Wall-laminated self-setting type strong-power cable

A kind of bonding type and form technology, applied in the direction of power cable, insulated cable, cable with shielding layer/conductive layer, etc., can solve the problems of affecting the aesthetics of the wall, the safety cannot be guaranteed, and the damage of the cable, etc., to achieve the laying The method is simple and quick, excellent electrical insulation, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

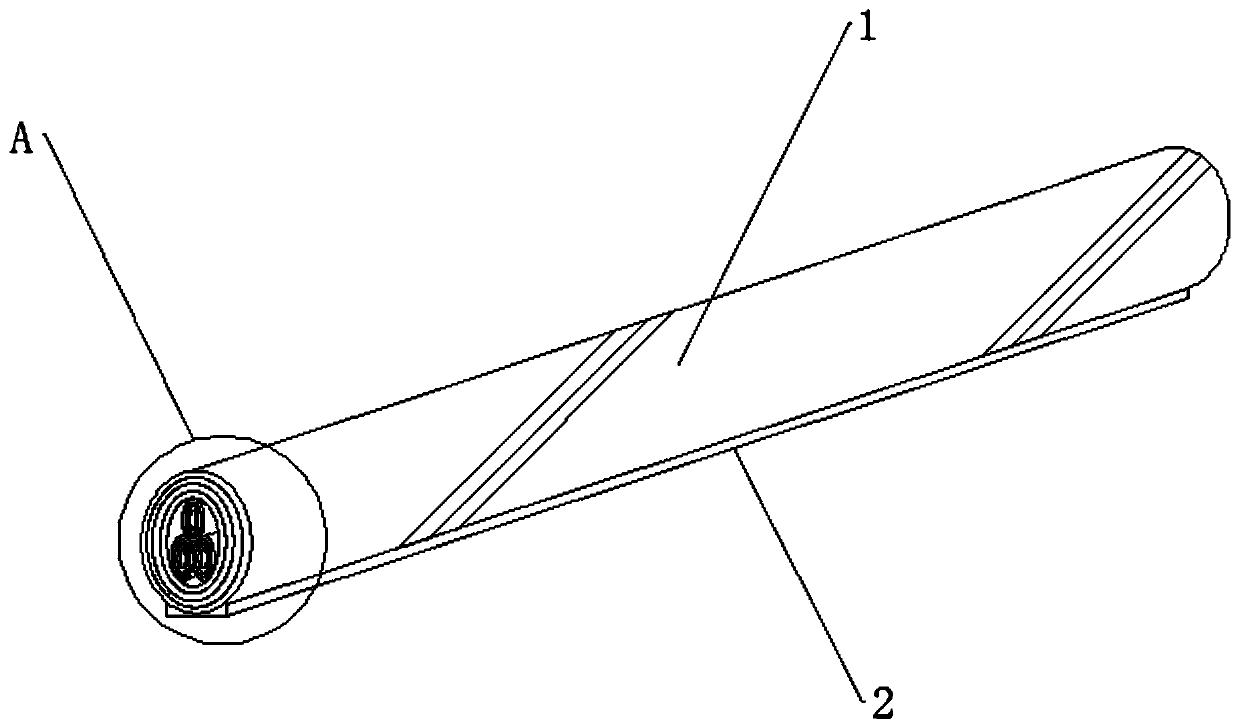

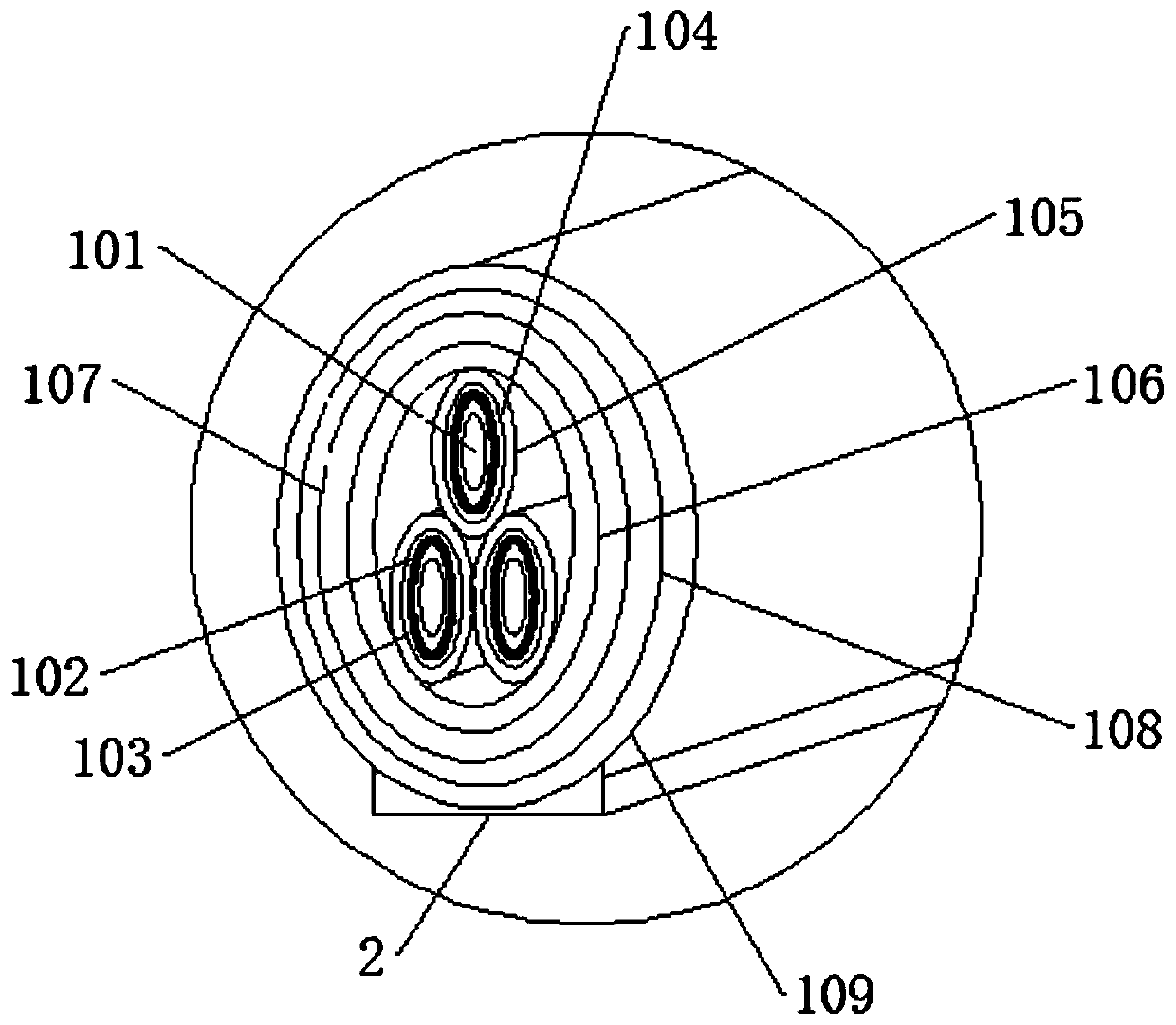

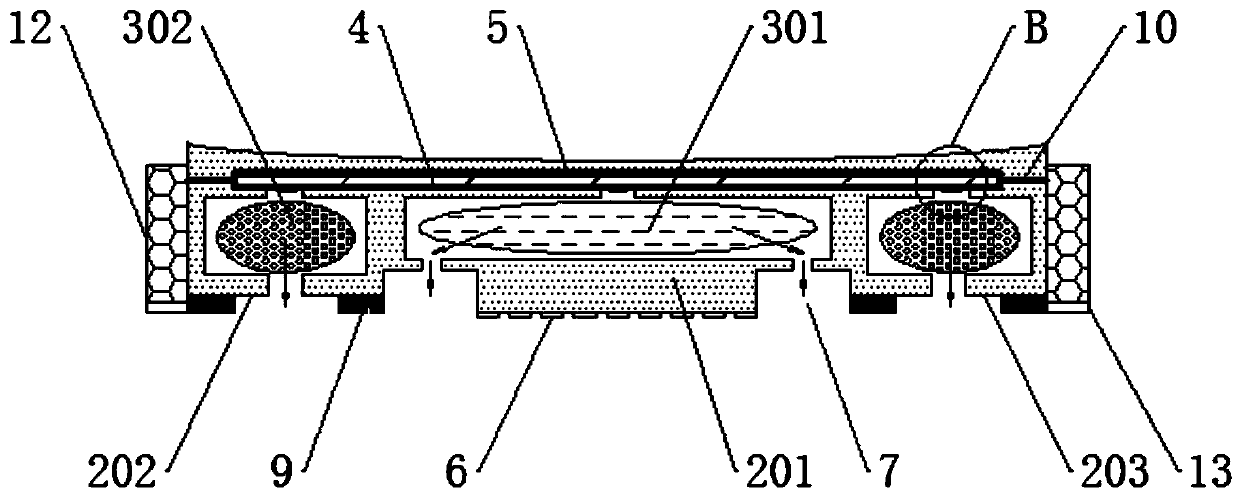

[0049] see Figure 1-2 , a wall-fitting self-defining form strong electric cable, including a cable body 1, the cable body 1 includes three conductors 101 and an outer sheath 109, and the three conductors 101 are evenly distributed inside the outer sheath 109, and the conductor 101 is composed of a plurality of wires Twisted, the outer end of the conductor 101 is connected with a semiconductor shielding layer 102, and a semiconductor shielding layer 102 of a semi-conductive material is added on the surface of the conductor 101, which has the same potential as the shielded conductor 101 and is in good contact with the insulating layer 103, thereby To avoid partial discharge between the conductor 101 and the insulating layer 103, the outer end of the semiconductor shielding layer 102 is connected to the insulating layer 103, the outer end of the insulating layer 103 is connected to the insulating shielding layer 104, and the outer end of the insulating shielding layer 104 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com