Bright yarn spinning device and application thereof

A smooth, yarn technology, applied in the field of cotton textiles, can solve problems such as increased energy consumption, and achieve the effects of reduced energy consumption, improved utilization, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

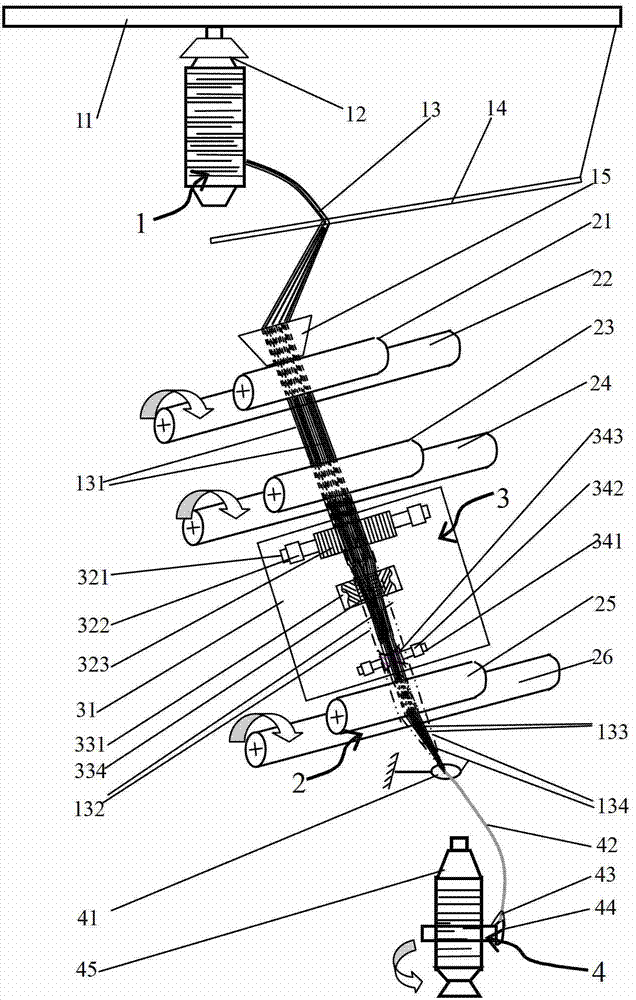

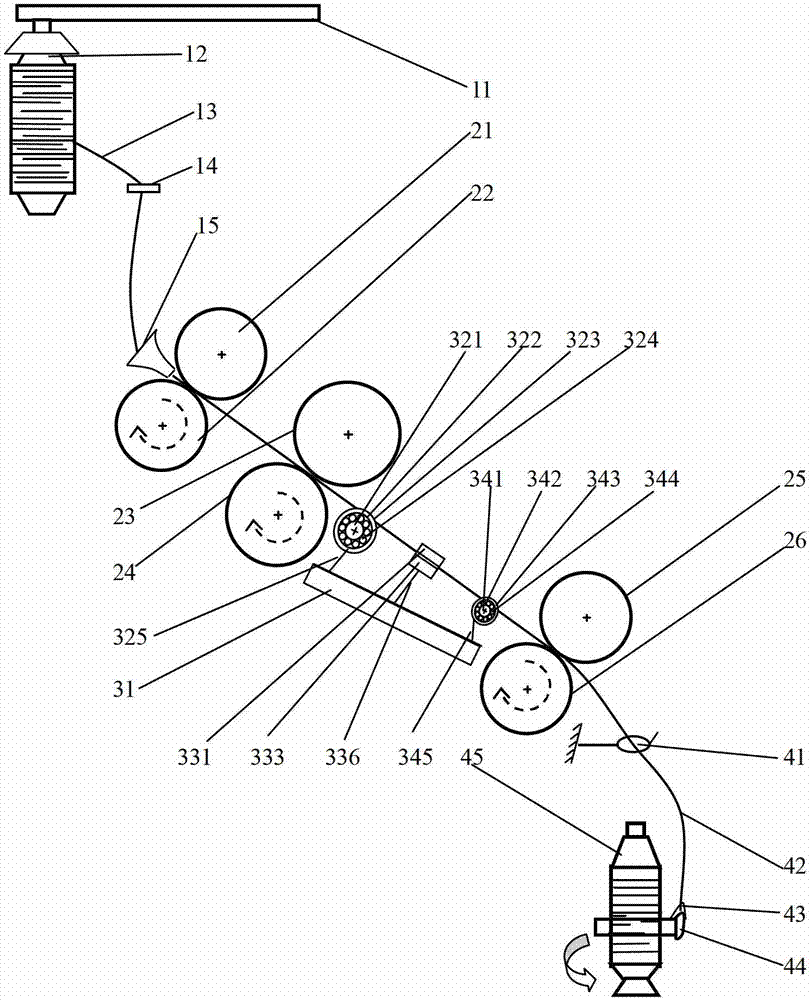

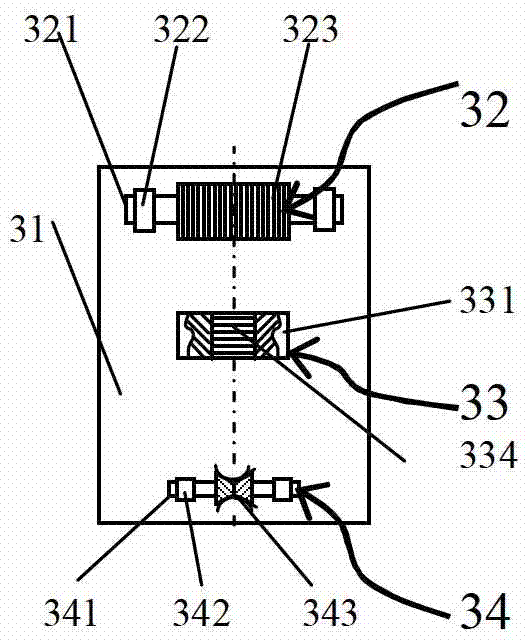

[0048] Example 1 Preparation of high-efficiency, low-energy consumption, and uniform polyester-cotton 65 / 35 blended yarn

[0049] The spinning device for smooth yarn of the present invention is used to prepare a polyester-cotton 65 / 35 blended yarn with high efficiency, low energy consumption, and evenness. The yarn guide rod 14 goes to the cluster horn 15; the roving 13 continues to be rotated and pulled by the rear upper roller 21 and the rear lower roller 22 to the middle upper roller 23 and the middle lower roller 24 to form the jaw; The hollow tube formed by the straight line 323 on the straightening mechanism 32 , the straight line 332 on the upper straight hollow tube 331 on the straightening mechanism 33 and the straight line 334 on the lower straight hollow tube 333 , is drawn to the jaws of the front top roller 25 and the front bottom roller 26 through the cluster pattern 343 on the cluster mechanism 34; The roving is twisted through the yarn guide hook 41 and the ...

Embodiment 2

[0050] Example 2 Preparation of high-efficiency, low-energy consumption, and uniform polyester-cotton 85 / 15 blended yarn

[0051] The spinning device for smooth yarn of the present invention is used to prepare a polyester-cotton 85 / 15 blended yarn with high efficiency, low energy consumption, and evenness. The yarn guide rod 14 goes to the cluster horn 15; the roving 13 continues to be rotated and pulled by the rear upper roller 21 and the rear lower roller 22 to the middle upper roller 23 and the middle lower roller 24 to form the jaw; The hollow tube formed by the straight line 323 on the straightening mechanism 32 , the straight line 332 on the upper straight hollow tube 331 on the straightening mechanism 33 and the straight line 334 on the lower straight hollow tube 333 , is drawn to the jaws of the front top roller 25 and the front bottom roller 26 through the cluster pattern 343 on the cluster mechanism 34; The roving is twisted through the yarn guide hook 41 and the...

Embodiment 3

[0052] Example 3 Preparation of High Efficiency, Low Energy Consumption and Uniform Evenness of Polyester-Viscose 85 / 15 Blended Yarn

[0053] The spinning device for smooth yarn of the present invention is used to prepare high-efficiency, low-energy-consumption, and uniform polyester-viscose 85 / 15 blended yarn. The yarn guide rod 14 goes to the cluster horn 15; the roving 13 continues to be rotated and pulled by the rear upper roller 21 and the rear lower roller 22 to the middle upper roller 23 and the middle lower roller 24 to form the jaw; The hollow tube formed by the straight line 323 on the straightening mechanism 32 , the straight line 332 on the upper straight hollow tube 331 on the straightening mechanism 33 and the straight line 334 on the lower straight hollow tube 333 , is drawn to the jaws of the front top roller 25 and the front bottom roller 26 through the cluster pattern 343 on the cluster mechanism 34; The roving is twisted through the yarn guide hook 41 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com