Pretreatment method for improving spinning property of rabbit fur fiber

A technology for rabbit hair fiber and performance, which is applied in the field of pretreatment for improving the spinnability of rabbit hair fiber, can solve the problems of poor cohesion performance, easy slipping and spinnability of rabbit hair fiber, etc., so as to improve the cohesion performance and reduce spinning breakage. head rate, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare detergent 209 with a concentration of 2g / L, use Na 2 CO 3 Adjust the pH to 8, wash the rabbit hair fiber with water for 25 minutes at a bath ratio of 25 and a temperature of 30°C, and dry at 90°C. Then be 1.5% sodium dichloroisocyanurate (DCCA) treatment agent with respect to fiber mass fraction, and be the detergent 209 of 2g / L with concentration, adjust the pH of treatment solution with acetic acid to be about 4.5, at bath ratio Under the conditions of 30°C and 25°C, the rabbit hair fibers were modified for 30 minutes, rinsed with water, and dried in an oven at 90°C. Finally, use 2g / L NaHSO 3 , dechlorinated at a bath ratio of 25 and a temperature of 40°C for 15 minutes, then rinsed with a large amount of tap water, and dried at 80°C.

Embodiment 2

[0022] Prepare detergent 209 with a concentration of 3g / L, use Na 2 CO 3 Adjust the pH to 9, wash the rabbit hair fiber with water for 20 minutes at a bath ratio of 30 and a temperature of 20°C, and dry at 80°C. Then be 1.0% sodium dichloroisocyanurate (DCCA) treatment agent with respect to fiber mass fraction, and be the washing agent 209 of 3g / L with concentration, adjust the pH of treatment solution with acetic acid to be about 4.0, at bath ratio Under the conditions of 20°C and 30°C, the rabbit hair fibers were modified for 35 minutes, rinsed with water, and dried in an oven at 85°C. Finally, use 1g / L NaHSO 3 , dechlorinated at a bath ratio of 20 and a temperature of 50°C for 10 minutes, rinsed with a large amount of tap water, and dried at 90°C.

Embodiment 3

[0024] Prepare detergent 209 with a concentration of 1g / L, use Na 2 CO 3 Adjust the pH to 7.5, wash the rabbit hair fiber with water for 40 minutes at a bath ratio of 20 and a temperature of 25°C, and dry at 85°C. Then be 2.0% sodium dichloroisocyanurate (DCCA) treatment agent with respect to fiber mass fraction, and be the washing agent 209 of 1g / L with concentration, adjust the pH of treatment solution with acetic acid to be about 5.0, at bath ratio Under the conditions of 30°C and 28°C, the rabbit hair fibers were modified for 25 minutes, rinsed with water, and dried in an oven at 80°C. Finally, use 2g / L NaHSO 3 , dechlorinated at a bath ratio of 30 and a temperature of 45°C for 20 minutes, then rinsed with a large amount of tap water, and dried at 80°C.

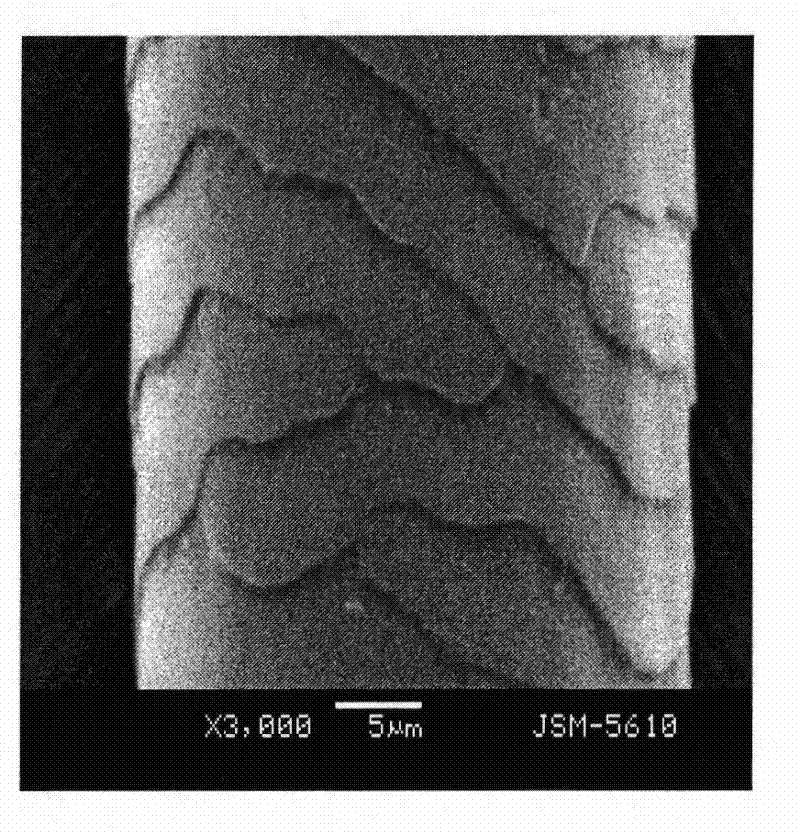

[0025] The morphology of rabbit hair fibers after treatment with sodium dichloroisocyanurate (DCCA) is shown in the figure.

[0026] In the present invention, all medicaments are conventional chemical reagents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com