A fireproof cable and its production process

A fireproof cable and production process technology, applied in the direction of insulated cables, cables/conductors, cables, etc., can solve the problems of limited fireproof performance, fire, affecting the safety of use, etc., to save labor costs, reduce production costs, and stabilize fireproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

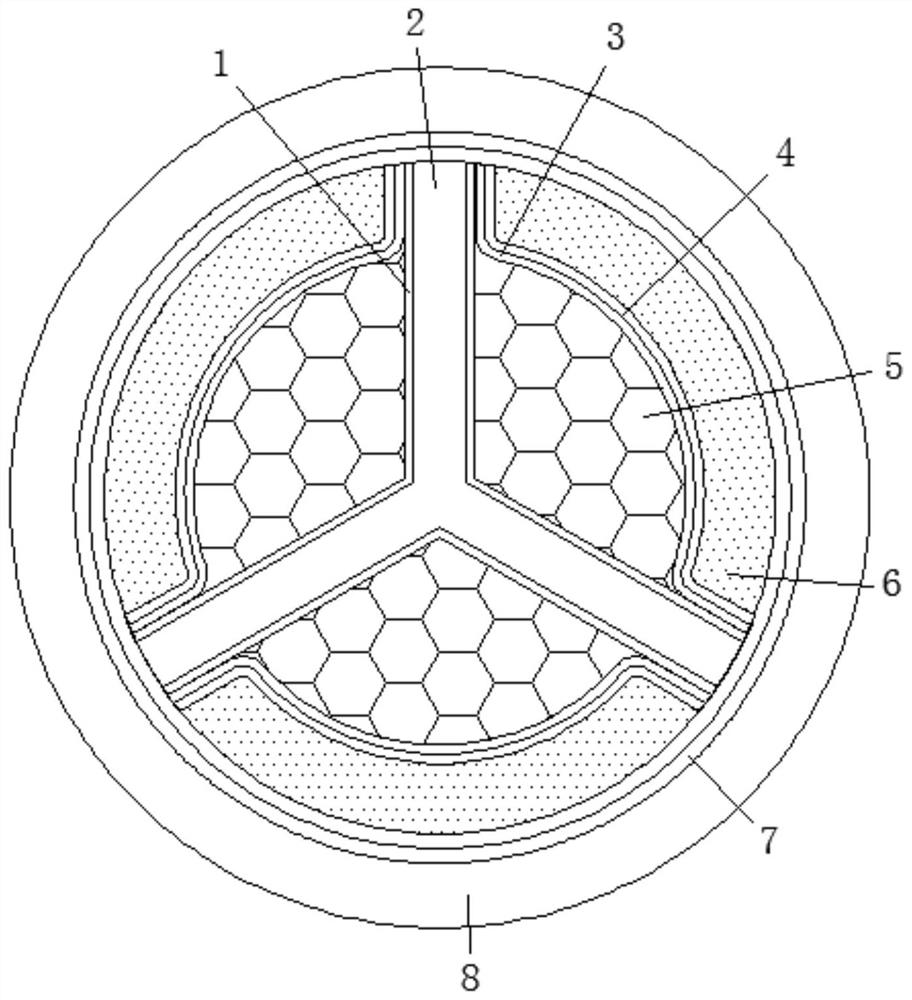

[0033] see figure 1 As shown, it is a structural schematic diagram of a fireproof cable provided in this embodiment, which specifically includes: from inside to outside, it includes a fireproof skeleton 2, an insulating and heat insulating layer 1, a conductive core 5, a shielding layer 3, an insulating coating 4, Refractory filling layer 6, mica tape layer 7 and protective cover 8; wherein:

[0034] The refractory skeleton 2 is provided with at least three clamping grooves in an annular array; the insulating and heat insulating layer 1 is coated on the inner wall of the clamping groove; the conductive core 5 is filled in the clamping groove, and there are multiple conductive cores in each clamping groove 5. The shielding layer 3 is covered on the outside of the conductive core 5 and bonded to the refractory frame 2; the insulating coating 4 is bonded to the outside of the shielding layer 3, and the refractory filling layer 6 is filled in the clamping groove and matched with t...

Embodiment 2

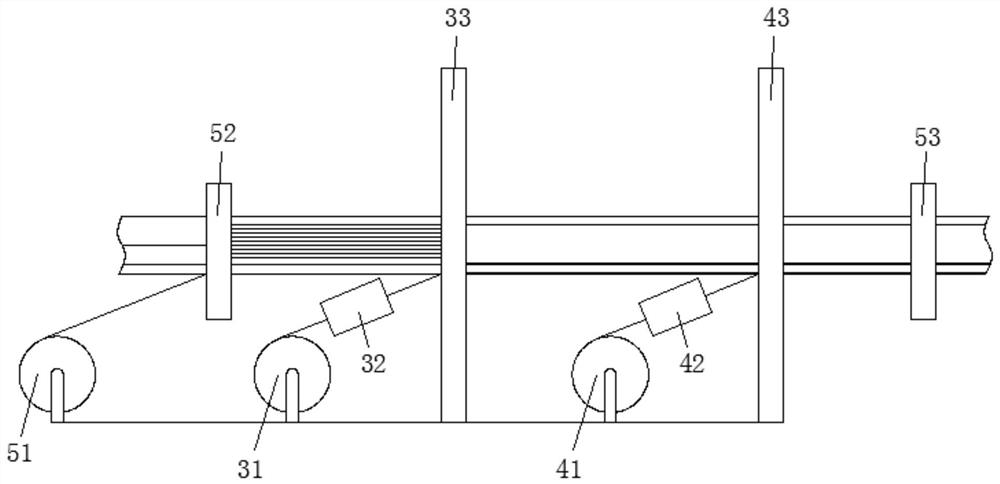

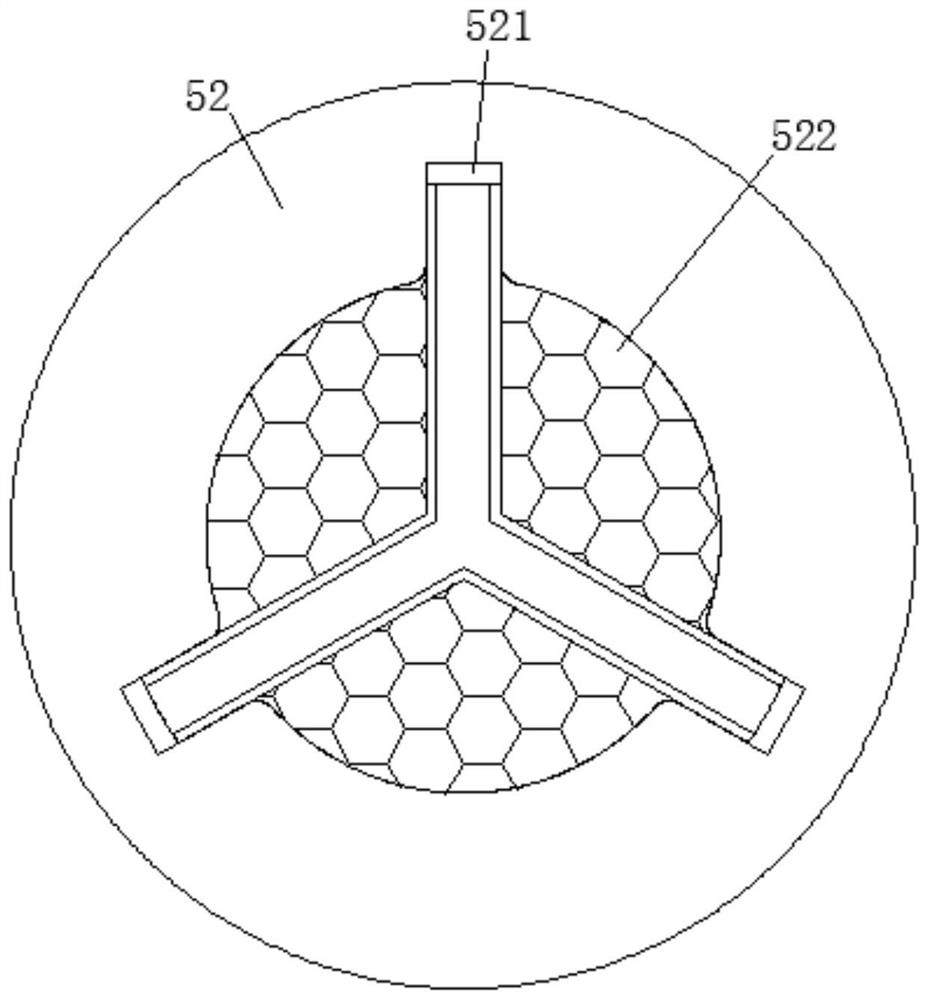

[0040] see Figure 2-7 As shown, it is a structural diagram of equipment used in the production process of a fireproof cable provided in this embodiment, and the final produced fireproof cable is the fireproof cable disclosed in the embodiment, which specifically includes the following production steps:

[0041] S1. Wire-drawing forming of the conductive core 5 (not shown in the figure): wire-drawing the metal blank with a forming die to form the conductive core 5 with a diameter meeting the requirements.

[0042] S2. Composite molding of the conductive core 5 and the refractory skeleton 2: the refractory skeleton 2 is formed based on an extruder (not shown in the figure), and a plurality of conductive cores 5 and the refractory skeleton 2 are introduced into the wire production system to obtain a composite type wire.

[0043]Wherein: the wire production system is provided with a feeding mechanism, an assembling mechanism and a discharging mechanism sequentially along the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com