Bamboo pulp cellulosic fiber/hydrated magnesium silicate based composite and preparation method thereof

A technology of cellulose fiber and composite materials, which is applied in the field of bamboo pulp cellulose fiber/hydrated magnesium silicate-based composite materials and its preparation, can solve the problems of fast coagulation speed, poor water resistance, and shrinkage of strength, and achieve the reduction of fiber Effect of deterioration, improvement of flexural performance, and effect of increased retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

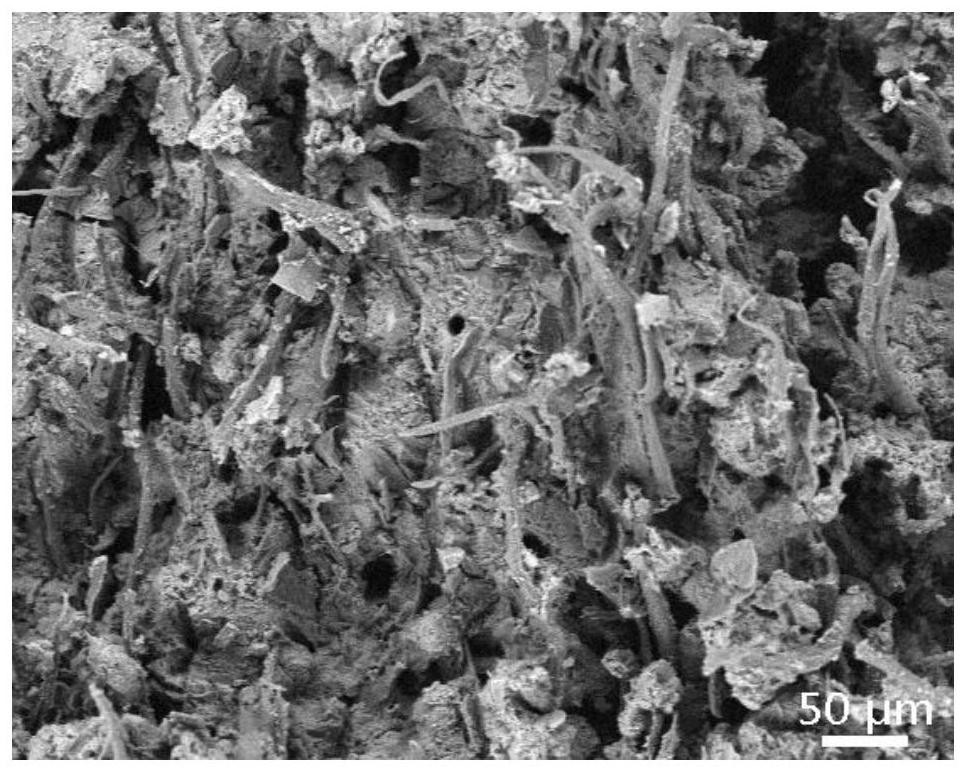

Image

Examples

preparation example Construction

[0031] The preparation process of the present invention comprises the following steps:

[0032] Step 1: According to the experimental ratio, weigh a certain quality of dried and pulverized cellulose fiber, put it into a beater and add water to stir for 2.5-5min; after the stirring is completed, pour it into a beaker, and add the weighed Magnesium and silica fume, stir for 2-4min in an electric stirrer.

[0033] Step 2: Quickly pour the uniformly stirred slurry into a mold of a certain size and vacuum filter out excess water under a pressure of 0.05-0.10MPa until the surface of the sample is solidified.

[0034] Step 3: Place the sample obtained in Step 2 in a steel mold, and hold the pressure for 3-8 minutes under a pressure of 3.0-3.5 MPa to obtain a finished product;

[0035] Step 4: Put the finished product into a plastic bag, seal it and place it at room temperature for 1 day, then put it in a curing box until the test age, and steam curing can also be carried out according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com