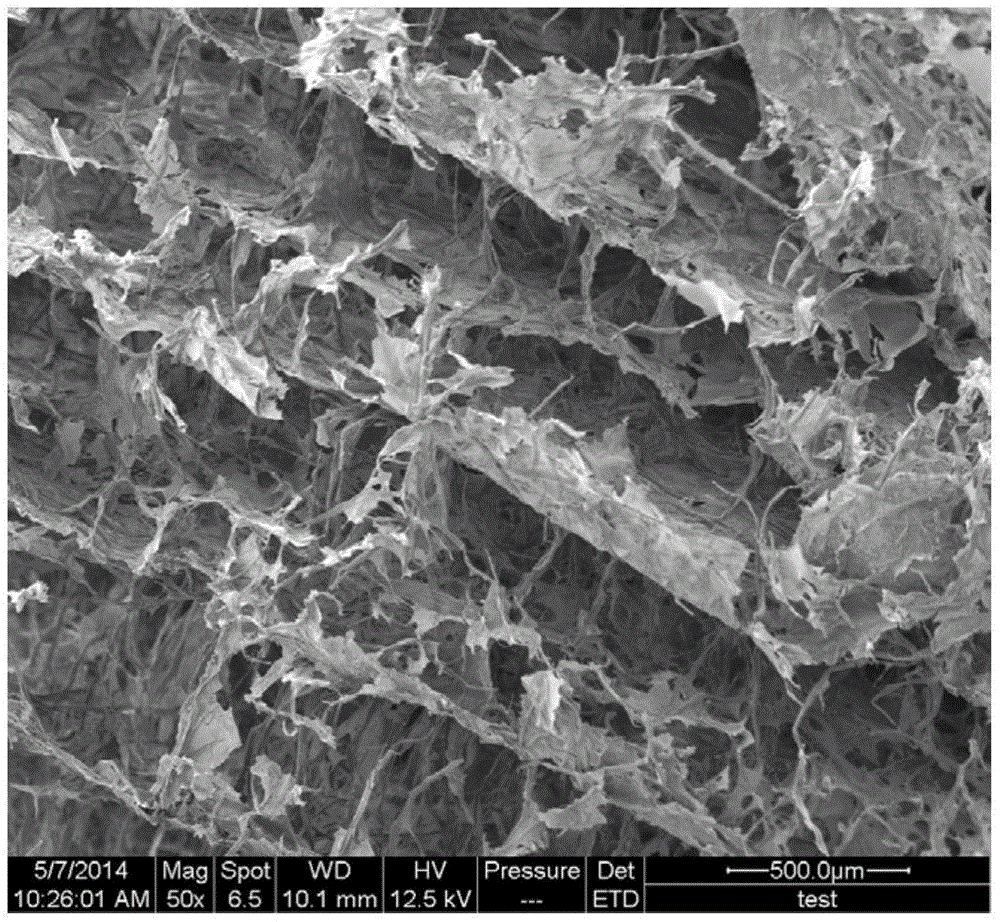

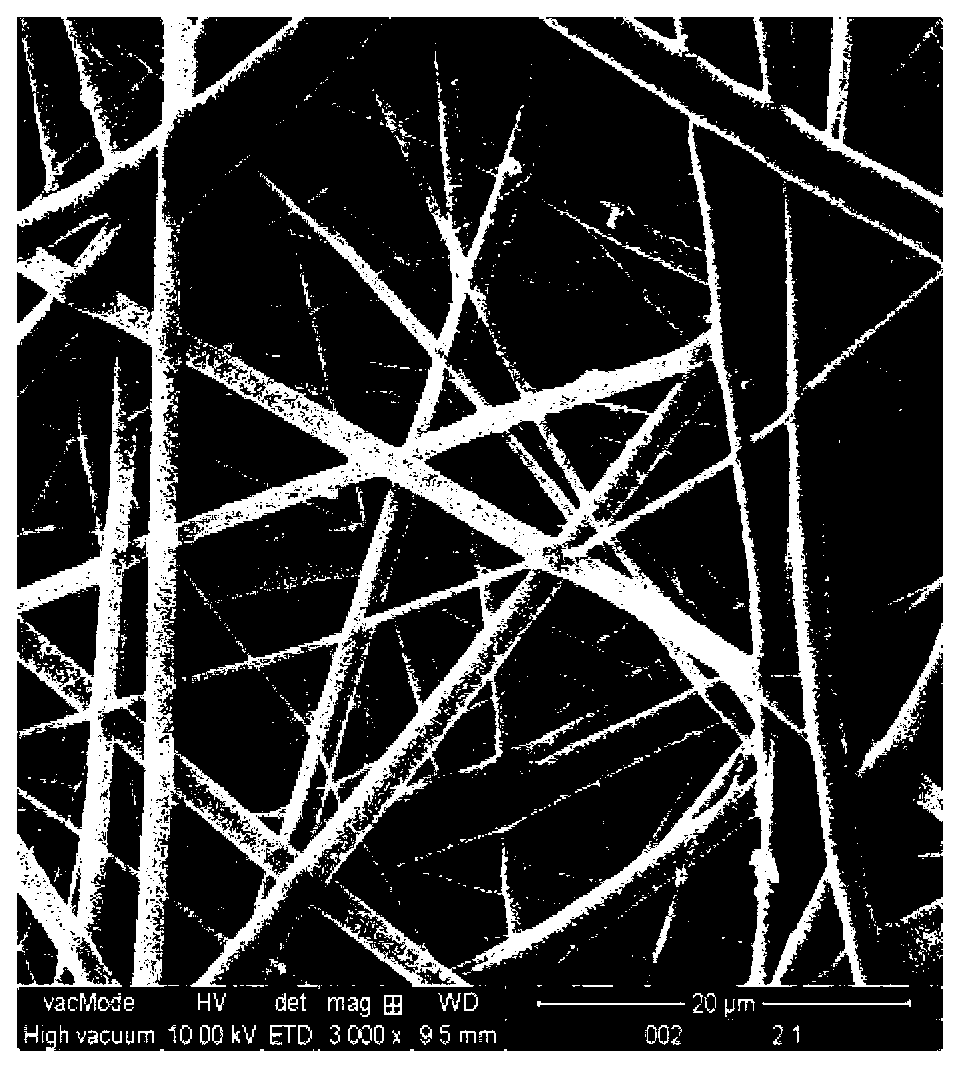

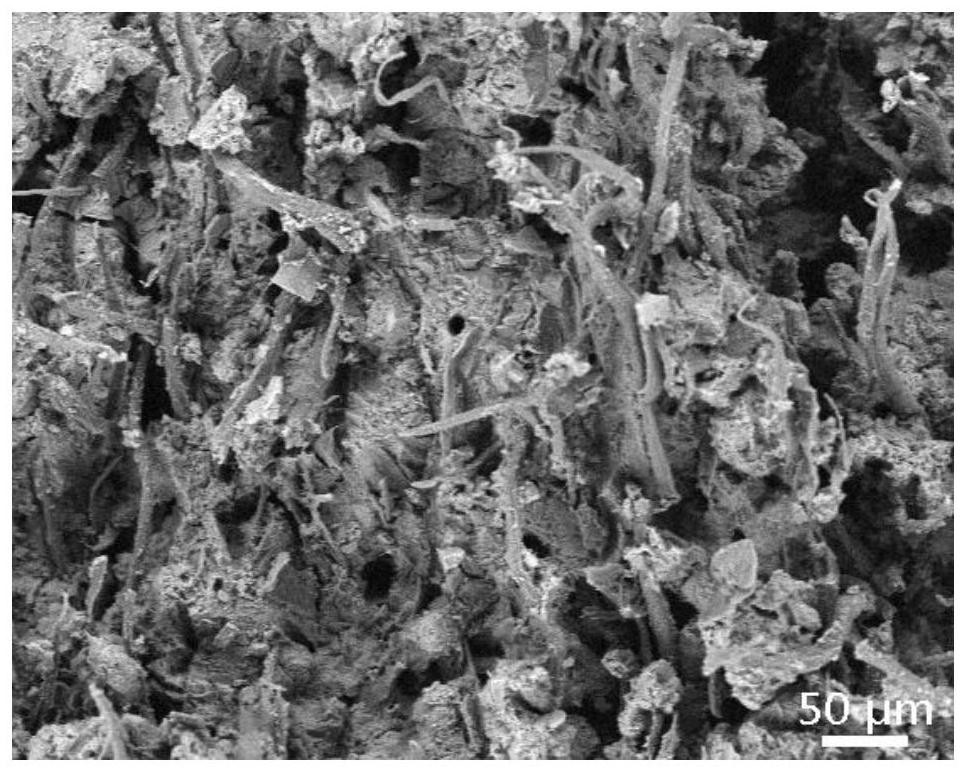

Preparation method of nano cellulose/chitosan composite foam

The invention discloses a preparation method of nano cellulose / chitosan composite foam, relates to the field of cellulose composite materials, and aims at solving the problems of poor biocompatibility of traditional materials such as foam and aerogel and low thermostability of a chitosan composite material. The preparation method of the composite foam comprises the following steps: 1 carrying out chemical treatment and mechanical fiber degradation treatment on a biomass material containing cellulose to prepare a nano cellulose turbid liquid; 2 adding chitosan to an acetic acid glacial solution to prepare a chitosan mixed liquid; 3 mixing the nano cellulose turbid liquid with the chitosan mixed liquid to obtain a nano cellulose / chitosan composite liquid; 4 carrying out low-temperature freezing treatment on the composite liquid; and 5 carrying out drying treatment on the frozen mixed liquid to obtain the nano cellulose / chitosan composite foam. The used raw materials are natural high polymer materials, so that the nano cellulose / chitosan composite foam is good in biocompatibility, low in thermal volume shrinkage rate and good in heat stability.

Owner:NORTHEAST FORESTRY UNIVERSITY

Composite microbial preparation as well as preparation method and application thereof

The invention discloses a composite microbial preparation as well as a preparation method and an application thereof. The composite microbial preparation comprises Bacillus subtilis, Lactobacillus plantarum and Saccharomyces cerevisiae. The composite microbial preparation is used for fermentation process of microbial silage forage, and can be used for effectively improving fiber degradation rate and biotransformation rate of the forage, improving NDF digestibility, increasing crude protein content, inhibiting breeding of harmful bacterium, and shortening fermentation period with wide application prospects and market values.

Owner:TIANJIN BIOFEED TECH CO LTD

Process for producing organic fertilizers with fruit residues as main material

InactiveCN106631399ATake advantage ofRich in nutrientsCalcareous fertilisersBio-organic fraction processingGrowth plantMixed materials

The invention discloses a process for producing organic fertilizers with fruit residues as a main material. The process includes steps: using a grinder for grinding fruit peels into 1-2cm fruit residues, adding a deodorizing agent, and completely mixing to obtain mixed material powder; grinding organic auxiliary materials by the grinder to obtain organic auxiliary material mixed powder; well stirring the mixed material powder and the organic auxiliary material mixed powder, adding activated coarse fiber degradation complex bacteria, stacking for ridging, and covering with straw mats to realize coarse fiber degradation; adding a composting complex bacterium expanding culture agent, and spreading a small quantity of pesticides; spreading out for airing after turning, measuring the moisture content, allowing fermented materials to enter a finished product workshop, and performing grinding, stirring, screening and packaging to obtain finished products of the organic fertilizers with fruit residues. The process has advantages that waste orange peel residues are made into the organic fertilizers through harmless biological fermentation, and the biological organic fertilizers meeting plant growth can be obtained by conversion after fermentation; since the raw materials are all recovered materials, environmental friendliness is achieved.

Owner:东兴易新环保科技有限公司

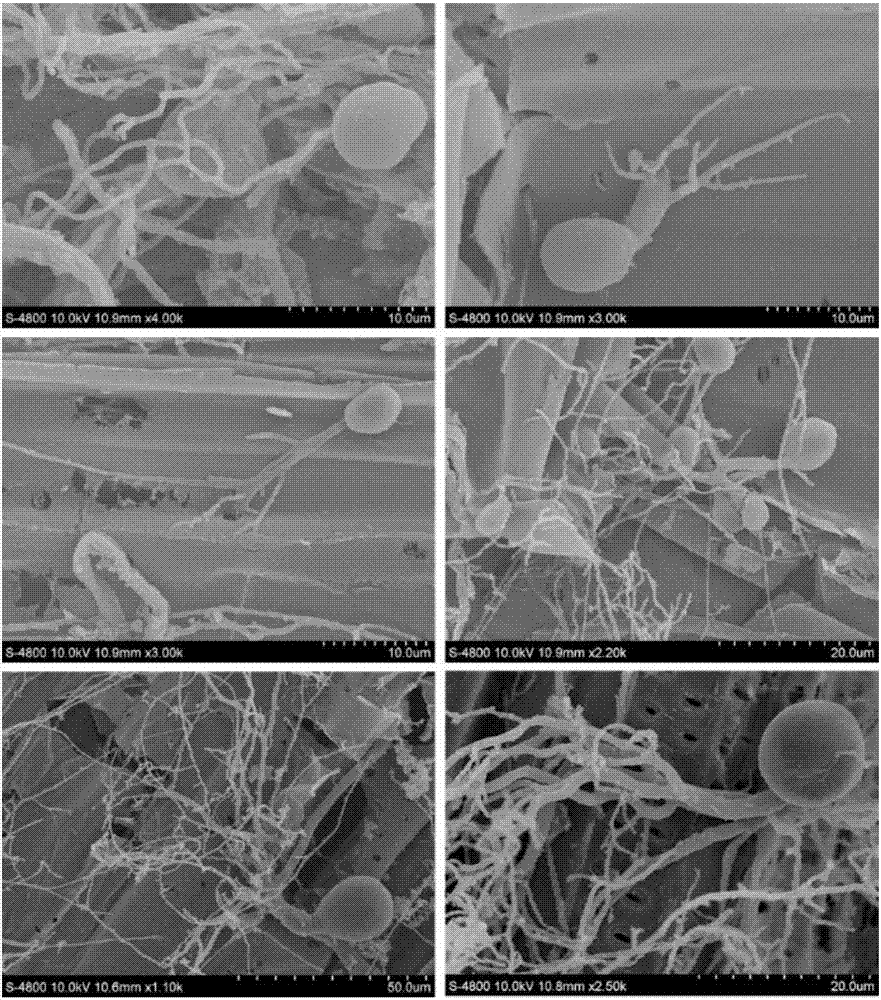

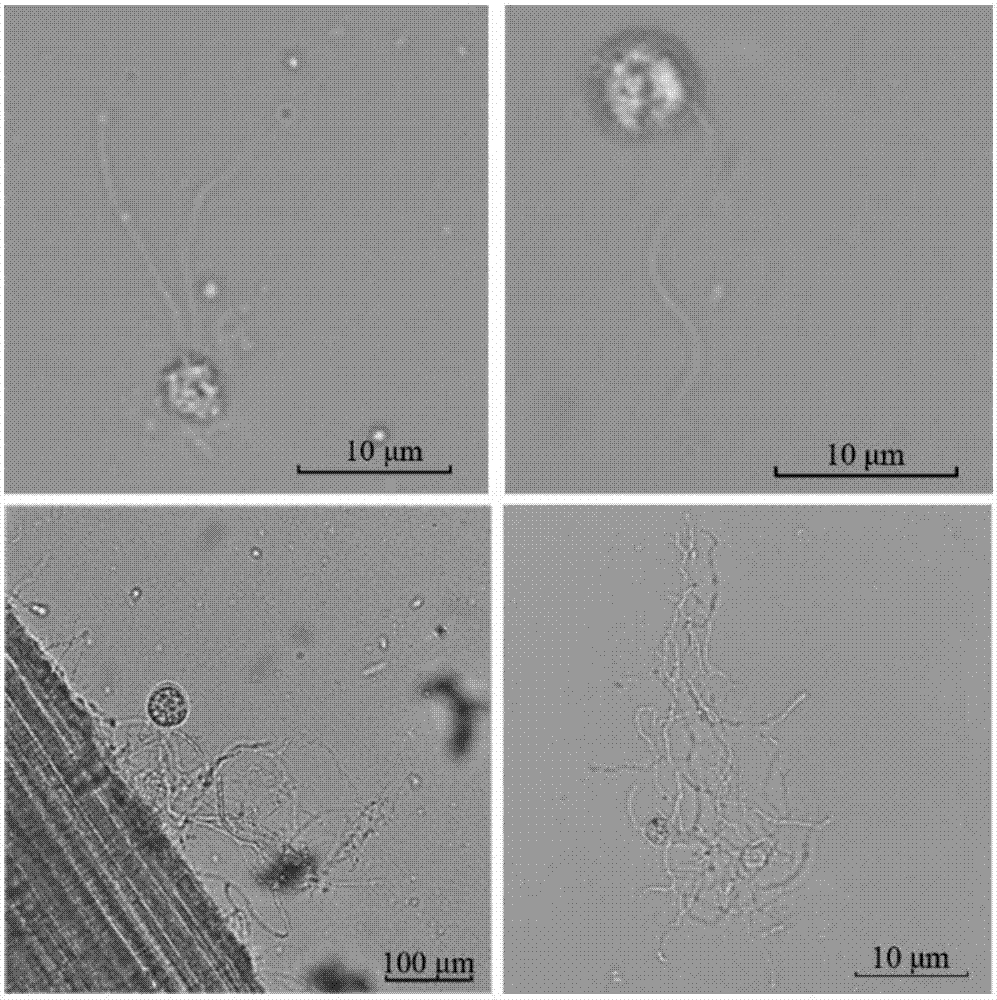

High plant cell wall degradation activity rumen fungi, and applications thereof in feed ensiling

ActiveCN107325974AImprove fermentation qualityImprove in vitro digestibilityFungiMicroorganism based processesPlant cellRumen

The invention discloses a high plant cell wall degradation activity rumen fungi, and applications thereof in feed ensiling, and belongs to the technical field of microorganism and feed processing. According to a preparation method, Hungate anaerobic roll-tube technique is adopted to obtain an anaerobic fungi with cell wall degradation enzyme activity via separating and selecting from the rumens of Xinong Saanen dairy goats, finally obtained Piromyces sp.CN6 is capable of producing xylanase and acetylesterase with relatively high activity in a wide temperature and pH range, and excellent thermal stability and acidic and alkaline stability, the preservation number is CGMCC No.14449. The bacteria strain is capable of improving fermentation quality of silage, increasing crude fiber degradation rate, and can be applied in practical production as a silage additive.

Owner:NORTHWEST A & F UNIV

Method for manufacturing non-glued bamboo fiber board

InactiveCN103707381AAntibacterialAnti-mildewWood working apparatusFlat articlesChemical compositionHigh pressure

The invention discloses a method for manufacturing a non-glued bamboo fiber board. The method sequentially comprises the following processes of hot-grinding fiber degradation, drying, pavement, prepressing, saw cutting, hot-pressing molding, cooling and edge clipping, wherein in the hot-pressing process, the hot-pressing temperature ranges from 160 DEG C to 230 DEG C, the hot-pressing pressure ranges from 30 kg / cm<2> to 85kg / cm<2>, and the hot-pressing time lasts for 5 minutes to 30 minutes, and then the non-glued bamboo fiber board is obtained. Chemical substances in bamboo fibers are degraded at a high temperature and under high pressure to generate a low-molecular-weight substance with properties of natural glue, and then bamboo fibers which are not degraded are glued together under the action of the temperature and the pressure to form a non-glued environment-friendly board with high mechanical properties. Since the board is made from the bamboo fibers through degradation and combination, glue is not needed in the process, usage of the glue is reduced effectively, and production cost and pollution are reduced.

Owner:宁波新缅新材料研发有限公司

Method for recycling waste polyester/cotton blended fabric

ActiveCN103319331ARecycling is completeEasy to recyclePreparation from carboxylic acid esters/lactonesCarbon preparation/purificationCarbonizationEthylene glycol

The invention provides a method for recycling a waste polyester / cotton blended fabric. The method comprises the following steps: performing a hydrothermal reaction on the waste polyester / cotton blended fabric fragment dispersing solution at the temperature of 240-260 DEG C to carry out a degradation reaction of cotton fibers and polyester fibers, continuously performing the hydrothermal reaction at the temperature of 300-320 DEG C to carry out a carbonization reaction of the cotton fiber degradation product, and separating and purifying to respectively obtain a carbon material, terephthalic acid and ethylene glycol so as to recycle the waste polyester / cotton blended fabric. The method for recycling the waste polyester / cotton blended fabric is advanced and simple in process flow, an acid-base catalyst is not used in the process, secondary pollution of the environment is avoided, and the waste polyester / cotton blended fabric is completely and totally recycled.

Owner:TAIYUAN UNIV OF TECH

Black fungus cultivation method

The invention discloses a black fungus cultivation method. The black fungus cultivation method comprises the following steps of culture medium making, black fungus bag making, black fungus bag sterilization, inoculation and daily management. The black fungus cultivation method fully utilizes fiber degradation and fermentation, so that cellulose in raw materials is very well released, obtained black fungi is comprehensive in nutrition, the nutrition demand of the black fungi in the growth process is met, the cultured black fungi are high in yield and good in quality, and planting time is shortened.

Owner:昆明旭日丰华农业科技有限公司

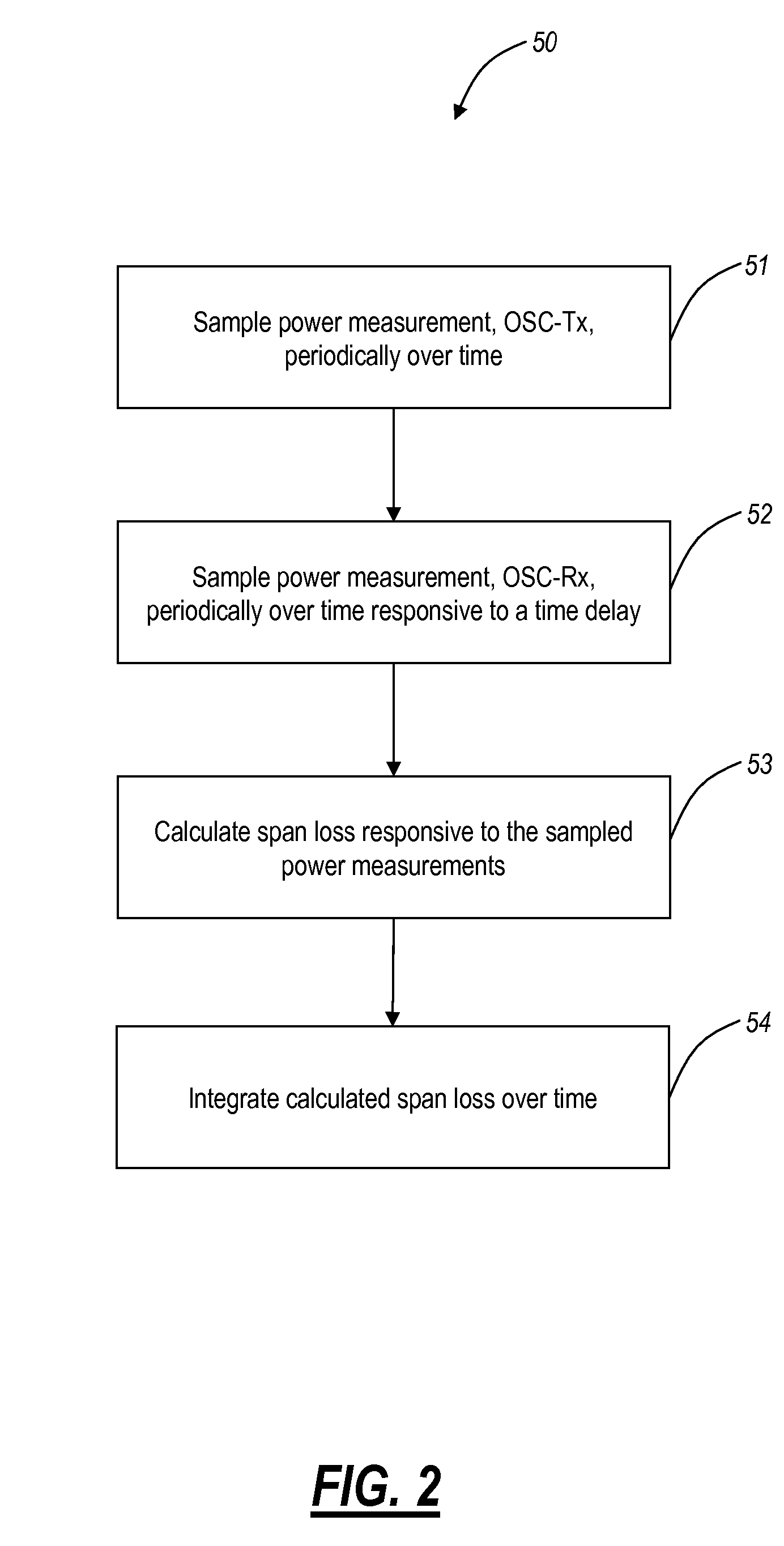

Methods and systems for detecting small span loss changes in fiber optic networks

ActiveUS8116625B2Transmission monitoringTransmission monitoring/testing/fault-measurement systemsPropagation delayEngineering

The present disclosure provides methods and systems for detecting small span loss changes in fiber optic networks. The present invention utilizes existing equipment without additional hardware to provide span loss measurements in a highly accurate manner. In an exemplary embodiment, the present invention utilizes power measurements associated with an optical supervisory channel (OSC) at both ends of a fiber span. These measurements are periodically sampled taking into account propagation delay along the fiber span. Further, these measurements are integrated or time-averaged to account for temporary fluctuations. The present invention can be utilized for intrusion detection (i.e., unwanted fiber taps), fiber degradation, and fiber aging performance. The present invention satisfies the criteria for a feasible (i.e., makes use of current architecture), cost-effective (i.e., does not require additional hardware), and highly accurate solution (i.e., capable of detecting span loss changes of 0.01 dB or 0.03%).

Owner:CIENA

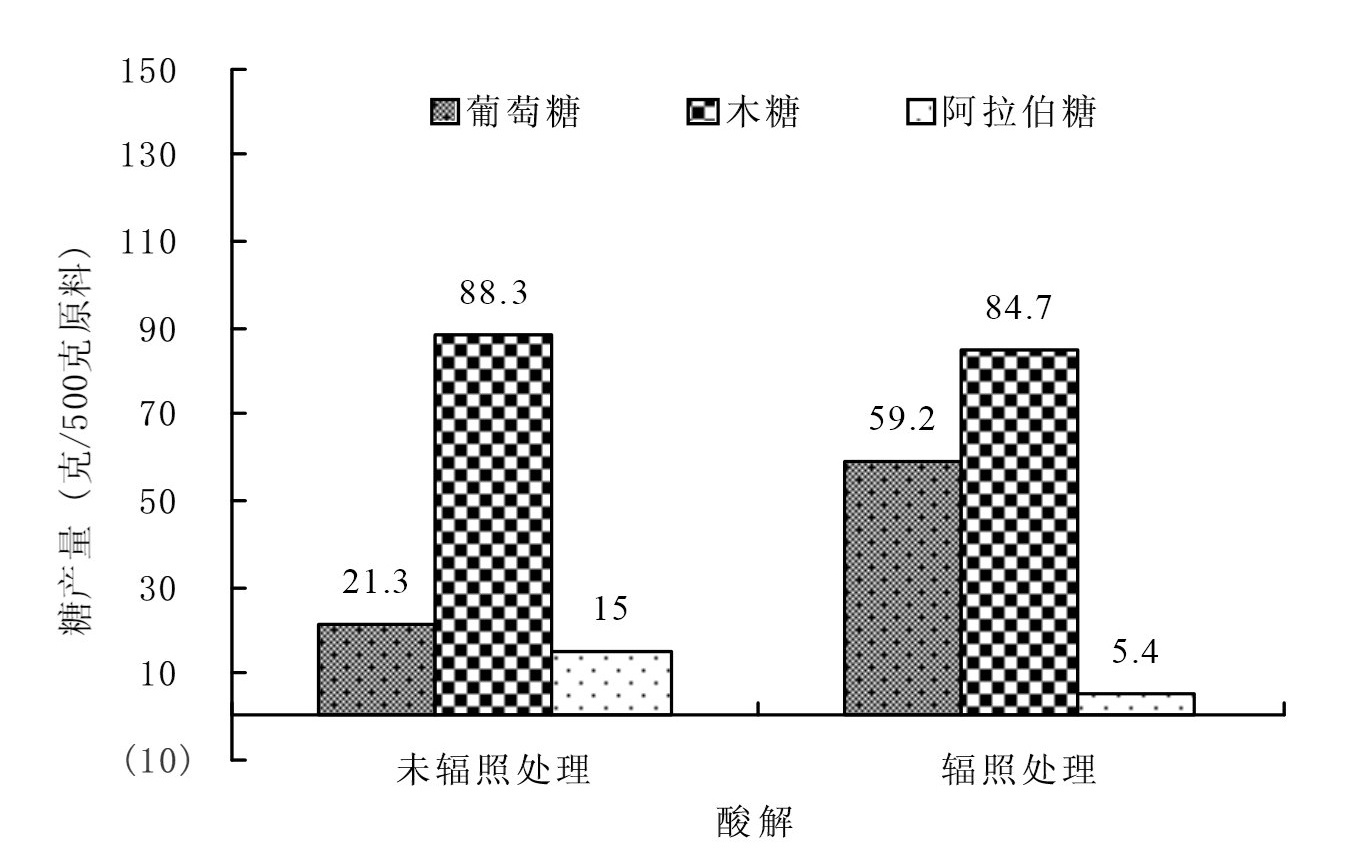

Method for refining sugar by rapidly degrading reed fibers

InactiveCN101979641ADestroy organizational structureIncreased sugar production efficiencyFermentationPulp and paper industryChemistry

Owner:HUNAN AGRICULTURAL UNIV

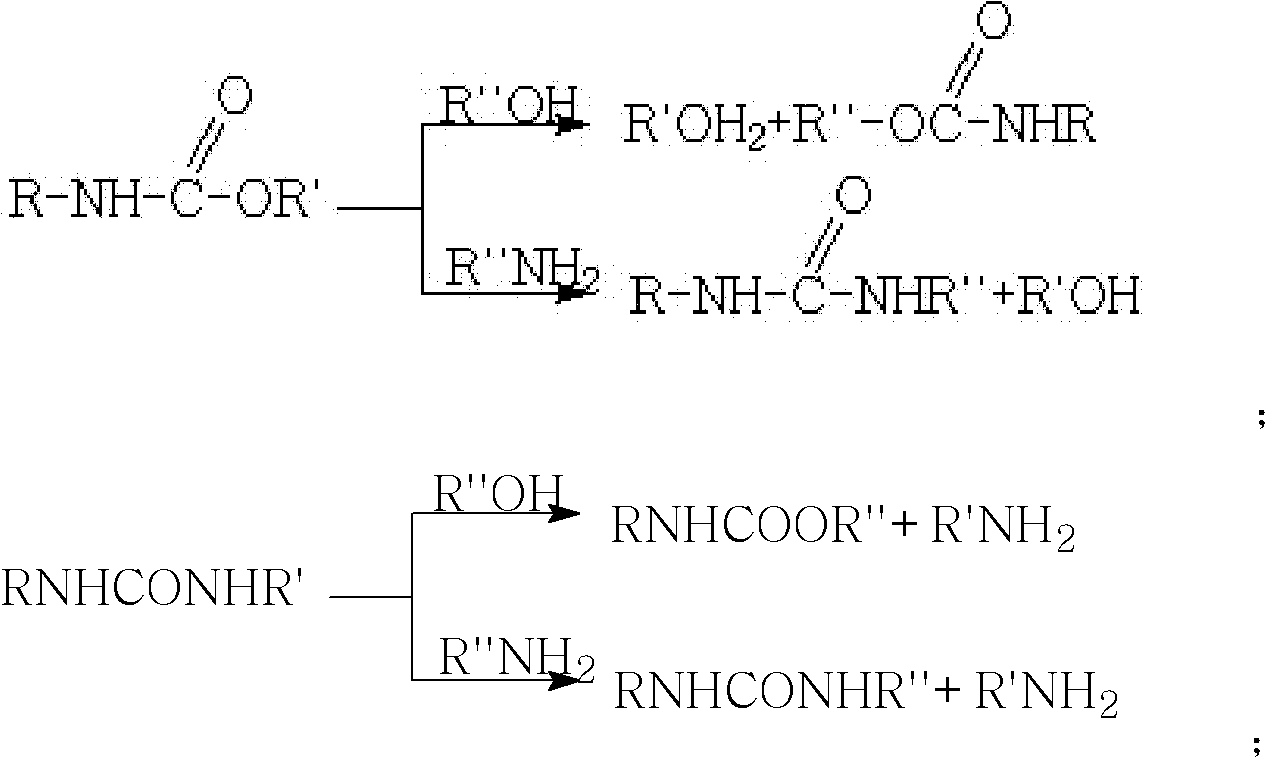

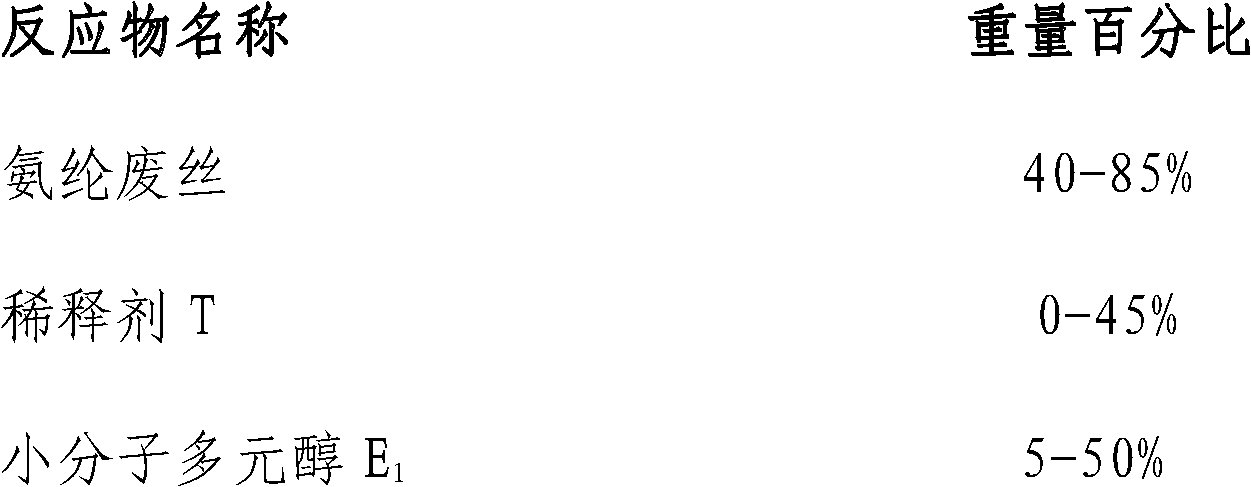

Process for manufacturing thermoplastic urethane (TPU) by utilizing waste spandex fiber

The invention relates to the technical field of reutilizing waste spandex, in particular to a process for manufacturing thermoplastic urethane (TPU) by utilizing waste spandex fiber. The process is characterized by comprises the steps of: waste spandex fiber degradation step and TPU synthesis step, the degradation step comprises pretreatment and degradation reaction, and the TPU synthesis step comprises synthesis reaction and posttreatment. The process method can recover and transform the waste spandex fiber into TPU, is simple in operation steps, can solve the problem of environmental pollution due to generation of waste fiber during production process, has low production cost and excellent product performance, as well as better economic benefits and environment-friendly benefits, and simultaneously develop a new approach for recycling of waste spandex fiber.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

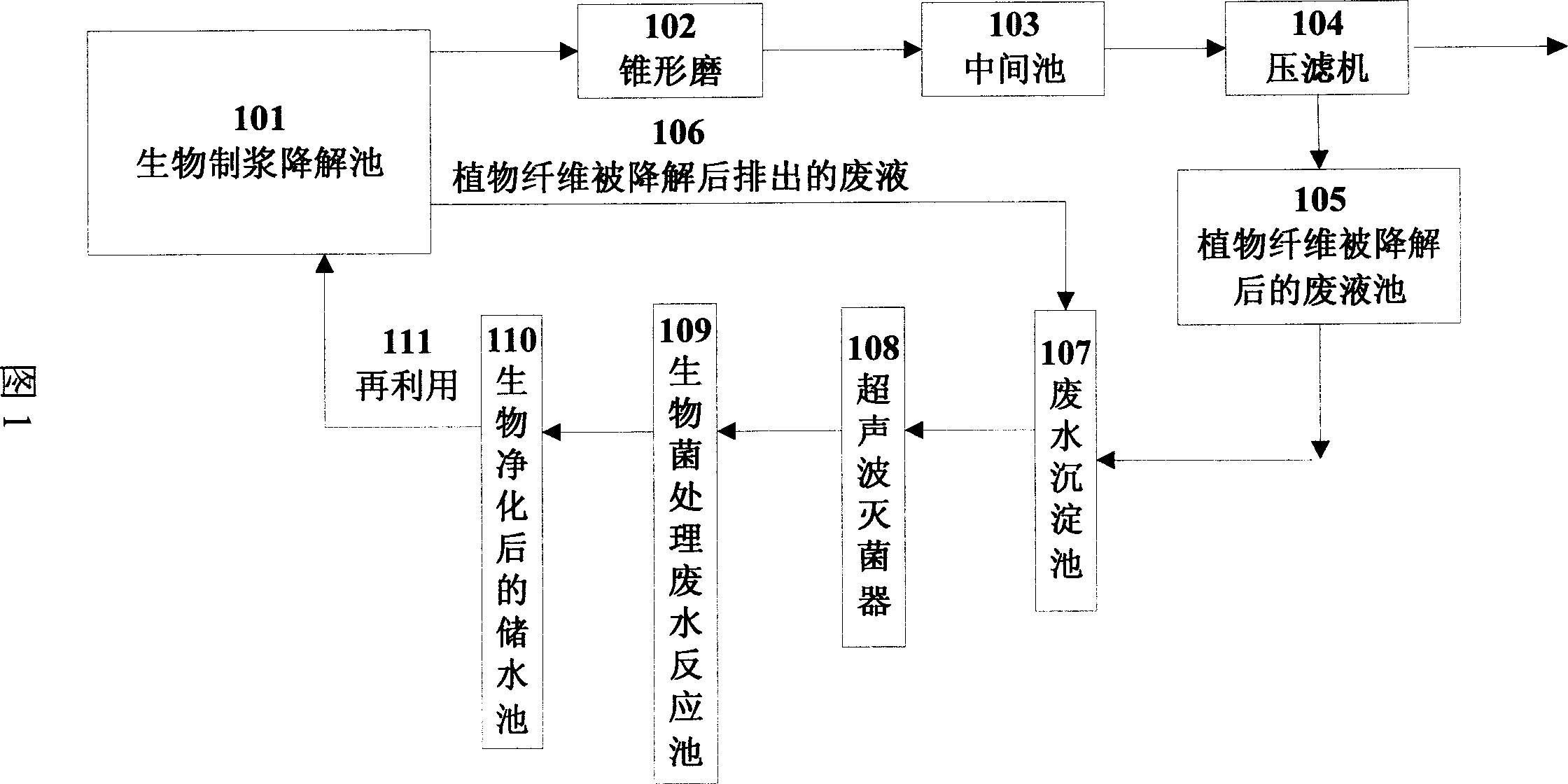

Multiple microbe waste water treating agent and its waste water recovering and utilizing process

InactiveCN1931741ASolve processing problemsEasy to handleMicroorganismsWaste water treatment from plant processingP-Aminobenzoic acidBiotin

The present invention discloses multiple microbe waste water treating agent and its waste water recovering and utilizing process. The multiple microbe waste water treating agent consists of K2HPO4, KH2PO4, MgSO4.7H2O, CaCl2.2H2O, NH4Cl, DL-sodium malate, yeast extract paste, EDTA-2Na, FeSO4.7H2O, H3BO4, CaCl2.6H2O, ZnCl2, biotin, nicotinic acid, L-sodium glutamate, growth factor liquid, trace element liquid, MnCl2.2H2O, Na2MoO4.2H2O, NiCl2.6H2O, CuCl2.2H2O, p-aminobenzoic acid, vitamin B1, vitamin B2, vitamin B6 and water. When the waste water treating agent is used in treating waste water, optimized microbe seeds are thrown in certain proportion. The present invention is used in treating waste water from plant fiber degradation with biological enzyme, and has high treating effect, short treating period and low treating cost.

Owner:郑克强

Electrostatic spinning preparation method for hybrid nanofiber membrane containing P(LLA-CL) and magnesium metal

The invention relates to an electrostatic spinning preparation method for a hybrid nanofiber membrane containing P(LLA-CL) and magnesium metal. The method comprises the steps of adding magnesium powder into a lactate caprolactone copolymer P(LLA-CL) solution, dissolving to obtain an electro-spinning solution, and conducting electrostatic spinning, so that the hybrid nanofiber membrane containing P(LLA-CL) and magnesium metal is obtained, and the mass ratio of the P(LLA-CL) to the magnesium metal is (2-10):1. The method is simple, efficient, novel, convenient to operate and good in application prospect; and according to the method, the nanofiber membrane is prepared through electro-spinning of the mixed solution of the P(LLA-CL) and the magnesium powder, and the method is applicable to simulation of fiber degradation performance analysis inside bodies of organisms.

Owner:DONGHUA UNIV

High-slow-release organic compound fertilizer for ulmus pumila

InactiveCN107118017AAvoid infringementGood slow releaseExcrement fertilisersBioloigcal waste fertilisersLivestock manureMonocalcium phosphate

The invention discloses a high-slow-release organic compound fertilizer for ulmus pumila. The high-slow-release organic compound fertilizer comprises raw materials, namely livestock manure, corn stalk, orange peel, rich hull, manioc wastes, turf, rice husk, furfural residues, phosphate solubilizing bacteria, potassium bacteria, nitrogen-fixing bacteria, crude fiber degradation bacteria, compost fermentation bacteria, urea phosphate, ammonium dihydrogen phosphate, humic acid, carbamide, monoammonium phosphate, monopotassium phosphate, potassium sulfate, ammonium sulfate, ferrous sulfate, boric acid, potassium nitrate, calcium nitrate, monocalcium phosphate, sodium glutamate, sodium alginate, a modified slow-release agent, a modified antibacterial anti-molding agent and a soil conditioning agent. The high-slow-release organic compound fertilizer disclosed by the invention is excellent in slow-release property and excellent in anti-molding property, nutrition requirements of the ulmus pumila in the whole growth period can be met, the yield of the ulmus pumila is effectively increased, the quality of the ulmus pumila is effectively improved, the ulmus pumila can be effectively prevented from mold on fertilizers, meanwhile structures of soil in which the ulmus pumila grows can be conditioned, soil caking is avoided, and thus the quality of the ulmus pumila is improved.

Owner:天长市翔净蔬菜种植发展有限公司

Microbial fertilizer for improving acidity and alkalinity of soil

InactiveCN106748418ARaise the pHImprove nutrient contentExcrement fertilisersBioloigcal waste fertilisersAlkalinityMicroorganism

The invention discloses a microbial fertilizer for improving acidity and alkalinity of soil. The microbial fertilizer is characterized by being prepared from the following raw materials in parts by weight: 60-120 parts of poultry and livestock manure, 30-80 parts of straw, 5-15 parts of soybean meal, 2-8 parts of sweet potato vine, 1-5 parts of peanut vine, 2-4 parts of rotten cucumber, 3-6 parts of tea seed shell carbon granules, 2-6 parts of coarse fiber degradation bacteria, and 2-8 parts of a soil improvement agent. The microbial fertilizer provided by the invention contains rich organic substances, mineral substances and microbes, and can provide various nutrition substances and microelements required by growth of plants, the improvement agent added into the fertilizer can effectively improve the acidity, alkalinity and nutrient content of the soil, and can effectively improve the fertility of the soil and improve the efficiency and quality of planting.

Owner:HUANGSHAN UNIV

Preparation method of modified cellulose insulating paper

ActiveCN108505374APromote productionGood for condensationPulp beating methodsPaper/cardboardSilanesHigh pressure

The invention relates to a preparation method of modified cellulose insulating paper, and belongs to the technical field of preparation of insulating materials. The preparation method comprises the steps of: firstly adopting micro-explosion to generates a pressure difference inside fiber during pressurization and instantaneous pressure releasing under the condition of maintaining intrinsic physical mechanical properties and complete appearance of birch fiber so as to form high-pressure airflow which impact from inside to outside inside the birch fiber, destroying cell walls, pit membranes andother weak tissue of the birch fiber so as to achieve preliminary fiber degradation, then mixing the obtained fiber after preliminary fiber degradation is conducted with tartaric acid, performing cooking at high temperature and high pressure, carrying out beating and oxidizing to obtain modified paper pulp, then utilizing a reaction of sodium silicate, hydrochloric acid and aminopropyl triethoxy silane so as to prepare modified nano silica, mixing the modified nano silica with the modified paper pulp, then carrying out papermaking, and performing a hot pressing reaction to obtain the modifiedcellulose insulating paper. The obtained insulating paper has good insulation performance, high mechanical strength and a broad application prospect.

Owner:江苏源清环保科技有限公司

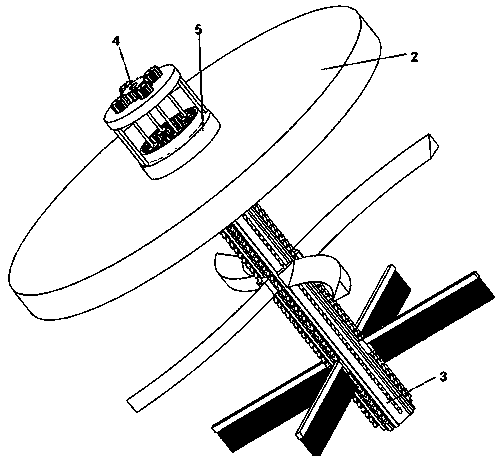

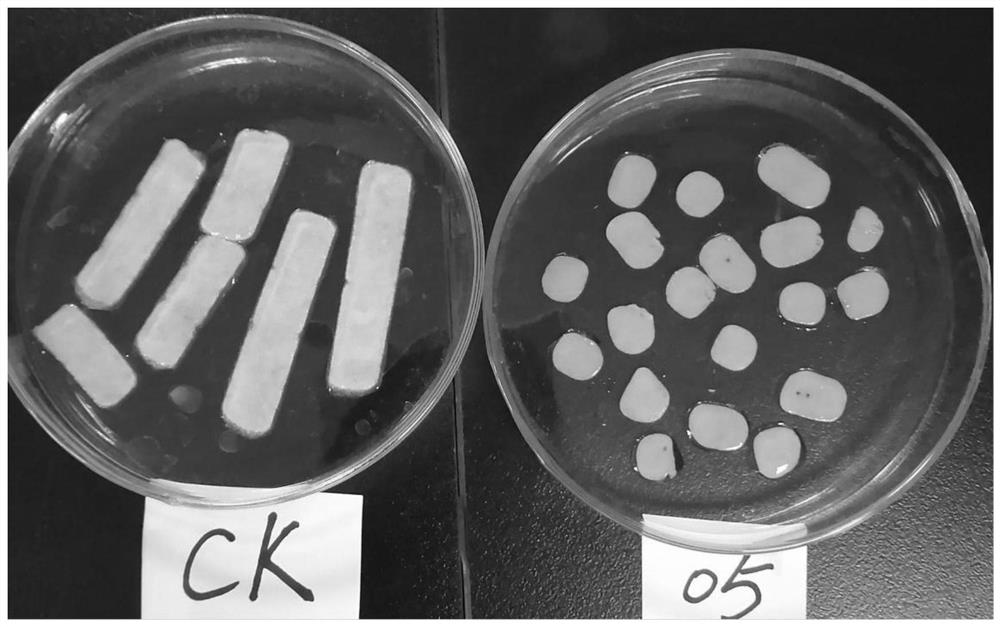

Sample bag for measuring feeder rumen organic substance, protein, neutral detergent fiber (NDF) and acid detergent fiber (ADF) degradation rate and application thereof

InactiveCN104760747AOvercome operabilityOvercome efficiencyWeighing by removing componentBagsPolyesterNutritive values

The invention provides a sample bag for measuring feeder rumen organic substance, protein, NDF and ADF degradation rate and an application thereof. A certain amount of to-be-measured feed samples are put in sample bags to be put in the ruminant rumen after mechanical sealing, the feed samples are taken out after being digested in the ruminant rumen for certain time to be washed and dried, and the ruminant feeder rumen organic substance, protein, NDF and ADF degradation rate is measured by processing polyester mesh bags including residues. Compared with measuring of ruminant feeder rumen organic substance, protein, NDF and ADF degradation rate through a nylon bag method, the method has the advantages of being capable of performing batch processing, simple and rapid in operation step, good in repeatability, low in cost, simple in analysis method, high in data accuracy and the like and capable of providing a simple and efficient measuring method for ruminant feed nutritive value evaluation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

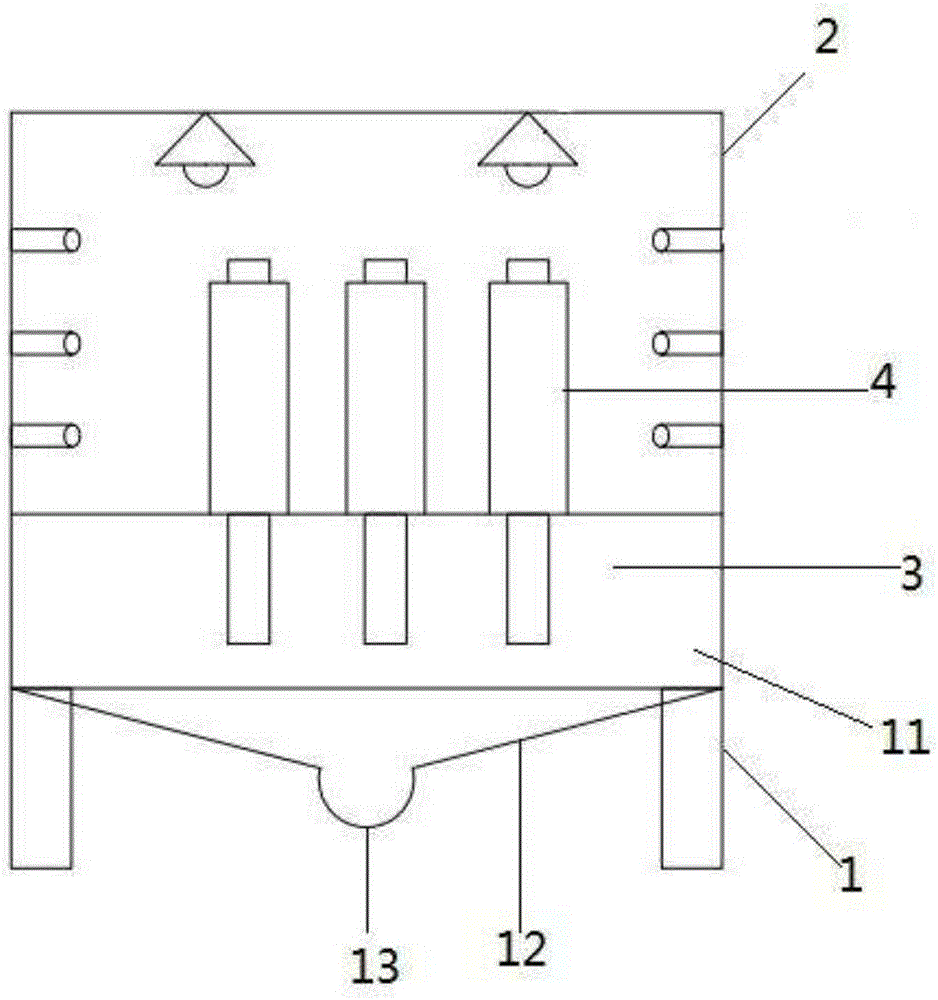

Preparation method of composite biological organic fertilizer granule

PendingCN109627075ARealize separate granulation and cuttingImprove granulation efficiencyCalcareous fertilisersBio-organic fraction processingDecompositionOxygen

The invention discloses a preparation method of a composite biological organic fertilizer granule, which comprises the following steps of: adding crude fiber degrading bacteria into rice bran, uniformly mixing to prepare a fermentation material, then crushing and mixing corn straws, wheat straws and rice hulls, adding the fermentation material into the mixture, spraying water into the mixture while stirring so that the humidity of the mixture is kept between 55-60%, then fermenting the mixture for 15 days at 37-40 DEG C, and turning over the mixture every day so that sufficient oxygen is contained in the mixture and the degradation of straws and rice hulls by coarse fiber degradation bacteria is satisfied. According to the invention, the crude fiber is firstly reduced before the crude fiber is fermented, so that the fermentation efficiency of the crude fiber can be improved, the content of small molecular saccharides in the product can be improved, the fertilizer efficiency can be improved, the problem that the decomposition of the crude fiber is difficult through direct fermentation in the prior fermentation process is solved, so that the content of small molecular saccharides inthe prepared organic fertilizer is reduced, and the fertilizer efficiency is further reduced.

Owner:新昌县大船畈生物科技有限公司

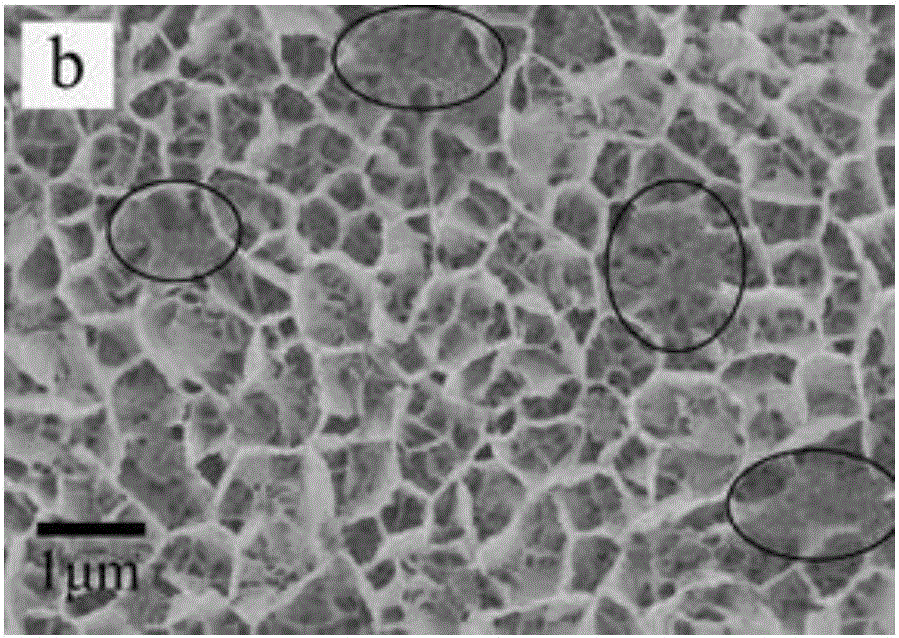

Bamboo pulp cellulosic fiber/hydrated magnesium silicate based composite and preparation method thereof

InactiveCN111958760AReduce the effect of deteriorationImprove bending resistanceCeramic shaping apparatusMagnesium matrix compositeCellulose fiber

The invention discloses a bamboo pulp cellulosic fiber / hydrated magnesium silicate based composite and a preparation method thereof. The bamboo pulp cellulosic fiber / hydrated magnesium silicate basedcomposite comprises, by weight, 4-16 parts of bamboo pulp cellulosic fiber, 33.6-55 parts of magnesium oxide, and 37.8-60 parts of silica ash. According to the bamboo pulp cellulosic fiber / hydrated magnesium silicate based composite, the bamboo pulp cellulosic fiber serves as a reinforced phase of the magnesium silicate based composite, and the bending strength and fracture toughness of the composite are improved; meanwhile, the pH value of a magnesium silicate matrix is lower than that of Portland cement, the influence of the alkalinity on fiber degradation can be reduced, the fiber in the composite can achieve the long-term reinforcement effect, and the durability is improved. Moreover, magnesium oxide is rich in reserves and excellent in performance. The bamboo pulp fiber is short in growth cycle, high in yield, green and renewable. The bamboo pulp cellulosic fiber / hydrated magnesium silicate based composite and the preparation method thereof provide a new approach to utilization ofbamboo fiber and magnesium oxide. The prepared bamboo pulp cellulosic fiber / hydrated magnesium silicate based composite has the advantages of high strength, high fracture toughness, light weight, lowalkalinity and the like, and follow the concept of sustainable development of a building material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for black fungus household cultivating utilizing agaric fungus bag

InactiveCN106588392AIncrease productionImprove qualityCalcareous fertilisersSuperphosphatesBiotechnologyAgaric

The invention discloses a method for black fungus household cultivating utilizing an agaric fungus bag. The cultivating method comprises the following steps that (1) a cultivation substrate is made; (2) a black fungus bag is made; (3) black fungus bag sterilizing is conducted; (4) a cultivation auxiliary device is constructed; (5) inoculation is conducted; and (6) daily management is conducted. The method for black fungus household cultivating utilizing the agaric fungus bag is simple, and fiber degradation and fermentation are fully utilized by the substrate to enable cellulose in raw materials to be released very well; the obtained agaric fungus bag has comprehensive nutrition, nutritional requirements in the black fungus growth process are met, and operation is easy; the yield of the cultivated black fungus is high, and the emergence time is short; and the requirements of growth of the black fungus in an indoor environment are met.

Owner:昆明旭日丰华农业科技有限公司

Novel degradation method for polyvinyl alcohol fibers

InactiveCN106362773APhysical/chemical process catalystsPlastic recyclingEnvironmental resistancePVA - Polyvinyl alcohol

The invention provides a novel degradation method for polyvinyl alcohol fibers. A novel composite magnetic material Fe3O4@NiO@CoS@WO3 is prepared and successfully used for polyvinyl alcohol fiber degradation. Preparing of the modified composite material is complex, but adopted materials are common and low in cost. The prepared composite catalyst can effectively and catalytically degrade polyvinyl alcohol fibers and can also be easily recycled. A preparing technology of the catalyst is simple and environmentally friendly.

Owner:JIANGNAN UNIV

Fiber degradation strain and enzyme production method thereof

The invention discloses a fiber degradation strain and an enzyme production method thereof, and particularly relates to Ochrobactrumintermedium XW2020005 which is separated from a sugarcane leaf decomposition material. The preservation registration number is CGMCC No.20427. The strain has the advantages that the strain is separated from a sugarcane leaf decomposition material, can generate filter paper enzyme activity, endoglucanase, beta-glucosidase and other cellulase in the growth and reproduction process, and can decompose sugarcane leaves and other straw in a low-temperature environment.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Special shadow copying paper and processing method

InactiveCN101914878AGood transparencyHigh strengthNon-fibrous pulp additionSpecial paperPolyesterEmulsion

The invention discloses shadow copying paper and a processing method. The method comprises the following processes: performing wet beating on commercial pulp serving as a raw material by adopting two-stage pulping and a double-millstone abrasive sheet to make the brooming rate of pulp fibers reach over 20 percent and reach high strength and strong water permeability resistance of paper; and performing a papermaking step with the pulp, namely adding water impermeable fluorine-containing copolymerization emulsion in an innovative U-shaped three-layer polyester net, adding papermaking-grade CMC in the production flow to perform retention aid, quantifying the formed and dried product at 16+ / 1 g / m<2>, and controlling the water permeability to be less than or equal to 2.5 millimeters so that the product has the characteristics of writing breakage resistance, water permeability resistance, high definition and myopia prevention. The method produces the special shadow copying paper by using the commercial pulp as the raw material, combining the novel S-shaped double-millstone abrasive sheet and the innovative U-shaped three-layer polyester net, adding the water impermeable fluorine-containing copolymerization emulsion and combining the preferred fiber degradation chemical enzyme.

Owner:FUJIAN NAOSHAN PAPER IND GROUP

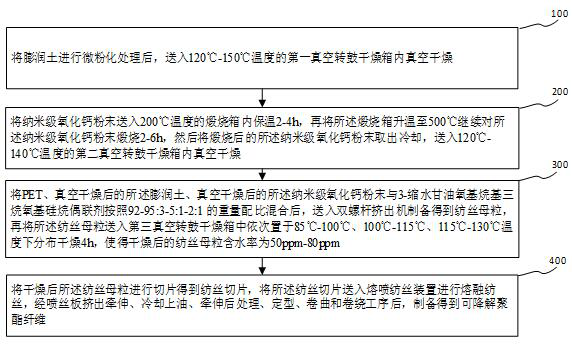

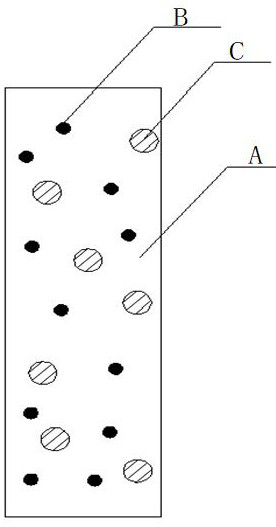

Degradable polyester fiber and preparation method thereof

PendingCN112176450AIncreased degradation rateAccelerated agingMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterCalcium hydroxide

The invention discloses a degradable polyester fiber and a preparation method thereof, and relates to the technical field of polyester fiber materials. According to the degradable polyester fiber andthe preparation method thereof provided by the invention, bentonite and nanoscale calcium oxide powder are added into a PET material for melt spinning to prepare the degradable polyester fiber, afterthe degradable polyester fiber meets water in a humid environment, the bentonite uniformly distributed in the fiber material absorbs water to expand, so that cracks are generated on the surface of thefiber to accelerate the aging of the polyester fiber. A small amount of nanoscale calcium oxide powder uniformly distributed in the fiber material slowly reacts with water to generate calcium hydroxide, and the reaction process slowly releases (OH-) for a long time, so that ester bonds in the degradable polyester fiber are in hydrolysis for a long time under an alkaline condition, the degradationrate of the degradable polyester fiber is further promoted, and when the degradable polyester material is applied to fiber material products, especially disposable fiber products, the degradation rate of the polyester fiber can be greatly increased while the fiber performance is not affected.

Owner:JIAXING UNIV

Bamboo fiber/polypropylene composite material as well as preparation method and application thereof

The invention discloses a bamboo fiber / polypropylene composite material as well as a preparation method and application thereof. The bamboo fiber / polypropylene composite material specifically comprises the following raw materials in parts by weight: 50-100 parts of polypropylene, 10-30 parts of calcium carbonate, 3-15 parts of modified bamboo fibers, 0.1-0.5 part of a coupling agent, 0-5 parts ofa compatilizer, 0.1-0.3 part of an antioxidant, 0.2-0.6 part of an auxiliary antioxidant and 0.2-0.4 part of a lubricating agent. According to the bamboo fiber / polypropylene composite material disclosed by the invention, bamboo fibers in the raw materials are modified, and interfacial adhesion between the bamboo fibers and the polypropylene is increased. Moreover, by combining the coupling agent and the compatilizer, the problems that bamboo fibers are difficult to disperse in the polypropylene resin, the compatibility between the bamboo fibers and the polypropylene resin is poor and fiber degradation is easily caused in the processing flow are solved. The bamboo fiber / polypropylene composite material disclosed by the invention can be used for manufacturing automotive interior structure parts, decorations, kitchen utensils and the like.

Owner:浙江明江新材料科技股份有限公司

Sporotrichum pulverulentum strain and application thereof

InactiveCN106399116AReduce manufacturing costEfficient secretionFungiMicroorganism based processesMicrobiologyFodder

The invention discloses a novel unique Sporotrichum pulverulentum strain QY-001 wich an accession number of CGMCC No. 10762, and application of the strain to solid-state fermentation of agriculture waste. The Sporotrichum pulverulentum strain QY-001 is screened out from humus soil of a mountain and has strong fiber degradation and utilization effect on agriculture waste; and through solid-state fermentation, the strain enables the content of crude fiber in agriculture waste to be reduced by 40 to 90% and the content of crude protein to be increased by 30 to 300%, so an approach is opened up for a novel biological feed source in China. The Sporotrichum pulverulentum strain QY-001 is simple in nutritional requirements; a fermentation medium is low in production cost; a solid-state fermentation process is simple; and the strain has wide application prospects.

Owner:烟台启元微生物技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com