A production process of prefabricated GRC formwork structural columns integrating decoration, electromechanical

A production process and decorative structure technology, which is applied in the field of prefabricated GRC formwork structure column production process, can solve the problems of low construction efficiency and high construction cost, and achieve the effects of improving construction efficiency, avoiding decoration entry and reducing comprehensive construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

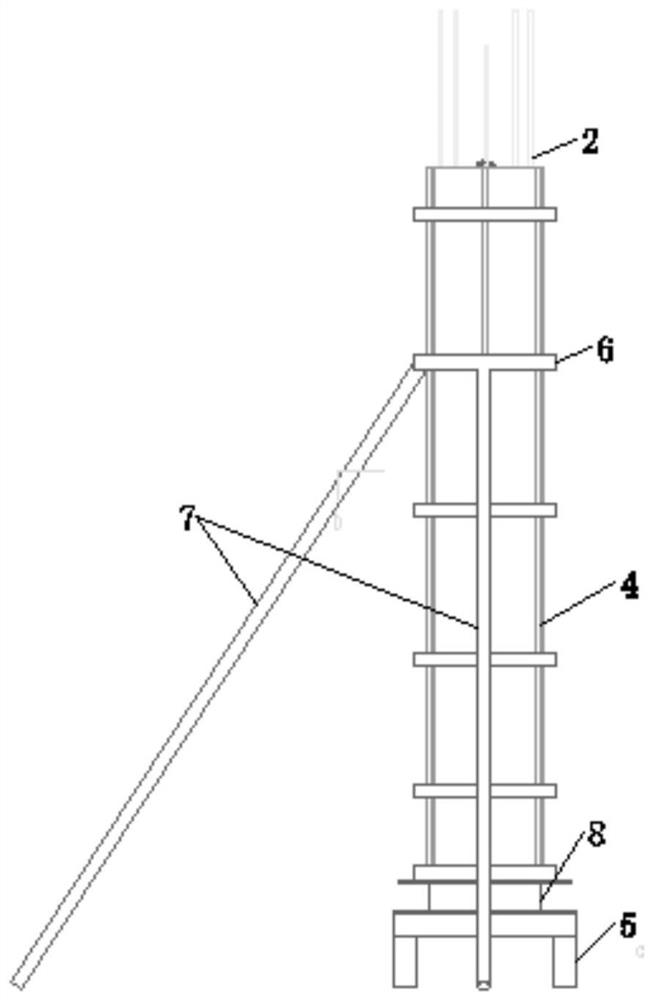

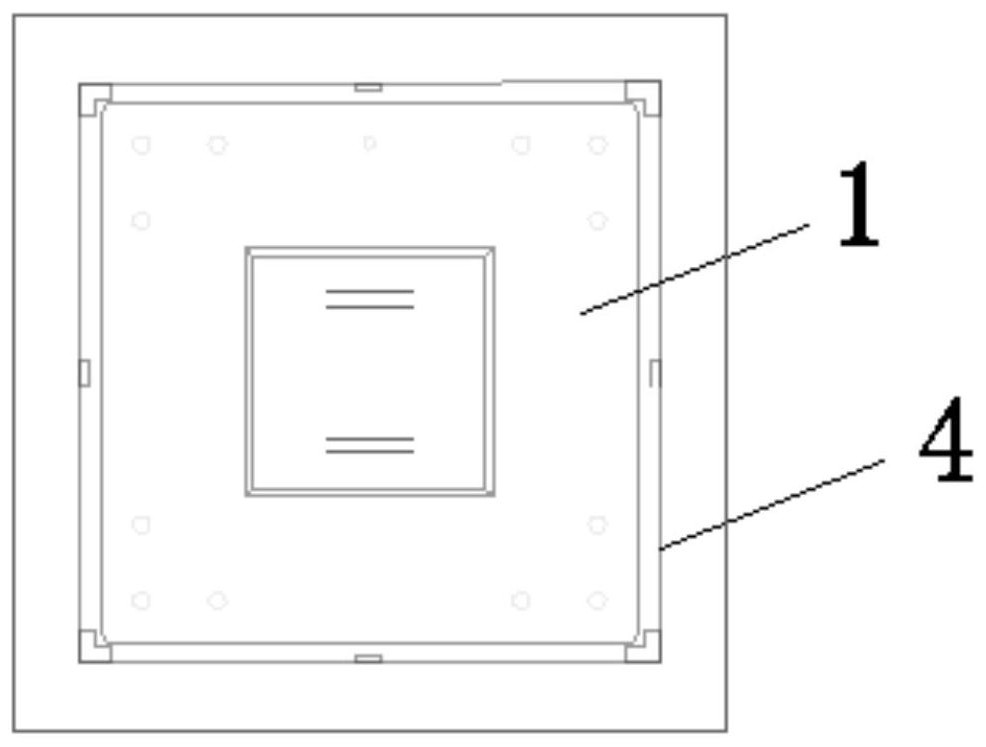

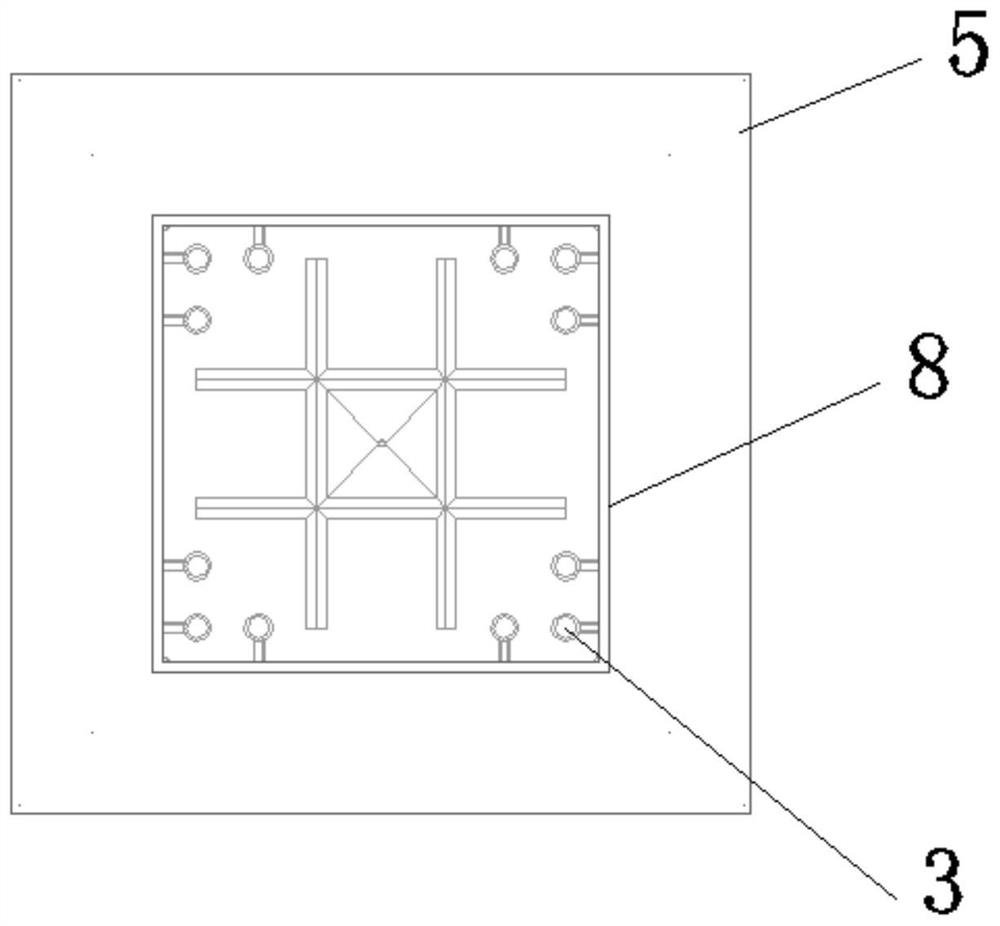

[0027] refer to Figure 1-3 , the invention discloses a production process of a prefabricated GRC formwork structural column integrating decoration, electromechanical, and the specific steps are as follows:

[0028] Step 1. Clean the installation base 5 of the GRC column to ensure that the surface of the installation base 5 is clean and smooth without concrete residue. Apply release oil evenly on the surface of the installation base 5 of the GRC column without oil accumulation, and use the crane to lift the finished steel cage 2 On the GRC column installation base 5 with a size of 1100mm in length * 1100mm in width * 450mm in height, temporarily fix the reserved holes on the GRC column installation base 5 with the grouting sleeve 3 at the bottom of the reinforcement cage 2 through fastening bolts, and the reinforcement cage 2. After the verticality check, thoroughly fix the fastening bolts at the bottom of the installation base 5, install the embedded parts on the reinforcemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com