High-slow-release organic compound fertilizer for ulmus pumila

A compound fertilizer and high-slow technology, applied in the field of fertilizers, can solve the problems of weak fertilizer efficiency of inorganic fertilizers, unfavorable growth of elm, and easy fermentation of organic fertilizers, and achieve the effects of avoiding soil compaction, excellent slow-release performance, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

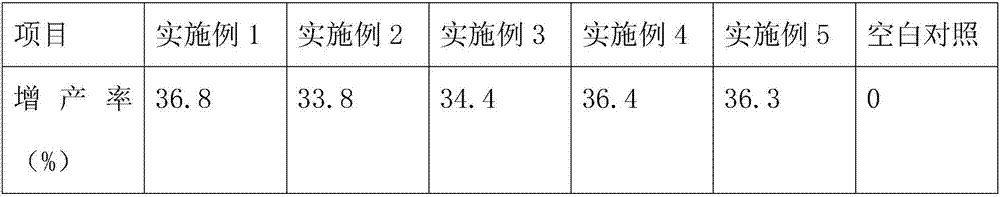

Examples

Embodiment 1

[0023] The high slow-release organic compound fertilizer of a kind of elm money that the present invention proposes, its raw material comprises by weight: 90 parts of poultry manure, 20 parts of corn stalks, 9 parts of orange peel, 6 parts of chaff, 6 parts of cassava dregs, 10 parts of peat 5 parts of rice husk, 2.5 parts of furfural slag, 4.5 parts of phosphorus solubilizing bacteria, 5 parts of potassium solubilizing bacteria, 3 parts of nitrogen fixing bacteria, 4 parts of crude fiber degrading bacteria, 6 parts of compost decomposing bacteria, 2.5 parts of urea phosphate, 2.5 parts of ammonium phosphate 5 parts, humic acid 5 parts, carbonamide 3.5 parts, monoammonium phosphate 6 parts, potassium dihydrogen phosphate 3 parts, potassium sulfate 2.5 parts, ammonium sulfate 3.5 parts, ferrous sulfate 3.5 parts, boric acid 5 parts, potassium nitrate 3 parts, 4.5 parts of calcium nitrate, 5 parts of calcium dihydrogen phosphate, 2.5 parts of sodium glutamate, 3 parts of sodium a...

Embodiment 2

[0029] The high slow-release organic compound fertilizer of a kind of elm that the present invention proposes, its raw material comprises by weight: 60 parts of poultry manure, 25 parts of corn stalks, 6 parts of orange peel, 8 parts of chaff, 3 parts of cassava dregs, 12 parts of peat 2 parts of rice husk, 4 parts of furfural slag, 3 parts of phosphorus solubilizing bacteria, 8 parts of potassium solubilizing bacteria, 1 part of nitrogen fixing bacteria, 6 parts of crude fiber degrading bacteria, 4 parts of compost decomposing bacteria, 4 parts of urea phosphate, 1 part of ammonium phosphate 8 parts of humic acid, 1 part of carbonamide, 9 parts of monoammonium phosphate, 2 parts of potassium dihydrogen phosphate, 4 parts of potassium sulfate, 2 parts of ammonium sulfate, 6 parts of ferrous sulfate, 2 parts of boric acid, potassium nitrate 5 parts, 3 parts of calcium nitrate, 8 parts of calcium dihydrogen phosphate, 1 part of sodium glutamate, 5 parts of sodium alginate, 6 part...

Embodiment 3

[0035] The high slow-release organic compound fertilizer of a kind of elm money that the present invention proposes, its raw material comprises by weight: 120 parts of poultry manure, 15 parts of corn stalks, 12 parts of orange peel, 4 parts of chaff, 9 parts of cassava dregs, 8 parts of peat 8 parts of rice husk, 1 part of furfural slag, 6 parts of phosphorus solubilizing bacteria, 2 parts of potassium solubilizing bacteria, 5 parts of nitrogen fixing bacteria, 2 parts of crude fiber degrading bacteria, 8 parts of compost decomposing bacteria, 1 part of urea phosphate, 4 parts of ammonium phosphate 2 parts of humic acid, 6 parts of carbonamide, 3 parts of monoammonium phosphate, 4 parts of potassium dihydrogen phosphate, 1 part of potassium sulfate, 5 parts of ammonium sulfate, 1 part of ferrous sulfate, 8 parts of boric acid, potassium nitrate 1 part, 6 parts of calcium nitrate, 2 parts of calcium dihydrogen phosphate, 4 parts of sodium glutamate, 1 part of sodium alginate, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com