Method for Improving the Molar Phenomenon of Stitching Exposure

A phenomenon and sub-exposure technology, which is applied in microlithography exposure equipment, photolithography exposure equipment, optics, etc., can solve the problems of splicing mura, uneven brightness at splicing places, etc., and achieve the effect of improving quality and weakening the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

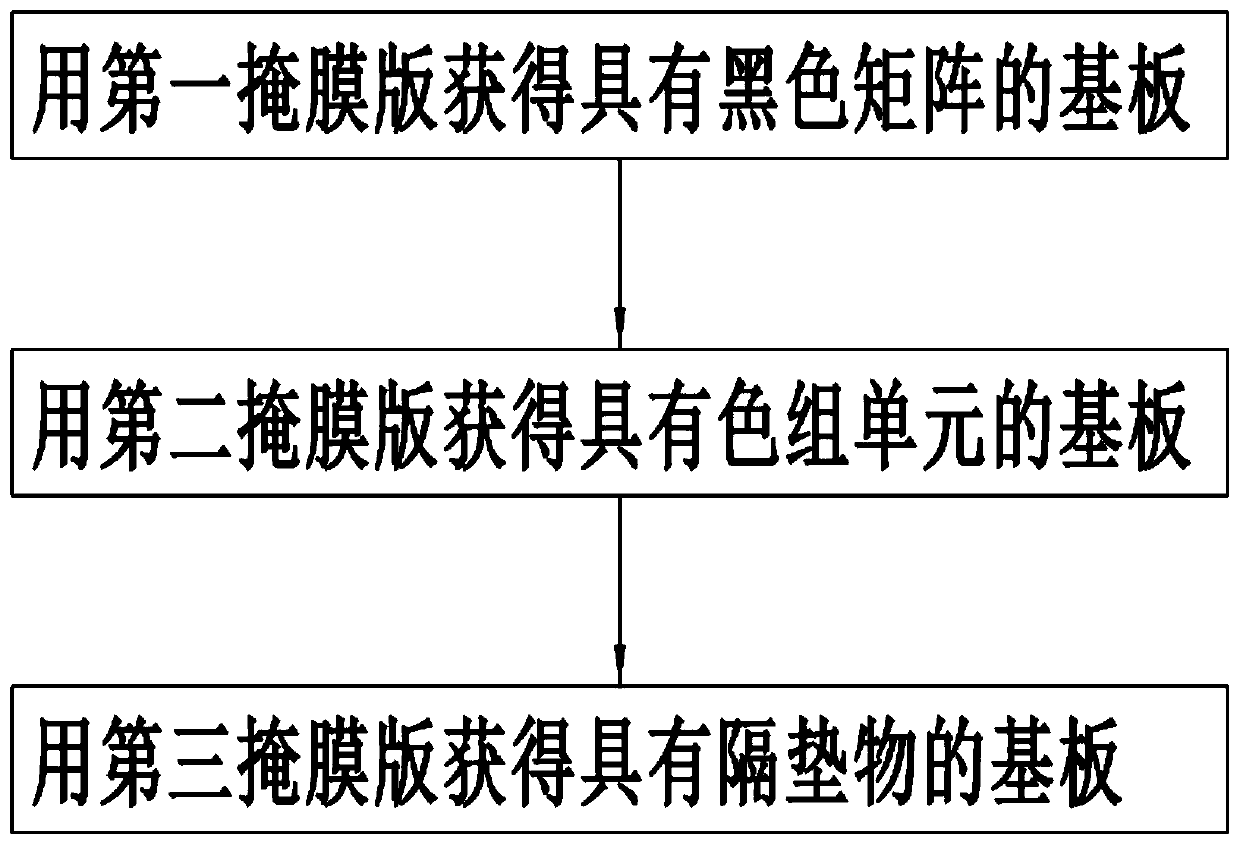

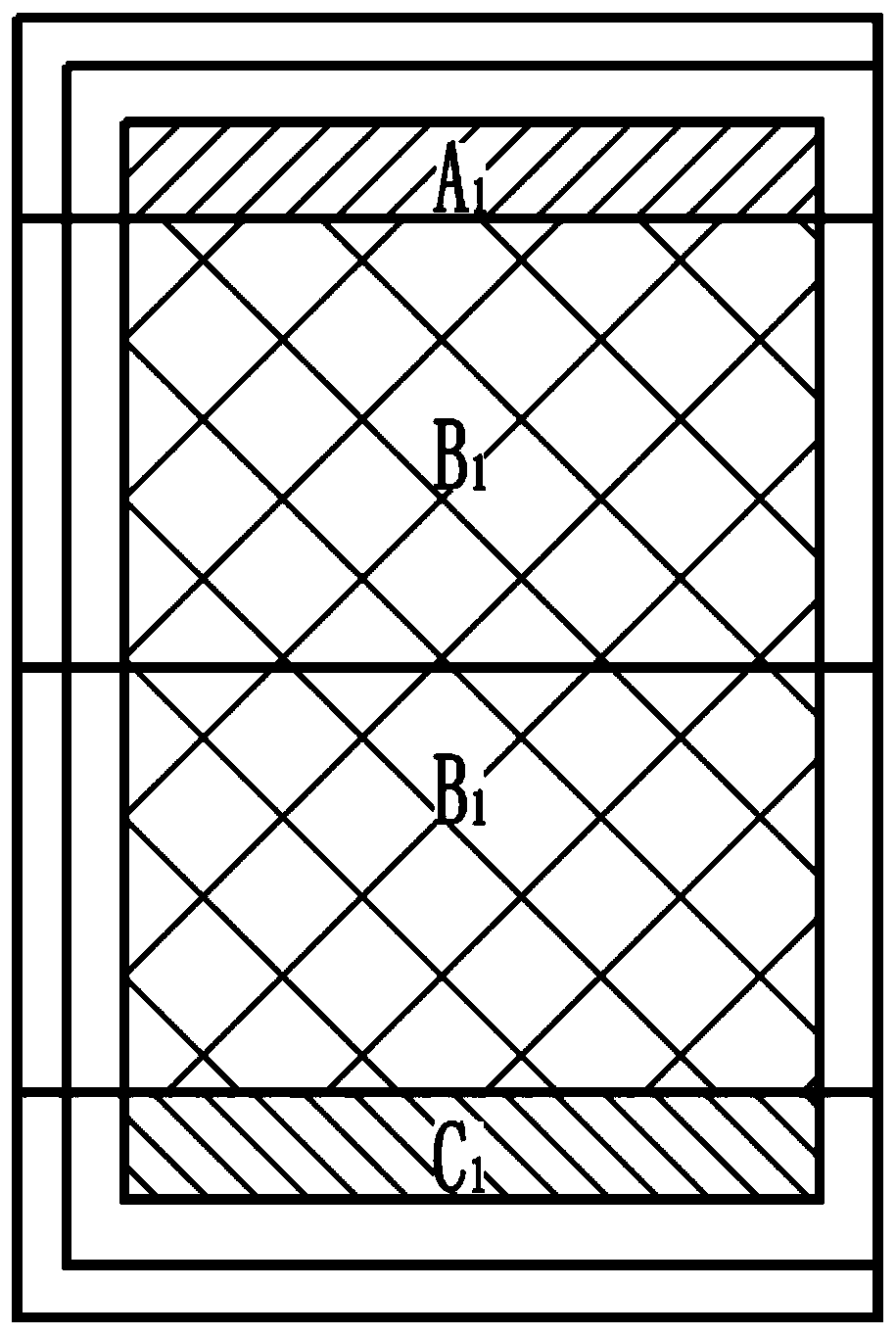

[0035] Such as figure 1 As shown, the present invention provides a method for improving the molar phenomenon of splicing exposure, which includes the steps of obtaining a substrate with a black matrix with a first mask, that is, the first manufacturing process (BM), and obtaining a black matrix with a second mask. The step of the substrate with the color group unit, that is, the second process (R / G / B) and the step of obtaining the substrate with the spacer with the third mask, that is, the third process (PS), wherein the first mask Areas of exposure regions on the stencil, the second mask and the third mask are all different.

[0036] In the prior art, since the splicing position on the substrate is the same in each process, the splicing Mura will be further aggravated and deteriorated after each process at the splicing position at the same position, so that the splicing M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com