One-step preparation method for tetrahydrofuran by employing maleic anhydride gas phase hydrogenation

A technology for tetrahydrofuran and maleic anhydride, applied in the field of one-step preparation of tetrahydrofuran, can solve the problems of high content of by-product butyric acid, increased investment cost of corrosion reaction equipment, expensive catalyst production cost, etc., achieves high conversion rate and selectivity, improves productivity, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

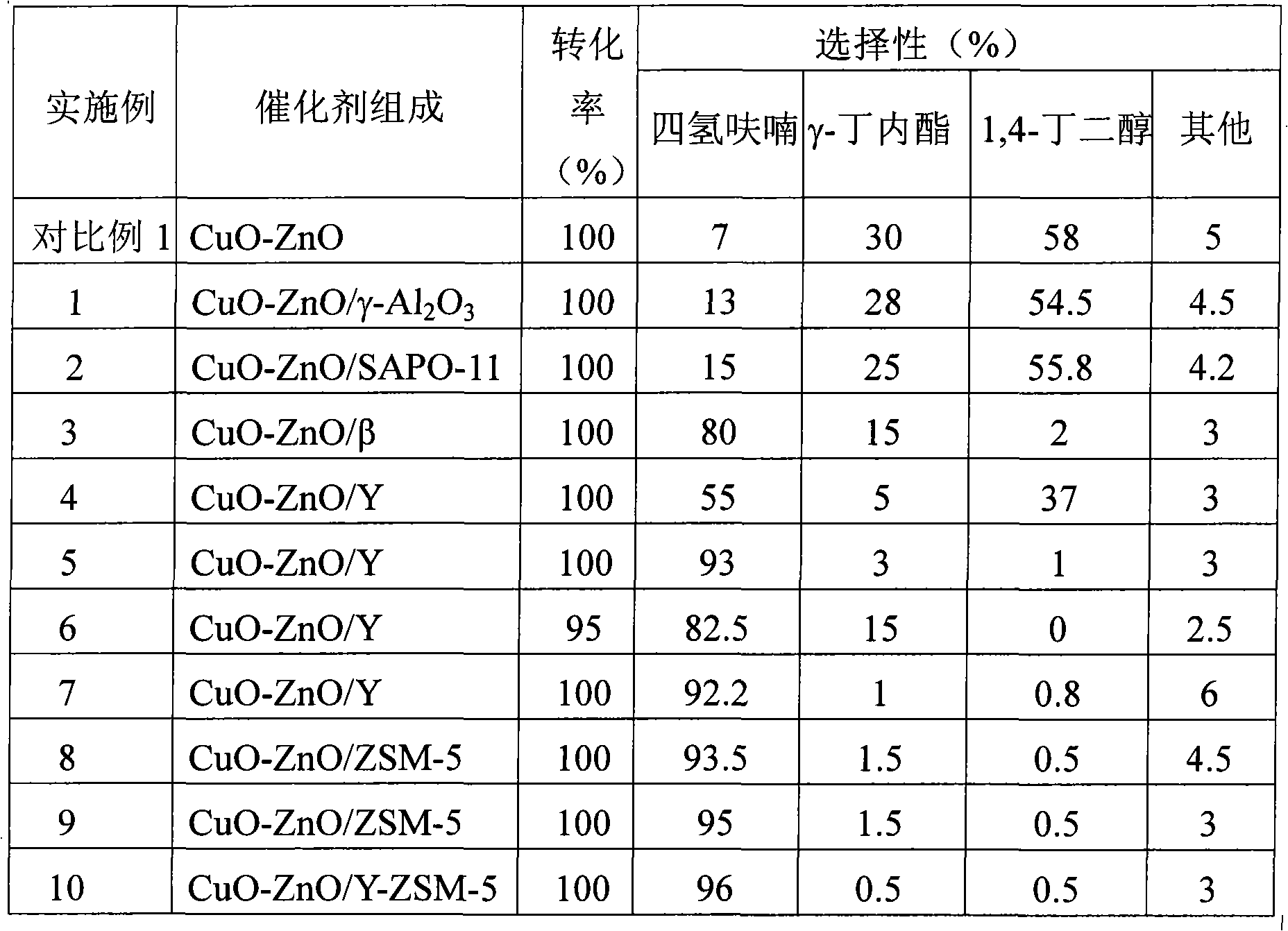

Examples

Embodiment 1

[0033] First, prepare 1 mol / L copper nitrate and zinc nitrate mixed solution (Cu / Zn molar ratio = 1:1), then prepare 1 mol / L sodium carbonate solution as a precipitant, and mix copper nitrate and zinc nitrate in a 70°C water bath Add the mixed solution of the sodium carbonate solution dropwise to the sodium carbonate solution, stir, stop the dropwise addition when the pH value is 7-8, and add a certain amount of γ-Al 2 o 3 (to make the γ-Al 2 o 3 The content is 10% of the total weight of the catalyst), aged for 12h, filtered, washed, dried at 110°C for 12h, and calcined at 450°C for 4h to obtain CuO-ZnO / γ-Al 2 o 3 Catalyst (the content of each component is 45 / 45 / 10 respectively).

[0034] Fill the CuO-ZnO / γ-Al prepared above in the fixed bed reactor 2 o 3 Catalyst, using maleic anhydride as raw material for gas-phase hydrogenation reaction; process conditions: 220°C, 2.2MPa, maleic anhydride liquid weight space velocity 0.05h -1 , the reaction results are shown in Table...

Embodiment 2

[0036] First, prepare 1 mol / L copper nitrate and zinc nitrate mixed solution (Cu / Zn molar ratio = 1:1), then prepare 1 mol / L sodium carbonate solution as a precipitant, and mix copper nitrate and zinc nitrate in a 70°C water bath Add the mixed solution of the solution dropwise to the sodium carbonate solution, stir, stop the dropwise addition when the pH value is 7 to 8, add a certain amount of SAPO-11 molecular sieve (make the content of the molecular sieve be 10% of the total weight of the catalyst), aging for 12h, Filter, wash, dry at 110°C for 12 hours, and bake at 450°C for 4 hours to obtain a CuO-ZnO / SAPO-11 catalyst (the content ratio of each component is 45 / 45 / 10).

[0037] Fill the CuO-ZnO / SAPO-11 catalyst prepared above in the fixed-bed reactor, and use maleic anhydride as raw material to carry out gas-phase hydrogenation reaction; the process conditions are: temperature 220 ° C, pressure 2.2 MPa, maleic anhydride liquid weight space velocity 0.05 h -1 , the reactio...

Embodiment 3

[0039] First, prepare 1 mol / L copper nitrate and zinc nitrate mixed solution (Cu / Zn molar ratio = 1:1), then prepare 1 mol / L sodium carbonate solution as a precipitant, and mix copper nitrate and zinc nitrate in a 70°C water bath Add the mixed solution dropwise to the sodium carbonate solution, stir, stop the dropwise addition when the pH value is 7 to 8, add a certain amount of β molecular sieve (making the content of the molecular sieve be 10% of the total weight of the catalyst), aging for 12h, filter, Washing, drying at 110° C. for 12 hours, and calcining at 450° C. for 4 hours to obtain a CuO-ZnO / β molecular sieve catalyst (the content ratio of each component of the catalyst is 45 / 45 / 10).

[0040] Fill the CuO-ZnO / β catalyst prepared above in a fixed-bed reactor, and use maleic anhydride as a raw material to carry out gas-phase hydrogenation reaction; the process conditions are: temperature 220°C, pressure 2.2MPa, maleic anhydride liquid weight space velocity 0.05h -1 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com