False twisting device

A technology of false twisting and winding rod, applied in the field of spinning, can solve the problem of high end breakage rate of false twisting device, improve spinning efficiency and yarn production rate, reduce production cost, and reduce spinning end breakage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

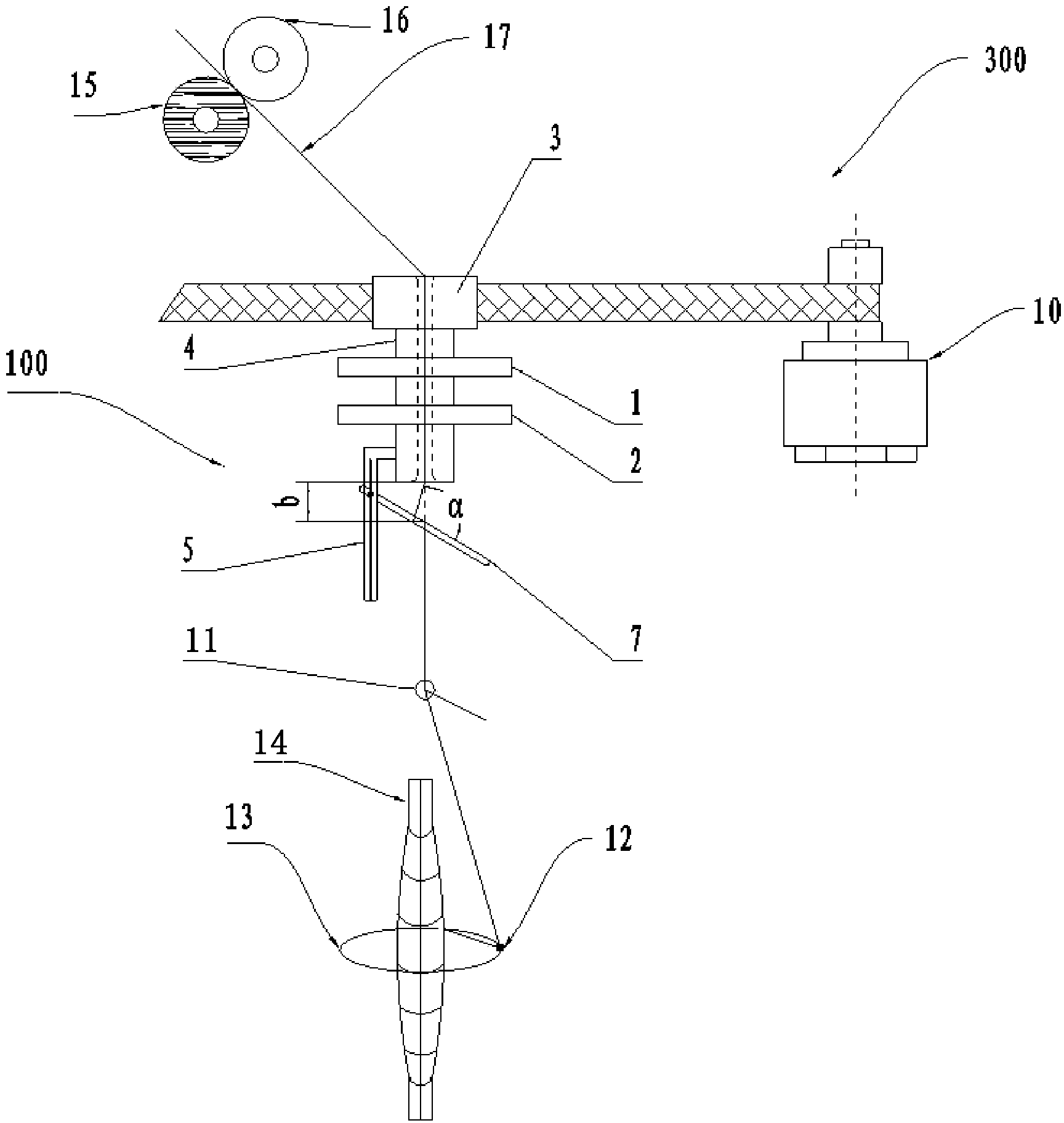

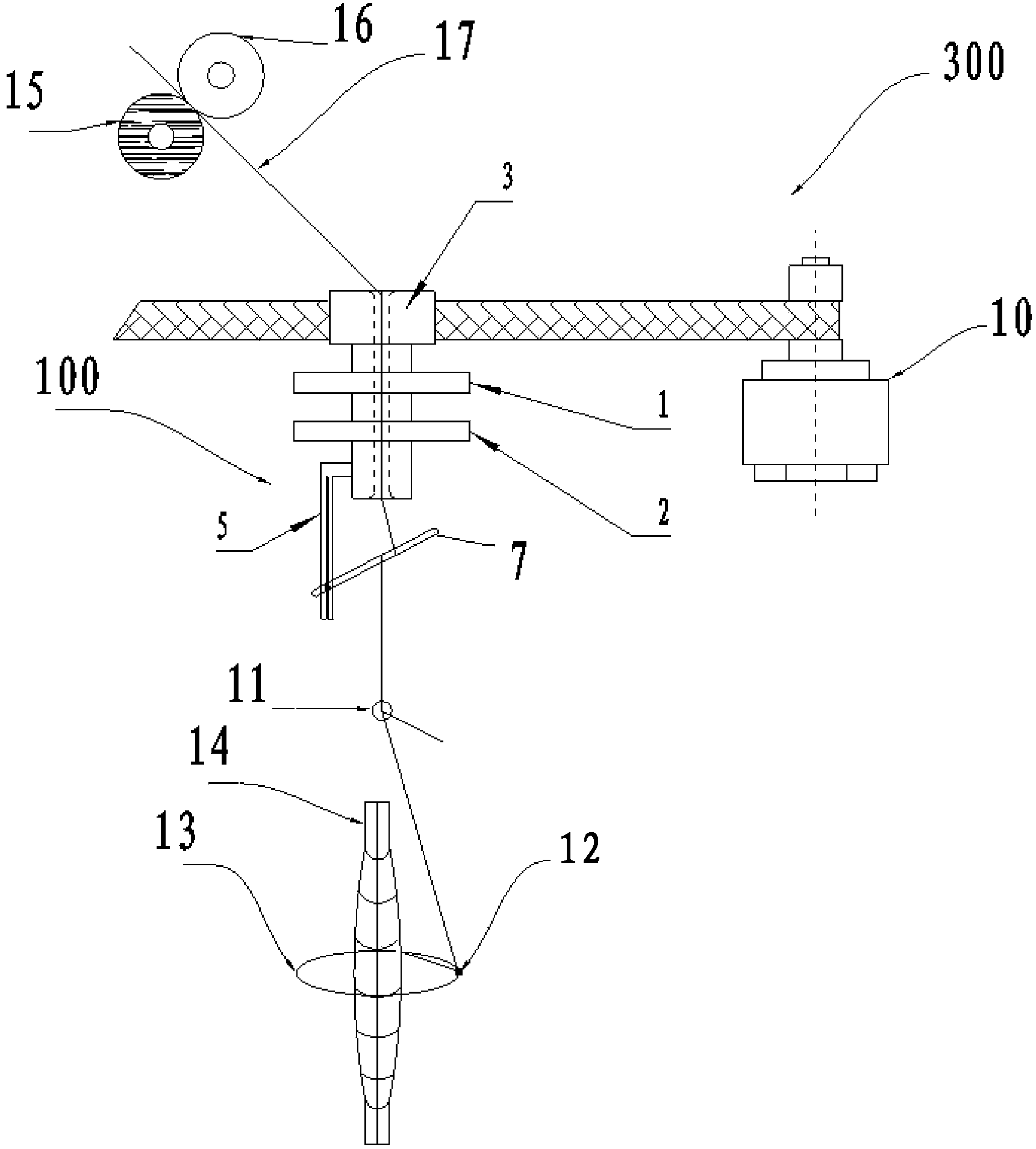

[0031] The false twisting device of the present invention will be described in further detail below in conjunction with the accompanying drawings. A kind of false twist device, comprises false twist applying system 100 and transmission system 300; The tube 4, the central hole 30 communicates with the through hole in the hollow tube 4, and the winding rod 7 for yarn bypassing is provided under the hollow tube 4; the transmission system 300 includes a motor 10, a transmission belt connecting the motor 10 and the rotating disk 3 202, there is a belt drive between the motor 10 and the rotating disk 3, such as figure 1 with Figure 4 shown.

[0032] The false twist application system 100 is provided with a false twist point and can be adjusted up and down, and the transmission system 300 can be independently controlled. The false twist application system 100 also includes an upper fixed bearing 1 and a lower fixed bearing 2 which function as fixed supports. The upper fixed beari...

Embodiment 2

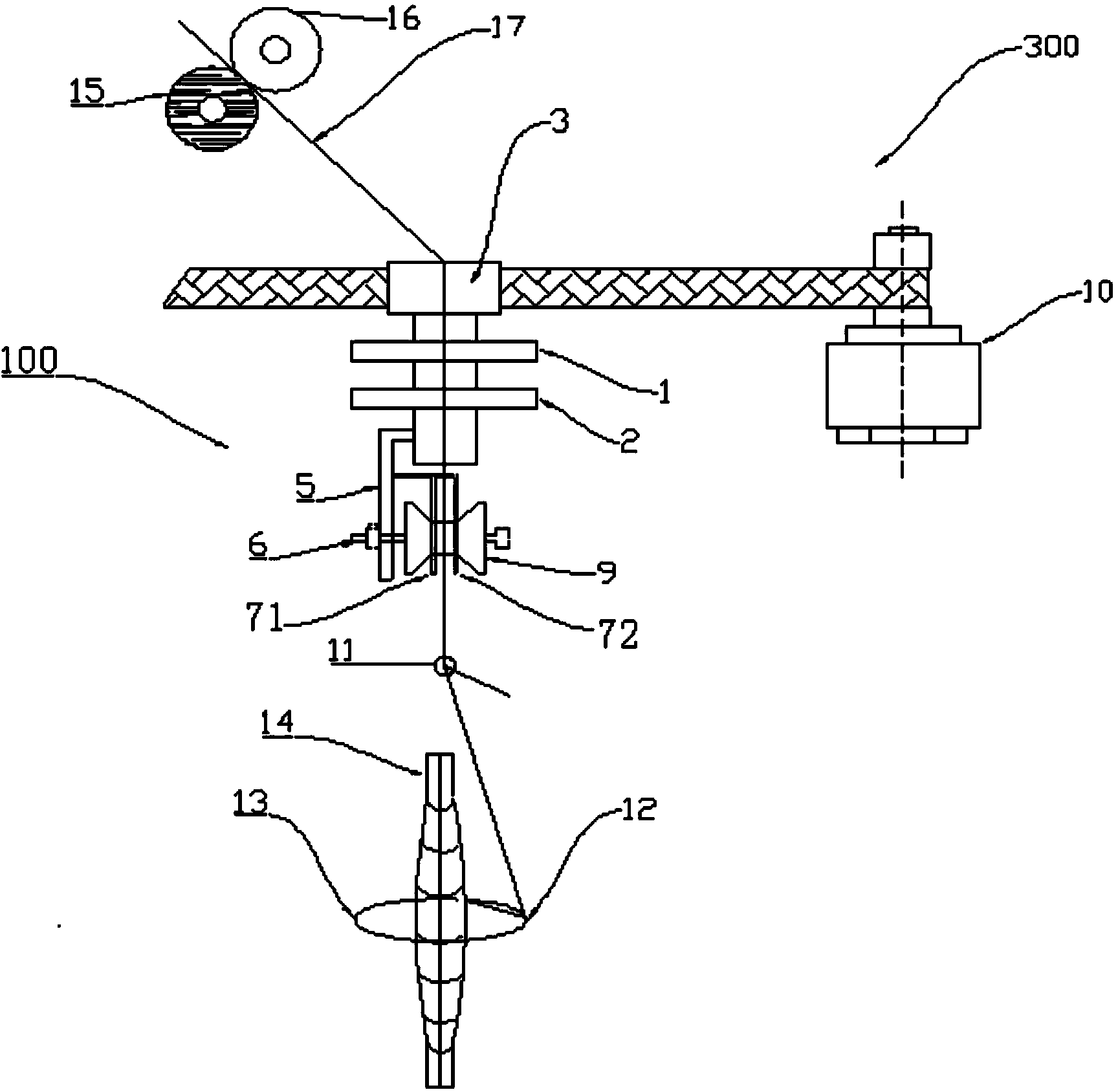

[0042] The false twisting device of the present invention will be described in further detail below in conjunction with the accompanying drawings. A kind of false twist device, comprises false twist applying system 100 and transmission system 300; The tube 4, the central hole 30 communicates with the through hole in the hollow tube 4, and the winding rod 7 for yarn bypassing is provided under the hollow tube 4; the transmission system 300 includes a motor 10, a transmission belt connecting the motor 10 and the rotating disk 3 202, there is a belt drive between the motor 10 and the rotating disk 3, such as image 3 with Figure 4 shown.

[0043] The difference between this embodiment and Embodiment 1 includes: the hollow tube 4 is provided with a guide wheel 9 for the yarn to bypass, the center line of the guide wheel 9 is arranged along the horizontal direction, and the circumferential surface of the guide wheel 9 is provided with an annular groove 91.

[0044] The outside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com