Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Self-extinguishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-smoke bittern-free highly fire-proof elastic polyolefin electric cable material

InactiveCN101041731AGood flexibilityIncrease elasticityInsulated cablesInsulated conductorsBenzenePolyolefin

The invention discloses a low-smoke non-halogen high-flameproof elastic polyolefin wire and cable plastic, which comprises the following parts: 40-80% EVA elastics (ethene-vinyl acetate copolymer), 20-50% POE elastics (ethene-hexaethene copolymer), 5-15% EMA elastics (ethene-methyl acrylate copolymer), 30-70% magnesium hydroxide or aluminium hydroxide, 20-40% nanometer magnesium hydroxide, 0.1-0.6% DCP (peroxide diisopropyl benzene), wherein the hardness is not more than 85 A with strength not less than 9.0Mpa and extending rate not less than 150%; the flameproof property reaches UL1581 VW-1, which is excellent flexible macromolecular mixing material.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Halogenn-free flame retardant polyurethane sealant and preparation method thereof

ActiveCN104099055AAdd lessMeet application requirementsOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePlasticizer

A halogen-free flame retardant polyurethane sealant and a preparation method thereof belonging to the technical field of sealant. The method is as below: first of all, preparing a polyurethane prepolymer; stirring and mixing the polyurethane prepolymer with a halogen-free flame retardant, a flame retardant synergistic agent, a carbon forming agent, a filler, a thixotropic agent, an ultraviolet absorbent, an antioxidant, a toner and a plasticizer under low vacuum condition less than 2 kPa at 35-60 DEG C in a double planetary mixer with high speed dispersing head or a three-roller grinding machine for 0.5-2 h; and then adding a water-removal agent and a catalyst A under the protection of nitrogen, mixing and dispersing for 0.1-0.5 h, and then mixing and dispersing under the condition with vacuum degree less than 2 KPa for 0.1-1 h to obtain the halogen-free flame retardant sealant. The invention inhibits the shortcomings of heavy smoke during burning, difficulty in self-extinguishing and severe droplet of the product.

Owner:广东国望精细化学品有限公司 +3

Ceramic flame-retardant and fireproof silicone rubber and preparation method thereof

The invention discloses ceramic flame-retardant and fireproof silicone rubber and a preparation method thereof. The silicone rubber contains the following components in parts by weight: 100 parts of raw silicone rubber, 10-50 parts of white carbon black, 10-100 parts of aluminum hydroxide, 10-50 parts of low-melting-point glass powder, 10-100 parts of sericite powder, 1-20 parts of hydroxyl silicone oil, 1-20 parts of hexamethyl disilazane, 0.1-3 parts of a platinum compound and 0.1-5 parts of a vulcanizing agent. The silicone rubber is good in flame retardance, excellent in mechanical property, safe and environmentally friendly, has good mechanical strength and insulating property after being ablated, is capable of preventing burnt objects from being damaged and keeping a circuit completefor a long time and can play a good fireproof role.

Owner:GUANGDONG POLYSIL TECH CO LTD

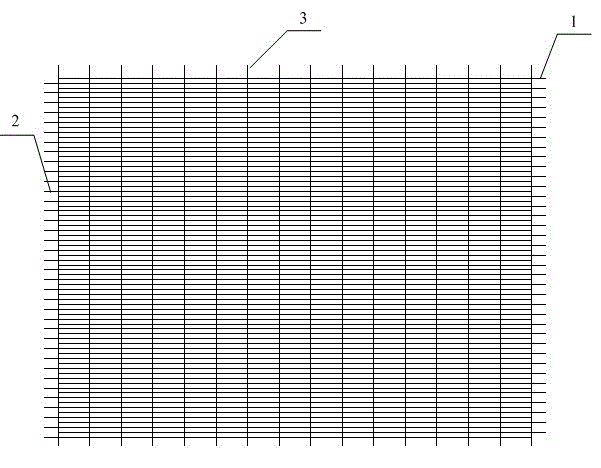

Flame-retardant fabric

The invention relates to a flame-retardant fabric, which is made of fiber materials, and specially comprises fiber materials in a weaving, knitting or non-woven form. The flame-retardant fabric is prepared by using a flame-retardant process, and the main ingredients of the flame-retardant fabric include a low molecular pre-shrinking body of tetrakis hydroxymethyl phosphonium sulfate (THPS) and amide, a surfactant, a flame-retardant finishing liquid of high-concentration polyethylene, so that the flame-retardant fabric has a durable flame retardant performance, and the flame retardant performance is not reduced with the increasing of the number of washing times; the flame-retardant finishing does not change the original features of the fabric fibers, so that the fabric is soft in handfeel, and small in strength loss, and the comfortableness and durability of the fabric are basically kept, therefore, the flame-retardant fabric has a characteristic that the fabric is carbonized after meeting fire and self-extinguished after leaving fire, and the spread of flames is effectively prevented; and the protective clothing prepared by using the fabric can prevent flames from causing harm to the human body.

Owner:魏延杰 +1

Polyphenylene sulfide/polyamide composite material and method for making same

The present invention discloses one kind of polyphenyl thioether / polyamide composite material and its preparation process. The polyphenyl thioether / polyamide composite material is prepared with polyphenyl thioether 23-69.3 wt%, polyamide 10-30 wt%, glass fiber 20-40 wt%, heat stabilizer 0.2-2 wt%, silane coupler 0.1-2 wt%, processing lubricant 0.2-2 wt% and crystallization promoter 0.1-1 wt%. The polyphenyl thioether / polyamide composite material has high shock toughness, simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

Economic and environment-friendly polymer-based cable bridge

InactiveCN102964725AImprove performanceIncrease coefficient of frictionChemical industryParaffin wax

The invention discloses an economic and environment-friendly polymer-based cable bridge which comprises the components with the content as follows: 100phr of polyvinyl chloride (PVC), 5phr of Ca-Zn compound stabilizer, 10phr of chlorinated polyethylene (CPE), 3phr of P83, 0.5phr of paraffin wax, 0.3phr of polyethylene (PE) wax, 0.4phr of acrylic acid (ACR), 10phr of calcium carbonate whisker, 8phr of DBDPE, 5phr of nano antimonous oxide, 2phr of compound zinc borate, 5phr of titanium dioxide, 0.5phr of 1010 and 0.2phr of UV-531. The economic and environmentally friendly polymer-based cable bridge breaks through the key technology of strength and water resistance of fire-proof and environment-friendly multi-element composite material, and has the characteristics of being environment-friendly, attractive, light in mass, flame retardant, corrosion-resistant, low in manufacturing cost, convenient in field installation, long in service life and the like, thus being widely applied to industries such as chemical industry, petroleum and the like and being more suitable for being used in the environmental conditions such as dampness, salt mist and chemical gas.

Owner:QINGDAO XINWANTONG PLASTIC IND

Refractory flame-retardant silicone rubber sheath material for cables and preparation method thereof

InactiveCN103571210AStable fire resistanceImprove insulation performanceRubber insulatorsInsulated cablesMicrocrystalline waxGas phase

The invention discloses a refractory flame-retardant silicone rubber sheath material for cables and a preparation method thereof. The refractory flame-retardant silicone rubber sheath material for cables is prepared from the following raw materials in parts by weight: 70-90 parts of methylvinyl silicone rubber, 15-25 parts of epichlorohydrin rubber, 10-20 parts of bisphenol A polycarbonate, 2-3 parts of zinc oxide, 3-4 parts of 2-thiolbenzimidazole, 4-6 parts of microcrystalline wax, 1-2 parts of stearic acid, 3-5 parts of dimethyl silicone oil, 10-15 parts of nano silicon nitride, 20-30 parts of gas-phase silica white, 8-12 parts of calcined argil, 3-6 parts of fiberglass, 5-10 parts of alundum powder, 5-10 parts of epoxy soybean oil, 0.3-0.6 part of dicumyl peroxide, 1-2 parts of triallyl cyanurate and the like. The sheath material has the characteristics of stable fire resistance, favorable insulating property, high mechanical strength and the like, has excellent flame retardancy, oil resistance, freezing resistance, acid / alkali resistance, radiation aging resistance, wear resistance and other properties, and is completely reliable and durable.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Polyimide paper honeycomb core and preparation method thereof

InactiveCN103806342ALow water resistanceLow hygroscopicitySpecial paperPaper/cardboard articlesAdhesiveHoneycomb

The invention discloses a polyimide paper honeycomb core and a preparation method thereof. The polyimide paper honeycomb core is prepared by the following methods: (1) performing gluing treatment, namely coating a polyimide adhesive on the surface of polyimide paper, superposing multilayer glued polyimide paper in a staggered mode, and finally performing hot-pressing to prepare a honeycomb laminate by utilizing a hot press; (2) performing setting treatment, namely stretching the honeycomb laminate, forming regular hexagon honeycomb hole lattices, and setting in a drying box to preparw white honeycomb blocks; (3) performing impregnation treatment, namely impregnating and curing the white honeycomb blocks to prepare the polyimide paper honeycomb core. The polyimide paper honeycomb core prepared by the method has the characteristics of high temperature resistance and low moisture absorption property, and the strength of the polyimide paper honeycomb core can be further improved.

Owner:吉林高琦聚酰亚胺材料有限公司

Halogen-phosphorus-free flame retardant epoxy resin composition and application thereof in bonding sheet and copper-clad plate

InactiveCN102093672AIncrease flame retardancySelf-extinguishingCircuit susbtrate materialsMetal layered productsEpoxyThermal expansion

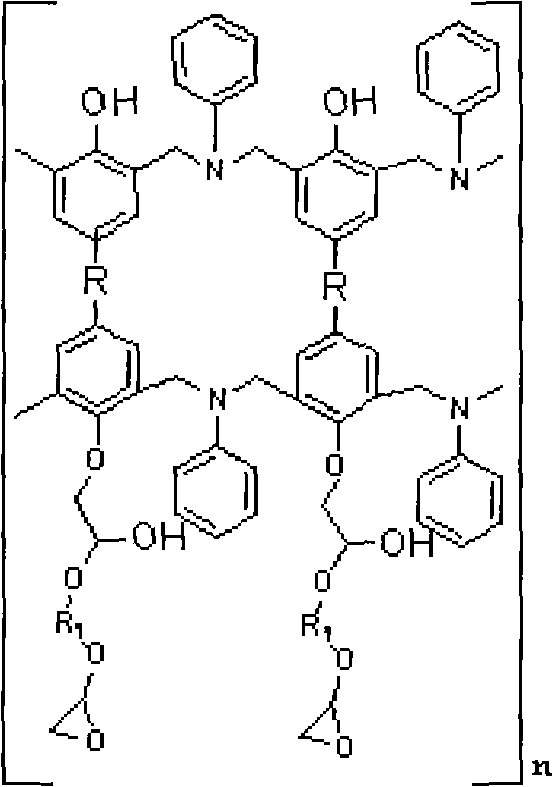

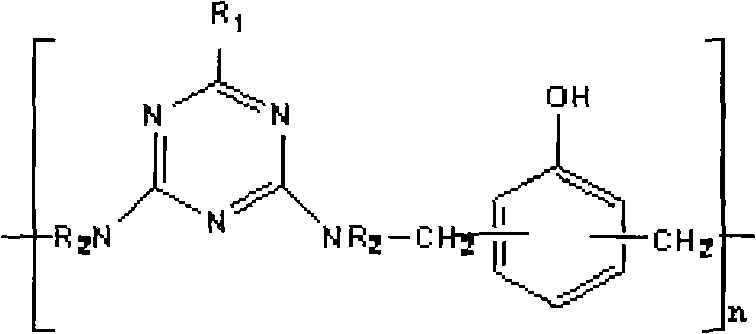

The invention relates to a halogen-phosphorus-free flame retardant epoxy resin composition, which comprises inorganic fillers such as benzoxazine epoxy resin, a modified phenolic resin curing agent, imvite and the like, an inorganic auxiliary flame retardant material and the like, wherein the modified phenolic resin curing agent is nitrogen-containing phenolic resin; a resin condensate system has higher flame retardancy due to the self-extinguishment of the nitrogen-containing phenolic resin during combustion; and the glass-transition temperature of a condensate can be improved further by a unique structure formed by nano-level imvite and condensate molecules, and particularly the condensate has a lower thermal expansion coefficient. The resin composition does not contain halogen and phosphorus elements, and does not generate harmful substances, so a bonding sheet and a copper-clad foil layer, which are produced by the composition, for a printed circuit board have higher heat resistance and flame retardance, and are environmentally-friendly.

Owner:力森诺科电子材料(广州)有限公司

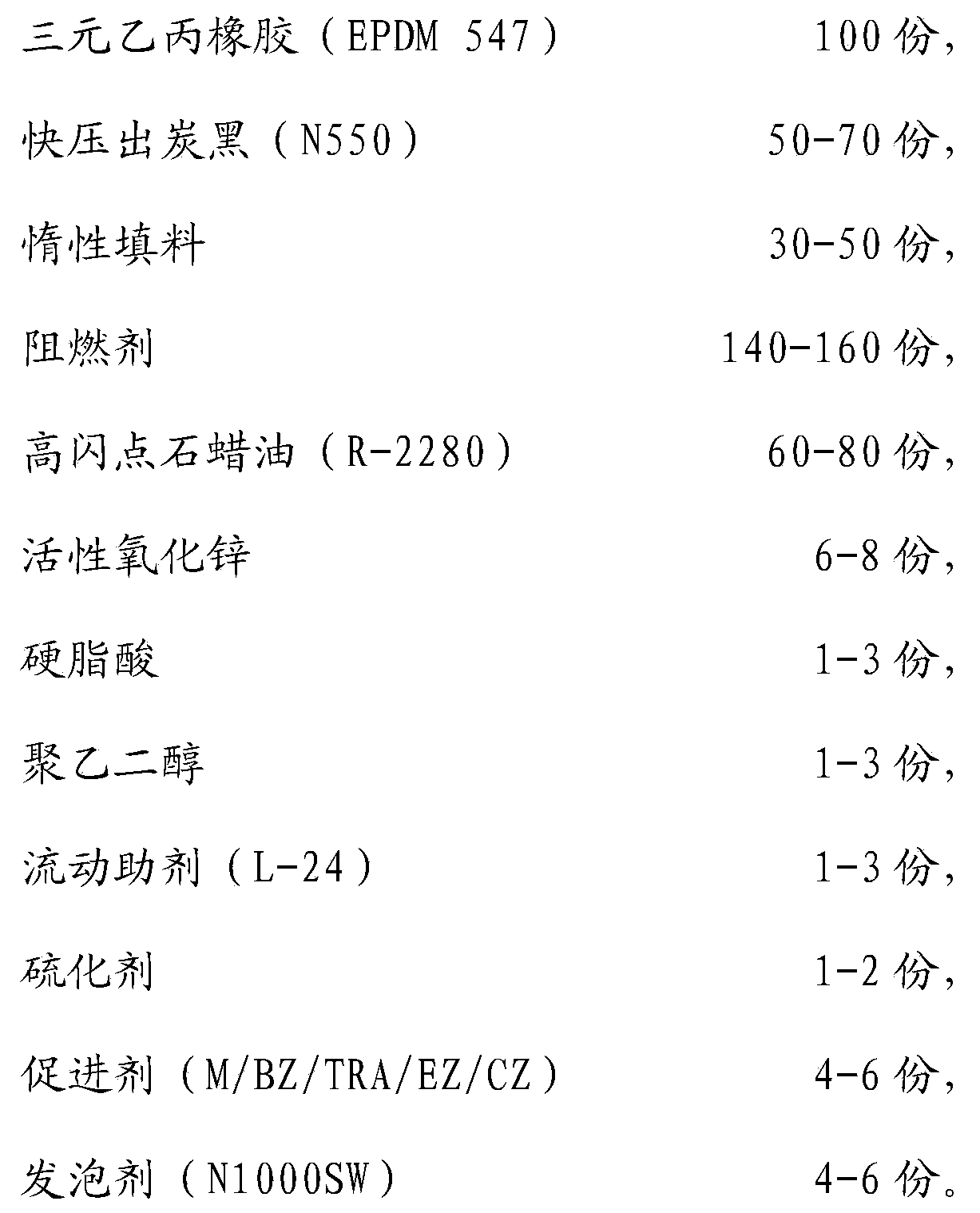

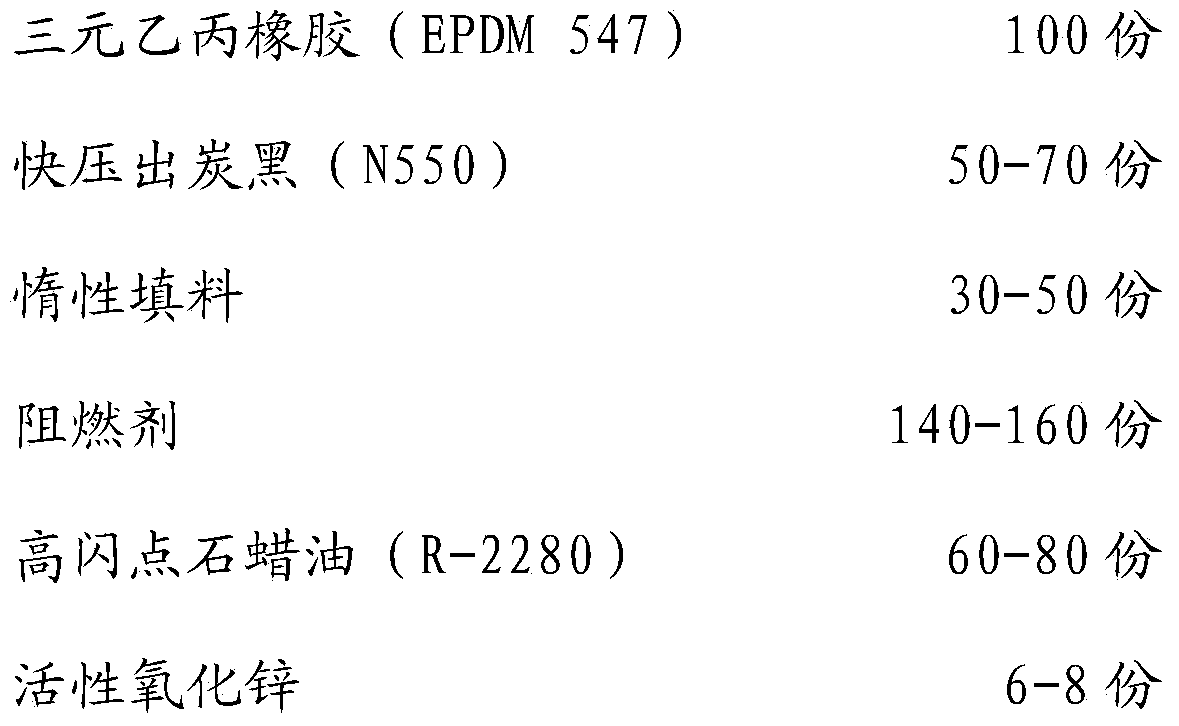

EPDM flame-retardant sponge sealing strip for high-speed rail

The invention discloses an EPDM flame-retardant sponge sealing strip for a high-speed rail. The EPDM flame-retardant sponge sealing strip comprises the following components in parts by mass: 100 parts of high-ENB-content EPDM (ethylene propylene diene monomer), 50 to 70 parts of fast extruding furnace black, 30 to 50 parts of inert filler, 140 to 160 parts of flame-retardant agent, 60 to 80 parts of high-flash-point paraffin oil, 1 to 2 parts of anti-aging agent TMQ, 6 to 8 parts of activated zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of polyethylene glycol, 1 to 3 parts of flow additive, 1 to 2 parts of vulcanizing agent, 4 to 6 parts of accelerant and 4 to 6 parts of foaming agent. By adopting the flame-retardant sponge formula, a better material performance can be obtained, the density is 0.5 to 0.6 g / cm<3>, the flame-retardant grade reaches a burning-resisting grade, and the requirement of the high-speed rail sponge sealing strip on light weight and flame retardant property can be met.

Owner:TIANJIN XINZHONGHE RUBBER IND

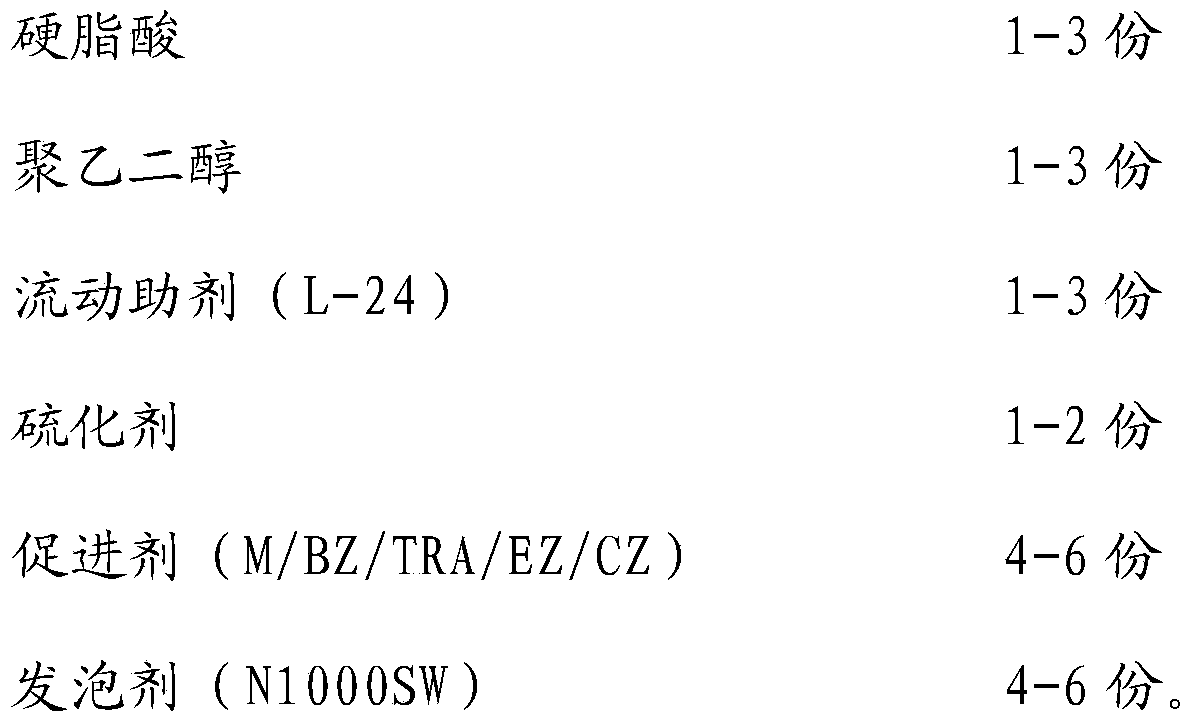

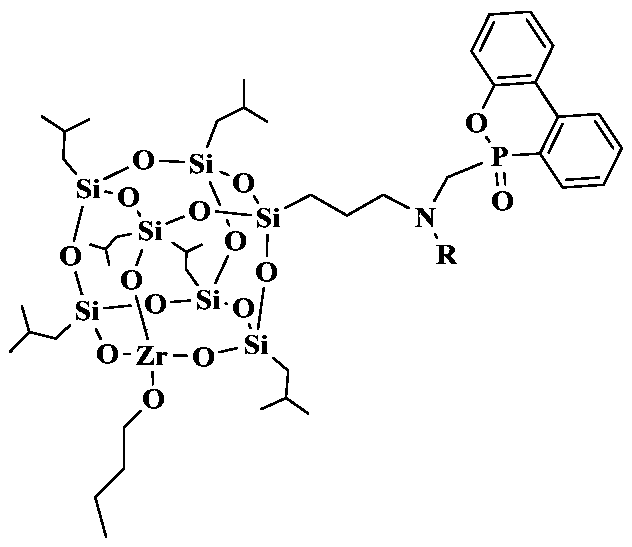

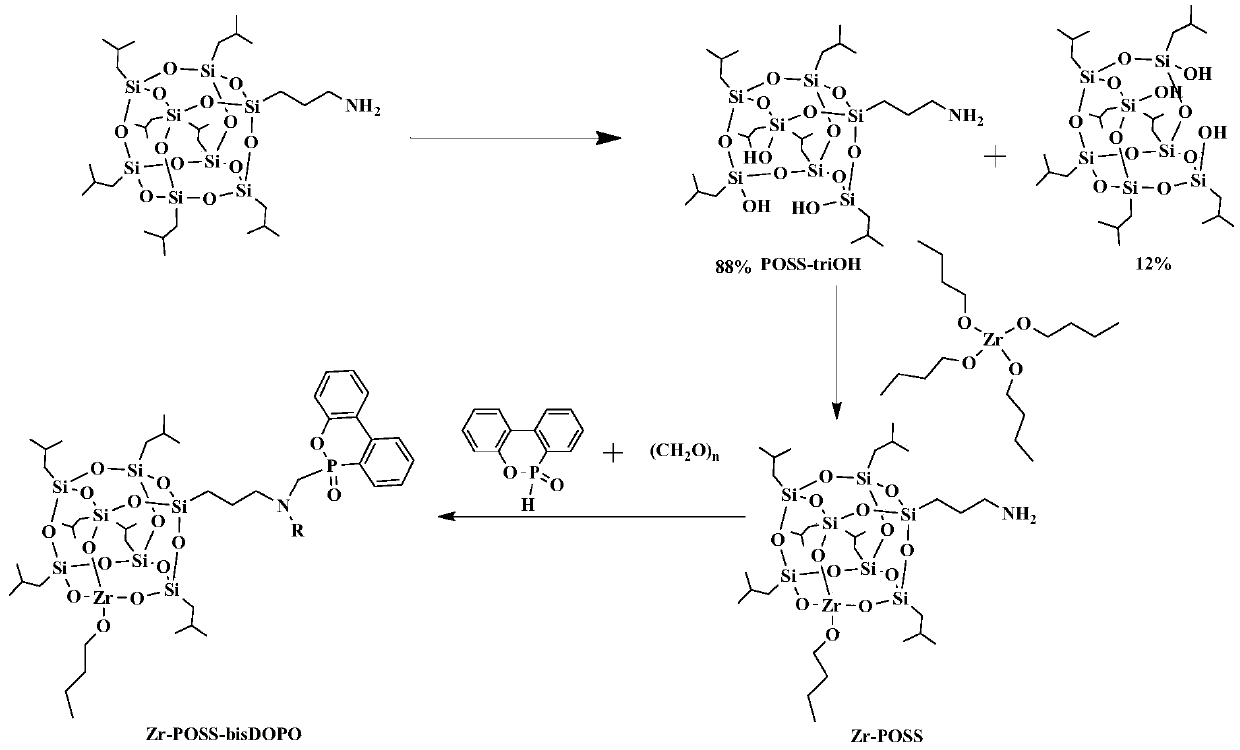

Metal hybrid POSS flame retardant as well as preparation method and application thereof

The invention discloses a metal hybrid POSS flame retardant as well as a preparation method and application thereof. The chemical structural formula of the metal hybrid POSS flame retardant is shown in the specification, wherein R is -H or a group disclosed in the invention. The metal hybrid POSS flame retardant is obtained by taking oligomeric polyhedral silsesquioxane (POSS-NH2) as a raw material through vertex-opening, vertex-capping and nucleophilic substitution chemical reaction. The synthesized POSS derivative simultaneously contains three flame-retardant elements, namely silicon, phosphorus and zirconium, and can be used as an efficient flame retardant to modify various polymers, so that the application range of the polymers is expanded.

Owner:XIAMEN UNIV +1

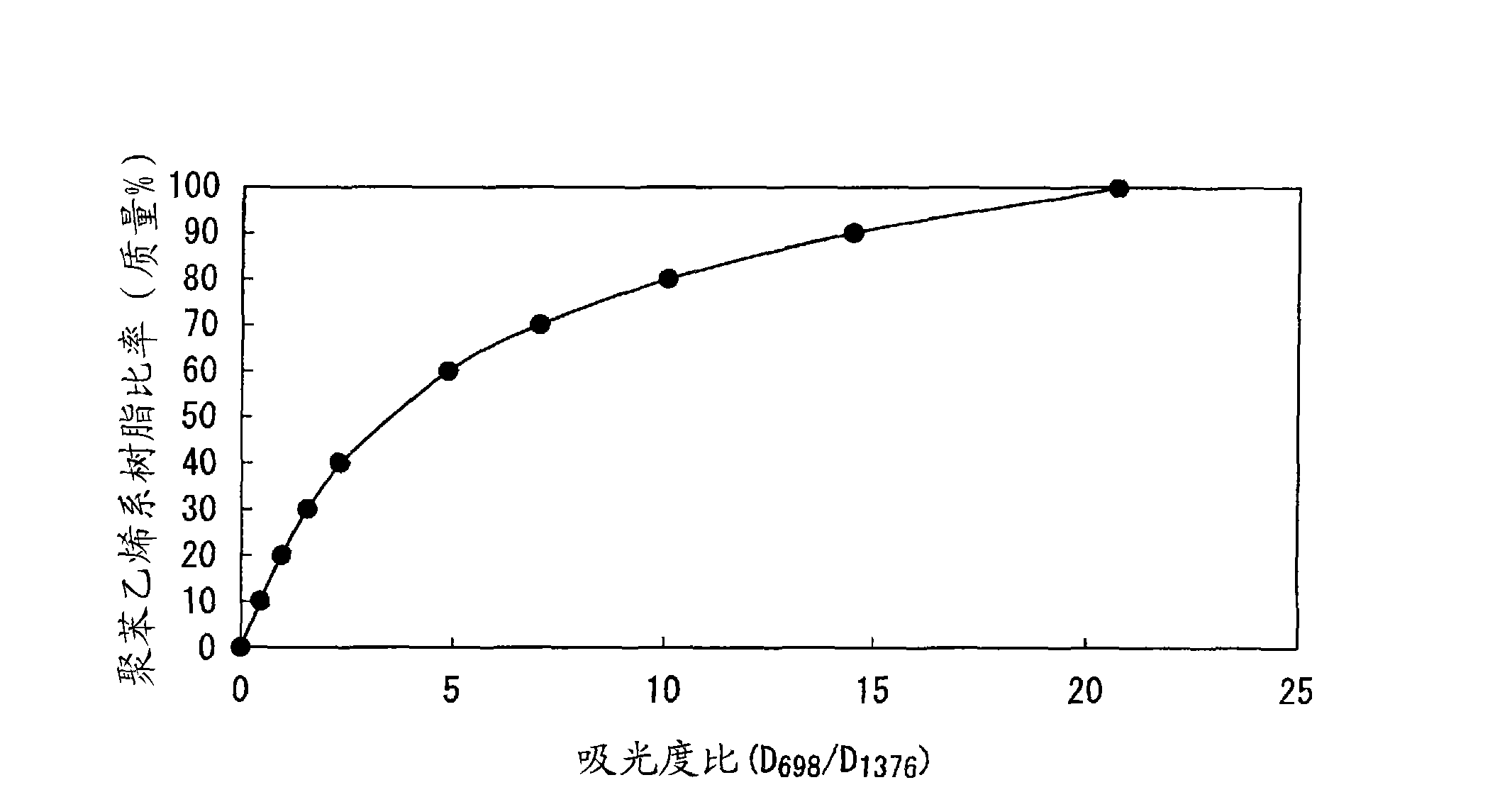

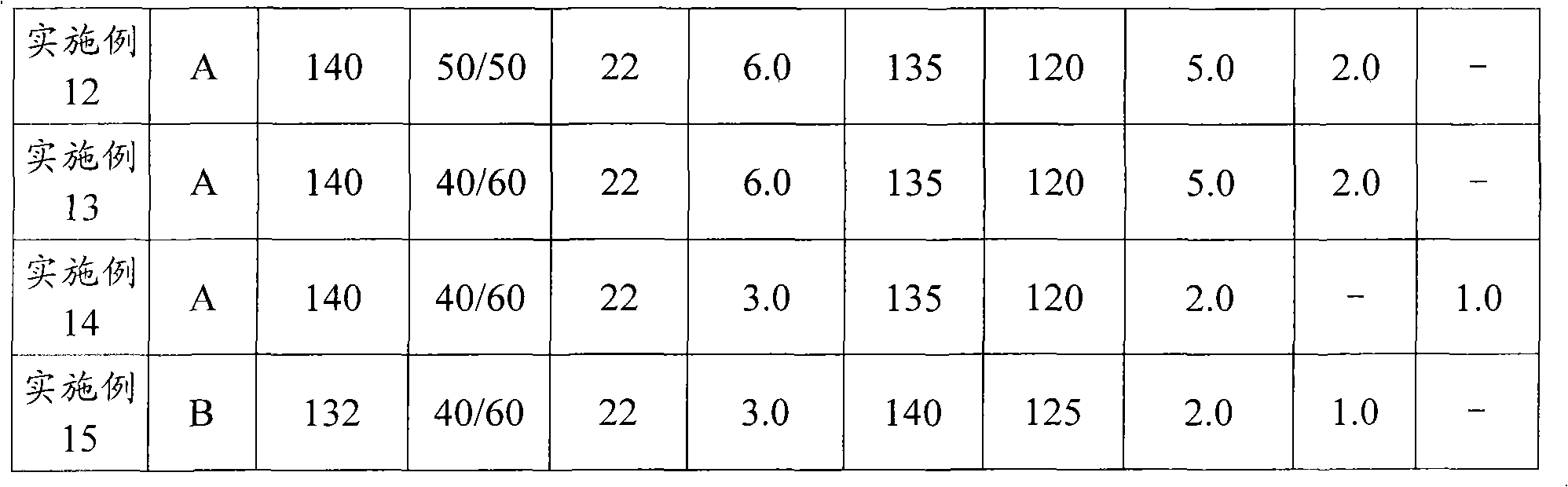

Particle of carbon-containing modified polystyrene resin, expandable particle of carbon-containing modified polystyrene resin, expanded particle of carbon-containing modified polystyrene resin, molded

Carbon-containing modified polystyrene resin particles which contain a carbon-containing polypropylene resin and contain a polystyrene resin in an amount of 100-400 parts by mass, excluding 400 parts by mass, per 100 parts by mass of the carbon-containing polypropylene resin. The polystyrene resin proportion in a central part of each particle as calculated from the ratio between absorbances at 698 cm<-1> and 1,376 cm<-1> (D698 / D1376) obtained from an infrared absorption spectrum for the central part in infrared spectroscopic analysis by the ATR method is at least 1.2 times the polystyrene resin proportion in the whole particle.

Owner:SEKISUI PLASTICS CO LTD

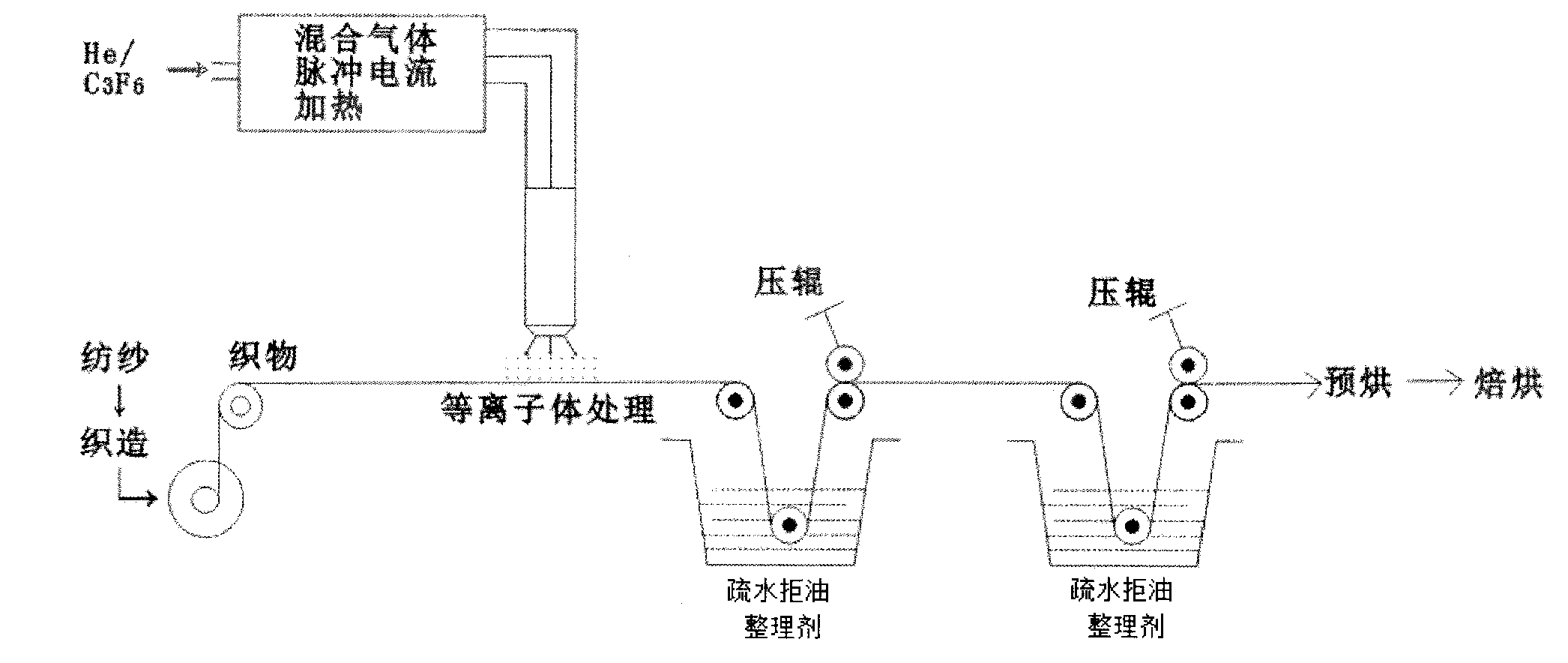

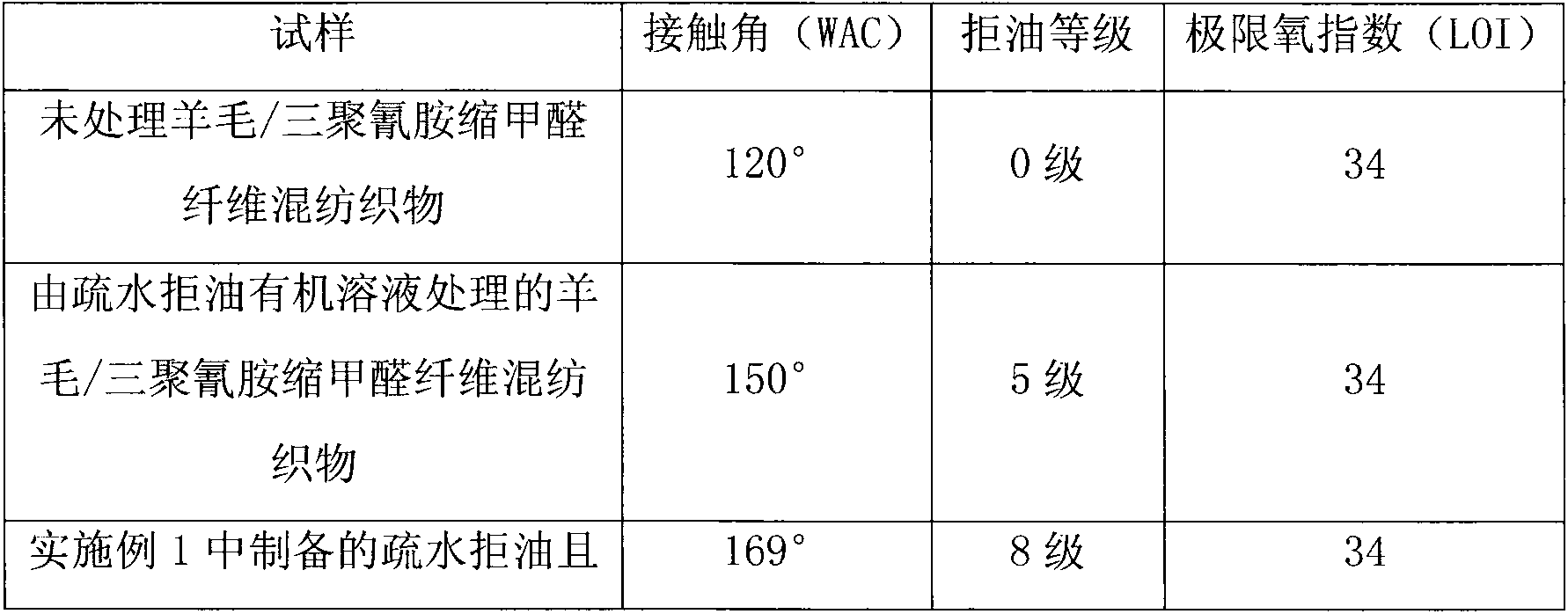

Preparation method for water-repellent oil-repellent flame-retardant protective suit fabric

The invention provides a preparation method for water-repellent oil-repellent flame-retardant protective suit fabric. The preparation method is characterized by comprising the steps of waving blended yarn made of wool and formalized melamine formaldehyde fibers into fabric; and subjecting the fabric to water and oil repellent finishing, wherein the water and oil repellent finishing comprises subjecting the fabric plasma treatment through a normal-pressure plasma treatment device firstly, then, padding the fabric after the plasma treatment in a water and oil repellent finishing agent, and finally, performing pre-curing and curing sequentially. The preparation method is obvious in effect, provided with the flame retardance and superior in water and oil repellent effect.

Owner:DONGHUA UNIV

Preparation process of high foaming phenolic resin foam material

The invention discloses a preparation process of a high foaming phenolic resin foam material. The preparation process comprises the following steps of: adding 90% to 92% by mass of thermosetting phenolic resin liquid, 4% by mass of Zn powder and 4% to 6% by mass of HMTA (hexamethylenetetramine) to a container for uniformly stirring, and heating and continuously stirring after uniformly stirring; and heating to 50 to 65 DEG C, and obtaining the phenolic resin foam material after 1 to 2 minutes of curing reaction. By adopting the process, the phenolic resin foam material with 8 to 10 times of foaming times can be prepared, the process is simple, and the cost is low.

Owner:SHANDONG UNIV

Energy saving fireproof paint and preparation method thereof

The invention provides energy saving fireproof paint and a preparation method thereof. The energy saving fireproof paint comprises the following components in parts by weight: 20-30 parts of a fire retardant, 7-12 parts of a carburization agent, 7-12 parts of a foaming agent, 9-15 parts of an inorganic hollow material, 10-22 parts of titanium dioxide, 31-43 parts of a cross-linking agent, 3-5 parts of an anti-aging agent, 2-5 parts of magnesium hydroxide, and 2-5 parts of diatomite. The energy saving fireproof paint has the advantages of solar heat reflection, heat insulation, water resistance, and corrosion resistance, and the advantages are identical to the advantages of energy saving paint; at the same time the energy saving fireproof paint has the advantages of self-extinguishing, flame retardation, formation of a compact heat insulating protective layer by expansion during fire hazard, and the like, and the advantages are identical to the advantages of fireproof paint.

Owner:广州市环康机电工程安装有限公司 +2

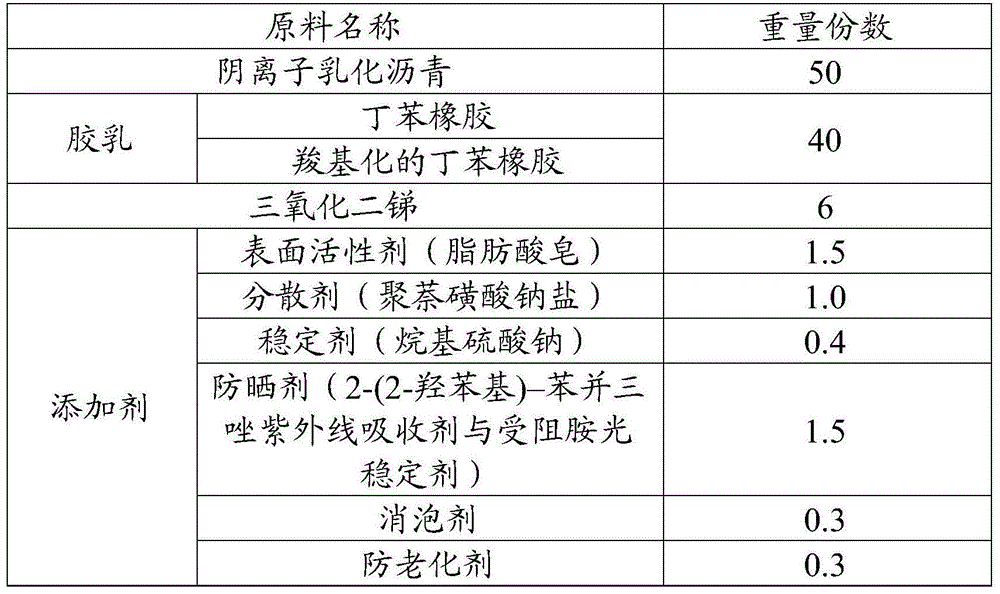

Aqueous flame-retardant rubber asphalt coating film waterproof material and preparation and construction method thereof

ActiveCN105623508AEnhanced vulcanized constructionHigh physical strengthConjugated diene hydrocarbon coatingsCarboxyl rubber coatingsAsphaltCoating

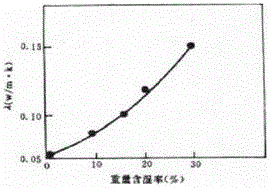

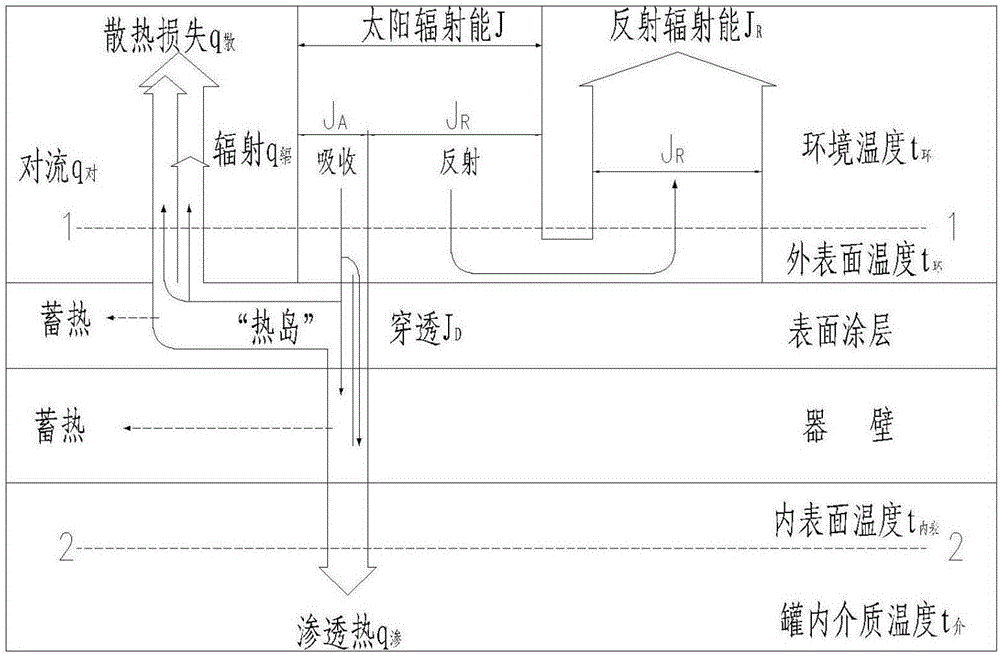

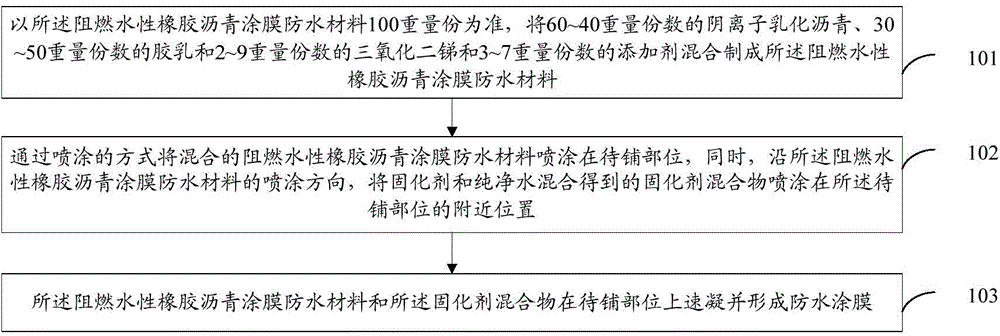

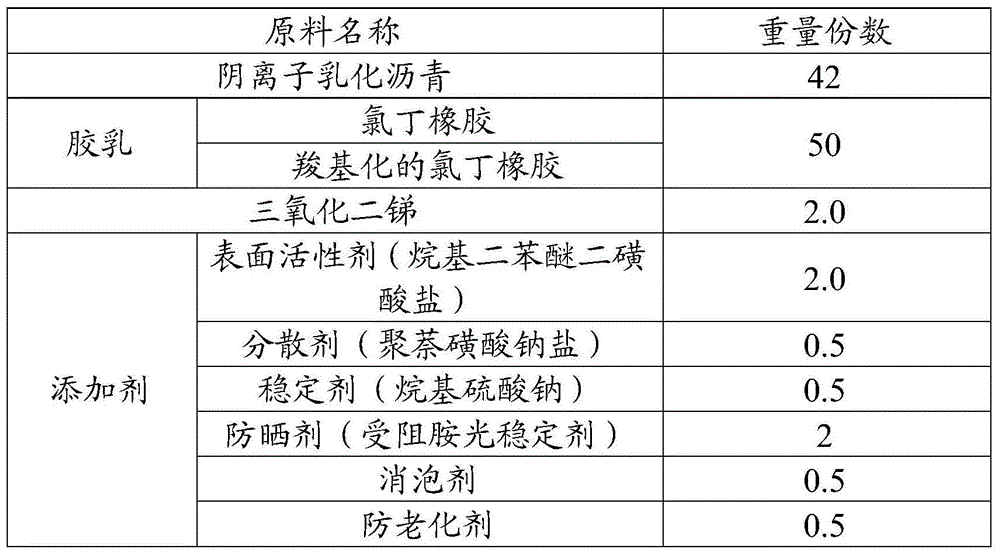

The present invention provides an aqueous flame-retardant rubber asphalt coating film waterproof material and a preparation and construction method thereof. The preparation and construction method comprises: by adopting 100 parts by weight of a aqueous flame-retardant rubber asphalt coating film waterproof material as the reference, mixing 60-40 parts by weight of anionic emulsification asphalt, 30-50 parts by weight of latex, 2-9 parts by weight of diantimony trioxide, and 3-7 parts by weight of an additive to prepare the aqueous flame-retardant rubber asphalt coating film waterproof material, spraying the aqueous flame-retardant rubber asphalt coating film waterproof material onto a site to be paved through a spraying manner while spraying a curing agent mixture obtained by mixing a curing agent and purified water onto the position near the site to be paved along the spraying direction of the aqueous flame-retardant rubber asphalt coating film waterproof material, carrying out rapid setting of the aqueous flame-retardant rubber asphalt coating film waterproof material and the curing agent mixture at the site to be paved, and forming the waterproof coating film.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

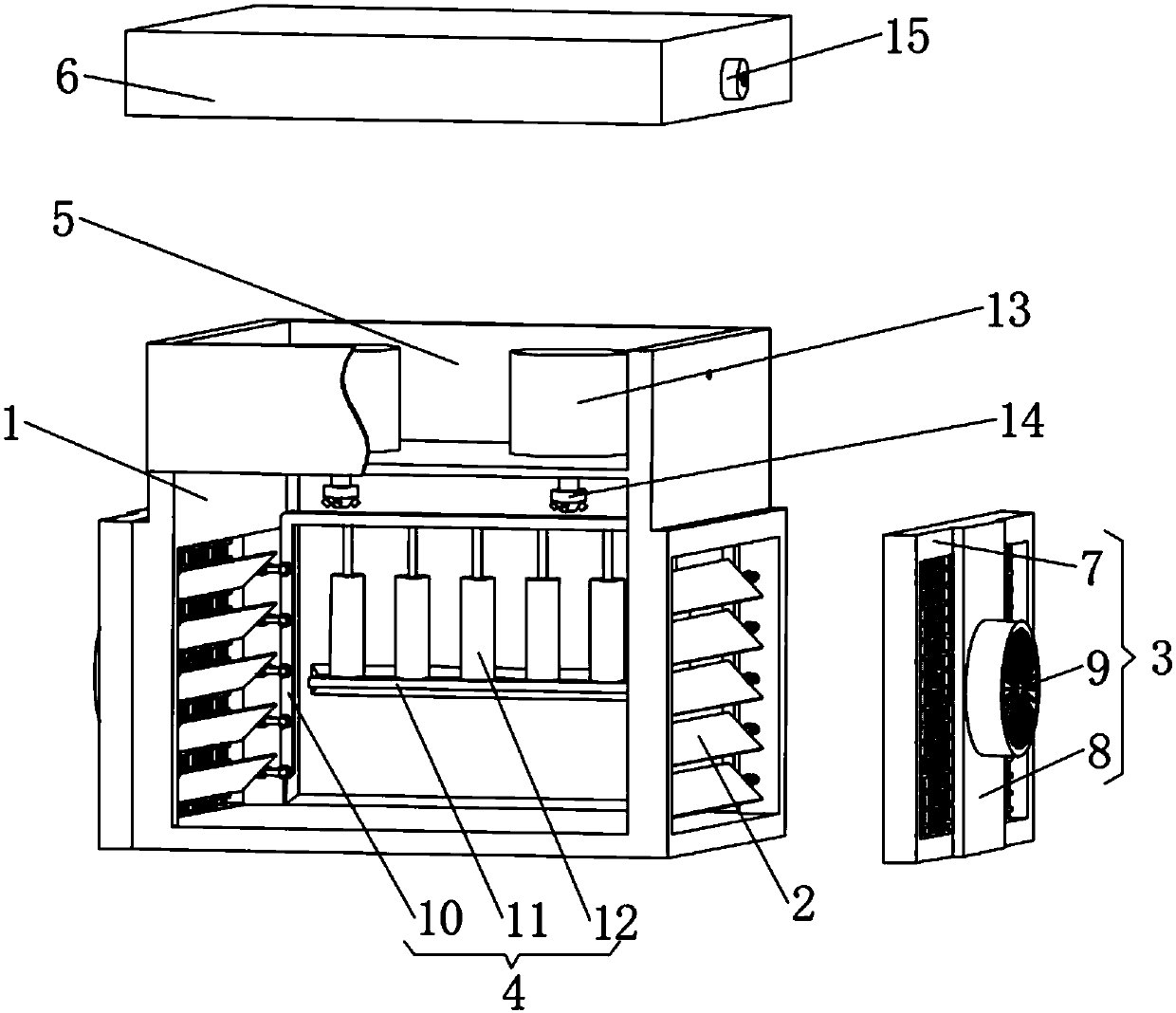

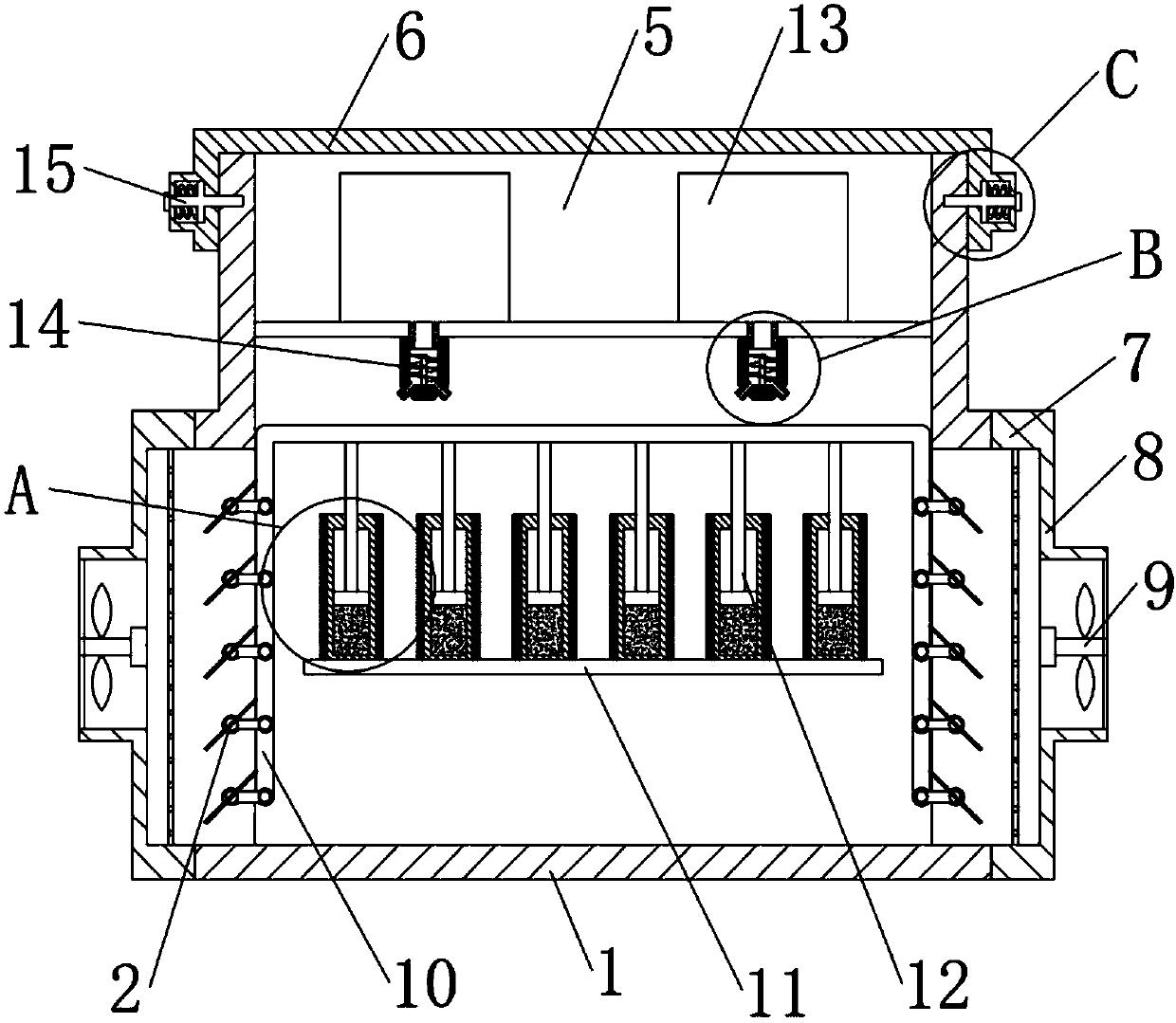

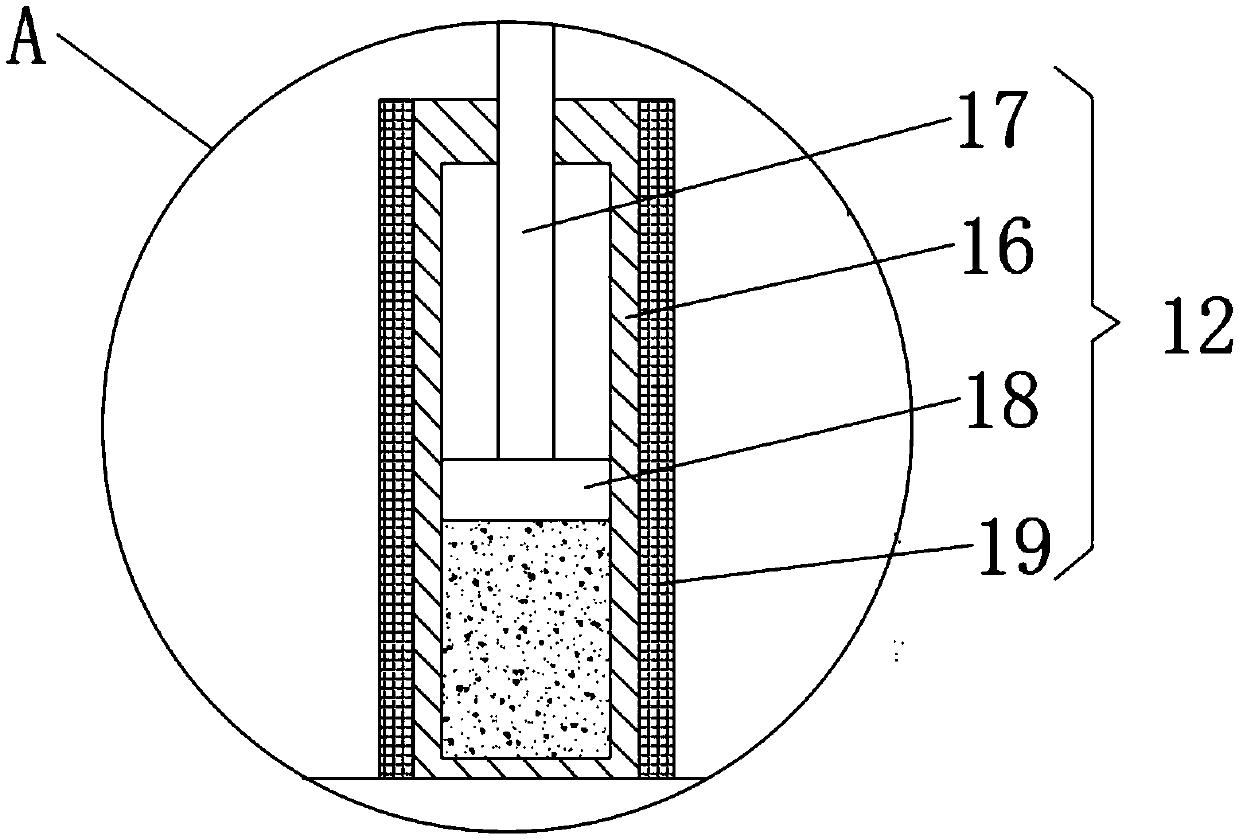

Fire extinguishing device for high-voltage equipment

InactiveCN109616881AHeated volume increasesReduce oxygen content in the airSubstation/switching arrangement casingsFire rescueCombustionEngineering

The invention discloses a fire extinguishing device for high-voltage equipment. The fire extinguishing device comprises a high-voltage switch cabinet body, an adjustment fan group, a fan blade controldevice and injection heads, wherein a cooling plate group comprises a cooling frame, an electric fan support plate and an electric fan, the fan blade control device comprises a driving support, a temperature sensing device support seat and a temperature sensing device, the temperature sensing device comprises a temperature sensing tank, a top rod, a piston and a heat preservation layer, two fireextinguishing tanks are arranged above the high-voltage switch cabinet body and in a fire extinguishing device placement cavity, and the injection heads are connected with lower ends of the fire extinguishing tank. The fire extinguishing device placement cavity is formed in an upper end of the high-voltage switch cabinet, the fire extinguishing tank can be used for injecting CO2 into the high-voltage switch cabinet body when a fire is generated to achieve automatic fire extinguishing, and the fire extinguishing device is relatively safe; and the adjustment fan group can be closed under controlof the fan blade control device, oxygen containing content of the high-voltage switch cabinet is reduced, and combustion is effectively suppressed.

Owner:盐城紫环工业机械有限公司

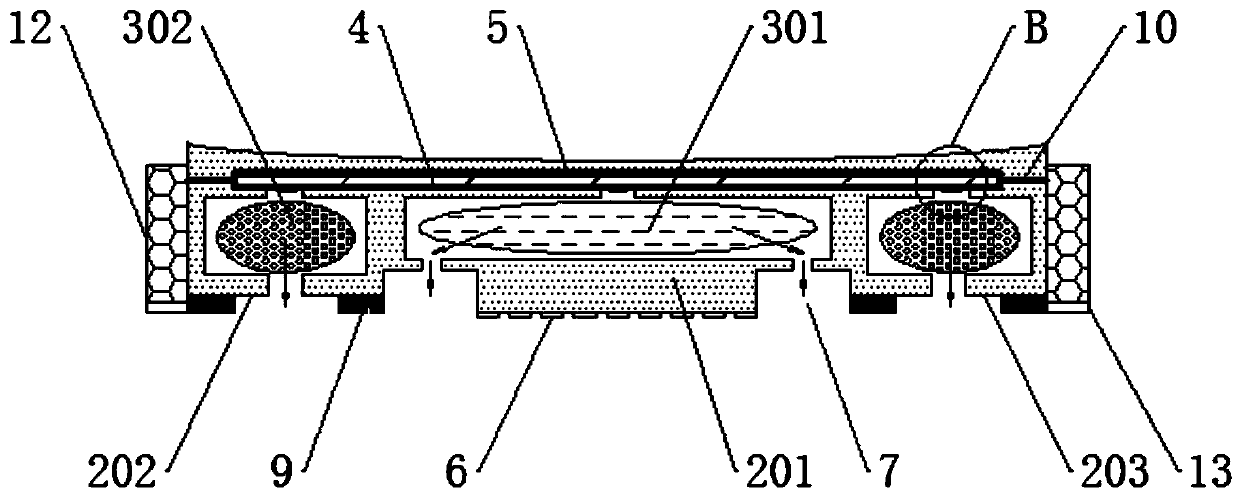

Gum dipping flame retarding canvas and manufacturing method thereof

ActiveCN103147206ASelf-extinguishingDipped adhesive strength improvedCarbon fibresWoven fabricsCarbon fibersPolymer science

The invention discloses gum dipping flame retarding canvas which comprises warps and wefts, wherein the warps are twisted aramid fibers (3), and the wefts are stranded dacron fibers (1) and stranded carbon fibers (2) that are arranged at intervals. The invention further provides a manufacturing method of the gum dipping flame retarding canvas. According to the gum dipping flame retarding canvas, an oxygen content of air is 21% generally, while the limit oxygen indices of the aramid fibers are greater than 28%, so that the aramid fibers are fire-retardant, cannot be burnt in the air or support combustion, and have self-extinguishment ability. The aramid fibers are flame-retardant permanently due to inherent characteristics of molecular structures of the aramid fibers, and have a good name of 'fire-proof fibers'; for the wefts, the stranded dacron fibers are adopted for reinforcement due to poor tenacity of the carbon fibers, so as to meet yield effect requirements and weft tension strength requirements; and gum dipping adhesion strength can be improved. Carbon contents of the carbon fiber do not exceed 90% generally, and the carbon fibers are good in flame retardancy, and cannot generate smoke and flame during high oxygen combustion.

Owner:BAODING HUAYUE RUBBER BELTS

Flame-retardant glass flake daub

The invention discloses flame-retardant glass flake daub. The flame-retardant glass flake daub is prepared from, by weight, 20-25 parts of flame-retardant epoxy vinyl ester resin, 10-15 parts of glass flake, 5-8 parts of curing agent, 10-13 parts of flame retardant, 5-8 parts of charring agent, 2-3 parts of flame-retardant fiber and 1-2 parts of adhesive. Compared with conventional glass flake daub, the mechanical property and heat resistance of the flame-retardant glass flake daub are unchanged, but the oxygen index is increased, the flame propagation velocity is reduced, and the flame-retardant glass flake daub has self-extinguishment performance.

Owner:武汉博奇玉宇环保股份有限公司

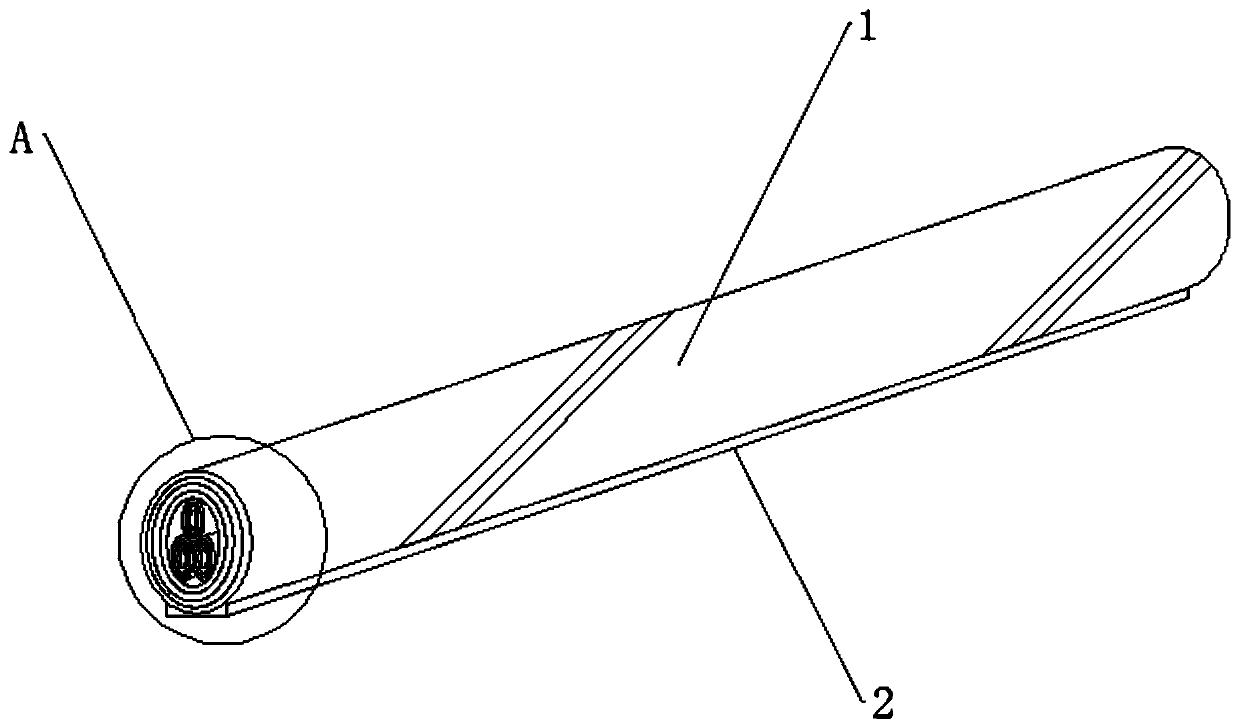

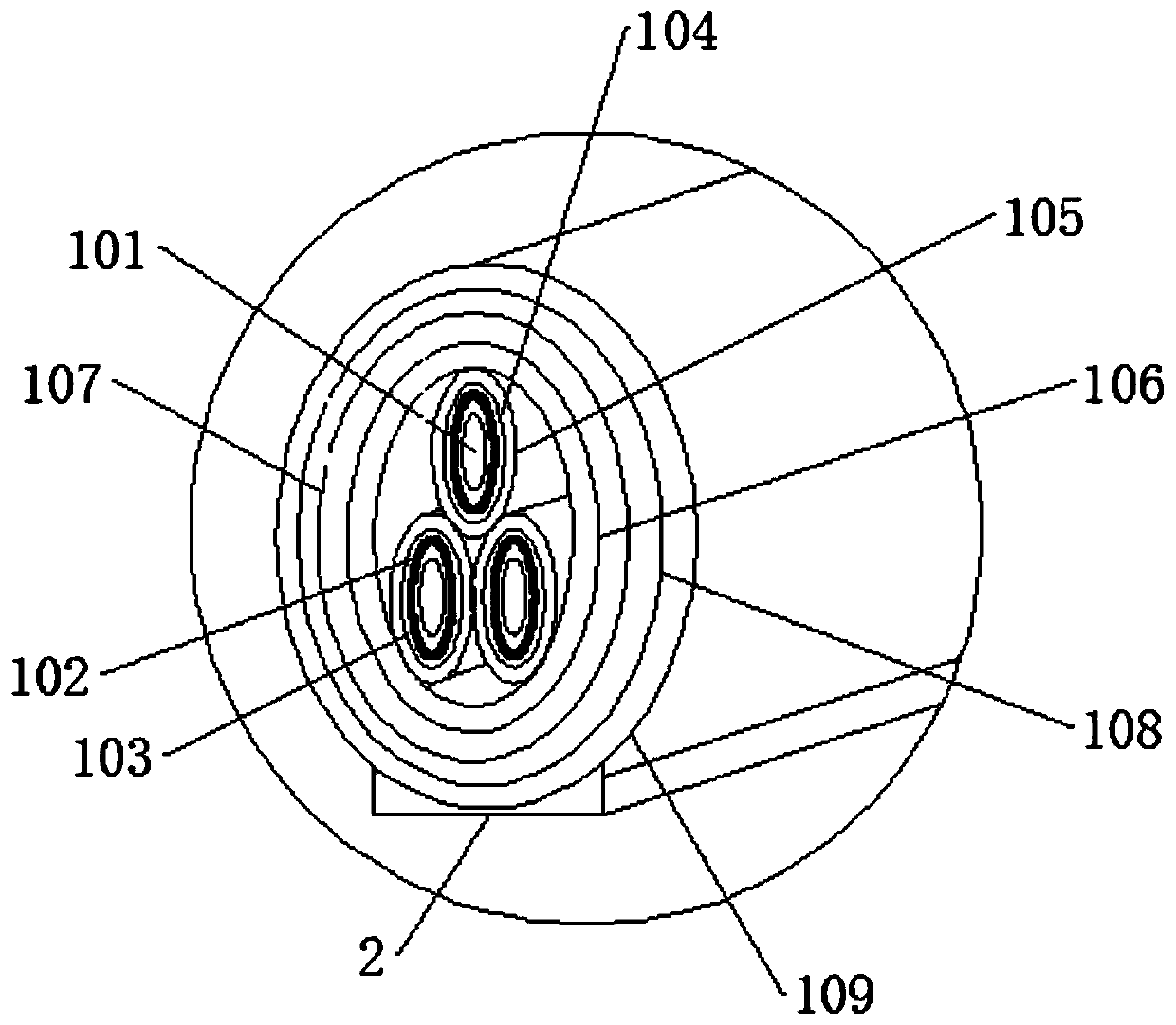

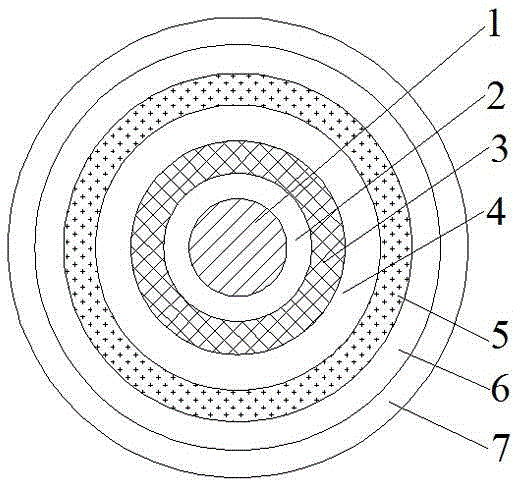

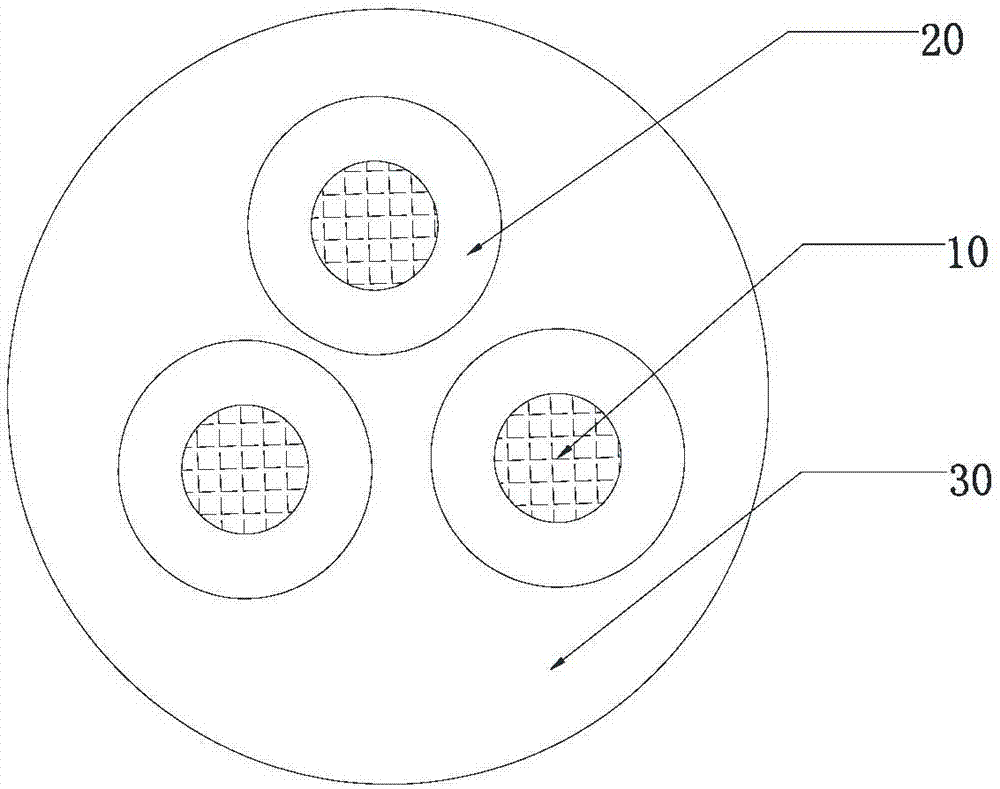

Wall-laminated self-setting type strong-power cable

ActiveCN109767870AEasy to layImprove insulation performanceClimate change adaptationPower cables with screens/conductive layersViscous liquidPower cable

The invention discloses a wall-laminated self-setting type strong-power cable and belongs to the technical field of cables. A wall-laminated self-setting type strong-power cable can be laid on the surface of a wall conveniently, the adsorption characteristic of a nanometer sucker is utilized, the cable is indirectly fixed for a long time under the action of the atmospheric pressure, effective fixing is realized under the condition of not damaging the cable, under the auxiliary action of liquid water and high-viscosity viscous liquid, the sealing performance of the nanometer sucker is improvedand the adsorption strength is further improved, a damping energy dissipation function is provided to counteract external force, meanwhile, the memory characteristic of shape memory alloy is used forhelping the cable to achieve self-setting, the laying mode is simple and fast, the lines laminated to the wall are straight, the aesthetic degree is remarkably improved, the cable is excellent in electrical insulation performance, high-temperature resistance and mechanical strength, and the service life of the cable is prolonged.

Owner:桂昌线缆集团有限公司

High temperature and high voltage resistant cable

InactiveCN105427921AImprove high temperature resistanceImprove anti-aging propertiesPower cables with screens/conductive layersInsulated cablesPolyolefinElectrical conductor

The invention belongs to the field of cables, and particularly relates to a high temperature and high voltage resistant cable. The cable comprises a conductor and a sheath layer externally wrapping the conductor, the sheath layer is orderly composed of an insulating layer, a mica belting layer, a low-smoke halogen-free flame retardant polyolefin inner jacket, a woven shielding layer, a low-smoke halogen-free flame retardant polyolefin outer jacket and an outer sheath from inside to outside; material of the insulating layer and material of the outer sheath both are modified fluoroplastic for cables, and the modified fluoroplastic for cables comprises the following constituents in parts by weight: 60-80 parts of polytetrafluoroethylene, 10-20 parts of wear-resistant agent, 5-10 parts of fire retardant, 7-16 parts of plasticizer, 5-9 parts of filler, 1-3 parts of antioxidant, 1-3 parts of paraffin oil, 0.1-0.2 parts of ratproof master batch and 0.1-0.2 parts of temite preventing master batch. The structure above can perform multi-angle protection for the cable, and can effectively reduce influence of high temperature and high voltage generated when conducting the conductor or outside severe environment on service life of the cable.

Owner:GUANGDONG ZHONGDE CABLE

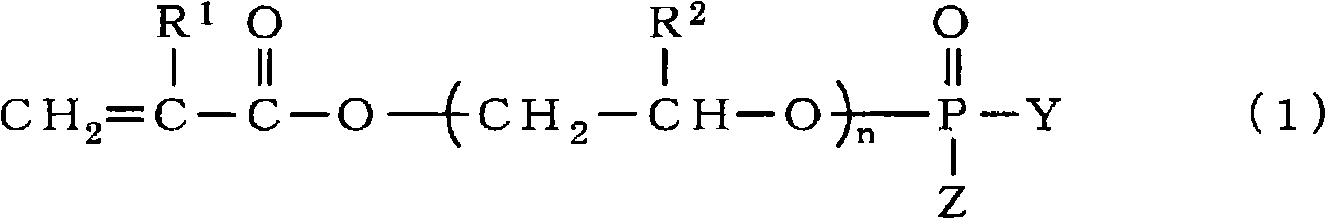

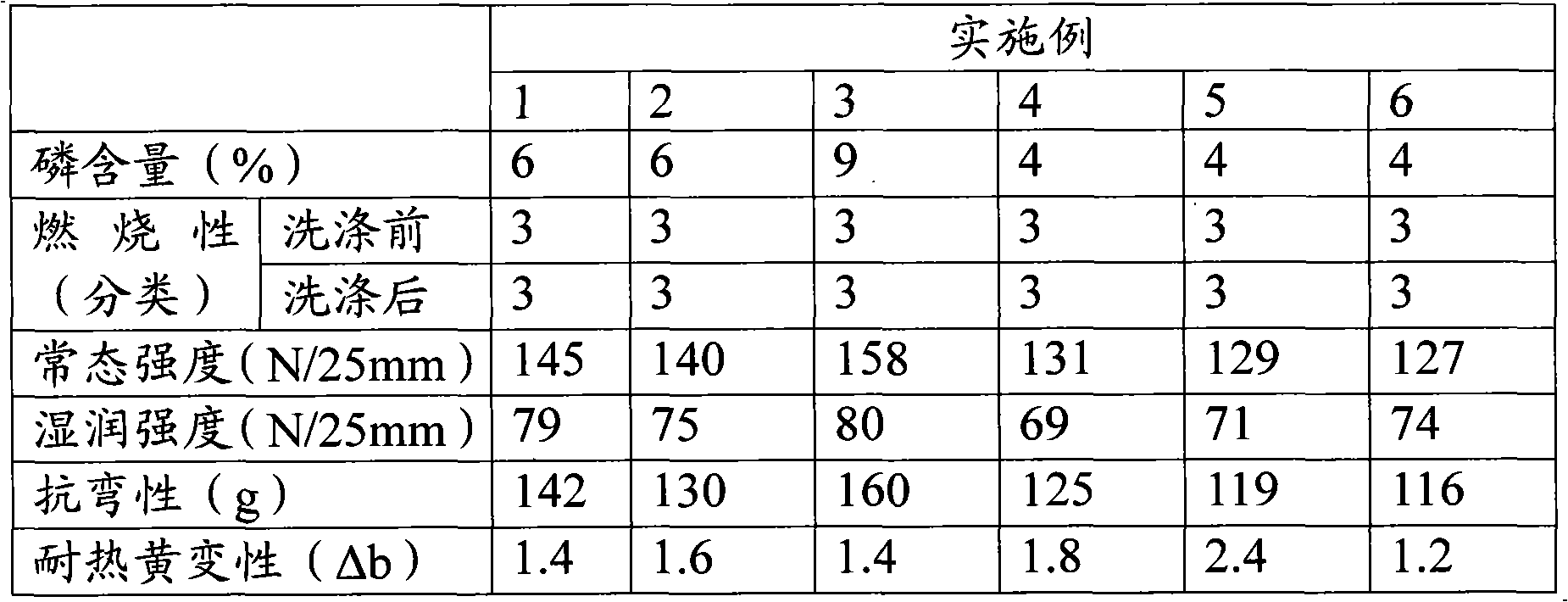

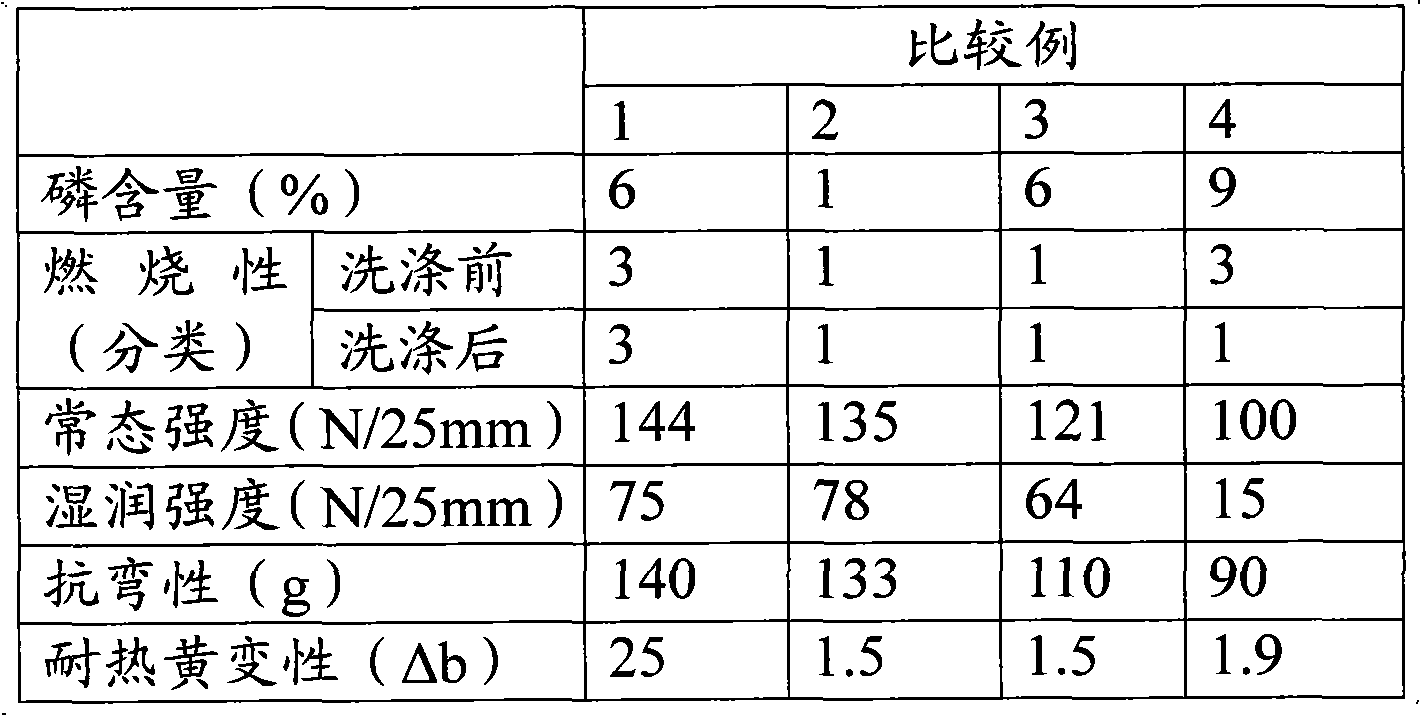

Resin composition and processed paper or fiber product treated therewith

ActiveCN102369224AHigh strengthImprove flame resistanceFibre treatmentPaper coatingFiberHydrogen halide

Disclosed is a resin composition, which is free from any halogen-based component with a risk of generating dioxins or hydrogen halides and can impart excellent strength, bending resistance, flame resistance and heat yellowing resistance to a processed paper or fiber product. Specifically disclosed is a resin composition obtained by copolymerizing an unsaturated monomer having a phosphate or phosphite group, an alkyl (meth)acrylate monomer and an unsaturated monomer having a carboxyl group, characterized by: having a definite phosphorus content in the solid components; and containing an alkyl (meth)acrylate monomer, wherein the alkyl chain has 1 to 4 carbon atoms, and an unsaturated monomer having a carboxyl group, each in a definite amount. A processed paper or fiber product, which has been treated with the aforesaid resin composition, has excellent strength, bending resistance, flame resistance and heat yellowing resistance.

Owner:RESONAC CORP

Flame-retardant acupuncture cotton and preparation method for same

InactiveCN104313792ASolve the droplet problemWon't burnHeating/cooling textile fabricsNon-woven fabricsCardingLaboratory oven

The invention relates to a preparation method for flame-retardant acupuncture cotton. The flame-retardant acupuncture cotton is prepared from 30 to 50 weight percent of aramid 1313 fiber and 70 to 50 weight percent of ES (ethylene-propylene side by side) fiber. A production process comprises procedures of material selection, opening, carding, lapping, needling, baking in a baking oven, roll cooling, forming and packaging, and the like, wherein the fibers are carded and formed at one time, and are directly lapped for pre-needling at one time through a one-time oscillating head, enter the baking oven for baking after down-stroke needling, upstroke needling, down-stroke needling and upstroke needling, and are roll-cooled and formed, the baking temperature is 150 to 190 DEG C, the baking time is 14 to 25 s, and the cooling temperature is -5 to 20 DEG C. The acupuncture cotton produced by the method has a high flame retardant property, and can be used as an automotive interior material, and meanwhile, the problem of molten drops of a flame-retardant material is effectively solved.

Owner:DANYANG CHAOCHAO FASHION

Low-smoke bittern-free highly fire-proof elastic polyolefin electric cable material

InactiveCN100556947CGood flexibilityIncrease elasticityInsulated cablesInsulated conductorsElastomerPolyolefin

The invention relates to a low-smoke, halogen-free and highly flame-retardant elastic polyolefin plastic for electric wires and cables. Ethylene-octene copolymer), with a content of 20 to 50 parts by weight; EMA elastomer (ethylene-methyl acrylate copolymer), with a content of 5 to 15 parts by weight; magnesium hydroxide or aluminum hydroxide, with a content of 30 to 70 parts by weight; Nano magnesium hydroxide has a content of 20-40 parts by weight; DCP (dicumyl peroxide) has a content of 0.1-0.6 parts by weight. The hardness of the material is ≤85 Shore A; the strength is ≥9.0MPa; the elongation is ≥150%; the flame retardancy meets the requirements of UL1581 VW-1.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

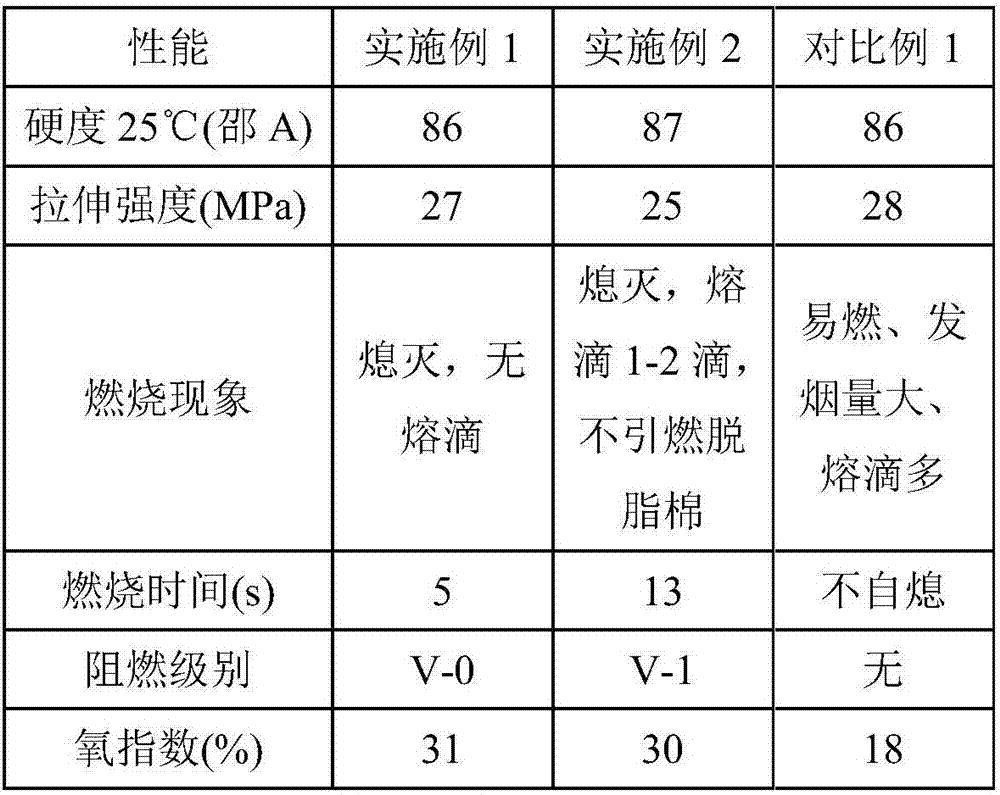

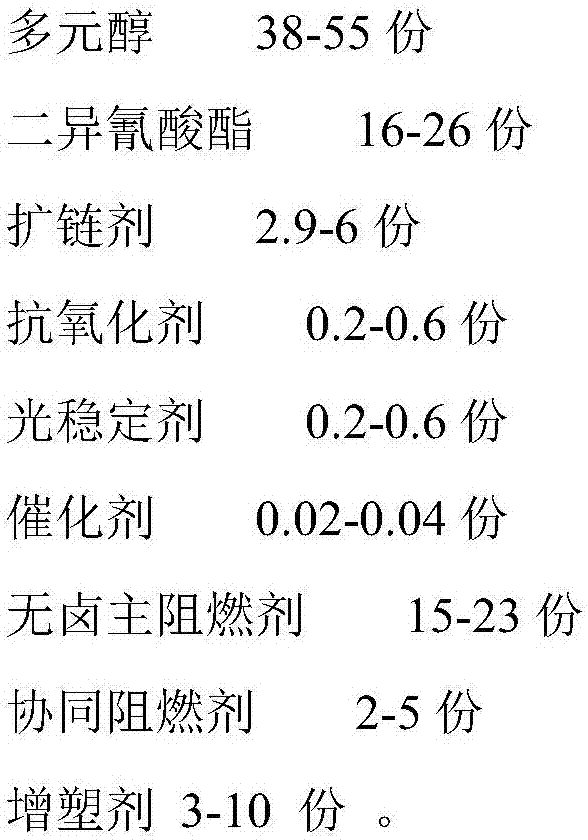

Halogen-free flame retardant TPU (Thermoplastic Urethane) glue coating material and preparation method thereof

ActiveCN108003605AAvoid high temperature melting and crackingImprove high temperature resistanceChemical synthesisAntioxidant

The invention belongs to the technical field of chemical synthesis, and particularly relates to a halogen-free flame retardant TPU (Thermoplastic Urethane) glue coating material and a preparation method thereof. The halogen-free flame retardant TPU glue coating material is prepared from the following raw materials including polyhydric alcohol, diisocyanate, chain expanding agents, antioxidants, light stabilizers, catalysts, halogen-free main flame retardants, cooperated flame retardants and plasticizing agents. The halogen-free main flame retardants are one or several kinds of materials from organic hypophosphorous acid metal salts, rare earth hypophosphorous acid salt or melamine derivative series flame retardants; the cooperated flame retardants are one or several kinds of materials fromaluminum hydroxide, magnesium hydrate, aluminum oxide or magnesium oxide. The invention also provides the preparation method of the halogen-free flame retardant TPU glue coating material. According to the method, the polyhydric alcohol, the diisocyanate and the chain expanding agents are mixed; auxiliary agents dispersed by the plasticizing agents are continuously added through a lateral feedingopening; then, extrusion processing and granulation is performed through screw extrusion; a finished product is obtained. The halogen-free flame retardant TPU glue coating material has the advantagesthat the flame retardant performance, the mechanical property and the processing performance are excellent; the self extinguishing effect can be realized; halogen hydride gas with toxic and harmful effect on the environment is not generated during the combustion in the air; the efficiency is high; the environment is protected.

Owner:SHANDONG INOV POLYURETHANE

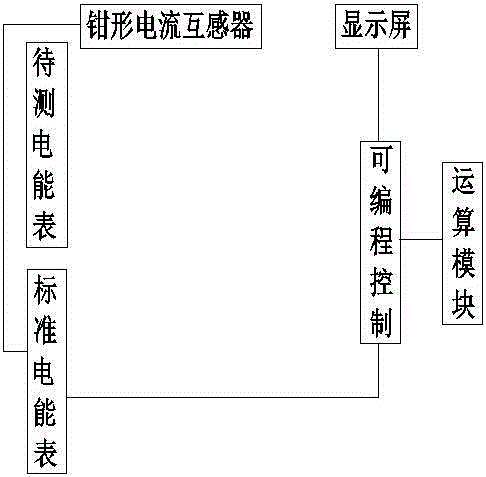

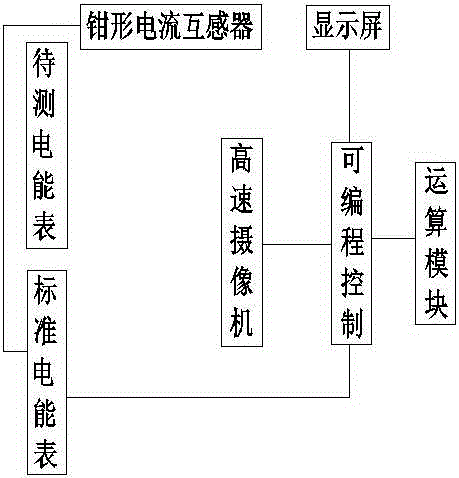

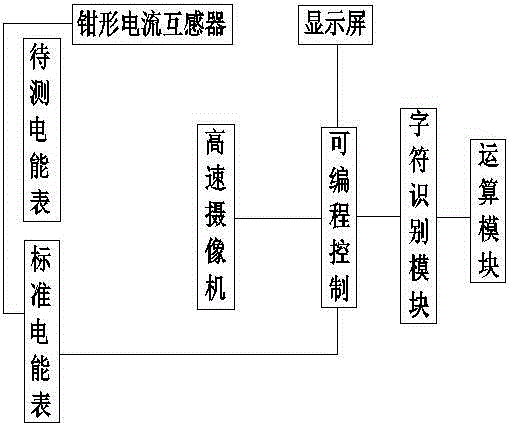

On-site rapid electricity-stealing-prevention tool and electricity-stealing detection method thereof based on ammeter degree verification

ActiveCN105182271AGood contact insulation performancePlay the effect of anti-magnetic field interferenceElectrical measurementsElectric energyElectricity

The invention discloses an on-site rapid electricity-stealing-prevention tool and an electricity-stealing detection method thereof based on ammeter degree verification. The on-site rapid electricity-stealing-prevention tool comprises a split-core-type current transformer, standard electric energy meters connected with the split-core-type current transformer and a programmable controller connected with the standard electric energy meter. The programmable controller is connected with an accurate calculating device; and the accurate calculating device comprises a high-speed camera connected with the programmable controller, an operation module connected with the programmable controller and a display screen connected with the programmable controller.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Fireproof mineral silicone rubber composition, fireproof mineral silicone rubber material, preparation method thereof and power line containing fireproof mineral silicone rubber material

ActiveCN107011662AInsulate heat transferImprove mixing and dispersing effectRubber insulatorsInsulated cablesPliabilityMineralogy

The invention provides a fireproof mineral silicone rubber composition, a fireproof mineral silicone rubber material, a preparation method thereof and a power line containing the fireproof mineral silicone rubber material. The fireproof mineral silicone rubber composition comprises, by weight, 50-100 parts of methyl vinyl silicone rubber, 30-50 parts of montmorillonite, 5-10 parts of quaternary ammonium salt surface modifier, 10-20 parts of low-melting-point glass powder, 30-50 parts of aluminum hydroxide and 5-10 parts of polyol. A ceramic layer structure formed by the fireproof mineral silicone rubber composition is stable and even in mechanical performance distribution, and the toughness and fireproof performance of the power line is further increased when the ceramic layer structure is used as the sheath of the power line.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

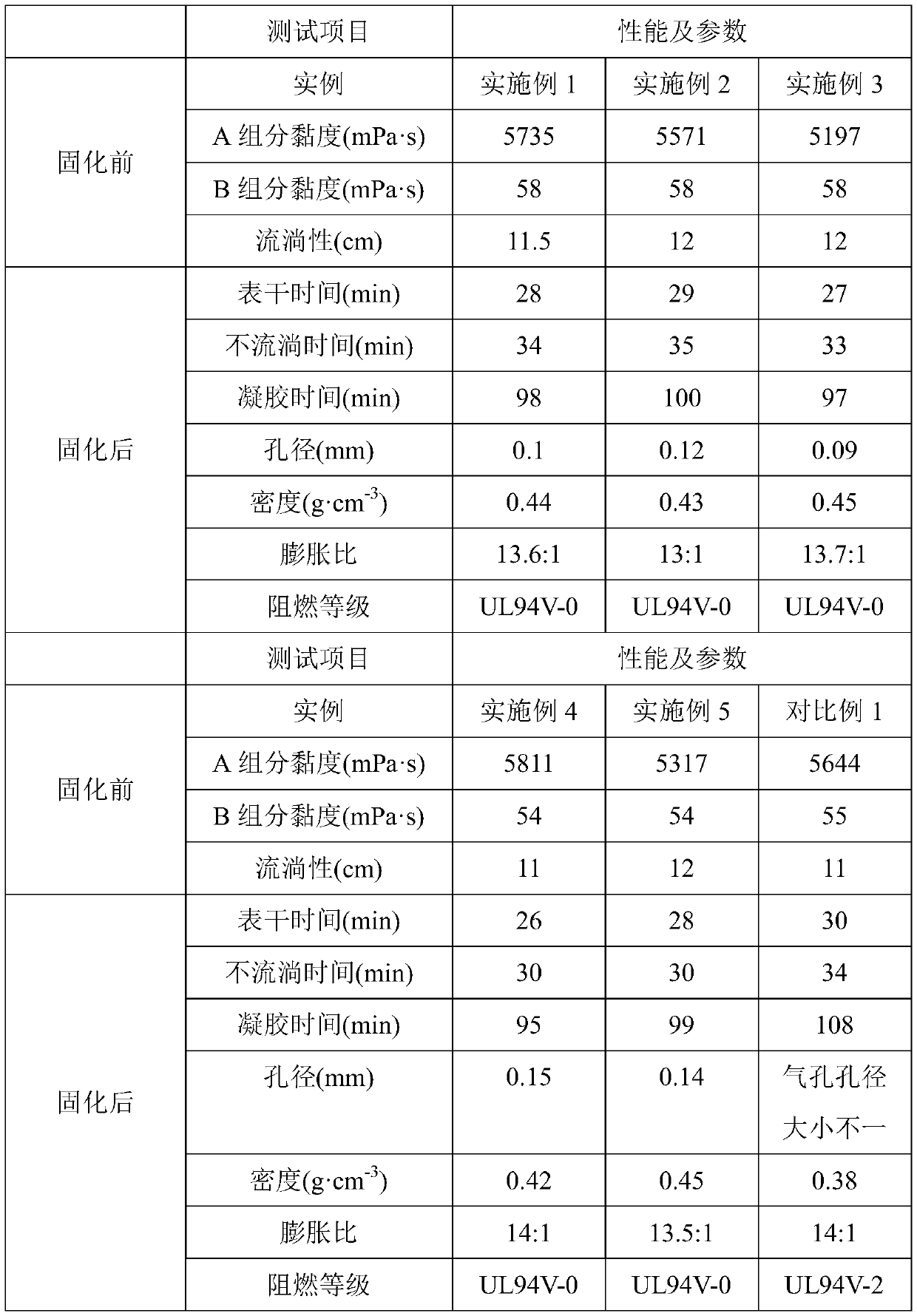

Foaming bi-component organic silicon pouring sealant and preparation method thereof

The invention discloses a foaming bi-component organic silicon pouring sealant which comprises a component A and a component B with the weight ratio of (5.5-6.5):1. The component A comprises, by weight, 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 1-20 parts of polyhydroxy polysiloxane, 5-50 parts of foaming agents, 20-90 parts of fillers, 0-5 parts of inhibitors, 1-15 parts of fluoro-alcohol treated MQ silicon resin and 1-15 parts of foaming rate-accelerating additives. The component B comprises, by weight, 100 parts of curing agent carriers, 40-60 parts of silane crosslinking agents, 10-20 parts of silane coupling adhesion accelerators and 0.05-1 part of catalysts. The foaming rate-accelerating additives are one or two of diphenyl silanediol and octanol. The invention further discloses a preparation method of the foaming bi-component organic silicon pouring sealant. The bi-component organic silicon pouring sealant has the advantages of simple production technology, foaming uniformity, high foam strength, good flame resistance, excellent storage performance and the like.

Owner:西卡(江苏)工业材料有限公司

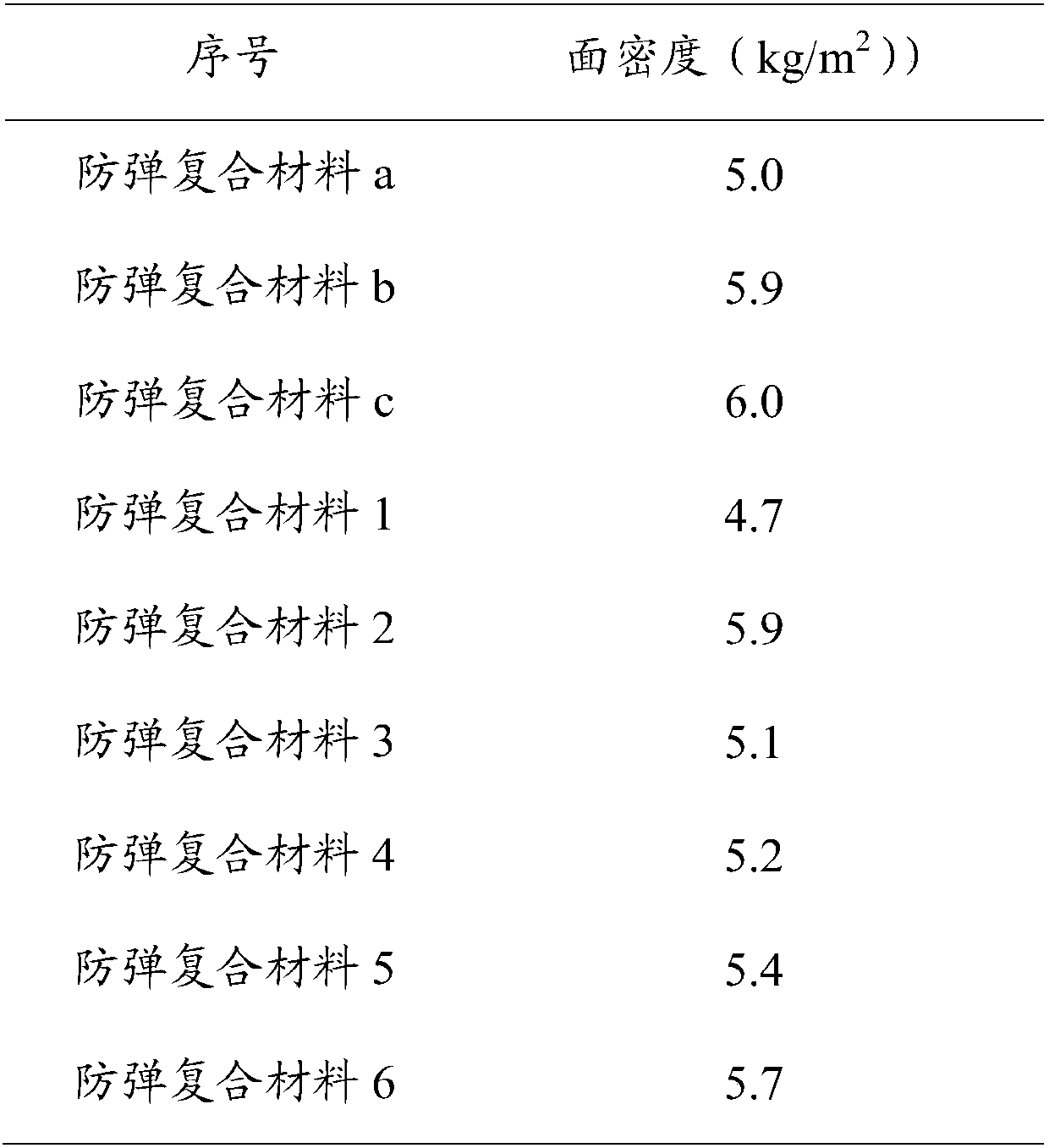

Bulletproof composite material and preparation method and application thereof

ActiveCN108673984AHigh tensile strengthHigh tensile modulusProtective equipmentFibre typesPolyolefinThermoplastic polyurethane

The invention discloses a bulletproof composite material, the bulletproof composite material is a resin-based composite material comprising polyimide fiber as a reinforcing body, wherein the mass ratio of the polyimide fiber is 60% to 90% by mass percentage, and the mass ratio of a resin matrix is 10% to 40%. The polyimide fiber is modified fiber which is subjected to interfacial treatment using an inert modifier, and the inert modifier is obtained by mixing aqueous thermoplastic polyurethane and aqueous polyolefin resin in a certain ratio. The invention also discloses a preparation method andapplication of the bulletproof composite material. The polyimide fiber is used as the reinforcing body, and the reinforcing body is subjected to the special interfacial treatment, infiltrated into the matrix resin according to a certain arrangement manner, and compounded with the resin matrix by a specific composite process, the prepared bulletproof composite material has the characteristics of good tensile strength and tensile modulus, good resistance to high and low temperature, light weight, and good flame retardancy and spinnability, and is suitable for preparation of soft and highly-comfortable-to-wear bulletproof clothing and bulletproof armor materials.

Owner:BEIJING PROTECH NEW MATERIAL SCI CO LTD

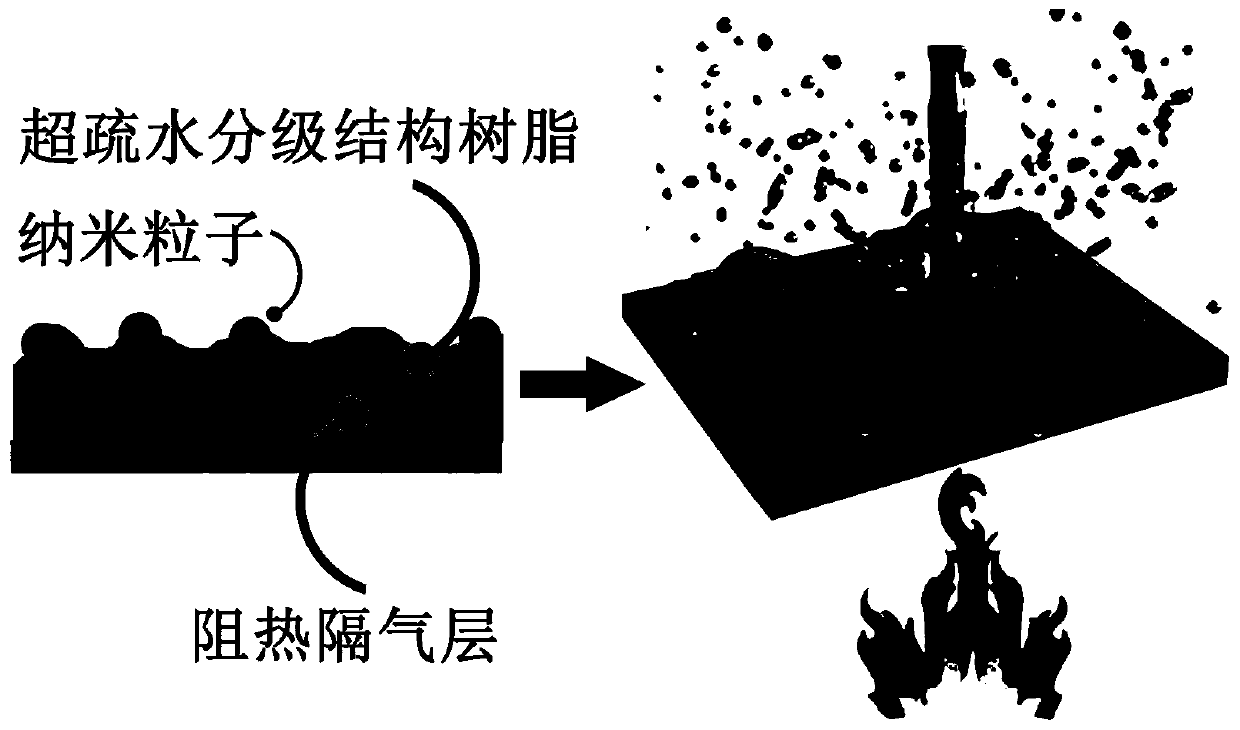

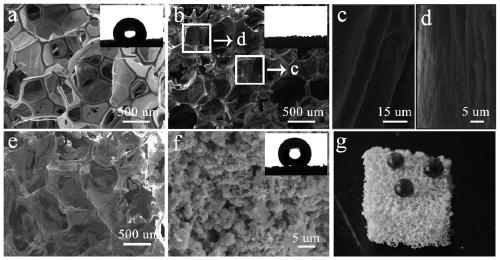

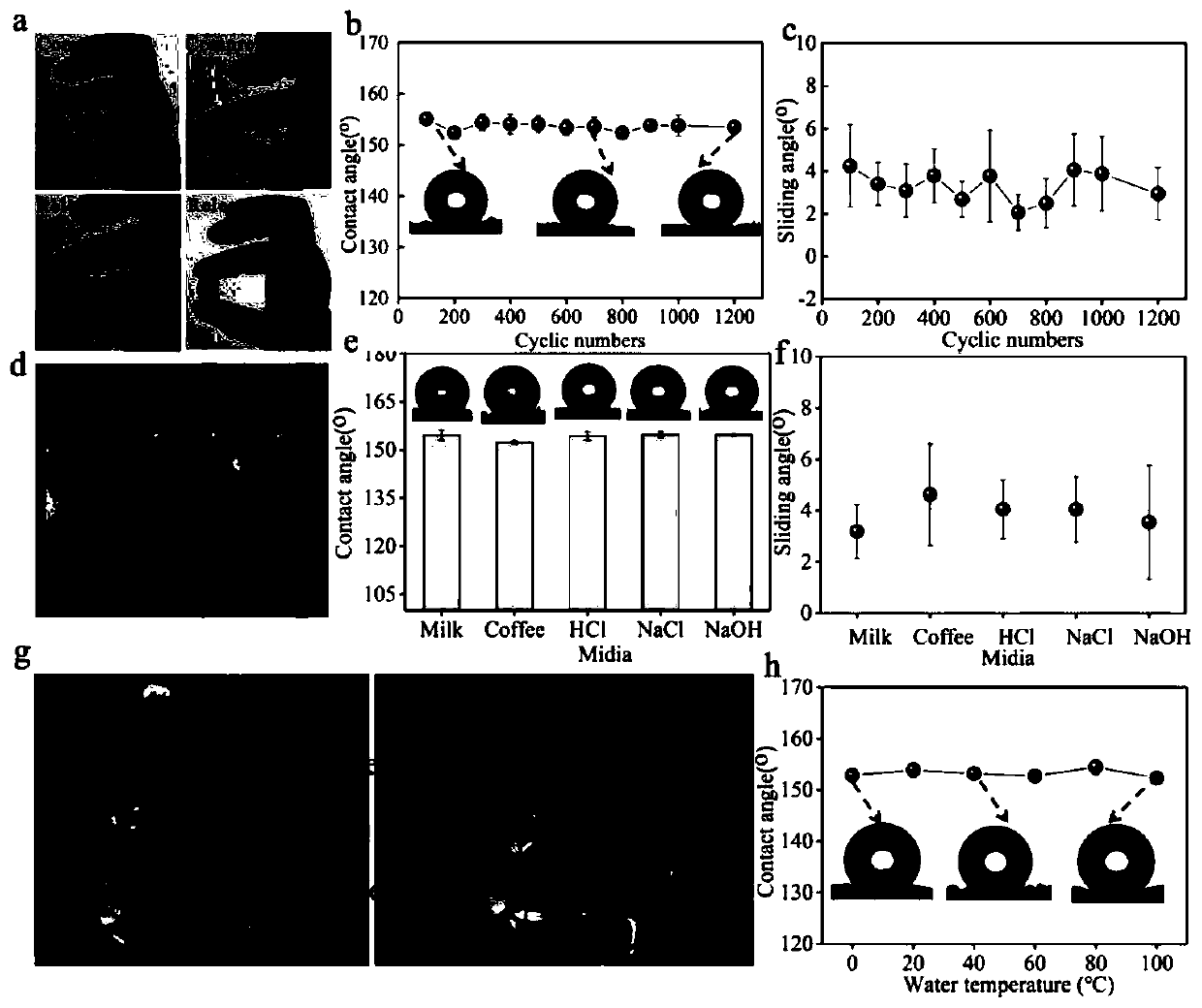

Fireproof super-hydrophobic coating, super-hydrophobic material and preparation method thereof

ActiveCN111171671AInhibition of diffusionImprove fire performanceFireproof paintsCoatings with pigmentsPolymer scienceMontmorillonite

The invention discloses a fireproof super-hydrophobic coating, which comprises super-hydrophobic hierarchical-structure resin and a heat-resistant gas-barrier layer embedded in the super-hydrophobic hierarchical-structure resin, wherein the heat-resistant gas-barrier layer is a compact flaky montmorillonite layer with consistent orientation. The invention further provides a fireproof super-hydrophobic material. The fireproof super-hydrophobic material comprises a substrate material and the fireproof super-hydrophobic coating located on the surface of the substrate material. The invention alsoprovides a preparation method of the fireproof super-hydrophobic material. The fireproof super-hydrophobic coating and the fireproof super-hydrophobic material have the characteristics of excellent fireproof performance and hydrophobic performance.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com