Preparation method of super-hydrophobic polymeric fiber

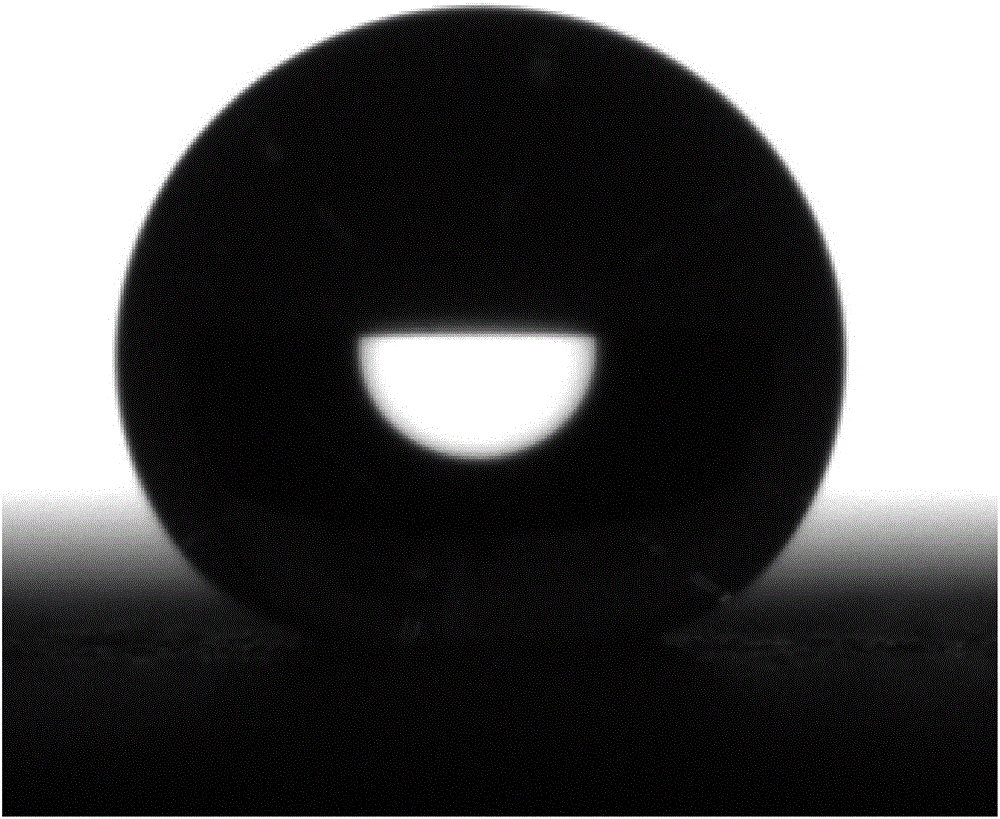

A polymer fiber, super-hydrophobic technology, used in fiber treatment, liquid repellent fibers, textiles and papermaking, etc., can solve the problem of poor hydrophobic effect, incomplete modification of low surface energy functional groups, and complex nanostructure construction process. and other problems, to achieve the effect of excellent affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of superhydrophobic fiber, and the step comprises:

[0026] a) Construction of nano-microstructure: the surface of the polymer fiber is coated with a coating to obtain a surface-functionalized polymer fiber (a polymer fiber with abundant -NH2, -NH, or -OH functional groups on the surface) ; Wherein, the mass ratio of the polymer fiber to the coating is 5:1 to 25:1; the coating is a material rich in functional groups, specifically dopamine, γ-glycidyl etheroxypropyltrimethoxysilane , tetraethoxysilane or aminopropyltrihexoxysilane;

[0027] b) Surface modification: the surface functionalized polymer fibers obtained in step a) are modified with low surface energy materials to obtain superhydrophobic polymer fibers; wherein, the low surface energy materials are alkyl trichlorosilane or hexamethyl base disilazane.

Embodiment 1

[0030] Preparation of polycarbonate beaded fiber: The fiber is prepared by electrospinning. The spinning process conditions are: the concentration of the spinning solution is controlled at 0.12-0.20g / L, the loading voltage is 13-15KV, and the receiving distance is 10-15cm. , the matrix fiber obtained by electrospinning technology is polycarbonate beaded fiber;

[0031] The construction of the nano-microstructure: then the polycarbonate beaded fiber is placed in a Tris-dopamine buffer solution with a pH of 7-10.5 and a dopamine concentration of 0.008-0.01mmol / L (the preparation method of the Tris-dopamine buffer solution is: Add trishydroxymethylaminomethane and dopamine in the volumetric flask and add deionized water to make it up to the scale line to configure dopamine buffer), through the self-polymerization of dopamine, coat the PDA layer on the surface of the fiber, take out the fiber for 18h and use deionized water water to clean, in this process, constantly feed air into...

Embodiment 2

[0035] Preparation of polyethersulfone beaded fiber: the fiber is prepared by electrospinning, and the spinning process conditions are: the concentration of the spinning solution is controlled at 0.21-0.24g / L, the loading voltage is 13-15KV, and the acceptance distance is 10-15cm. , the matrix fiber obtained by electrospinning technology is polyethersulfone beaded fiber;

[0036] Construction of nano-microstructure: then the polyethersulfone beaded fiber is placed at a pH of 7-10.5 and a dopamine concentration of

[0037] In the 0.02-0.04mmol / L Tris-dopamine buffer, the PDA layer was coated on the surface of the fiber through the self-polymerization of dopamine, and the fiber was taken out for 20 hours and washed with deionized water. During this process, the buffer was continuously injected Air (control the gas flow rate at 140-180ml / min);

[0038] Surface modification: Finally, the polyethersulfone fiber coated with polydopamine was placed in a hexamethyldisilazane-n-hexane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com