Method for continuously producing feed grade urea phosphate by using wet purified phosphoric acid

A wet purification, feed-grade technology, applied in the field of phosphorus chemical industry, can solve the problems of high content of polyurea, low purity of urea phosphate, impurity removal, etc., to achieve high product purity, good continuity and high promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

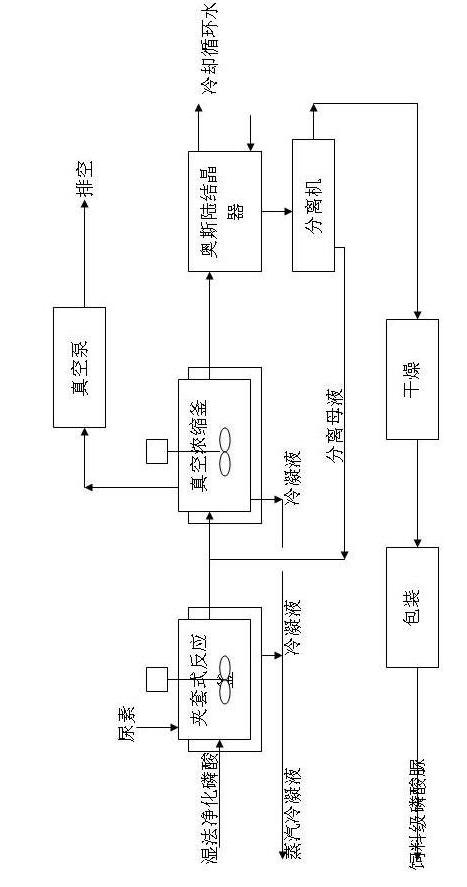

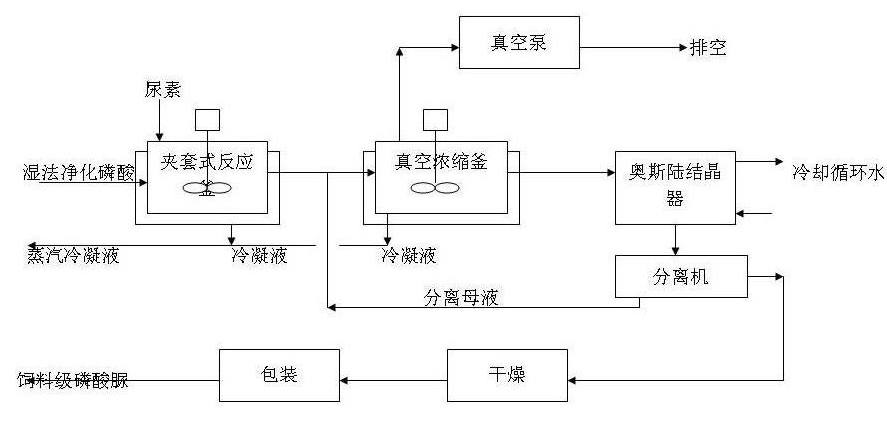

[0012] Such as figure 1 As shown, start the stirring device and add 300kg / h (concentration: 31%) wet-purified phosphoric acid into a 500L jacketed reactor, heat the wet-purified phosphoric acid at 70°C, add 62kg / h urea at the same time, and react The final feed liquid overflows to a 500L vacuum concentration tank, and is controlled under a vacuum condition of 38Kpa. The temperature of the concentration tank is maintained at 80°C. The concentrated material is placed in an Oslo crystallizer to cool down to 35°C for crystallization, and the crystallization liquid is separated and dried. , the drying temperature is controlled at 110°C, and the average yield of the product is 148kg / h, and the yield is 98.7%.

Embodiment 2

[0014] Such as figure 1 As shown, start the stirring device and add 300kg / h (concentration: 31%) wet-purified phosphoric acid into a 500L jacketed reactor, heat the wet-purified phosphoric acid at 85°C, add 62kg / h urea at the same time, and react The final feed liquid overflows to a 500L vacuum concentration kettle, and is controlled under a vacuum condition of 33Kpa. The temperature of the concentration kettle is maintained at 90°C. The concentrated material is placed in an Oslo crystallizer to cool down to 35°C for crystallization, and the crystallization liquid is separated and dried. , the drying temperature was controlled at 100°C, and the measured yield of the product was 98.8%.

Embodiment 3

[0016] Such as figure 1 As shown, start the stirring device and add 300kg / h (concentration: 70%) wet-purified phosphoric acid into a 500L jacketed reactor, heat the wet-purified phosphoric acid at 70°C, add 133kg / h urea at the same time, stir The rotating speed is 65 rpm, the temperature of the jacketed reactor is kept at 70°C, and the residence time is 60min. 80°C, the concentrated material was placed in an Oslo crystallizer to cool down to 35°C for crystallization, the crystallization liquid was separated and dried, and the drying temperature was controlled at 100°C to obtain an average product of 353kg / h with a yield of 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com