Refractory flame-retardant silicone rubber sheath material for cables and preparation method thereof

A fire-resistant, flame-retardant, silicone rubber technology, used in insulated cables, rubber insulators, cables, etc., can solve the problem of difficulty in ensuring the normal operation of cables, and achieve high mechanical strength, good flame retardant effect, and good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

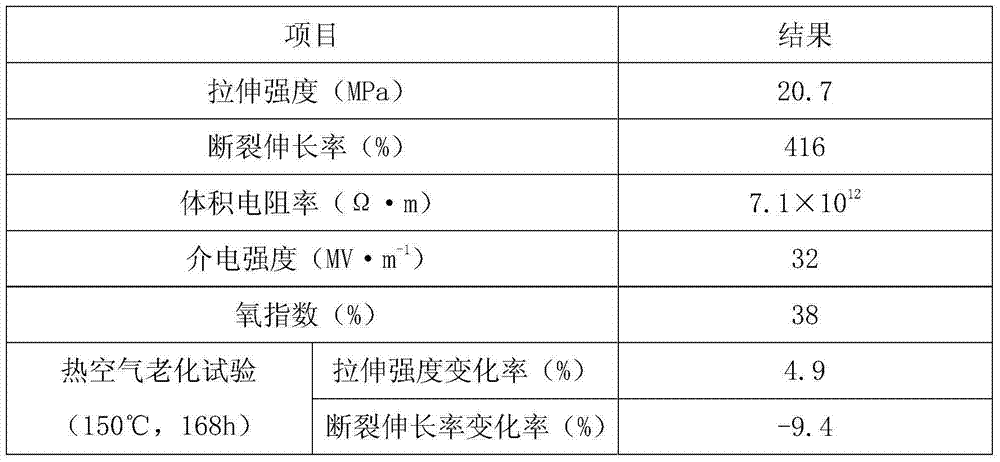

[0012] A fire-resistant and flame-retardant silicone rubber sheath material for cables, which is made of the following raw materials (kg): methyl vinyl silicone rubber 80, chlorohydrin rubber 20, bisphenol A polycarbonate 15, zinc oxide 2.5, 2-thiolbenzimidazole 3, microcrystalline paraffin 5, stearic acid 1.5, dimethyl silicone oil 4, nano-silicon nitride 12, fumed silica 25, calcined clay 10, glass fiber 4, corundum powder 8, Epoxidized soybean oil 7, dicumyl peroxide 0.4, triallyl cyanurate 1.5, bisphenol AF2, tetraisooctyl pyromellitic acid 10, diphenyloctyl phosphate 10, zinc borate hydrate 10, Magnesium hydroxide 12, sodium molybdate 8, ferrocene 5, trinonylphenyl phosphite 8, composite filler 4;

[0013] The preparation method of the composite filler is as follows: a. Weigh kaolin, diatomaceous earth, and dolomite in a weight ratio of 7:5:3, pulverize them, mix them uniformly, and then wet ball mill them for 20 hours, then dry them at 115° C., and then dry them at 570° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com