Preparation method of nano cellulose/chitosan composite foam

A nano-cellulose and composite foam technology, applied in the field of cellulose composite materials, can solve the problems of brittle texture, low thermal stability, poor biocompatibility, etc., and achieve large porosity, small thermal conductivity and thermal expansion coefficient, high The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

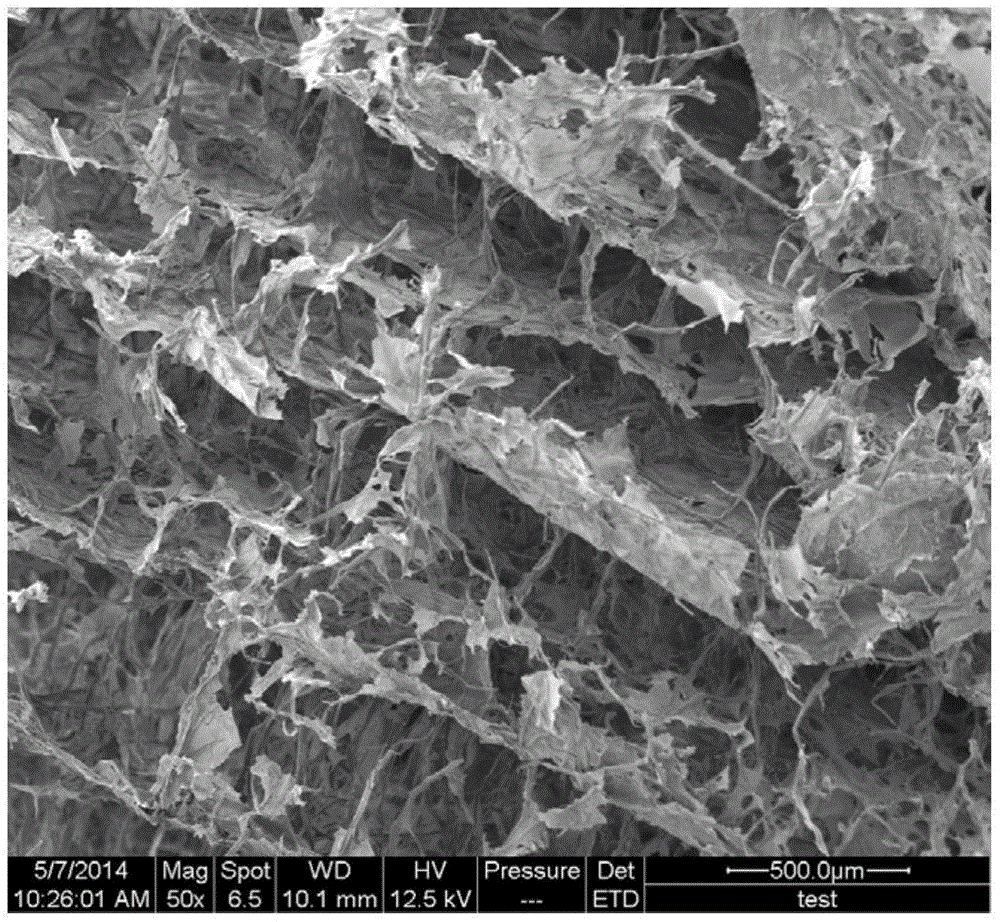

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of nanocellulose / chitosan composite foam of the present embodiment is implemented according to the following steps:

[0020] 1. Carrying out chemical treatment on biomass raw materials containing cellulose to obtain purified cellulose, and then performing mechanical defibrillation treatment on the purified cellulose to prepare nanocellulose aqueous suspension;

[0021] Two, glacial acetic acid and distilled water are mixed, obtain glacial acetic acid solution, then add chitosan, magnetically stir evenly, obtain chitosan mixed solution;

[0022] 3. The nanocellulose aqueous suspension obtained in step one is mixed with the chitosan mixed solution obtained in step two, and the nanocellulose / chitosan composite solution is obtained after stirring;

[0023] 4. Carry out low-temperature freezing treatment to the nanocellulose / chitosan composite solution at -20° C. to obtain a frozen mixed solution;

[0024] 5. Drying the frozen...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the cellulose-containing biomass raw material in step 1 is wood, bamboo, cotton, hemp, bacterial cellulose or ascidian cellulose. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the chemical treatment in step 1 is sequentially treated with sodium chlorite solution and alkali solution. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com