EPDM flame-retardant sponge sealing strip for high-speed rail

A technology of sealing strips and sponges, applied in the field of rubber products, can solve the problem that there are not many flame retardant sponge products, and achieve the effects of good material properties, fast vulcanization speed and high flame retardant grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

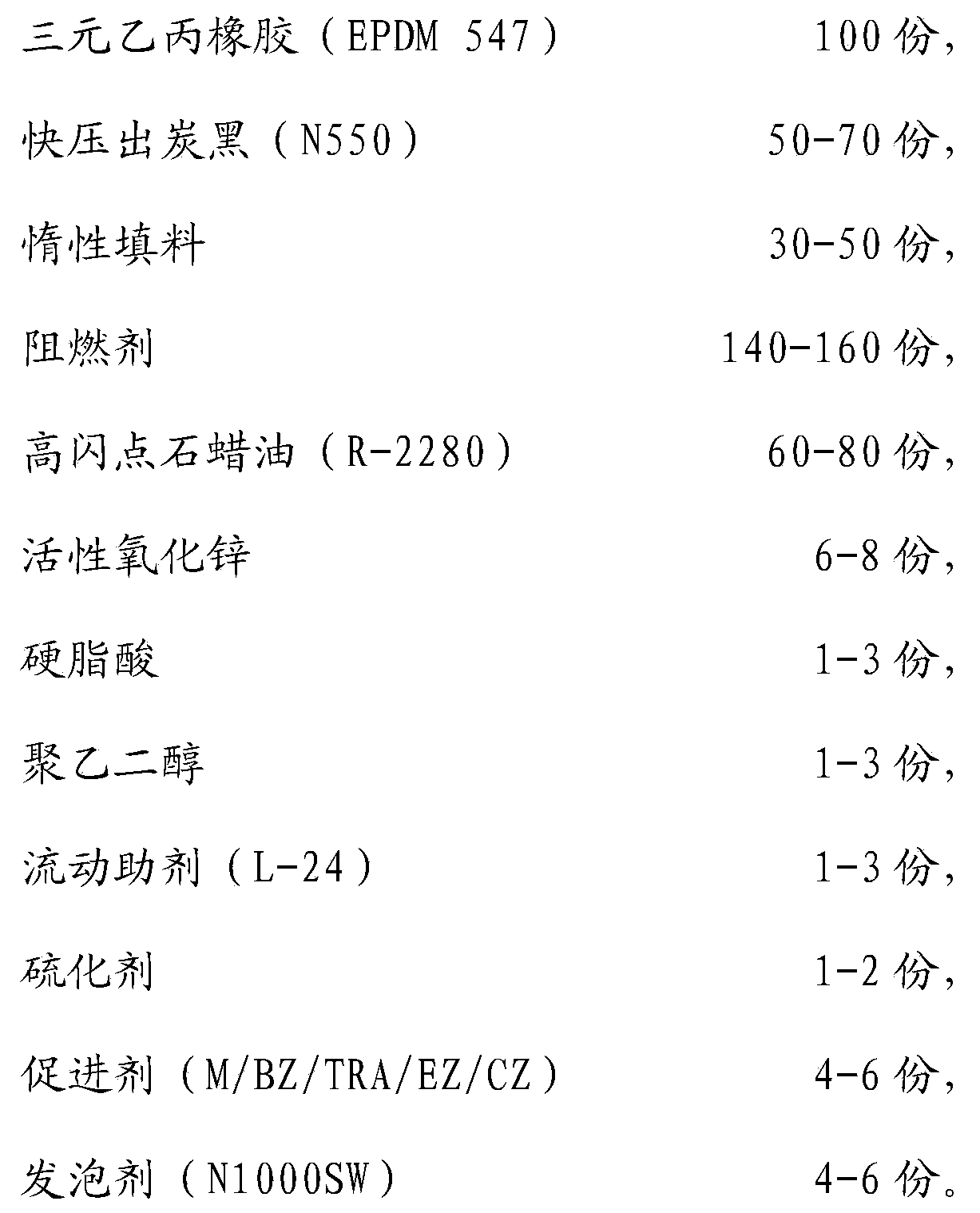

[0017] EPDM flame-retardant sponge sealing strip for high-speed rail, the components and parts by mass are as follows:

[0018]

[0019] After testing, the density and flame retardancy of the EPDM flame retardant sponge sealing strip for high-speed rail prepared in Example 1: the density is 0.65g / cm 3 , 6 seconds away from the fire, it self-extinguished, and a lot of smoke came out.

Embodiment 2

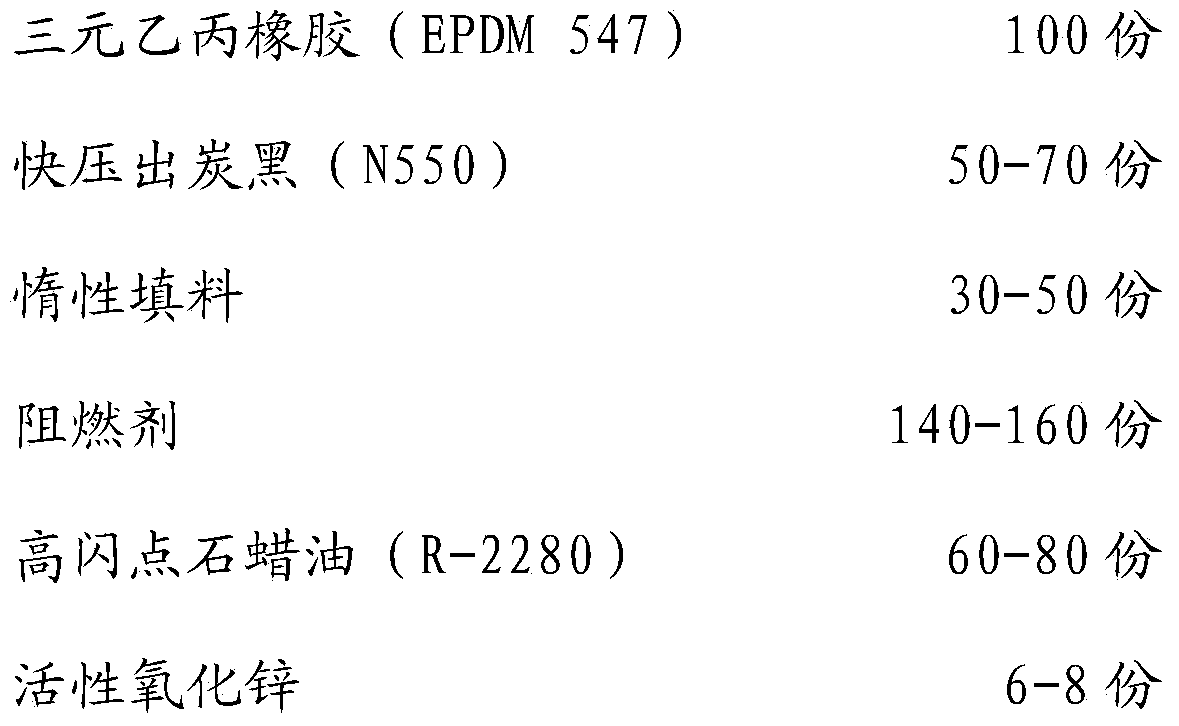

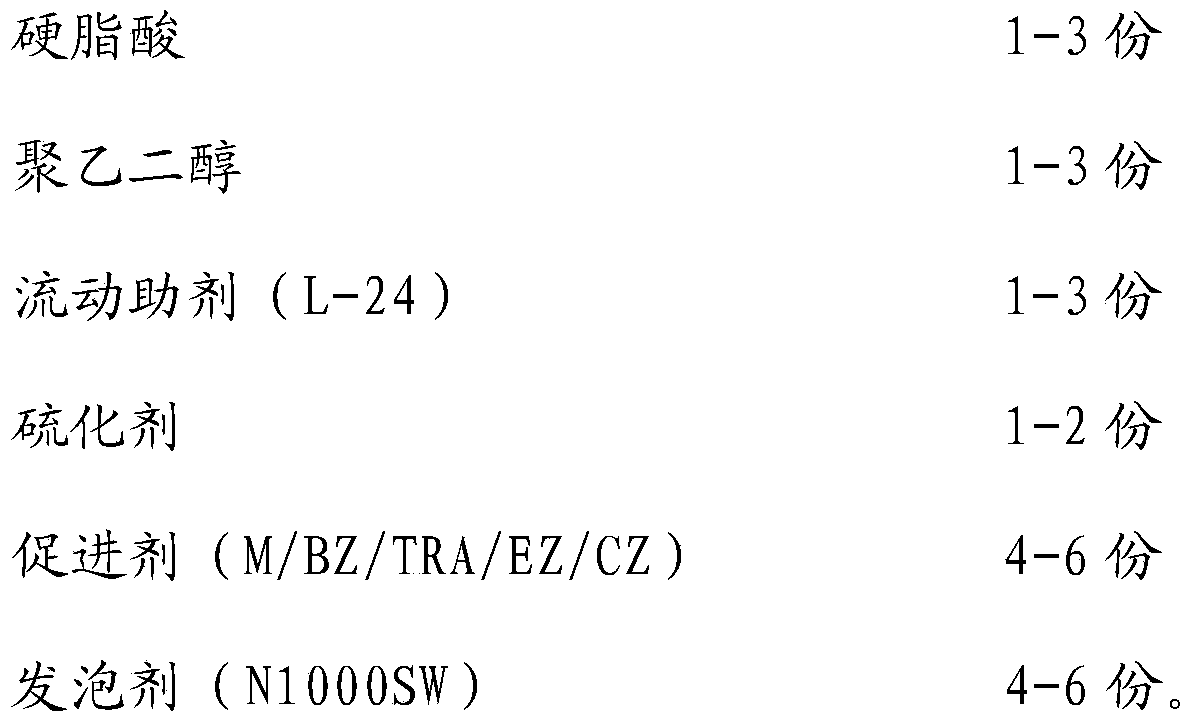

[0021] EPDM flame-retardant sponge sealing strip for high-speed rail, the components and parts by mass are as follows:

[0022]

[0023] After testing, the density and flame retardancy of the EPDM fire-retardant sponge sealing strip for high-speed rail prepared in Example 2: density 0.5g / cm 3 , self-extinguishing away from the fire, with a small amount of smoke coming out.

Embodiment 3

[0025] EPDM flame-retardant sponge sealing strip for high-speed rail, the components and parts by mass are as follows:

[0026]

[0027]

[0028] After testing, the density and flame retardant properties of the EPDM flame retardant sponge sealing strip for high-speed rail prepared in Example 3: density 0.6g / cm 3 , It extinguishes itself after 3 seconds away from the fire, and a small amount of smoke comes out.

[0029] It should be noted that the components in Examples 1-3 are commercially available products, and the sources are as follows:

[0030]

[0031] Antimony trioxide, aluminum hydroxide, and chlorinated paraffin were purchased from Hunan Yiyang, Jinan Taixing, and Anming Hengxin, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com