High-energy gas

A high-energy gas and gas technology, applied in cells, electrolysis process, electrolysis components, etc., can solve the problems of high cost, non-interchangeable connection of power sources, and potential safety hazards, and achieve the effect of simple equipment, non-toxic and no hidden dangers of detonation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

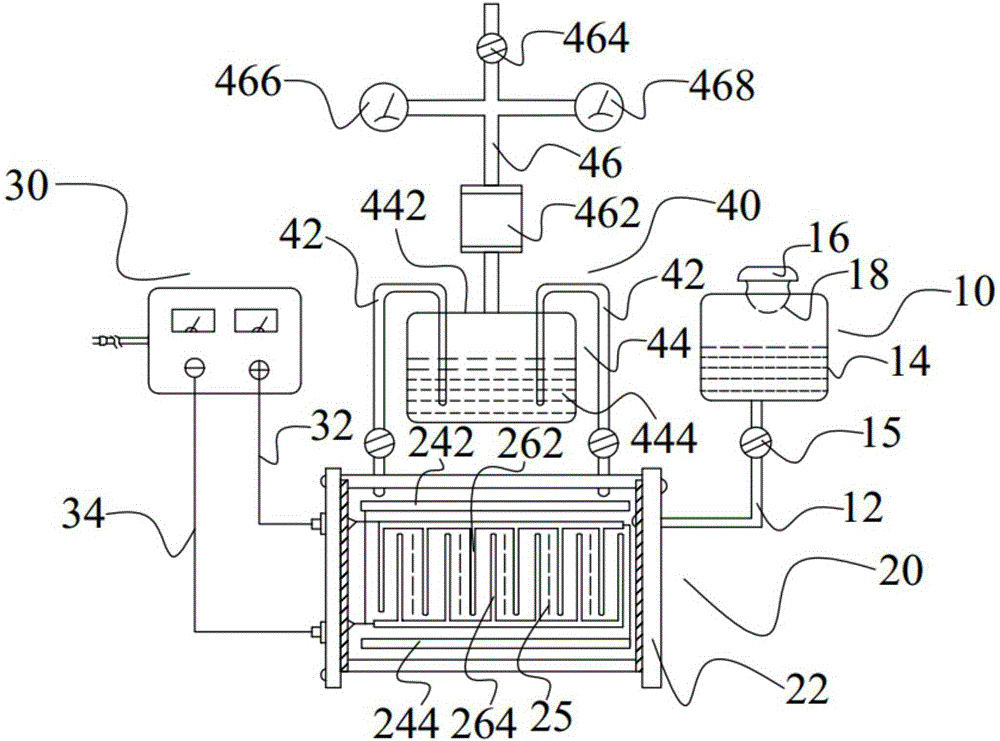

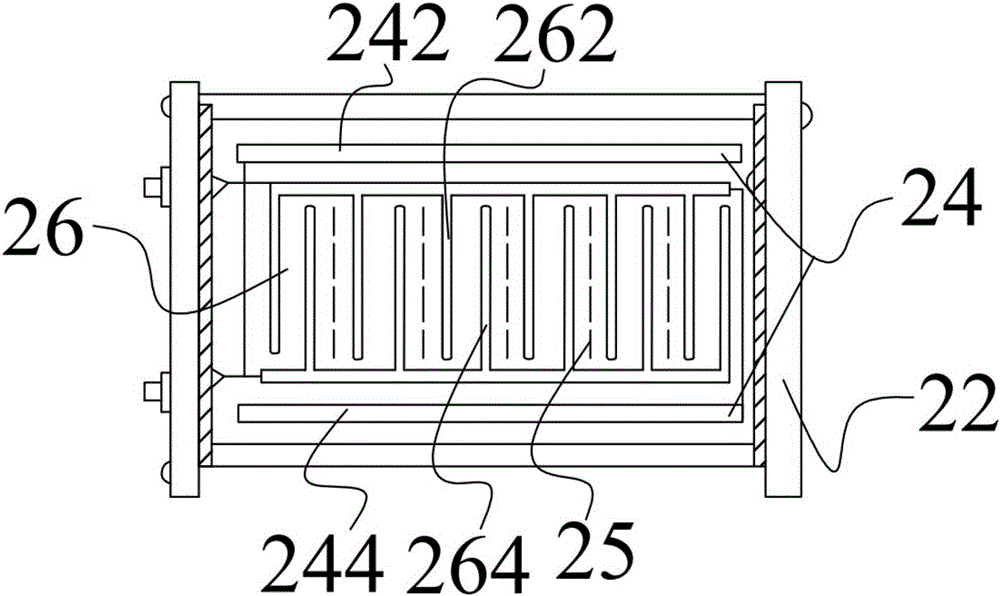

[0046] An embodiment of the high-energy gas of the present invention, the high-energy gas described in this embodiment is prepared by the following method:

[0047] (1) inject water into the water tank of the high-energy gas generating device, then open the water switch on the water inlet pipe, so that the water in the water tank flows into the reaction tank through the water inlet pipe;

[0048] (2) Turn on the switch of the power controller to provide electric energy to the electrode plate group A and the electrode plate group B in the reaction tank. By controlling the voltage of the power supply between 60V-100V, the current changes with the output power, so that Under the joint action of electrode plate group A and electrode plate group B, the water in the reaction tank is decomposed by electricity to generate a mixed gaseous substance in which the particle state of hydrogen and oxygen elements are relatively balanced and stable coexistence, that is, high-energy gas;

[00...

Embodiment 2

[0062] Performance test of the high-energy gas of the present invention

[0063] Through actual measurement of performance indicators such as calorific value, ignition point, burning speed, and explosion limit of the high-energy gas of the present invention prepared in Example 1, the test results are as follows:

[0064] The calorific value is 142.9kj / g;

[0065] The highest laminar burning velocity is 280cm / s;

[0066] The lowest explosion limit is 6.5Vol%;

[0067] The highest explosion limit is 0Vol%;

[0068] The ignition point is 400°C;

[0069] The combustion temperature varies with the substance being heated and can be higher than 5000°C.

[0070] It is also found that the high-energy gas of the present invention reaches 6.5 Vol%, and has the phenomenon of delayed ignition.

[0071] It is also found that the combustion temperature of the high-energy gas of the present invention can be changed: the combustion temperature of the general combustible gas including hydr...

Embodiment 3

[0074] Calorific value input and output test of high-energy gas of the present invention

[0075] A 600W high-energy gas generating device with a structure as described in Example 1 was used for the test, and the measured results were as follows:

[0076] Input 600Wh power consumption (60V / 10A)

[0077] Output 200L / h high energy gas

[0078] 1L of water can decompose 1866L of gas, weighing 1000g, 1L of high-energy gas = 1000g / 1886L = 0.53g

[0079] Therefore, the weight of the output high-energy gas is 200×0.53g=106g.

[0080] The calorific value of 1g of high-energy gas is 142.9Kj

[0081] The calorific value of 106g high-energy gas is 106×142.9=151470Kj (1j=1Ws)

[0082] 15147Kj=15147000Ws / 3600s=4200Wh

[0083] The output / input calorific value power ratio is: 4200Wh / 600Wh=7

[0084] That is, the output calorific value power is 7 times that of the input.

[0085] It is further confirmed by the results of Example 3 that the high-energy gas of the present invention has h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Ignite | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com