Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

426 results about "Urea phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

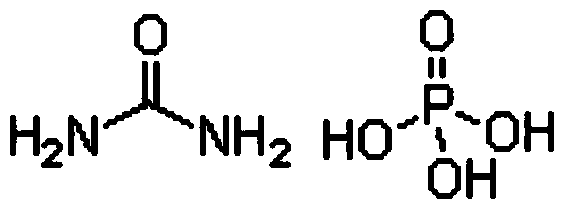

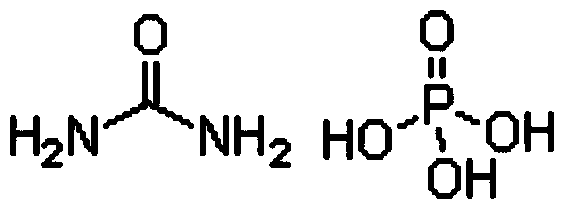

It is sometimes used as a fertilizer; as such, its NPK formula is 17-44-0. It is soluble in water, and produces a strongly acidic solution. Urea phosphate is sometimes added to blends which contain calcium nitrate, magnesium nitrate and potassium nitrate to produce water-soluble formulas such as 15-5-15 and 13-2-20. The acidity of urea phosphate allows Ca, Mg and P to co-exist in solution. Under less acidic conditions, there would be precipitation of Ca-Mg phosphates. Urea phosphate is often used in drip irrigation to clean pipe systems.

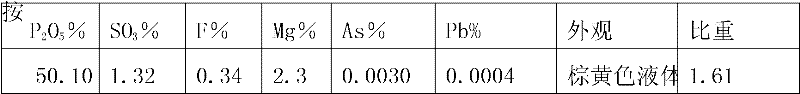

Production method for monoammonium phosphate

InactiveCN104016323AReduce energy consumptionReduce manufacturing costPhosphatesWater insolubleDecomposition

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for monoammonium phosphate. A monoammonium phosphate product is prepared by directly subjecting high pure urea phosphate and ammonia to a double decomposition reaction and reacting for 20-60 min with stirring by controlling a reaction temperature at 40-80 DEG C and a pH value at a reaction endpoint being 4.2-4.6, and through the steps of cooling for crystallization; separating by centrifugation and drying. Measurements of physical and chemical indexes of the produced product show that the physical and chemical indexes of the produced monoammonium phosphate product meet an industrial first level standard. Specifically, the total nutrient content of monoammonium phosphate is higher than 73%; the content of total nitrogen is 12.01-12.23%; the content of phosphorus pentoxide is 61.05-61.25%; the content of moisture is 0.35-0.52%; a pH value is 4.2-4.6; the content of water insoluble materials is 0.090-0.096%; and the content of fluoride is 0.15-0.19%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

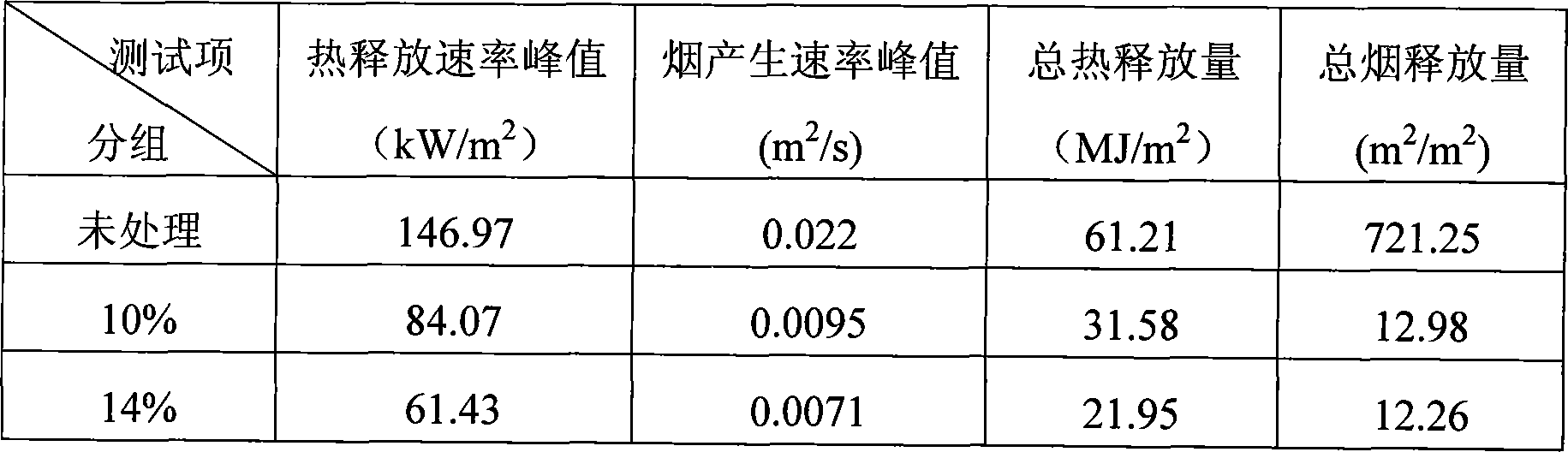

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

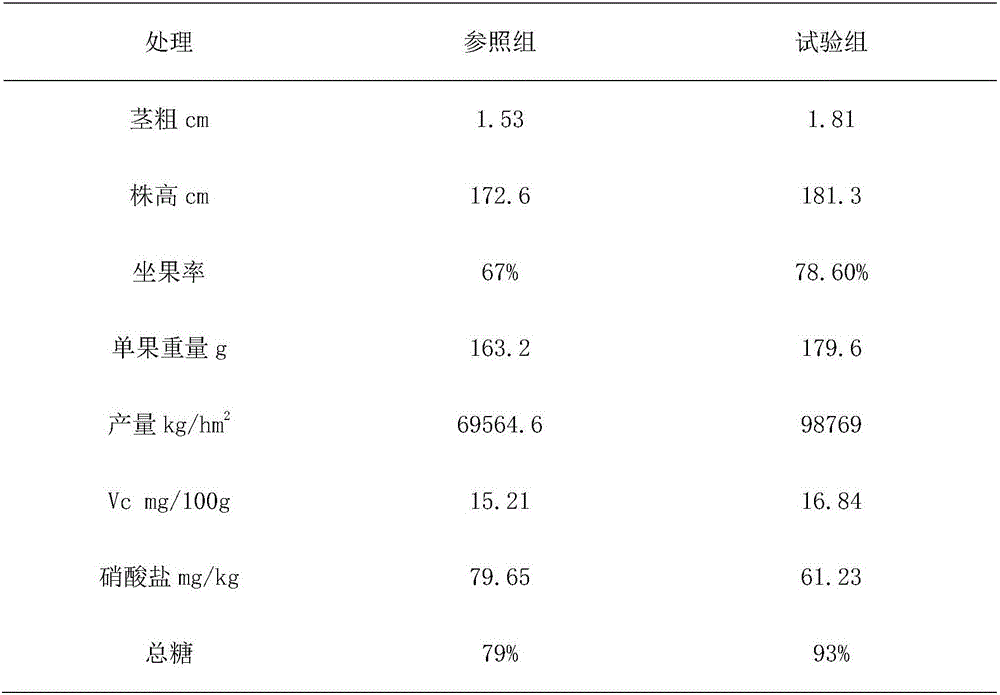

Soilless vegetable culture nutrient solution and preparation method

InactiveCN106699386AImprove stabilityHigh content of effective nutrientsCalcareous fertilisersMagnesium fertilisersAdditive ingredientNutrient solution

The invention relates to the field of nutrient solutions, in particular to a soilless vegetable culture nutrient solution and a preparation method. The soilless vegetable culture nutrient solution is prepared from sodium nitrate, urea phosphate, potassium nitrate, ammonium sulfate, magnesium chloride, Fe-EDTA, boric acid, manganese chloride, zinc sulfate, copper sulfate, sodium molybdate, mixed nitrogen-fixing bacterium solution and a nostoc extracting solution. The nutrient solution is simple and convenient to prepare, comprehensive in nutrient ingredient, high in biological activity and good in homogeneity, can decompose self-toxic materials produced by vegetables, remarkably improve the resistance, yield and the quality of the vegetables.

Owner:GUIZHOU UNIV

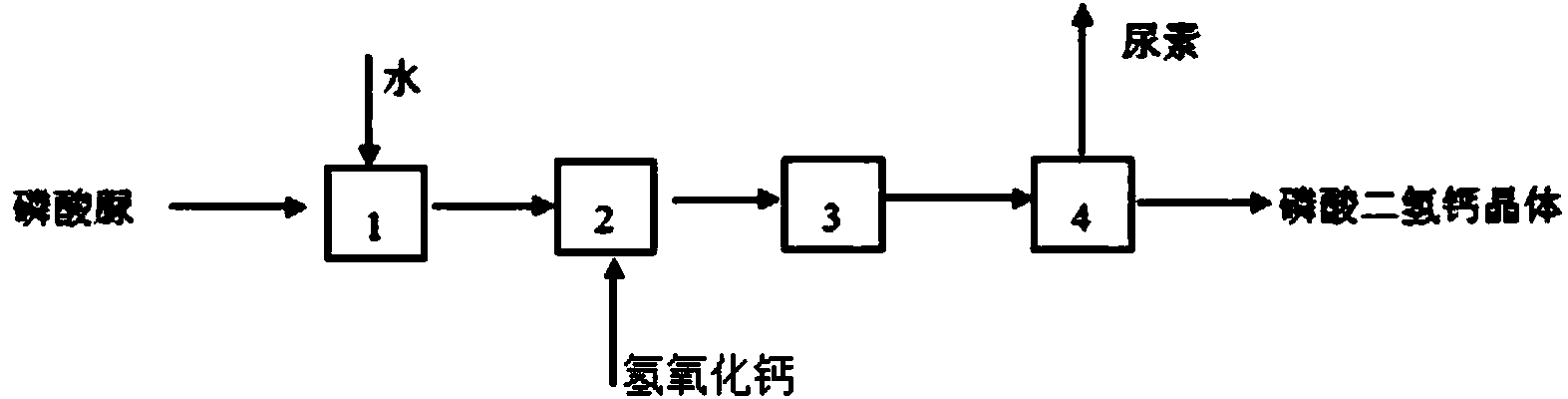

Production method of calcium dihydrogen phosphate

InactiveCN104003363AShort production processReduce manufacturing costPhosphorus compoundsCalcium hydroxidePhosphoric acid

The invention relates to the technical field of chemical engineering and in particular relates to a production method of calcium dihydrogen phosphate. According to the method, urea phosphate and calcium hydroxide directly react at 50-70 DEG C for 20-50 minutes under a stirring condition to prepare calcium dihydrogen phosphate. The method has the advantages that since calcium dihydrogen phosphate is prepared by reacting high-purity urea phosphate with calcium hydroxide, the defect in a production technology in which calcium dihydrogen phosphate is directly produced from phosphoric acid is overcome, the production process of calcium dihydrogen phosphate is simplified, and the production cost is reduced; the process conditions are accurately controlled, so that the purity of calcium dihydrogen phosphate is improved and the quality of calcium dihydrogen phosphate is stable and completely reach the standard of feed-grade calcium dihydrogen phosphate.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

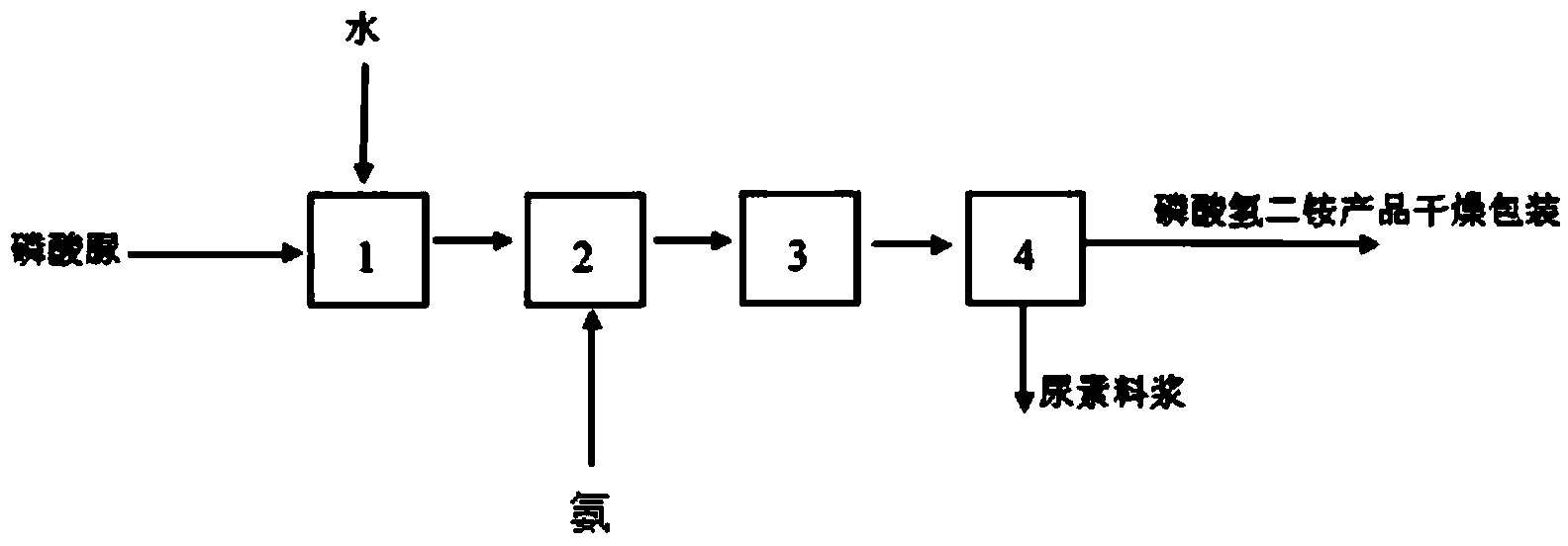

Production method for diammonium hydrogen phosphate

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for diammonium hydrogen phosphate. A diammonium hydrogen phosphate product is prepared by subjecting a high pure urea phosphate solution and ammonia to a double decomposition reaction, reacting for 20-60 min under stirring and at a temperature of 50-80 DEG C by controlling a pH value at 7.8-8.2. Physical and chemical indexes of the diammonium hydrogen phosphate product are as follows: the total nutrient content of diammonium hydrogen phosphate is higher than 74%; the content of total nitrogen is 21.02-21.20%; the content of phosphorus pentoxide is 53.0-53.52%; moisture content is 0.25-0.32%; the content of water insoluble substances is 0.087-0.096%; and the content of fluoride is 0.1-0.14%. The diammonium hydrogen phosphate product fully meets an industrial first level product standard.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

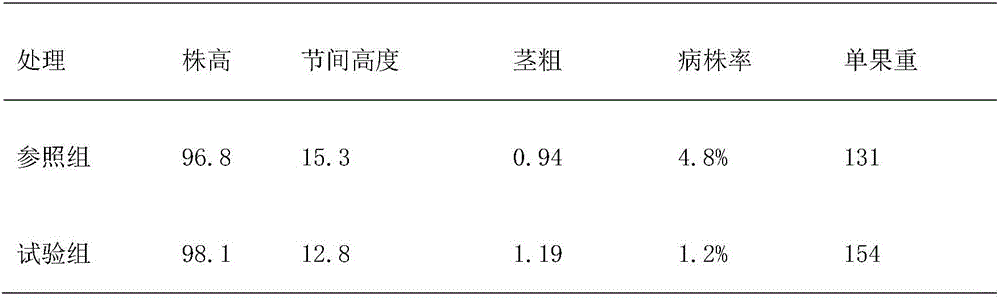

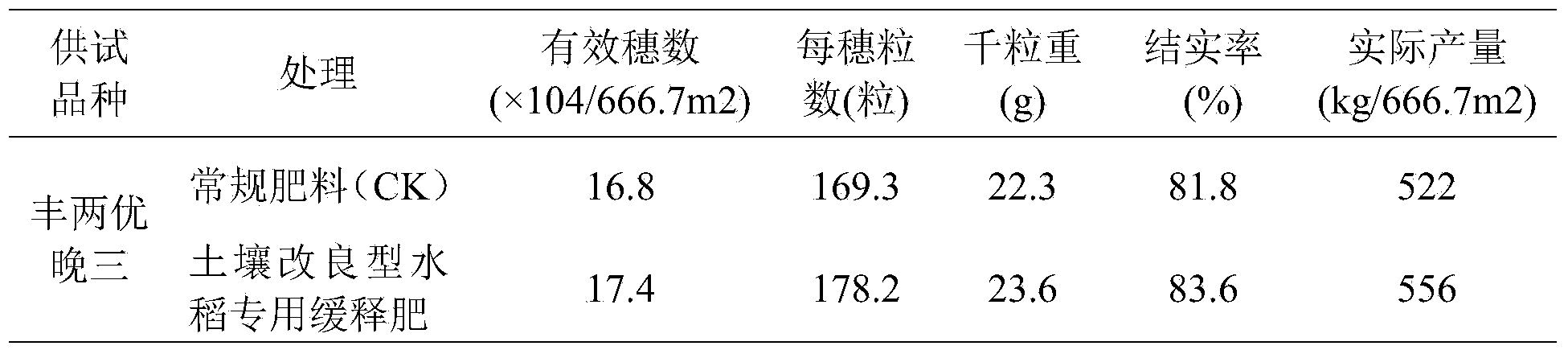

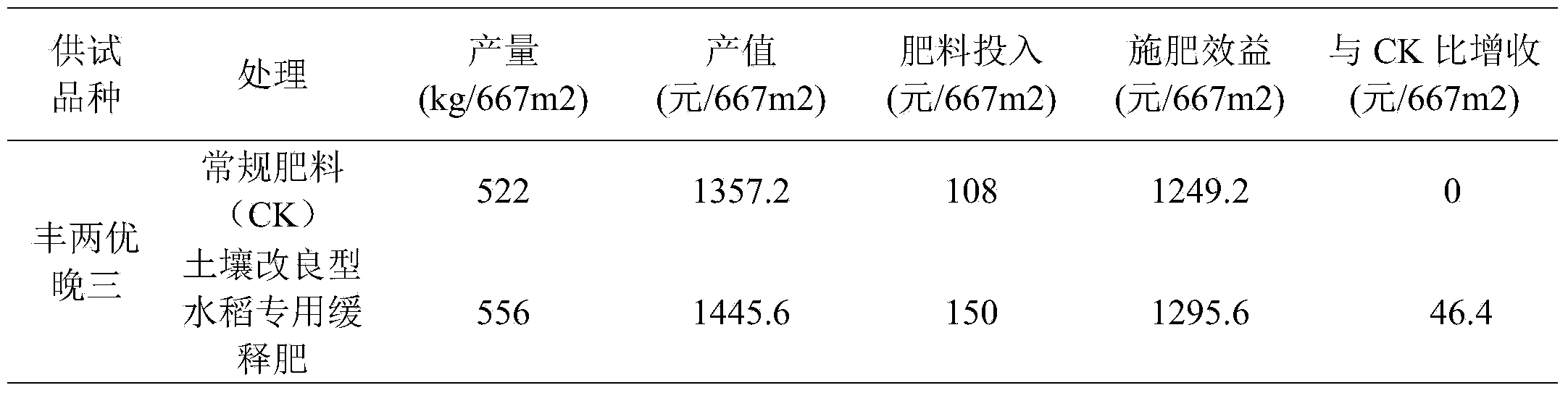

Compound fertilizer having growth promotion and high slow-release properties and used for rice planting as well as preparation method of compound fertilizer

InactiveCN106396982AIncrease productionQuality improvementCalcareous fertilisersMagnesium fertilisersCalcitePoultry manure

The invention discloses compound fertilizer having growth promotion and high slow-release properties and used for rice planting. The compound fertilizer is prepared from raw materials as follows: ammonium nitrate, monopotassium phosphate, urea, urea phosphate, calcium superphosphate, ammonium dihydrogen phosphate, potassium sulfate, magnesium sulfate, potassium nitrate, amino sodium dicarboxylate, Trichoderma, yeast powder, straw fermentation bacteria, cellulase, potassium mineral powder, rare earth, low-rank coal, silico-calcium powder, turf powder, fly ash, pine sawdust, kaolin, rice hull powder, poultry manure, maize straw, blue-green alga powder, dolomite, diatomite, calcite, humic acid, lignin, EDTA (ethylene diamine tetraacetic acid) chelate zinc, amino acid chelated molybdenum, dicyandiamide, phosphoric triamide and a modified slow-release agent. The invention further discloses a preparation method of the compound fertilizer having growth promotion and high slow-release properties and used for rice planting. The compound organic fertilizer has outstanding slow-release performance and can effectively increase the rice yield and improve the rice quality.

Owner:袁家和

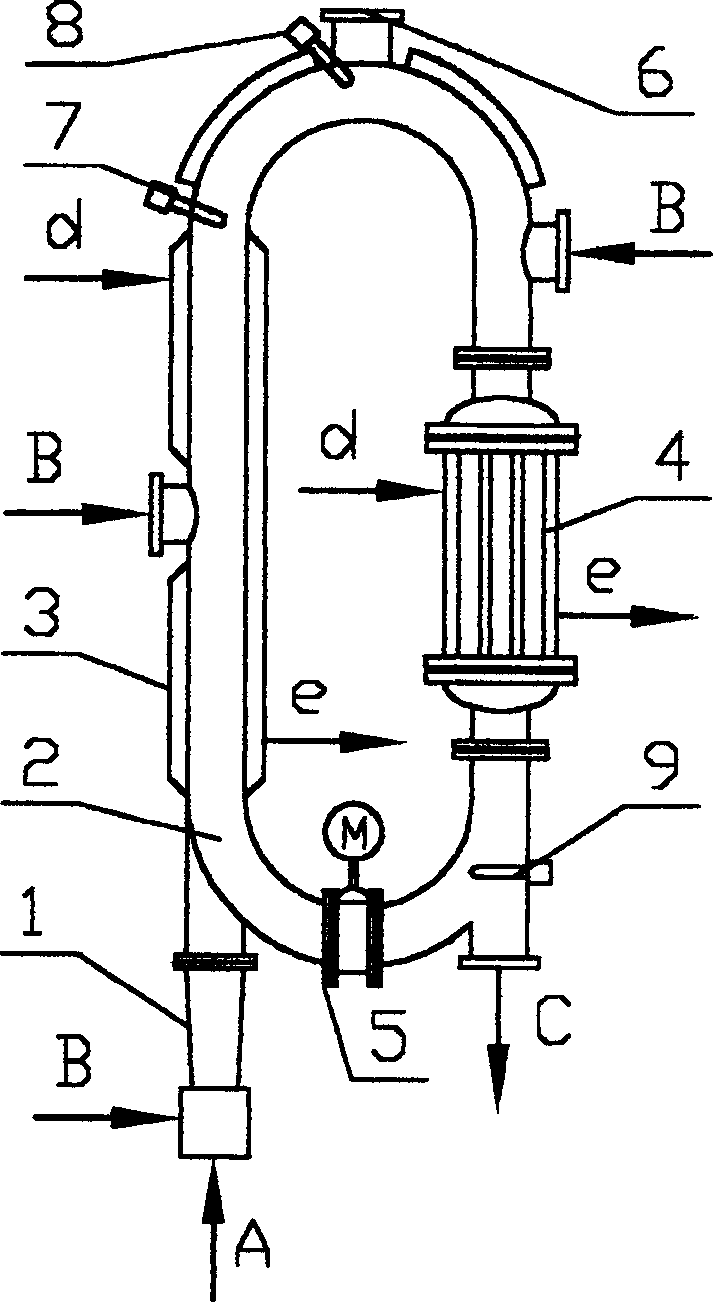

Method for preparing urea phosphoric acid with wet-process phosphoric acid

ActiveCN101318914AImprove conversion rateSimple processUrea derivatives preparationOrganic compound preparationPhosphoric acidReaction temperature

The invention discloses a method for producing urea phosphate by using wet-process phosphoric acid, belonging to the chemical engineering field. The method comprises the following steps of: taking the wet-process phosphoric acid with a concentration of between 25 and 50 percent of P2O5 as measured weight, and adding the wet-process phosphoric acid in a reaction kettle which is provided with a stirring device and a heating device; starting the stirring device to heat the wet-process phosphoric acid to a temperature of between 60 and 95 DEG C; adjusting a rotational speed of a stirrer to between 60 and 300 revolutions / min, and adding a reaction activating agent and a suspending agent in the reaction kettle, with a dosage of the activating agent being 0.1 to 1.2 per thousand of phosphoric acid in a reaction system, and a dosage of the suspending agent being 0.2 to 1.0 per thousand of the phosphoric acid in the reaction system; keeping stirring for 5 to 10 minutes, and adding urea, in which a mol ratio of the urea to the phosphoric acid is between 1.0 and 1.4, in the reaction kettle, and maintaining the reaction temperature for 0.5 to 1.5 hours; closing the heating device, cooling and crystallizing to room temperature, and separating a dried product; and using a separated mother solution to produce wood fire retardant or fertilizer. The method has the characteristics of simple process, high coefficient of recovery, high product purity, low manufacturing cost, cleanness without pollution and so on.

Owner:WENGFU (GRP) CO LTD

Disease-resistant plant fertilizer and preparation method thereof

InactiveCN104262027AImprove fertilityIncrease productionSuperphosphatesBio-organic fraction processingMicrobial agentPotassium carbonate

The invention relates to the field of agriculture and chemical industry, in particular to a disease-resistant plant fertilizer. The plant fertilizer is characterized by being prepared from the following raw materials in parts by weight: mashed garlic, plant ash, root bark of periploca sepeium, biochemical fulvic acid, carbendazim, waste defective tobacco leaves, radix sophorae flavescentis, distilled grains, a microbial agent, crofton weed, urea, calcium superphosphate, potassium carbonate, ammonium nitrate, borax, sodium humate, sodium selenite, urea phosphate, expanded perlite powder and tap water. The invention further discloses a preparation method of the plant fertilizer. The plant fertilizer is reasonable in formula, contains various nutrients and antibacterial components, and is suitable for fruits, vegetables and nursery stocks; by the plant fertilizer, the soil fertility can be effectively enhanced, the soil hardening phenomena can be reduced, viruses can be effectively resisted, the morbidity can be reduced, and the yield can be increased.

Owner:绥宁县纳金食品有限责任公司

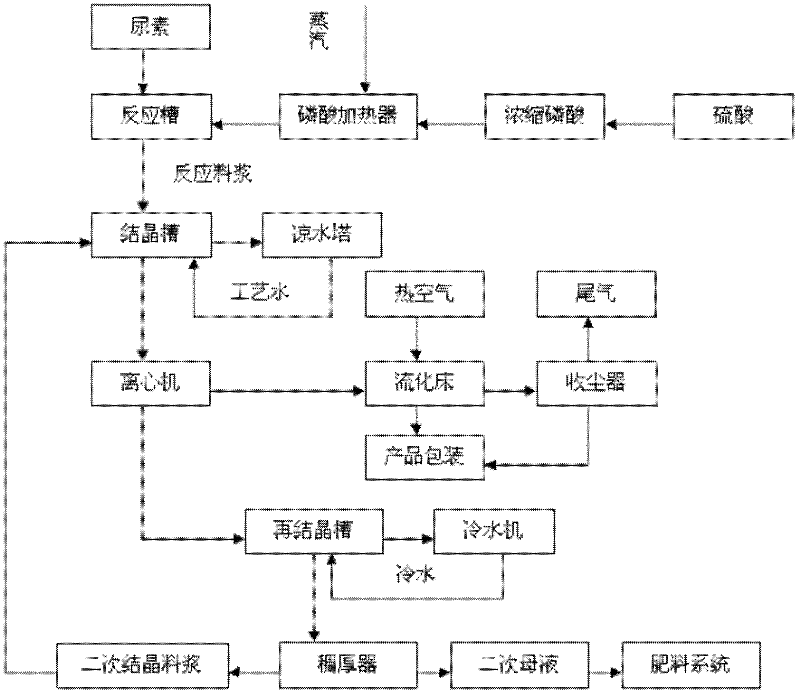

Urea phosphate production method

ActiveCN102391155AHigh yieldIncreased concentration of hydrogen ionsUrea derivatives preparationOrganic compound preparationPhosphoric acidSlurry

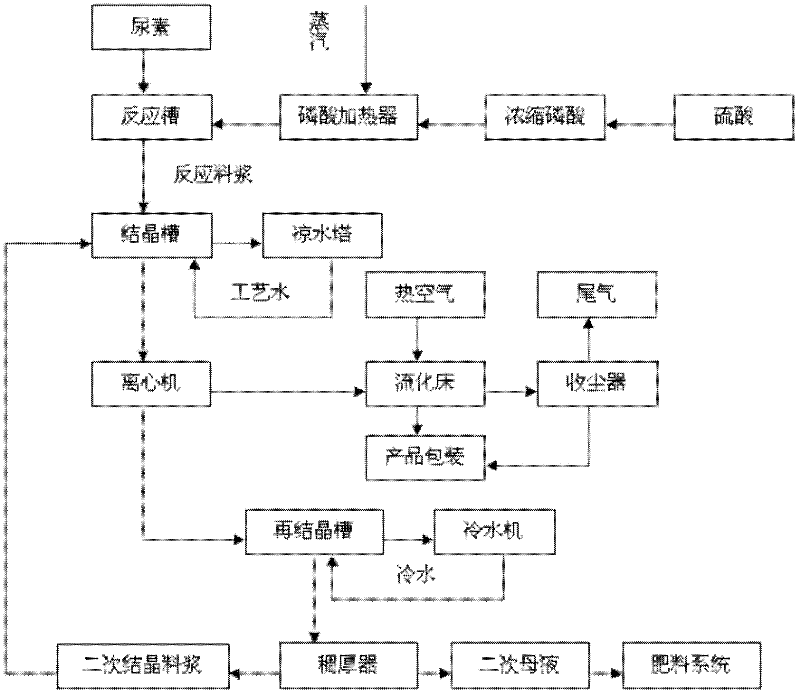

The invention relates to a urea phosphate production method, belonging to the field of chemical techniques. The technical problem solved by the invention is to provide a urea phosphate production method which is lower in production cost. The urea phosphate production method provided by the invention comprises the following steps of: a, mixed acidic solution preparation: adding a sulfuric acid into a phosphoric acid solution so as to obtain a mixed acidic solution; b, slurry preparation: heating the mixed acidic solution to 75-95 DEG C, then adding a reaction amount of urea into the mixed acidic solution, and stirring the obtained mixture so as to react the mixture, thereby obtaining a slurry; c, primary cooling crystallization: cooling the slurry to 45-65 DEG C so as to obtain a crystal-containing solution, filtering the crystal-containing solution so as to obtain crystals and filtrate, and then drying the obtained crystals so as to obtain urea phosphates; and d, secondary cooling crystallization: cooling the filtrate obtained in the step c to 20-25 DEG C, separating supernatant liquid to obtain lower thick liquid, mixing the lower thick liquid with the slurry obtained in the step b, and then operating the obtained mixture according to the step c.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method for producing type I ammonium polyphosphate with high degree of polymerization

The invention discloses a method for producing type I ammonium polyphosphate with high degree of polymerization. The method comprises the following steps: using urea phosphate, ammonium dihydrogen phosphate and urea as raw materials, mixing, melting and foaming the raw materials, and performing a condensation reaction on the mixture in an ammonia atmosphere, wherein the mol ratio of the urea phosphate to the ammonium dihydrogen phosphate to the urea is 1: (0-5.5): (0.2-8.0), the reaction temperature is between 200 and 320 DEG C, the reaction pressure is between 0.06 and 0.12 MPa, the reaction time is between 60 and 150 minutes, reaction products are crushed to prepare the type I ammonium polyphosphate with high degree of polymerization, and ammonia-containing exhaust gas is recovered. The method is simple to operate and easy to implement with high degree of polymerization of the products, and is conducive to the popularization of industrialization.

Owner:GUIZHOU CHANHEN CHEM CO LTD

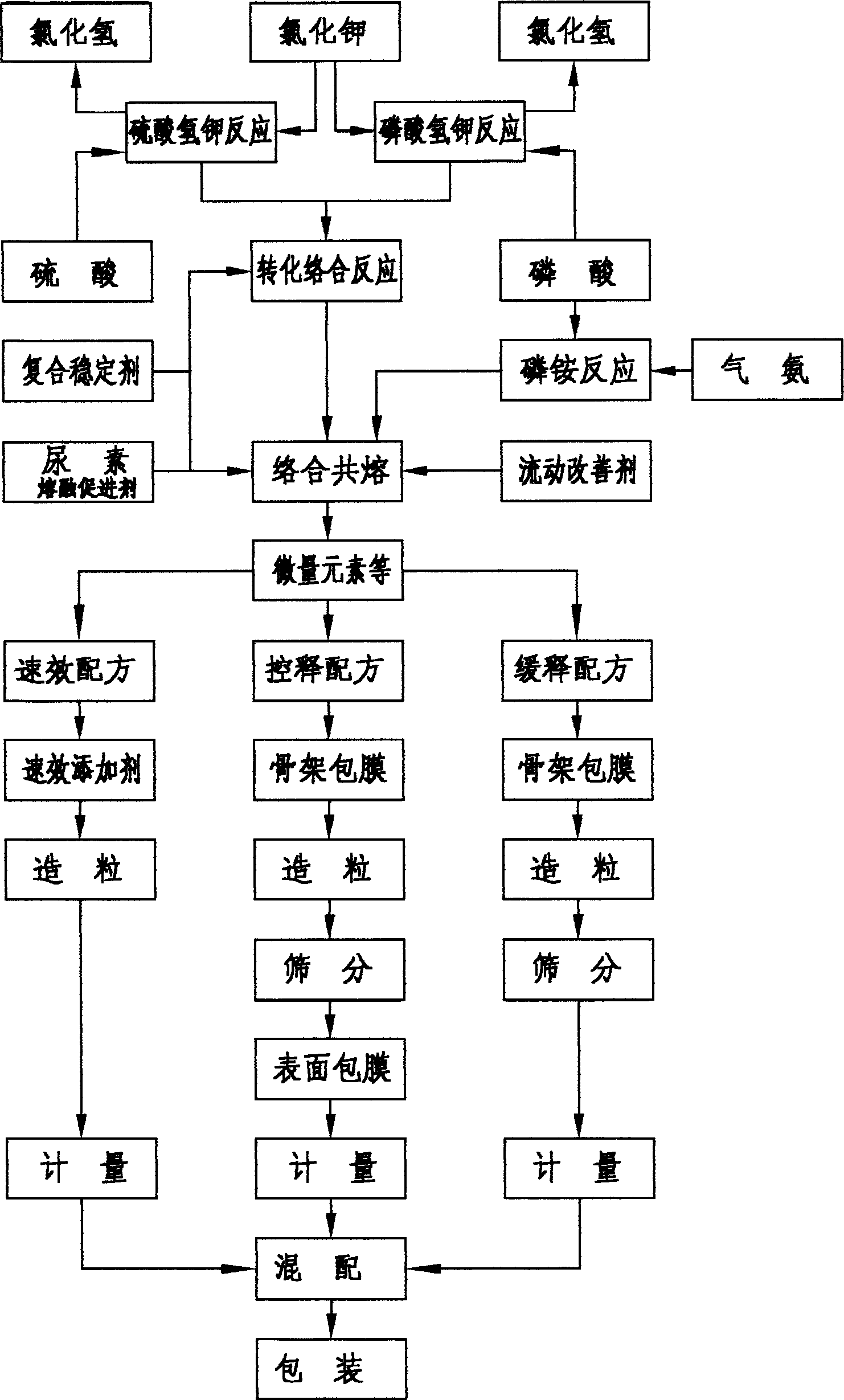

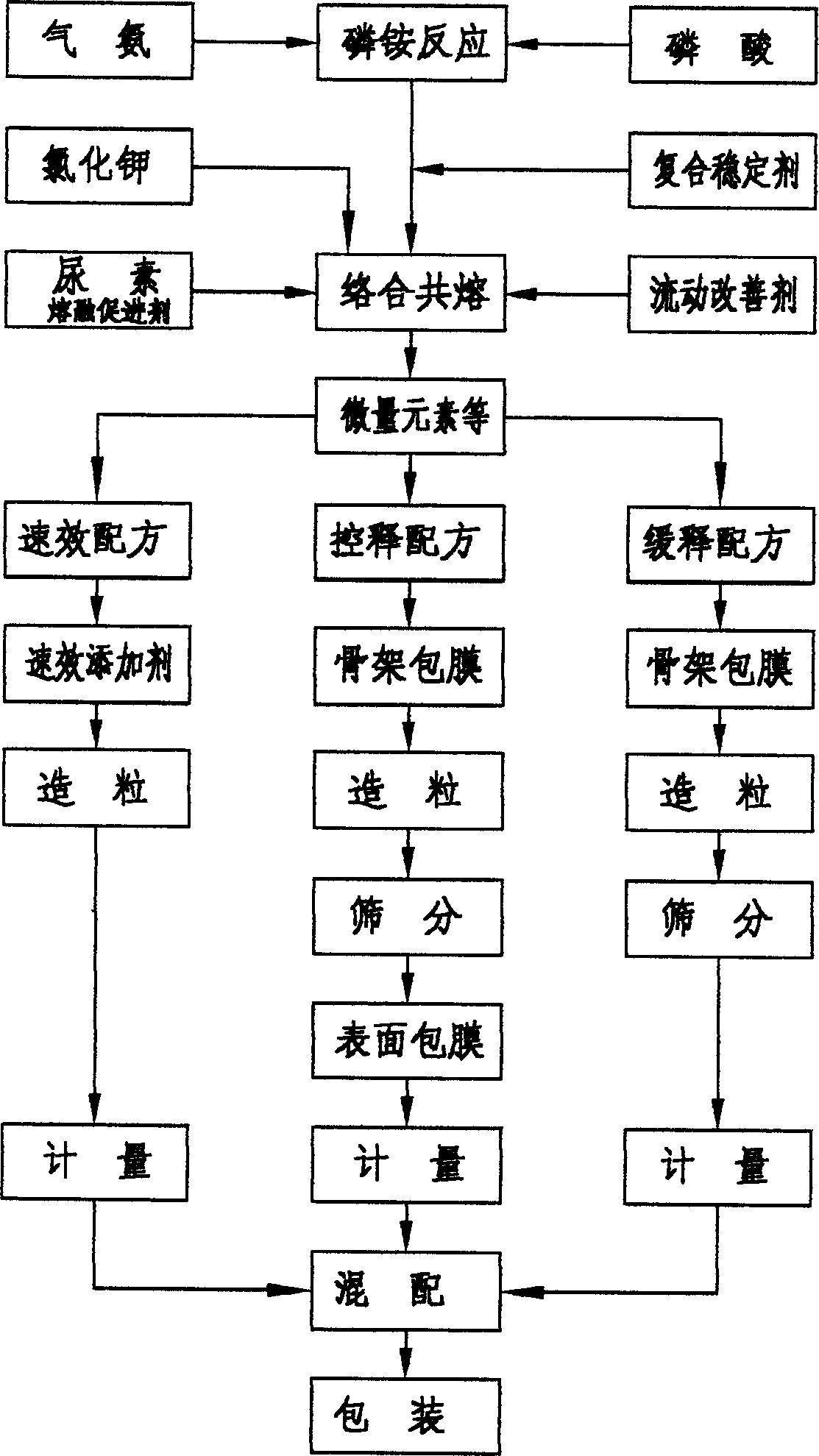

Nutrient released modle of compound controlled releasing and production thereof

InactiveCN1644568AWide range of choicesAdjustable release rateFertilizer mixturesPhosphoric acidSlurry

A controlling and releasing composite fertilizer nutrient releasing model and production are disclosed. The production is carried out by potassium chloride reacting with phosphoric acid and concentrated sulfuric acid, recovering hydrogen chloride, two products reacting, adding urine to obtain mixed slurry of potassium sulfate and urea phosphate, adding stabilizer and flowing-performance improver, reacting with urea to obtain ammonium phosphate mixing melt in melting boiler, regulating NPK proportion, adding functional additive, combing releasing mechanism with instant releasing, frame slow releasing and surface controllable releasing, granulating, coating, computing fertilizer proportion, and obtaining controllable releasing composite fertilizer. Its advantages include low cost, regulating releasing period and no environmental pollution.

Owner:周端午

Multiple-effect wood fire retardant and method for preparing the same

InactiveCN101134331ALow costAvoid anti-frost phenomenonWood impregnation detailsWater softeningMildew

The present invention relates to wood fire retardant, and is especially one kind of multiple effect wood fire retardant and its preparation process. The multiple effect wood fire retardant is prepared with boric acid, guanyl urea phosphate, ammonium dihydrogen phosphate, water softening agent and anti-mildew agent, and through mixing and drying. Once using the multiple effect wood fire retardant in treating timber can reach the protecting effects of preventing fire, inhibiting smoke, preventing corrosion, preventing moth, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY

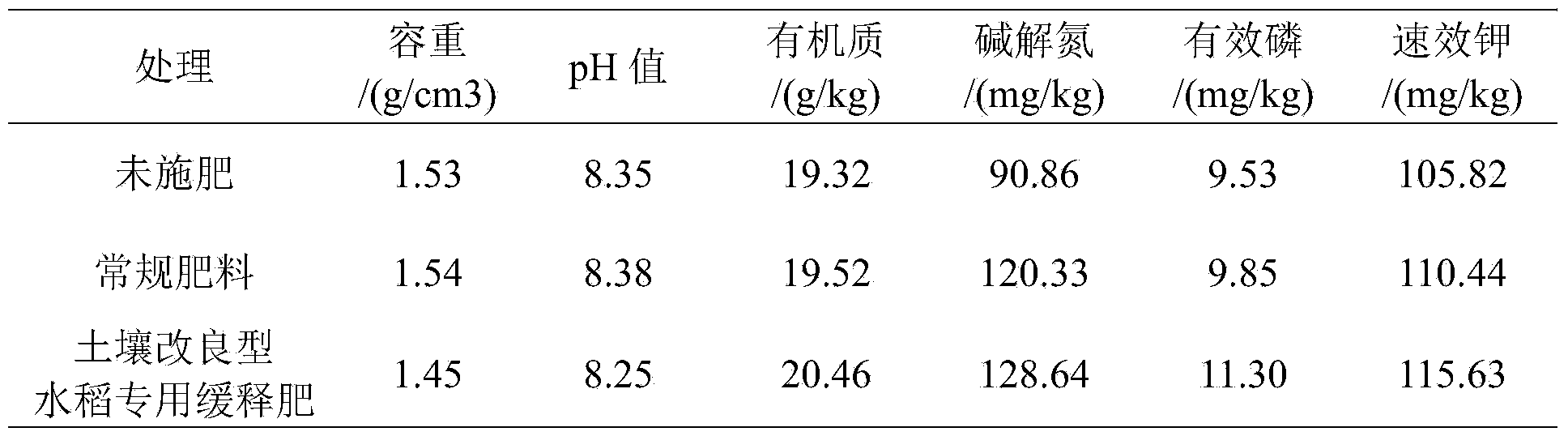

Soil-improvement special slow release fertilizer for rice, and preparation method thereof

ActiveCN103524219AReduce improvementReduce the fertilization effectFertiliser formsFertilizer mixtures2-ButanolUnsaturated polyester

The invention discloses a soil-improvement special slow release fertilizer for rice. The soil-improvement special slow release fertilizer for rice comprises 30-45wt% of powdery urea, 20-40wt% of urea phosphate, 8-15wt% of potassium chloride, 15-30wt% of a potash magnesium sulfate fertilizer, 2-8wt% of zinc humate, 1-6wt% of manganese humate, 1-5wt% of urea iron humate, 0.005-0.02wt% of compound sodium nitrophenolate, 1-5wt% of a slow release agent and 1.99-6wt% of an auxiliary material, wherein the slow release agent contains 5-15wt% of N-methylolacrylamide, 10-30wt% of an unsaturated polyester resin, 4-10wt% of cyclohexanol, 5-13wt% of 2-butanol, 1-5wt% of talcum powder, 1-4wt% of kaolin, 1-6wt% of ethyl cellulose, and the balance distilled water. The invention also discloses a preparation method of the soil-improvement special slow release fertilizer for rice.

Owner:ANHUI SIERTE FERTILIZER IND

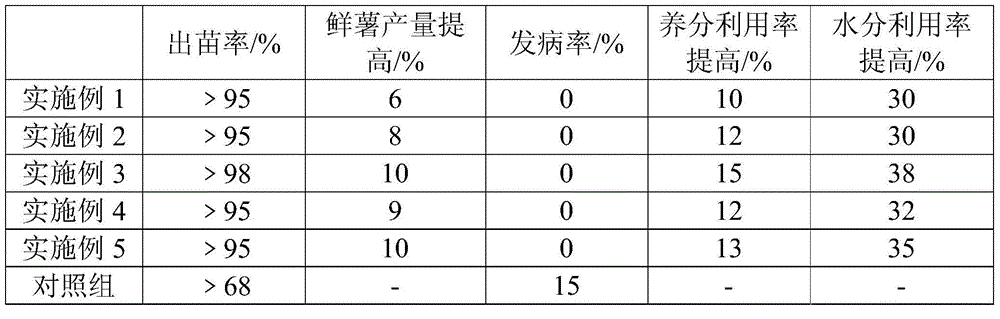

Slow-release fertilizer for potatoes

InactiveCN104892319AExtend the fertilizer periodReduce churnFertilizer mixturesBeta-CyclodextrinsChemistry

The invention relates to the technical field of fertilizers, in particular to a slow-release fertilizer for potatoes. The slow-release fertilizer for the potatoes comprises the following components in parts by weight: 30-50 parts of nitrogen-phosphorus-potassium compound fertilizer, 8-12 parts of fulvic acid potassium, 8-15 parts of urea phosphate, 2-4 parts of citric acid, 3-8 parts of EDTA-Zn, 8-10 billion / g of bacillus subtilis, 1.8-6.4 parts of a carbamide peroxide-beta-cyclodextrin inclusion compound, 0.8-4.8 parts of a controlled release agent, 1.2-3.6 parts of a water-retaining agent and 6-12 parts of a soil conditioner. The slow-release fertilizer for the potatoes is long in effective period, loss of fertilizer caused by volatilization and leaching can be greatly reduced, and the limited fertilizer and water can be fully absorbed and utilized by plants to achieve integrated water and fertilizer and improve soil. The slow-release fertilizer provided by the invention has excellent water retention and slow-release performance, the fertilizer element utilization is improved, the environmental pollution is reduced and the crop growth is promoted.

Owner:ZHANGJIAGANG HONGJIA DIGITAL TECH

Water soluble fertilizer additive, water soluble fertilizer composite containing same and application of water soluble fertilizer composite

ActiveCN103449933AReduce clogged drippersIncrease profitPressurised distribution of liquid fertiliserAgriculture gas emission reductionPolyaspartic acidFertigation

The invention discloses a fertilizer additive, a fertilizer composite containing the additive and application of the fertilizer composite and particularly relates to a water soluble fertilizer additive, a water soluble fertilizer composite containing the water soluble fertilizer additive and application of the water soluble fertilizer composite. The water soluble fertilizer additive comprises, by weight, 10 parts of urea phosphate, 1-2 parts of guar gum, 0.5-1 part of polyacrylamide, 0.5-1 part of potassium polyacrylate and 0.1-0.5 part of sodium of polyaspartic Acid. The water soluble fertilizer additive can effectively reduce the frequency of the phenomenon that a water dropper is blocked when water soluble fertilizer containing the water soluble fertilizer additive is applied to fertigation, and reduce the probability of the phenomenon that crops do not absorb the obtained water soluble fertilizer. Meanwhile, the water soluble fertilizer additive can effectively solve the problem that the use ratio of phosphorus fertilizer in the water soluble fertilizer is low.

Owner:SICHUAN ANDA CHEM CO LTD

Method for producing urea phosphate through vacuum crystallization

ActiveCN101665453AShorten crystallization timeIncrease production capacityUrea derivatives preparationOrganic compound preparationPhosphoric acidSuspending Agents

The invention discloses a method for producing urea phosphate through vacuum crystallization. The method comprises the following steps: adding 36-85wt% of phosphoric acid in a reaction device, starting an agitating device with the rotating speed of 100-200RPM, adding activator accounting for 0-0.012% of phosphoric acid and suspending agent accounting for 0-0.010% of phosphoric acid, heating with the rate of 4 DEG C / MIN to 60-100 DEG C, adding urea of which molar ratio to phosphoric acid is 1.4-1.0, keeping temperature for 30-120MIN, closing the heating device, concentrating under the vacuum degree of 0.01-0.50 MPA for 10-60MIN to obtain urea phosphate crystal paste solution with the solid content of 60-90%, reducing the temperature to 30-40 DEG C under vacuum, closing the vacuum system, separating and drying to obtain the urea phosphate product. The crystallization time of the method of the invention is short, the crystallizer is not easy to form scale, the yield is high, the process is simple and the production cost is low.

Owner:WENGFU (GRP) CO LTD

Disease and pest resistant flower fertilizer and preparation method thereof

InactiveCN104072263AFast absorptionWell developed root systemFertilizer mixturesFlowering seasonPhosphoric acid

The invention discloses a disease and pest resistant flower fertilizer and a preparation method thereof. The disease and pest resistant flower fertilizer consists of the following raw materials in parts by weight: 60-70 parts of urea, 13-15 parts of attapulgite, 12-14 parts of saw dust, 23-25 parts of expanded perlite powder, 20-30 parts of distillers' grains, 10-15 parts of potato peels, 2-3 parts of dicyandiamide, 1-3 parts of triple superphosphate, 2-4 parts of potassium sulfate, 8-10 parts of soil nutrient, 3-5 parts of zinc sulfate, 2-5 parts of urea phosphate, 4.5-5.5 parts of kieselguhr, 1-3 parts of sodium carboxymethyl cellulose and 10-15 parts of castor bean leaves. By adopting the flower fertilizer disclosed by the invention, the problem of single function of the traditional fertilizer is solved, and the problem of repeated fertilization and drug delivery by farmers is overcome; after the flower fertilizer is applied, the absorption by flowers is fast, the root system is very prosperous, the flowers grow vigorously, leaves are wide with bright color, flower buds are effectively increased, the flower season is prolonged, the flowers are bright, and the disease resistance is improved.

Owner:明光市业兴非金属材料厂

High-phosphorus high-zinc liquid compound fertilizer and preparation method thereof

ActiveCN103664359AHigh nutrient contentPhysical stabilityFertilising methodsFertilizer mixturesPhosphatePhosphoric acid

The invention discloses a high-phosphorus high-zinc liquid compound fertilizer and a preparation method thereof. The compound fertilizer comprises the following raw materials in parts by weight: 0.8-1.2 parts of disodium octoborate tetrahydrate, 0.7-1.1 parts of EDTA-Mn, 8-12 parts of zinc fertilizer, 0.6-1 part of magnesium fertilizer, 40-46 parts of phosphate, 5-7 parts of urea, 0.8-1.2 parts of ammonium nitrate, 1.5-2.5 parts of urea phosphate, 1.5-2.5 parts of ammonium polyphosphate, 4-6 parts of potassium hydroxide, 1.5-2.5 parts of potassium chloride, 1.5-2.5 parts of a cosolvent and 20-30 parts of water. The compound fertilizer is a three-element liquid fertilizer containing trace elements, is high in overall nutrient content, stable in physical and chemical shape, and free from the phenomena of crystallization, precipitation and layering under the high-temperature, low-temperature and ordinary temperature conditions, can obviously improve the fertilization efficiency, and meanwhile avoids the zinc deficiency symptoms of plants.

Owner:SOUTH CHINA AGRI UNIV

Biological compound fertilizer and preparation method thereof

InactiveCN106045683AImprove disease resistanceImprove immunityExcrement fertilisersBioloigcal waste fertilisersDiseaseLivestock manure

The invention relates to a biological compound fertilizer and a preparation method thereof. The biological compound fertilizer is prepared from, by weight, 10-15 parts of a microbial agent, 5-10 parts of lactobacillus plantarum, 5-10 parts of photosynthetic bacteria, 5-10 parts of yeast, 80-120 parts of straw, 30-50 parts of bagasse, 30-50 parts of peanut hulls, 30-50 parts of soybean meal, 30-50 parts of poultry and livestock manure, 30-50 parts of water, 30-50 parts of a modified carrier, 0.5-1 part of a water retaining agent, 3-6 parts of corn starch, 0.5-3 parts of sodium carboxymethylcellulose, 3-5 parts of alkyl glycoside, 0.5-2 parts of a complex enzyme preparation, 0.5-1 part of citric acid, 5-10 parts of fulvic acid potassium powder, 5-10 parts of ammonium molybdate, 5-10 parts of urea phosphate, 5-10 parts of sodium borate, 3-5 parts of zinc sulfate heptahydrate, 3-5 parts of carboxymethyl chitosan and 3-5 parts of crospolyvinylpyrrolidone. The biological compound fertilizer can enhance the disease resistance and immunity of crops, loosen soil, improve the ecological environment, effectively degrade pesticide residues and macromolecular organic matter, increase the crop yield and improve the crop quality.

Owner:杜兆龙

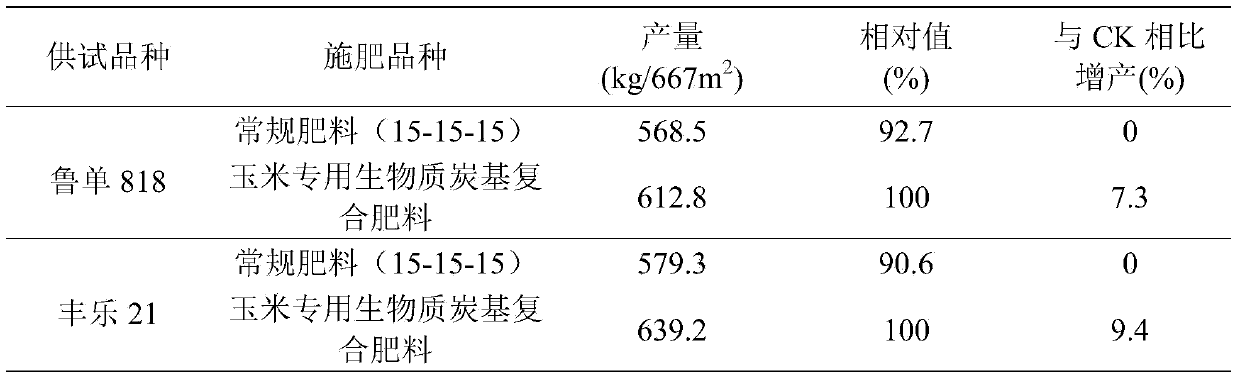

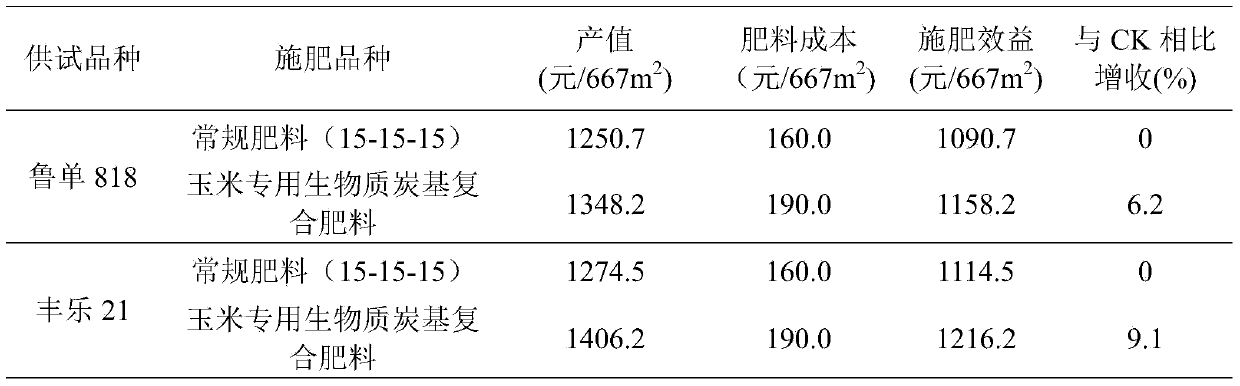

Special biomass charcoal-based composite fertilizer for corn and preparation method thereof

The invention discloses a special biomass charcoal-based composite fertilizer for corn. The special biomass charcoal-based composite fertilizer for the corn comprises the following components in parts by weight: 7-15 parts of potassium magnesium sulfate fertilizer, 3-7 parts of potassium chloride, 5-13 parts of fertilizer-grade calcium hydrogen phosphate, 15-20 parts of urea phosphate, 40-50 parts of powdery urea, 6-9 parts of rapeseed straw charcoal powder, 0.2-0.8 part of sodium silicate, 0.05-0.47 part of EDTA (ethylenediaminetetraacetic acid) chelated zinc, 0.05-1 part of EDTA chelated manganese and 1-7 parts of auxiliary materials. The invention further discloses a preparation method of the special biomass charcoal-based composite fertilizer for the corn. After the special biomass charcoal-based composite fertilizer for the corn, disclosed by the invention, is applied, the soil can be effectively improved and fertilized, the content of organic matters in the soil is increased, the soil bulk density is reduced, and the water-retaining and fertilizer-keeping capability of the soil is improved; furthermore, the utilization efficiency of fertilizer nutrients is relatively high, the release of nutrient elements is coordinated and lasting, the nutrients can be supplied to the corn in a relatively comprehensive and balanced manner, the yield of the corn is significantly improved, the quality of the corn is improved, and the economic benefits are obvious.

Owner:ANHUI SIERTE FERTILIZER IND

Soil conditioner and preparation method thereof

InactiveCN106966780AGuaranteed oxygen contentGuaranteed moisture contentCalcareous fertilisersAgriculture tools and machinesPorosityMicrobial agent

The invention provides a soil conditioner and a preparation method thereof. The soil conditioner comprises, by weight, 12 to 20 parts of plant ash, 5 to 10 parts of phosphorous slag, 5 to 9 parts of quicklime, 2 to 5 parts of zeolite, 2 to 5 parts of attapulgite, 1 to 3 parts of Yilong seaweed ooze, 2 to 5 parts of Chinese magnoliavine residues, 2 to 5 parts of large-flowered skullcap root residues, 20 to 30 parts of straw, 8 to 13 parts of hickory nut shells, 0.02 to 0.04 part of rotenone, 10 to 15 parts of mangosteen shells, 3 to 5 parts of an EM microbial agent, 7 to 20 parts of urea phosphate, 8 to 14 parts of urea, 10 to 15 parts of biochemical potassium fulvate and 9 to 12 parts of gamma-polyglutamic acid. The invention has the beneficial effects that the soil conditioner has high porosity and has specific adsorption effect on heavy metal ions; the soil conditioner can adjust the pH value of soil, is rich in trace elements and can elemental N, elemental P and elemental K at the same time; and the soil conditioner allows soil to maintain high porosity and to be long in fertility maintenance time and good in water retention performance.

Owner:嵊州市派特普科技开发有限公司

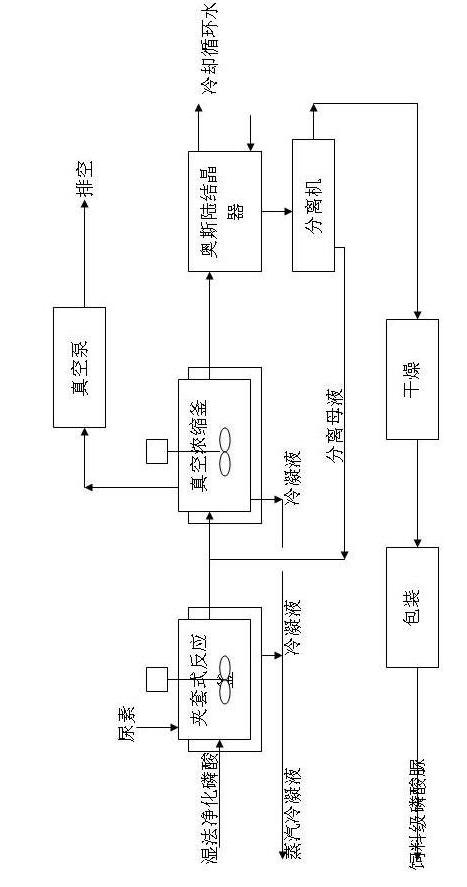

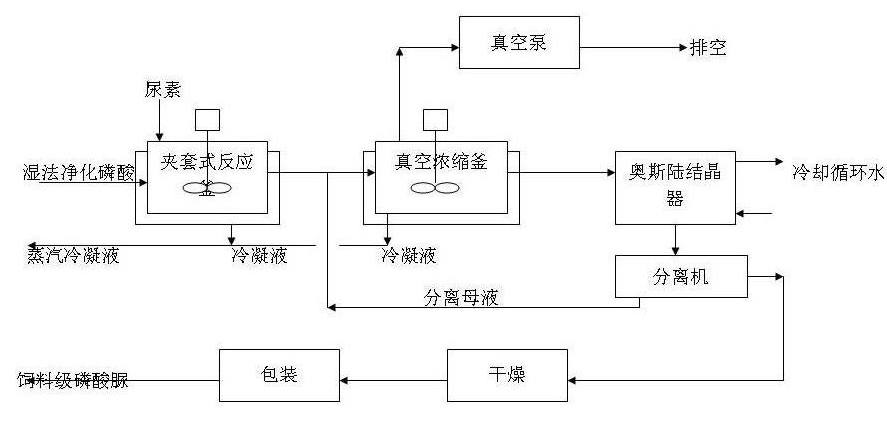

Method for continuously producing feed grade urea phosphate by using wet purified phosphoric acid

InactiveCN102040544AThe reaction process is simpleImprove continuityUrea derivatives preparationOrganic compound preparationActive agentPhosphoric acid

The invention discloses a method for continuously producing feed grade urea phosphate by using wet purified phosphoric acid, which is characterized by comprising the following steps of: continuously adding 5 to 7 percent wet purified phosphoric acid and urea according to a molar ratio of 1:(1.0-1.05) for mixing, reacting with stirring at the temperature of between 70 and 85 DEG C for 30 to 60 minutes, keeping the temperature of between 80 and 90 DEG C, performing vacuum concentration under the pressure of between 33 and 38Kp, concentrating materials, crystallizing and cooling to the temperature of 35 DEG C, separating and drying crystalline liquid to obtain the feed grade urea phosphate, and returning mother liquor to the vacuum concentration. In the method, the urea phosphate is continuously produced by taking the purified phosphoric acid on the basis of wet extraction purification technology as a raw material, namely the purified phosphoric acid and the urea are directly taken as raw materials, and are subjected to heating, vacuum concentration, cooling crystallization, separation and drying to obtain a feed grade urea phosphate product, and an active agent, a suspending agent and the like are not required to be added in the reaction, so that the reaction process is simple, and high in continuity, yield and product purity, ensures that the mother liquid is not generated, and has high promotional value for the subsequent product development of the purified phosphoric acid.

Owner:中化重庆涪陵化工有限公司

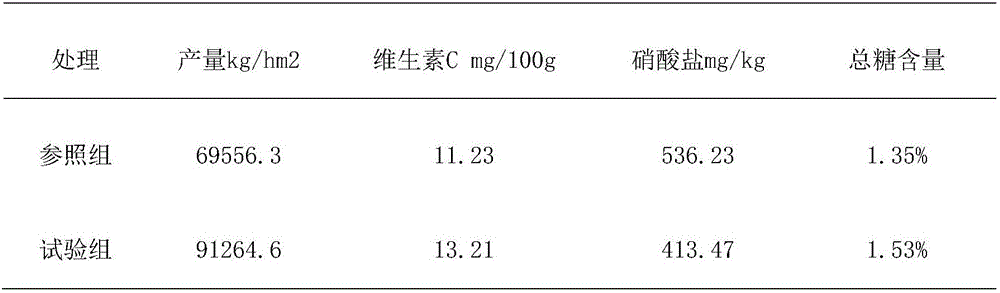

Compound organic fertilizer used for rice planting and having high slow release property as well as preparation method of compound organic fertilizer

InactiveCN106588308AGood slow releaseIncrease productionCalcareous fertilisersMagnesium fertilisersSodium BentoniteCalcite

The invention discloses compound organic fertilizer used for rice planting and having the high slow release property. The compound organic fertilizer is prepared from raw materials as follows: ammonium nitrate, monopotassium phosphate, urea, urea phosphate, calcium superphosphate, ammonium dihydrogen phosphate, potassium sulfate, magnesium sulfate, potassium nitrate, amino sodium dicarboxylate, trichoderma, yeast powder, a straw fermentation agent, cellulase, potassium mineral powder, mica powder, chitin, talc, turf powder, fly ash, conch powder, furfural residues, rice hull powder, poultry manure, corn straw, rapeseed cakes, dolomite, diatomite, calcite, humic acid, lignin, sodium bentonite, EDTA chelate, amino acid chelate, dicyandiamide, phosphoryl triamide, a slow release agent and a soil conditioning agent. The invention further provides a preparation method of the s compound organic fertilizer used for rice planting and having the high slow release property. The compound organic fertilizer has excellent slow release property and can effectively the yield and quality of crops.

Owner:安徽爱能洁生物科技有限公司

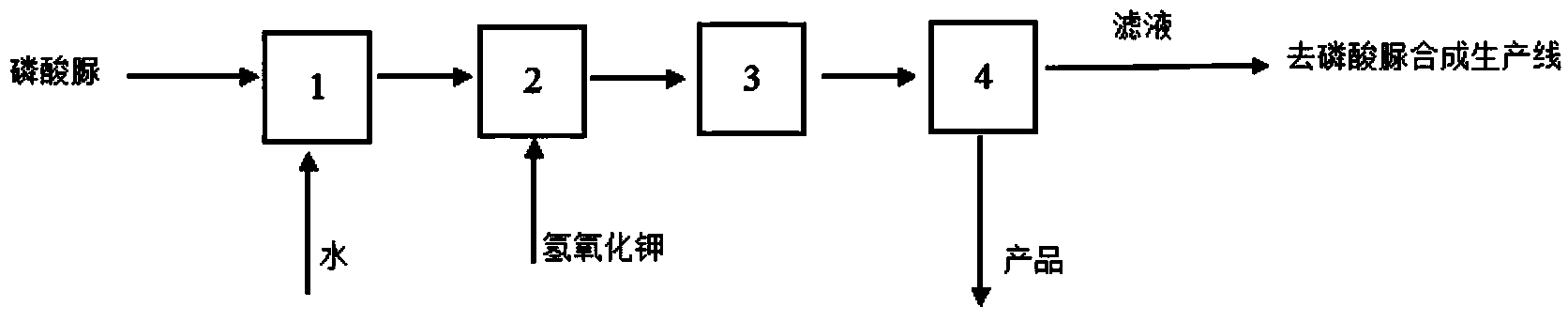

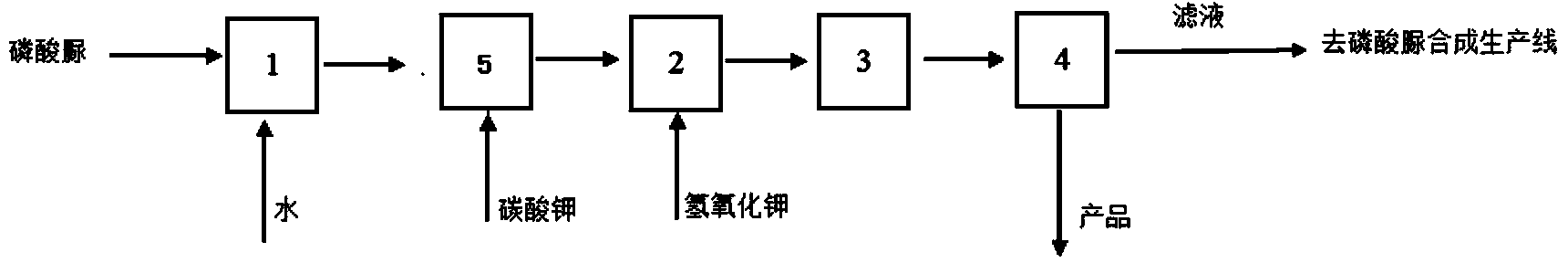

Production method for tripotassium phosphate

InactiveCN104016324AReduce manufacturing costEasy to getPhosphorus compoundsHigh energyPotassium hydroxide

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for tripotassium phosphate. A tripotassium phosphate product is prepared by directly reacting urea phosphate and potassium hydroxide according to a molar ratio of 1: 2.95-3.05 for 30-60 min at a reaction temperature of 40-80 DEG C, with stirring at a stirring speed of 30 r / min. The tripotassium phosphate product is prepared by directly reacting urea phosphate and potassium hydroxide, so that the whole process has no requirements for high energy consumption; raw materials can be obtained relatively easily; a process route is short and simple; and production cost of tripotassium phosphate is reduced. By adjusting the process route and controlling reaction conditions, the produced tripotassium phosphate completely meets a first level standard of industrial tripotassium phosphate.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Biomass charcoal-based compound fertilizer special for wheat and preparation method of biomass charcoal-based compound fertilizer

The invention discloses a biomass charcoal-based compound fertilizer for wheat. The biomass charcoal-based compound fertilizer comprises the following components in parts by weight: 8 to 14 parts of potash magnesium sulphate fertilizer, 12 to 17 parts of potassium chloride, 6 to 13 parts of fertilizer-level calcium hydrophosphate, 13 to 21 parts of urea phosphate, 30 to 40 parts of powdery urea, 8 to 14 parts of soybean straw powdered carbon, 2 to 7 parts of sodium silicate, 1 to 4 parts of EDTA chelate Zn, 1 to 4 parts of EDTA chelate Fe, 1 to 5 parts of ammonium molybdate and 3 to 7 parts of an auxiliary material. The invention further discloses a preparation method for the biomass charcoal-based compound fertilizer special for the wheat. According to the invention, after the biomass charcoal-based compound fertilizer special for the wheat is applied, not only can soil be effectively improved and fertilized, the content of soil organic matter can be increased, the volume weight of soil can be reduced, and the water retention and fertilizer retention capabilities of the soil can be improved, but also the fertilizer nutrient utilization efficiency is relatively high, nutrient element release is coordinated and lasting, nutrient can be supplied to the wheat relatively comprehensively and evenly, the output of the wheat can be obviously improved, the quality of the wheat can be improved, and obvious economic benefit can be achieved.

Owner:ANHUI SIERTE FERTILIZER IND

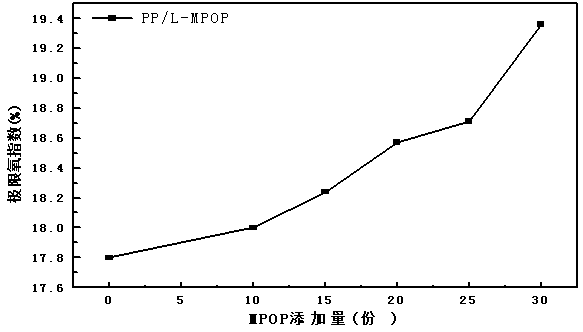

Preparation method of MPOP

InactiveCN105504292AHigh degree of polymerizationLow water solubilityOrganic chemistryFiltrationReaction temperature

The invention provides a preparation method of MPOP. The method comprises steps as follows: (1) preparation of an intermediate: urea phosphate is dissolved in water, the concentration of urea phosphate is controlled to range from 10% to 50%, a certain amount of melamine is added to react with urea phosphate, the molar ratio of urea phosphate to melamine is 1:(0.8-1.25), the reaction temperature is controlled within 25-100 DEG C, the reaction time is 0.5-2.5 h, filtration, washing and vacuum drying are performed, and the intermediate is obtained; (2) preparation of MPOP: the intermediate prepared in Step A is calcined at the temperature of 200-400 DEG C for 1-5 h, cooling, grinding and sieving are performed, and a flame retardant, namely, MPOP is obtained. The technology is simple, industrialization is easy to realize, the operation condition is mild, water is taken as a reaction medium, and the method is clean and pollution-free.

Owner:WENGFU (GRP) CO LTD +2

Nano saline alkali soil improvement agent and preparation technology thereof

InactiveCN103289705AHigh ion exchange capacityImprove fertilizer efficiencyAgriculture tools and machinesOrganic fertilisersAlkali soilIon exchange

The invention discloses a nano saline alkali soil improvement agent. The nano saline alkali soil improvement agent comprises the following components according to a formula: 48-92wt% of ardealite, 0.001-5wt% of boric acid, 0.01-10wt% of zinc sulphate, 2-30wt% of urea phosphate, 1-35wt% of potassium fulvic acid and 0.001-5wt% of nano photocatalyst. The nano saline alkali soil improvement agent contains the nano photocatalyst, and heavy metal content in ardealite can be reduced by utilizing photochemical characteristics of the nano photocatalyst; soil source microorganisms of disease are killed by utilizing sterilization characteristic of a nano material; besides, surface activation performance of the nano material is utilized for improving ion exchange performance of the improvement agent and improving fertilizer efficiency of the improvement agent; and meanwhile, the problems that a contact area between a calcium preparation and soil particles is small as particles of a calcium preparation are larger and the capacity for replacing Na<+> in soil colloid by virtue of Ca<2+> is poorer in an existing salinity soil improvement agent are solved.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

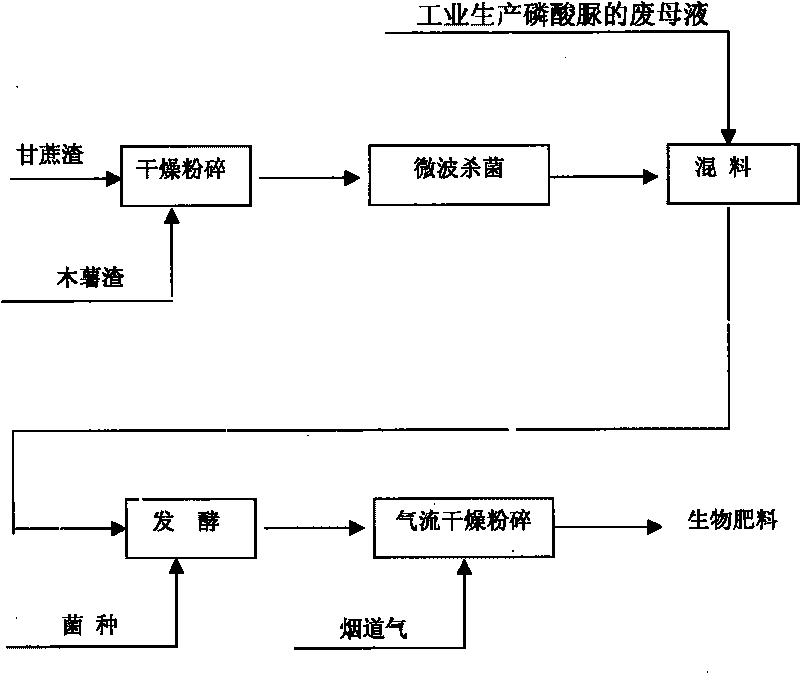

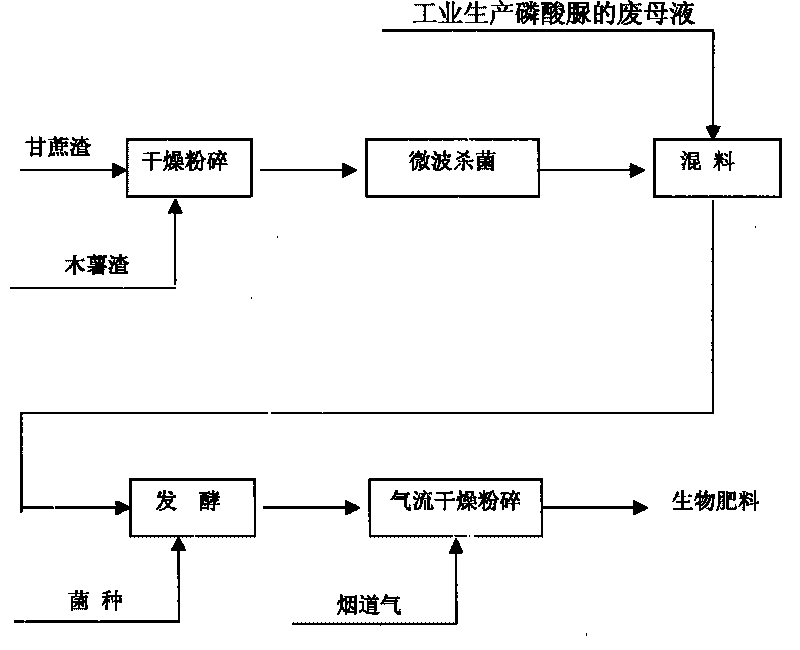

Bio-fertilizer produced by fermenting industrial organic wastes residue and waste mother solution

InactiveCN101691314ASimple methodEasy to implementBio-organic fraction processingClimate change adaptationEconomic benefitsMicrowave sterilization

The invention discloses a bio-fertilizer produced by fermenting industrial organic waste residues and a waste mother solution. The bio-fertilizer is produced through the following steps: firstly, performing pretreatments of microwave sterilization and the like on bagasse and manioc wastes; secondly, adding a waste mother solution in the industrial production of urea phosphate to the bagasse and the manioc wastes; and thirdly, adding a strain to the mixture to produce the bio-fertilizer through fermentation, drying and crushing. The bio-fertilizer solves the problems of environmental pollutions caused by two industrial residues and one industrial waste mother solution, has the advantages of treatment of waste by waste, simple method, easy implementation, and the change of wastes into valuable, and can obtain good economic benefits and environmental protection benefits. The bio-fertilizer is widely suitable for use in the harmless and resource treatments of the industrial organic waste residues.

Owner:罗健泉

Multi-element water-soluble fertilizer

InactiveCN104692976ASolve the problem that cannot be mixedPromote absorptionCalcareous fertilisersMagnesium fertilisersSolubilityPhosphate

The invention relates to a chemical fertilizer and specifically relates to a multi-element water-soluble fertilizer. The multi-element water-soluble fertilizer is used for solving the technical problem of degradation of the fertilizer efficiency activity of mediumtrace elements due to that the existing common phosphorus fertilizers are prone to generate insoluble phosphates in soil. The key point of the multi-element water-soluble fertilizer is to introduce organic phosphorus; the phosphorus fertilizer is chelated with calcium and magnesium in a certain ratio to generate soluble urea-modified superphosphates or urea-modified phosphates, and due to the addition of urea phosphate, the solubility of microelements such as copper, zinc, manganese and boron in aqueous solutions can be improved; especially, macroelements such as nitrogen and potassium are further added to the multi-element water-soluble fertilizer, and therefore, the multi-element water-soluble fertilizer is a unique comprehensively balanced nutritional fertilizer with coexisting major, medium and trace elements and free from precipitation in the market at present. The multi-element water-soluble fertilizer is an acidic fertilizer, and is capable of effectively controlling the pH value of soil and regulating the acid-base equilibrium of the soil; besides, the volatilization of ammonia in the soil is reduced and the utilization rate of the nitrogen fertilizer is increased; meanwhile, the medium trace elements can be activated to form complexes so that the fertilizer efficacy of the medium trace element fertilizers can be enhanced.

Owner:路永宽

Selenium titanium humate composite and preparation method thereof

The invention discloses a selenium titanium humate composite. The composite comprises, by mass, 70% of instant humic acid, 25% of urea phosphate (H3PO4CO (NH2)2), 2.5-3% of selenium potassium phosphate (K3SeP3O10.xH2O) and 2-3% of titanyl sulfate (TiOSO4). The preparation method includes placing the instant humic acid into a blender mixer and spraying the titanyl sulfate solution with stirring for 2 hours; spraying the selenium potassium phosphate solution for 1 hour; and mixing the urea phosphate powder for 1 hour at the temperature of 50-60 DEG C, and placing the mixture into a vacuum kettle for dehydration. The selenium titanium humate composite can either be used solely or be matched with other components for comprehensive usage, can strengthen photosynthesis of plant, has drought resistant and anti-water-logging capacities; and the volume increase effect is quite remarkable.

Owner:CHANGSHA FOSUMN AGRI SCI & TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com