Metal hybrid POSS flame retardant as well as preparation method and application thereof

A flame retardant and hybrid technology, which is applied in the field of metal hybrid POSS flame retardants, can solve the problems such as non-existence, and achieve the effects of good catalytic carbonization, high innovation and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

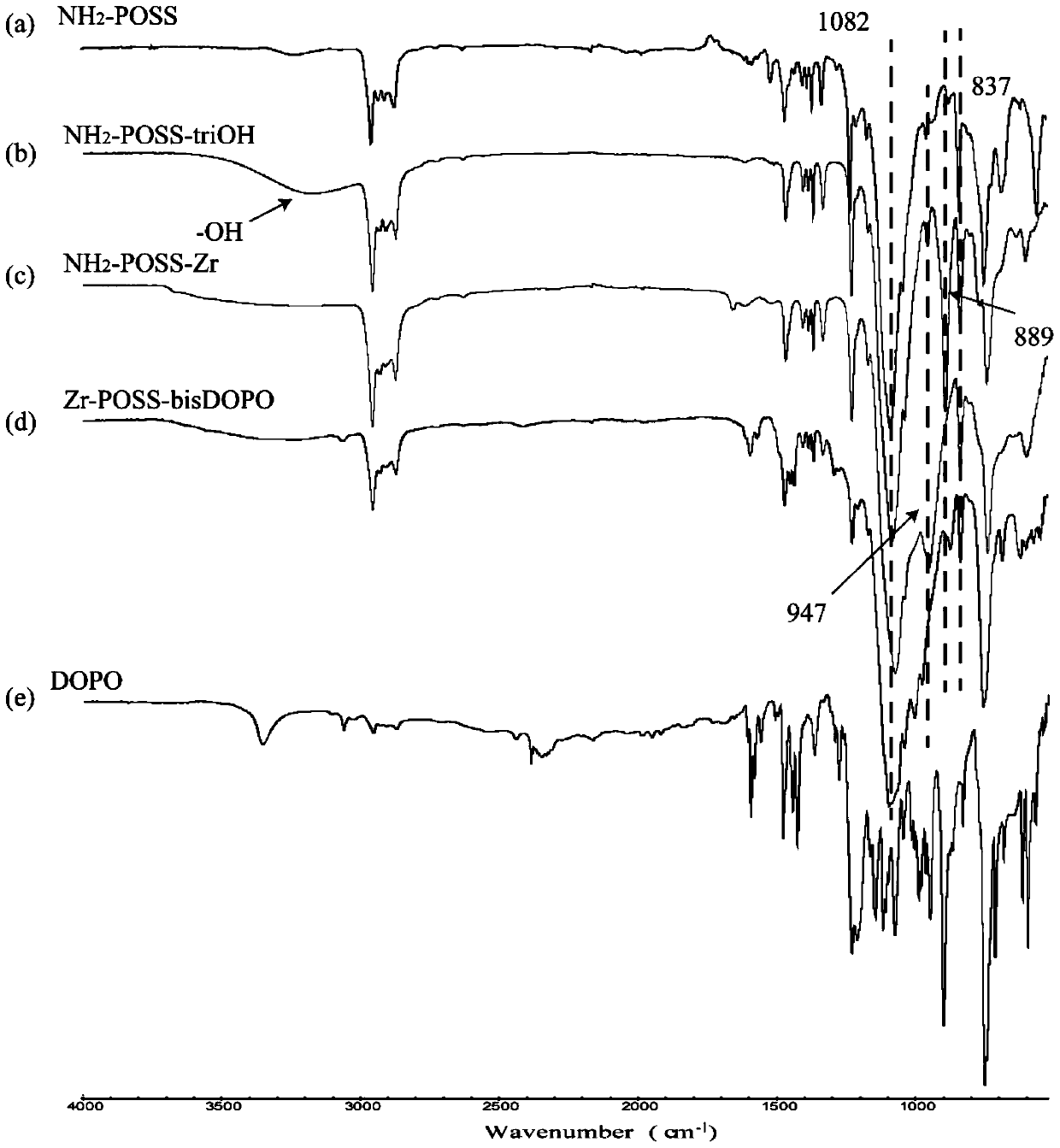

Image

Examples

Embodiment 1

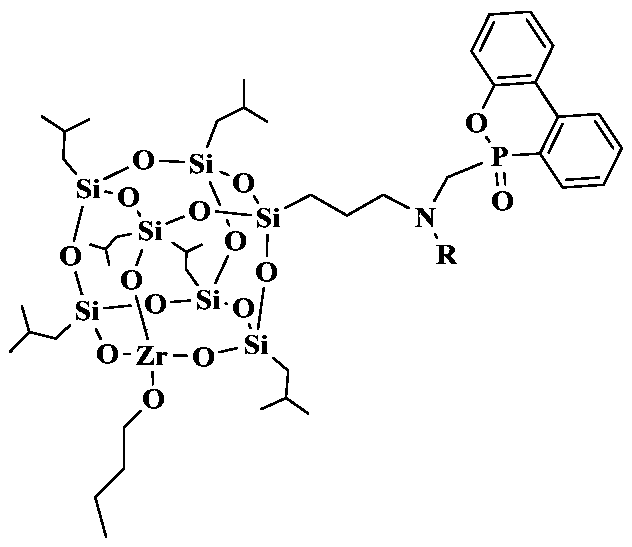

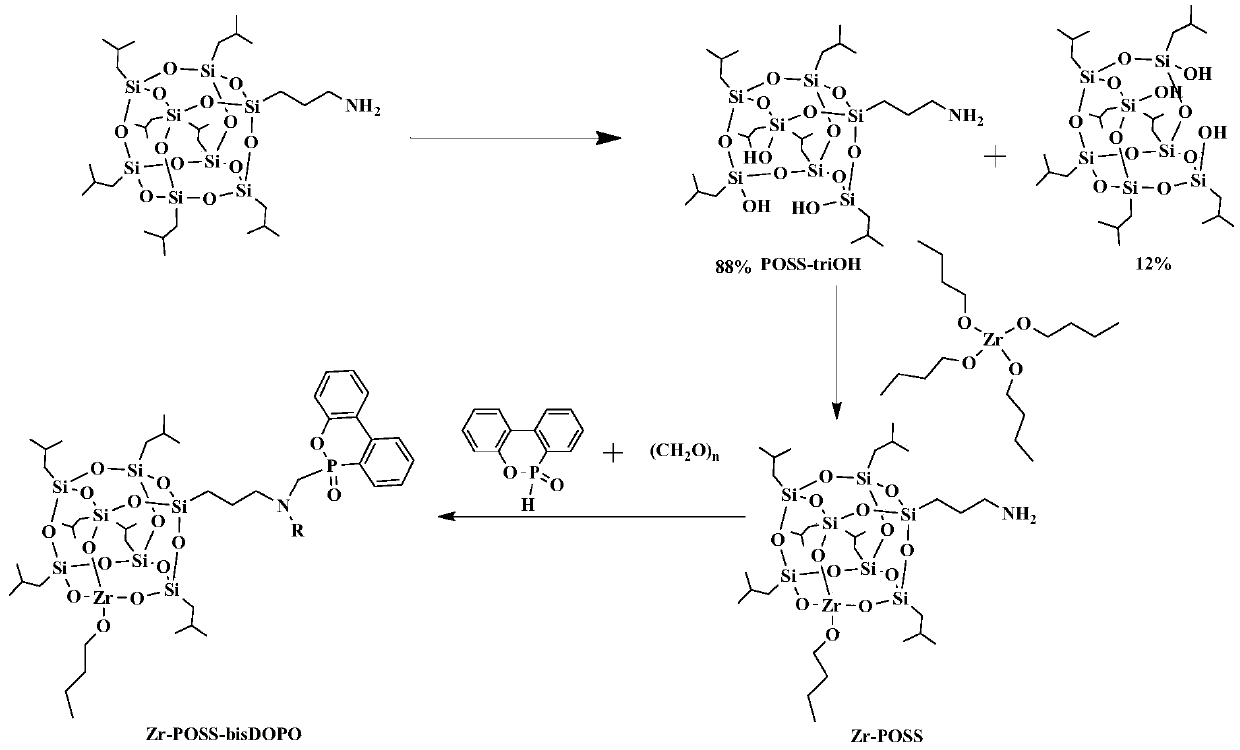

[0030] 1. Preparation of metal hybrid POSS flame retardant

[0031] (1) NH 2 -Synthesis of POSS-triOH

[0032] 2g (2mmol) of oligomeric polyhedral silsesquioxane (POSS-NH 2 ) was dissolved in 50 mL of tetrahydrofuran (the first organic solvent), and then the temperature was raised to 66° C. under rapid stirring. 360 μL (0.8 mmol) of tetraethylammonium hydroxide solution (organic strong base) was added, and after reacting for 5 hours, a certain concentration of hydrochloric acid solution (acid solution) was used to adjust the pH of the mixed liquid to be neutral (pH=7). Then rotary evaporation removes tetrahydrofuran, then dissolves in 50mL of dichloromethane (the second organic solvent), adds a certain amount of anhydrous magnesium sulfate (desiccant) to the mixed liquid obtained, stirs and dries for 15min, and filters off the desiccant after 15min. After the filtrate was concentrated, it was slowly added dropwise to acetonitrile (the third organic solvent). Then it was le...

Embodiment 2

[0046] 1. Preparation of metal hybrid POSS flame retardant

[0047] (1) NH 2 -Synthesis of POSS-triOH

[0048] 2g (2mmol) of oligomeric polyhedral silsesquioxane (POSS-NH 2 ) was dissolved in 50 mL of tetrahydrofuran, and then the temperature was raised to 66° C. under rapid stirring. 360 μl (0.8 mmol) of tetraethylammonium hydroxide solution was added, and after reacting for 5 hours, a certain concentration of hydrochloric acid solution was used to adjust the pH value of the mixed liquid to be neutral. Then the tetrahydrofuran was removed by rotary evaporation, and then dissolved in 50 mL of dichloromethane, a certain amount of anhydrous magnesium sulfate was added to the obtained mixed liquid, stirred and dried for 15 minutes, and then the desiccant was filtered off, and the filtrate was concentrated and slowly added dropwise to acetonitrile. Then it was left to stand at low temperature to obtain a white precipitate, and after filtration, the intermediate product NH 2 -P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com