Method for preparing fire resisting glass and special equipment

A manufacturing method and fire-resistant glass technology, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of shortened service life of rollers, long processing time, high energy consumption, etc., and achieve stable fire resistance performance and flexible processing specifications , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

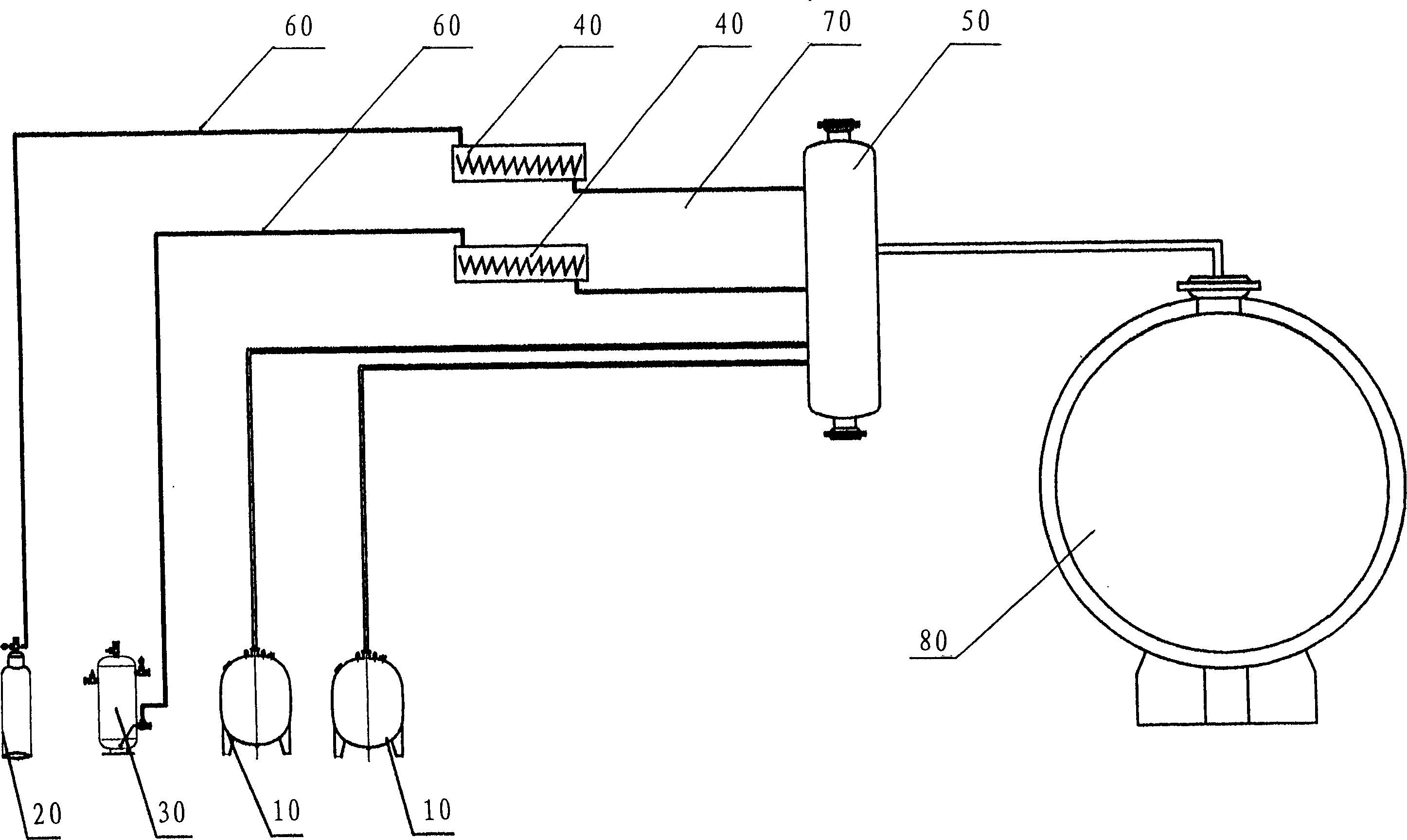

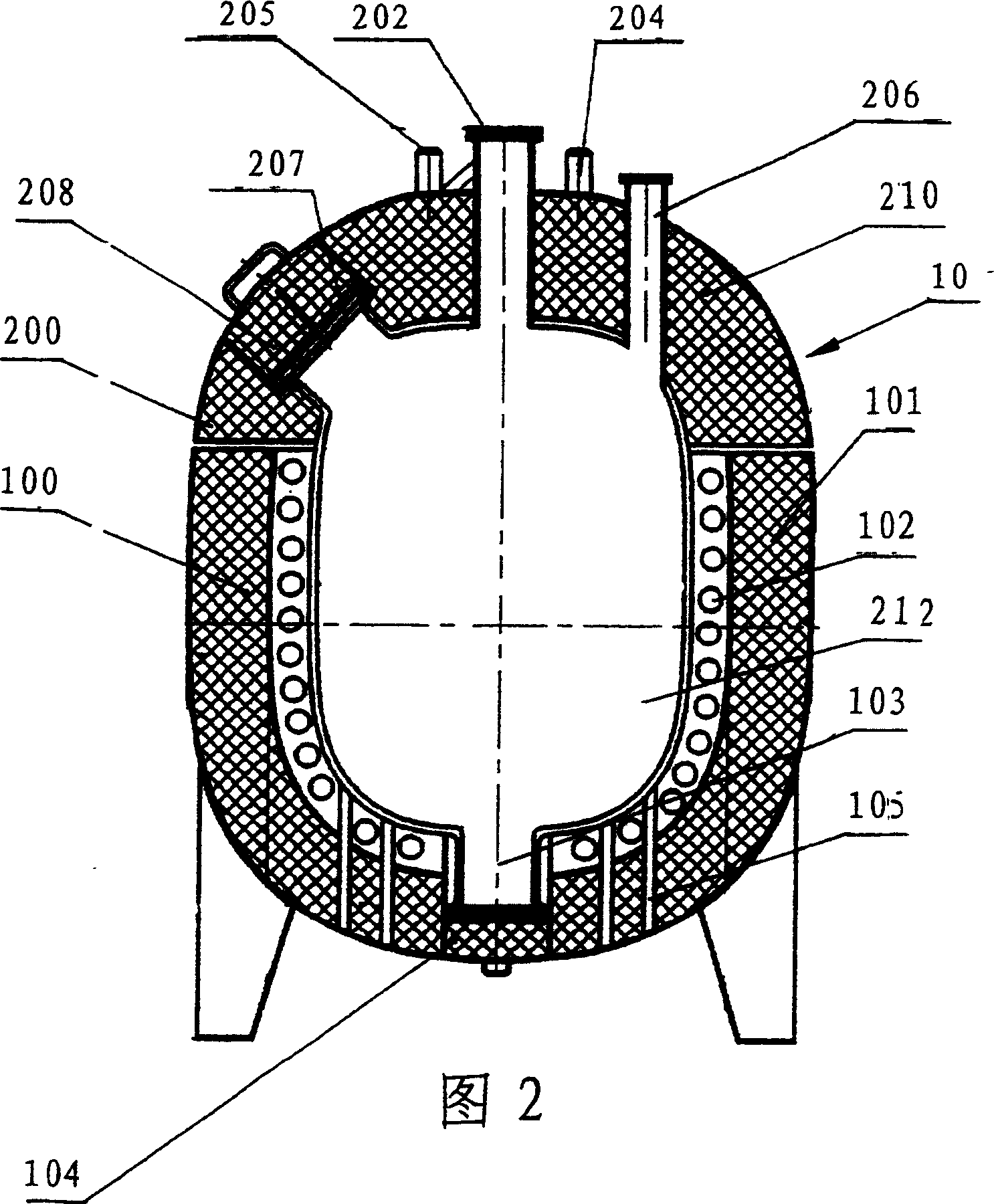

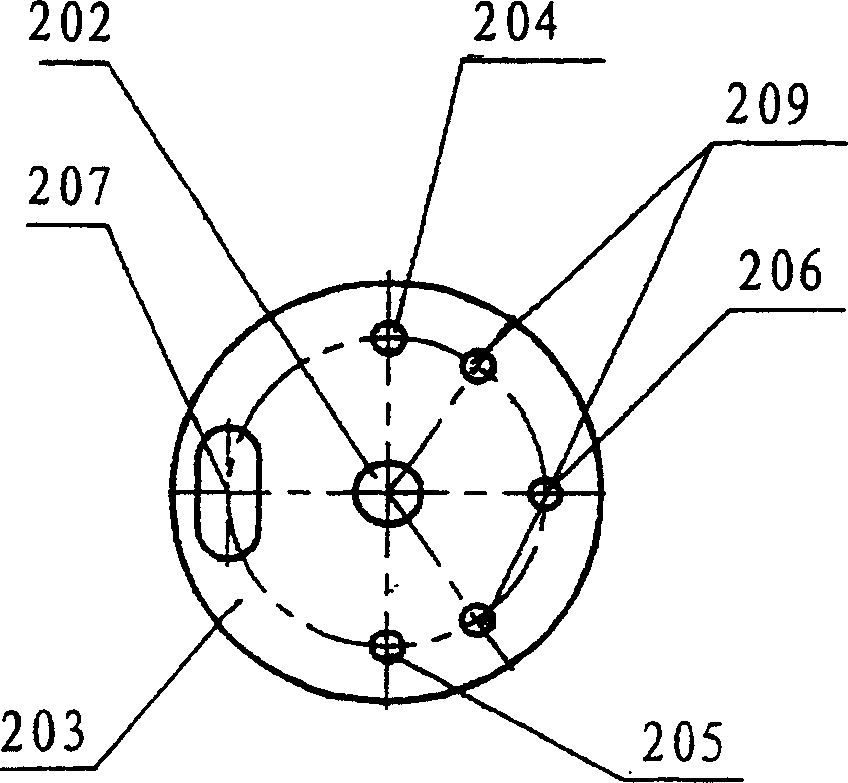

[0031] Cut and finely grind the specially selected 12mm white glass substrate; 3 (95.25%) KOH (0.7%), K 2 CO 3 (2%), AgNO 3 (2%), La 2 o 3 (0.05%) Potassium salt solution gasification (80%) and argon (10%), cupric chloride gas (6%), nitrogen (4%) high-pressure import special-purpose pyrolysis gasification equipment 10 in advance The cold-processed glass substrate is subjected to gas-phase heat treatment, and the temperature of the special thermal decomposition and gasification equipment 10 is controlled at 550°C, and the temperature is kept for three hours. After the temperature is cooled and lowered below 70°C, the glass is taken out, and the surface is coated with a fireproof protective film by CVD. treatment, and finally high-pressure quenching physical tempering.

Embodiment 2

[0033] Cut and finely grind the specially selected 8mm green glass substrate; 3 (77.25%)K 2 CO 3 (2.5%), KBF 4 (20%), Al 2 o 3 (0.25%) Potassium salt solution gasification (75%) and argon (9%), cupric chloride gas (10%), nitrogen (6%) high-pressure import special-purpose pyrolysis gasification equipment 10 in advance The cold-processed glass substrate is subjected to gas-phase heat treatment, and the temperature of the special thermal decomposition gasification equipment 10 is controlled at 480°C, and the temperature is kept for two hours. After the temperature is cooled and lowered below 70°C, the glass is taken out, and the surface is coated with a fireproof protective film layer by CVD. treatment, and finally high-pressure quenching physical tempering.

Embodiment 3

[0035] Cut and finely grind the specially selected 6 mm white glass substrate; 3 (33.5%) KCl (58%), K 2 SO 4(8.5%) potassium salt solution gasification (83%) and argon (8%), cupric chloride gas (7%), nitrogen (2%) high-pressure import special-purpose pyrolysis gasification equipment 10 in advance The cold-processed glass substrate is subjected to chemical vapor phase heat treatment, the temperature of the special thermal decomposition gasification equipment 10 is controlled at 380°C, and the temperature is kept for 36 minutes. After the temperature is cooled and lowered below 70°C, the glass is taken out, and the surface is coated with a fireproof protective film by CVD. Layer treatment, and finally high wind pressure quenching physical tempering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com