Novel degradation method for polyvinyl alcohol fibers

A technology of polyvinyl alcohol fibers and new methods, applied in chemical instruments and methods, plastic recycling, recycling technology, etc., can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

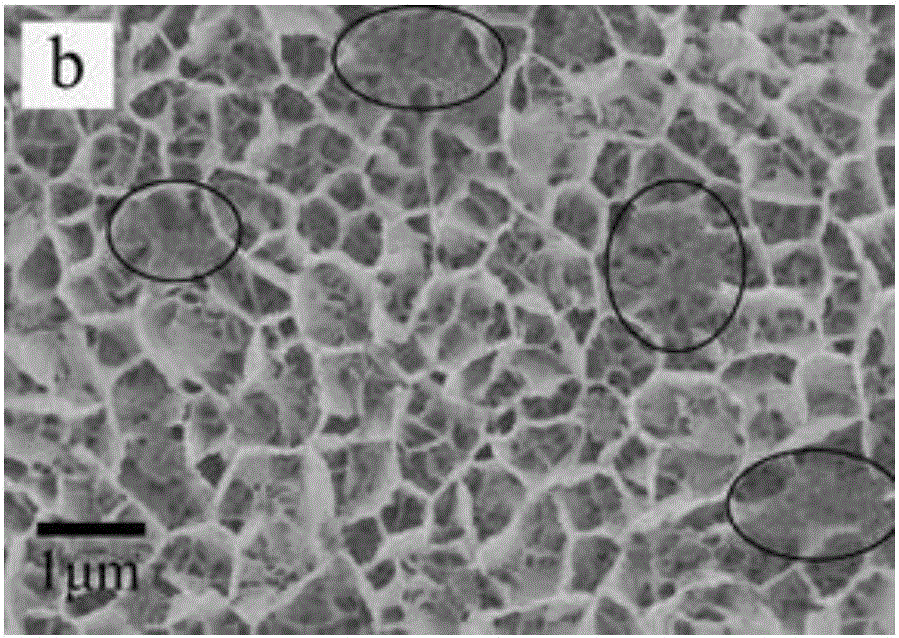

Image

Examples

Embodiment 1

[0009] Embodiment one: a kind of new method of polyvinyl alcohol fiber degradation, comprises the following processing steps:

[0010] The invention provides a new method for the degradation of polyvinyl alcohol fibers; concrete synthesis and degradation steps are as follows: (1) first adopt solvothermal method, polyacrylic acid and iron trichloride are dissolved in diethylene glycol with a ratio of 1:1 (15mL), heated to 250°C with vigorous stirring, stirred for 14h, and centrifuged to obtain black powder solid Fe 3 o 4 . (2) NiCl 2 , Fe 3 o 4 Mix in a mixed solvent of deionized water, absolute ethanol and n-butanol at a ratio of 3:1, stir at room temperature for 50 minutes, heat at 150°C for 12 hours, and centrifugally dry to obtain the product Fe 3 o 4 @NiO. (3) CoCl 2 with Fe 3 o 4 @NiO was mixed with deionized water at a ratio of 2:1, and ethylenediamine was added dropwise under stirring. When the solution turned yellow, hexadecyltrimethylammonium bromide and thi...

Embodiment 2

[0011] Embodiment two: a new method for polyvinyl alcohol fiber degradation, comprising the following process steps:

[0012] The invention provides a new method for polyvinyl alcohol fiber degradation; concrete synthesis and degradation steps are as follows: (1) first adopt solvothermal method, polyacrylic acid and iron trichloride are dissolved in diethylene glycol with the ratio of 2:1 (12mL), vigorously stirred and heated to 180°C, stirred for 12h, centrifuged and dried to obtain black powder solid Fe 3 o 4 . (2) NiCl 2 , Fe 3 o 4 Mix in a mixed solvent of deionized water, absolute ethanol and n-butanol at a ratio of 2:1, stir at room temperature for 80 minutes, heat at 190°C for 24 hours, and centrifugally dry to obtain the product Fe 3 o 4 @NiO. (3) CoCl 2 with Fe 3 o 4 @NiO is mixed with deionized water at a ratio of 2:1, and ethylenediamine is added dropwise under stirring. When the solution turns yellow, cetyltrimethylammonium bromide and thioacetamide are a...

Embodiment 3

[0013] Embodiment three: a new method for polyvinyl alcohol fiber degradation, comprising the following process steps:

[0014] The invention provides a new method for polyvinyl alcohol fiber degradation; concrete synthesis and degradation steps are as follows: (1) first adopt solvothermal method, polyacrylic acid and iron trichloride are dissolved in diethylene glycol with a ratio of 3:1 (5-15mL), heated to 250°C with vigorous stirring, and after stirring for 6h, centrifuged and dried to obtain black powder solid Fe3O4. (2) NiCl 2 , Fe 3 o 4 Mix in a mixed solvent of deionized water, absolute ethanol and n-butanol at a ratio of 3:1, stir at room temperature for 90 minutes, heat at 160°C for 36 hours, and centrifugally dry to obtain the product Fe 3 o 4 @NiO. (3) CoCl 2 with Fe 3 o 4 @NiO was mixed with deionized water in a ratio of 4:1, and ethylenediamine was added dropwise under stirring. When the solution turned yellow, hexadecyltrimethylammonium bromide and thioac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com