A kind of paste without self-breeding high heat automatic welding carbon steel type metal and its preparation method and use method

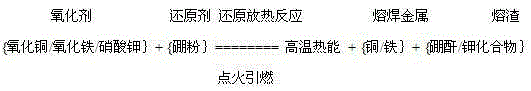

An automatic welding and welding paste technology, which is applied in aluminothermic welding equipment, welding equipment, welding equipment, etc., to achieve the effects of good welding slag discharge performance, stable burning speed and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

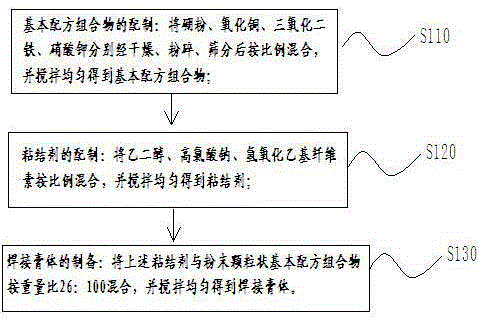

[0033] see figure 1 , a kind of preparation method of the paste that does not originate in high-heat automatic welding carbon steel type metal, comprises the following steps:

[0034] S110, 1) Preparation of the basic formula composition: Boron powder, copper oxide, ferric oxide, and potassium nitrate are respectively dried, pulverized, sieved and mixed in proportion, and stirred evenly to obtain the basic formula composition; preferably, the The specific operation of the drying process is to dry each component of the basic formula composition at a temperature of 100-110 ° C for no less than 1 hour;

[0035] S120, 2) Preparation of binder: mix ethylene glycol, sodium perchlorate, and ethyl cellulose hydroxide in proportion, and stir evenly to obtain binder;

[0036] S130, 3) Preparation of soldering paste: mix the above-mentioned binder with the basic formula composition in powder and granular form at a weight ratio of 26:100, and stir evenly to obtain a soldering paste. The...

Embodiment 1

[0041] A paste for high-heat automatic welding of carbon steel metals without self-proliferation, which includes a basic formula composition and a binder, and the weight ratio of the binder to the basic formula composition is 26:100, and the basic formula The components of the composition include boron powder, copper oxide, ferric oxide, and potassium nitrate, and the weight percentages of the above components are respectively: 8.2% of boron powder, 86.0% of copper oxide, 2.9% of ferric oxide, and 2.9% of potassium nitrate %. The components of the binder include ethylene glycol, sodium perchlorate, and ethyl cellulose hydroxide, and the weight percentages of the above components are respectively: ethylene glycol 54.0%, sodium perchlorate 45.1%, hydroxide Ethylcellulose 0.9%.

[0042] see figure 1 , the preparation method of the paste of the above-mentioned non-derived high-heat automatic welding carbon steel metal, which comprises the following steps:

[0043] 1) Preparatio...

Embodiment 2

[0047] A paste for self-propagating high-heat automatic welding of carbon steel metals without self-proliferation, which includes a basic formula composition and a binder, and the weight ratio of the binder to the basic formula composition is 26:100; the basic formula The components of the composition include boron powder, copper oxide, ferric oxide, and potassium nitrate, and the weight percentages of the above components are respectively: 8.2% of boron powder, 86.3% of copper oxide, 2.7% of ferric oxide, and 2.8% of potassium nitrate %; The components of the binder include ethylene glycol, sodium perchlorate, ethyl cellulose hydroxide, and the weight percentages of the above components are respectively: ethylene glycol 53.8%, sodium perchlorate 45.2%, Ethylcellulose Hydroxide 1.0%.

[0048] see figure 1 , the preparation method of the paste of the above-mentioned non-derived high-heat automatic welding carbon steel metal, which comprises the following steps:

[0049] 1) Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com