Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Increase combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

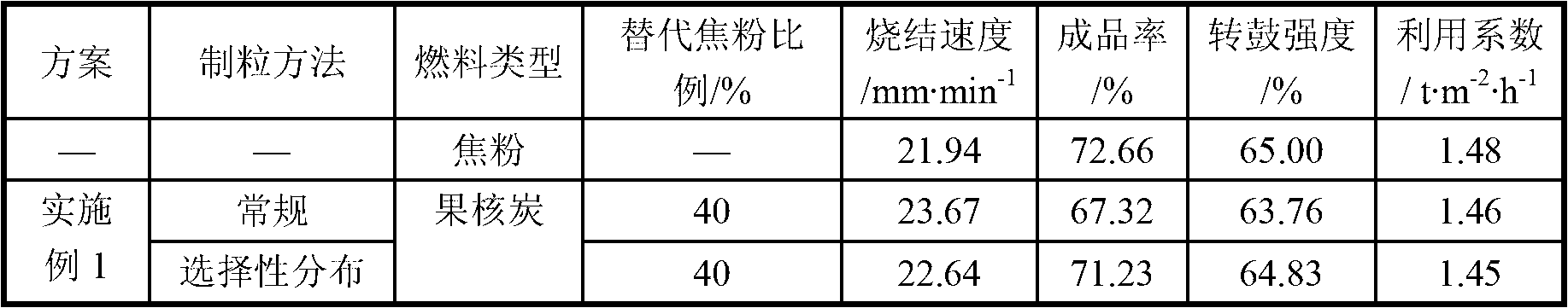

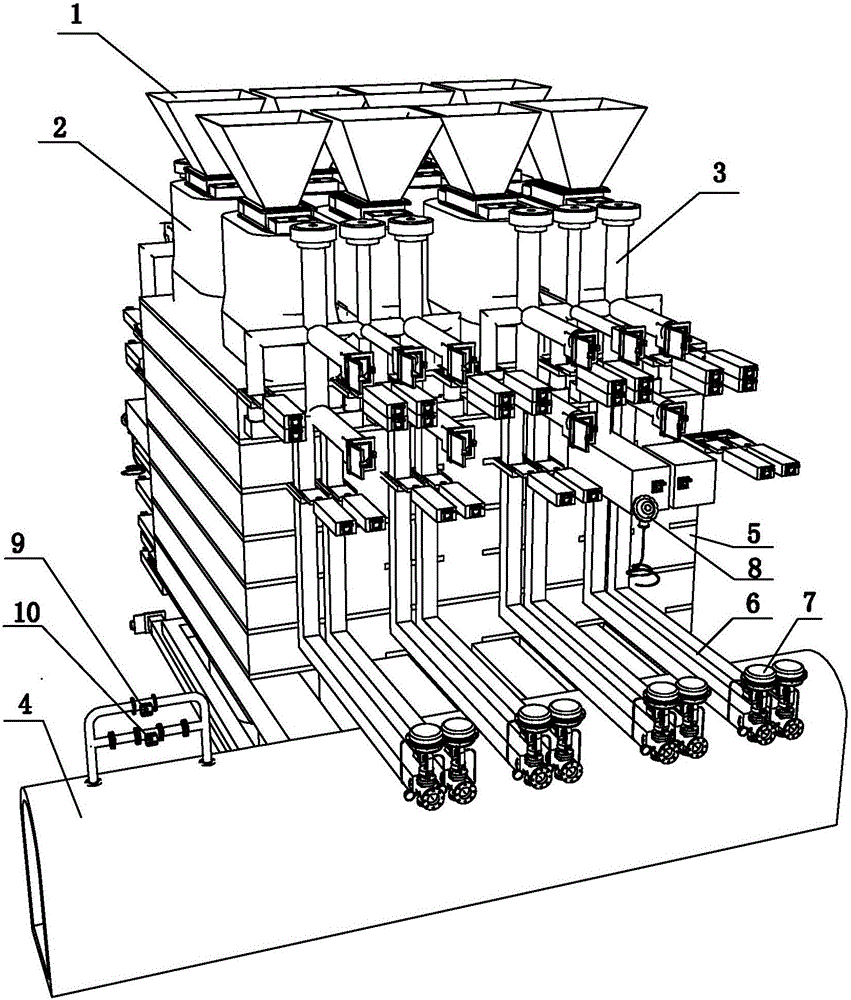

Selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy

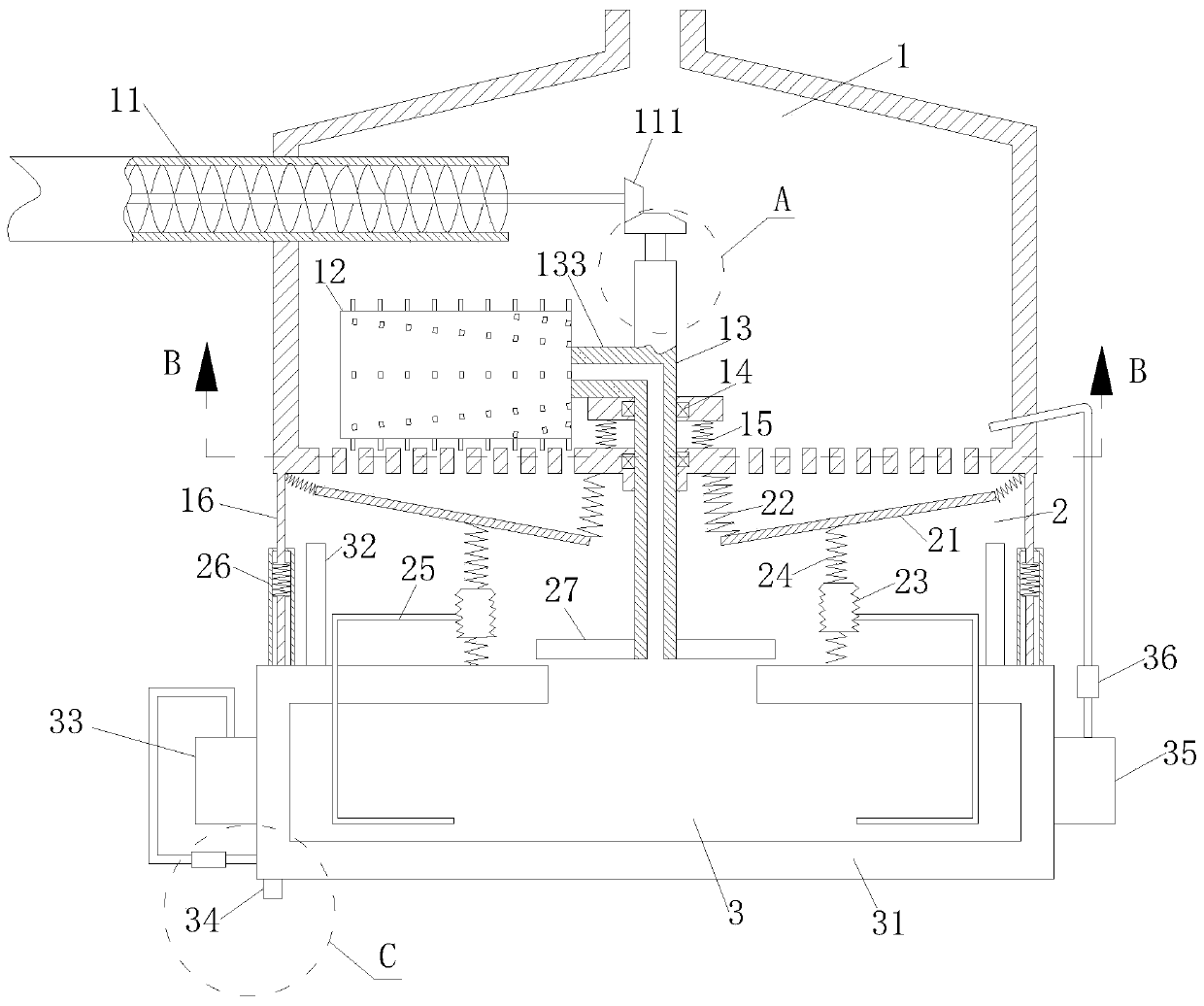

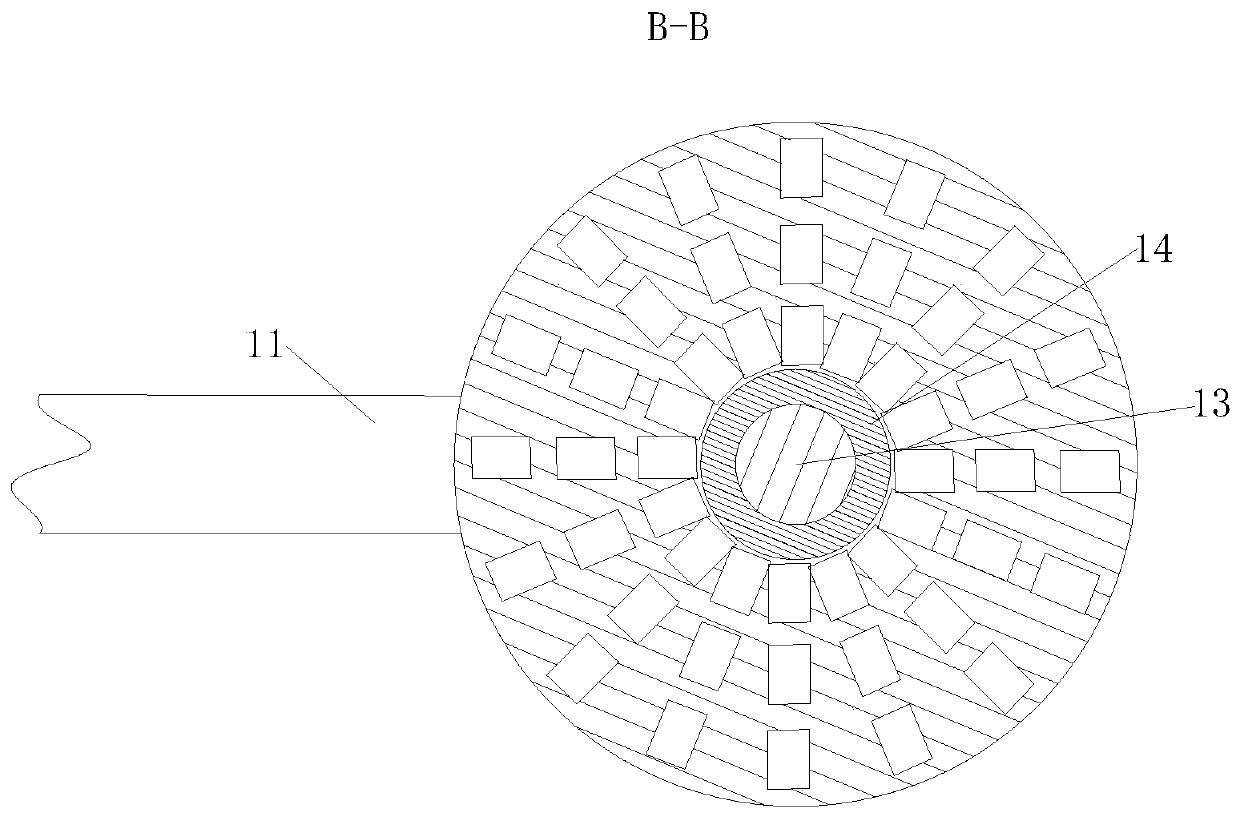

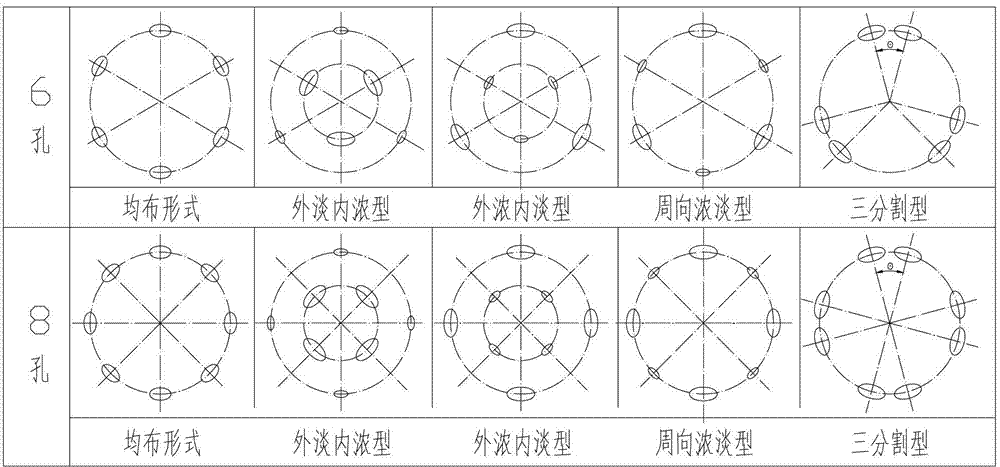

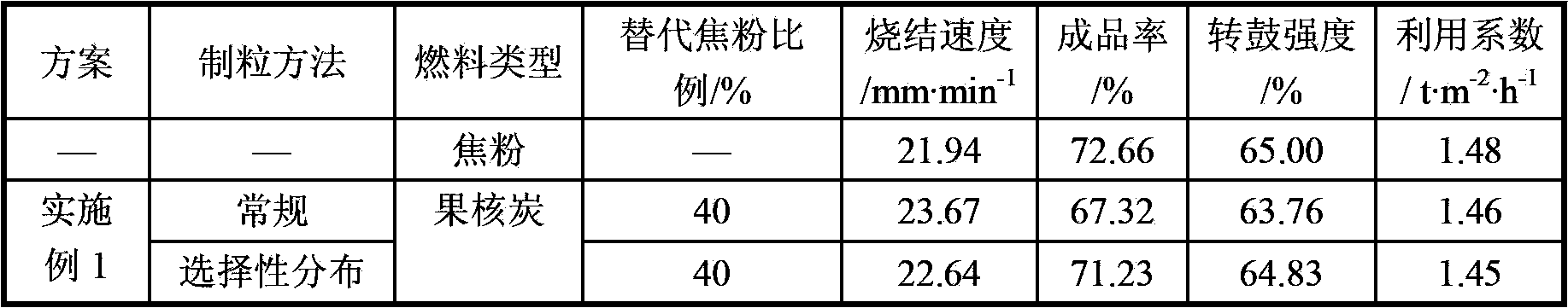

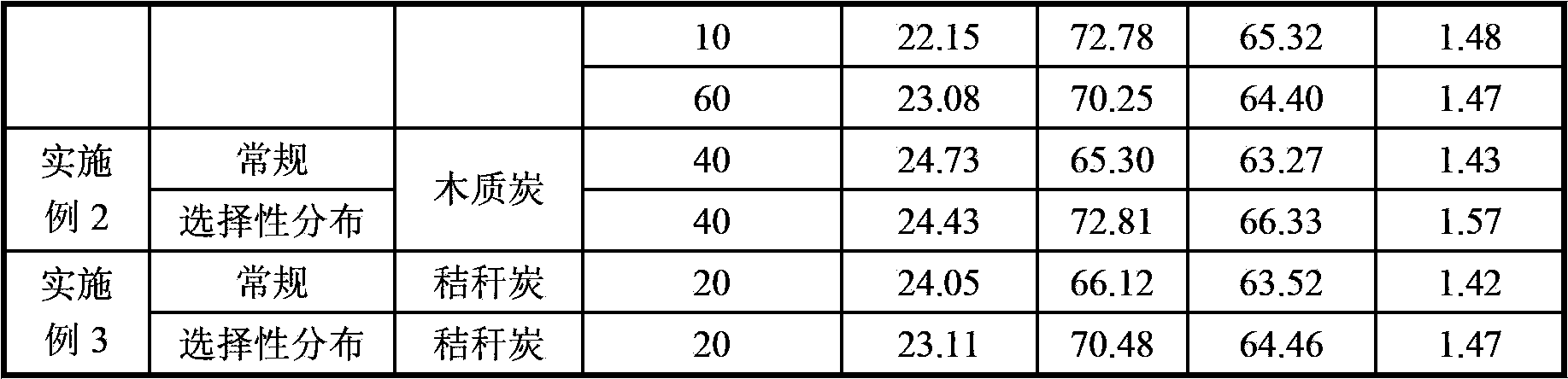

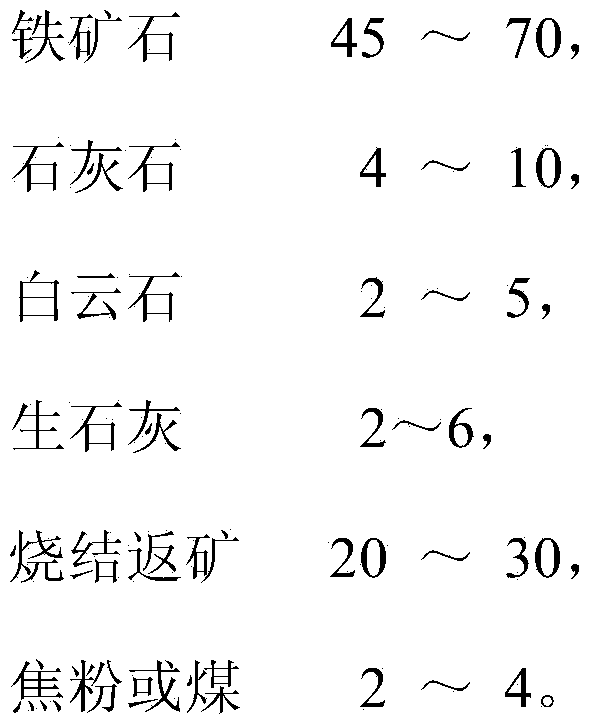

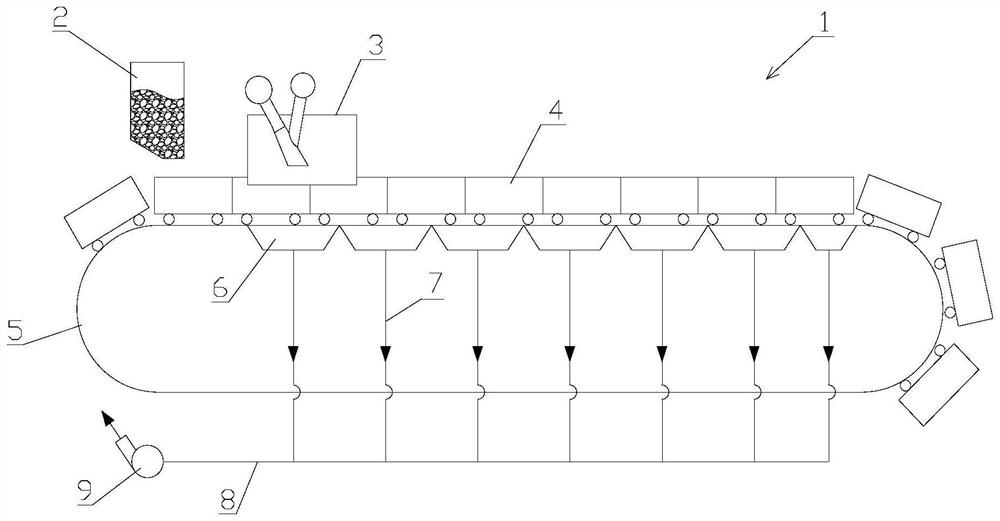

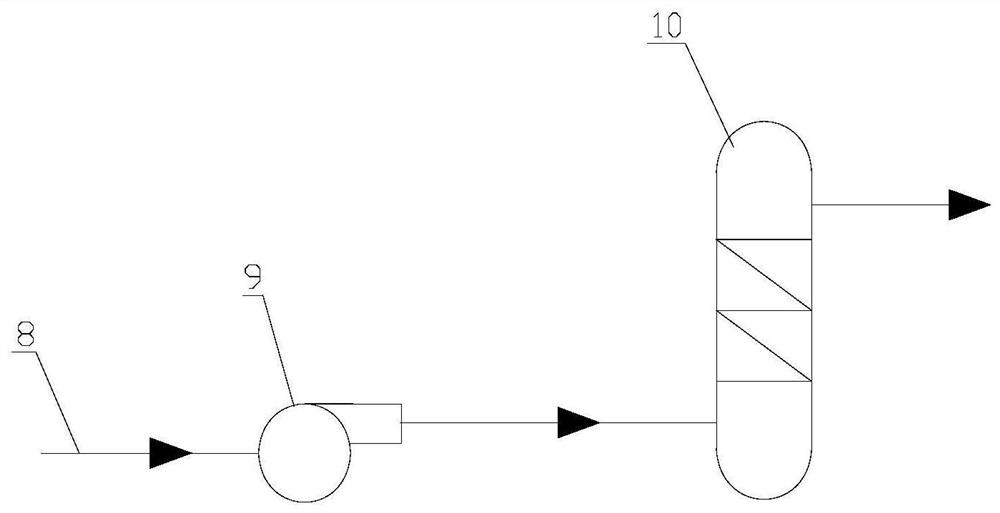

A selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy distributes biomass fuel at the core part of a mixture before sintering by two-stage granulation to properly reduce the burning rate of the biomass fuel and improve the burning degree of the biomass fuel, so as to achieve the purpose of enhancing biomass energy sintering, wherein the two-stage granulation comprises the steps of: firstly preparing biomass fuel, iron ore and quicklime in a granulating disc into mother nuclide with the granularity of 3-5mm, then mixing with iron ore, limestone, dolomite, quicklime, sinter returns and coke powder (or coal), and carrying out second granulation for 3-6min in a granulating drum, so as to obtain the mixture before sintering with the biomass fuel wrapped at the core part. By selective distribution technology of the biomass fuel, the biomass fuel can be applied to iron ore sintering so as to successfully substitute for 10-60% of coke powder and not to influence the yield and quality indexes of the sintered ore.

Owner:CENT SOUTH UNIV

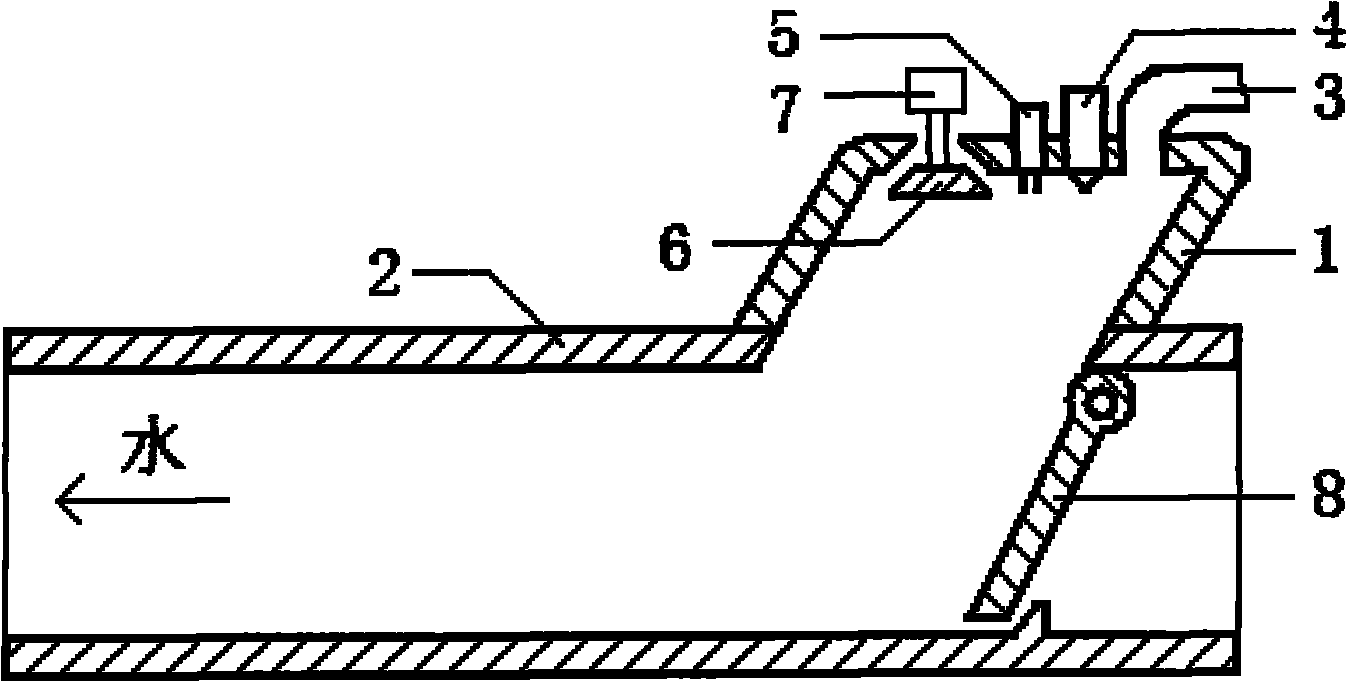

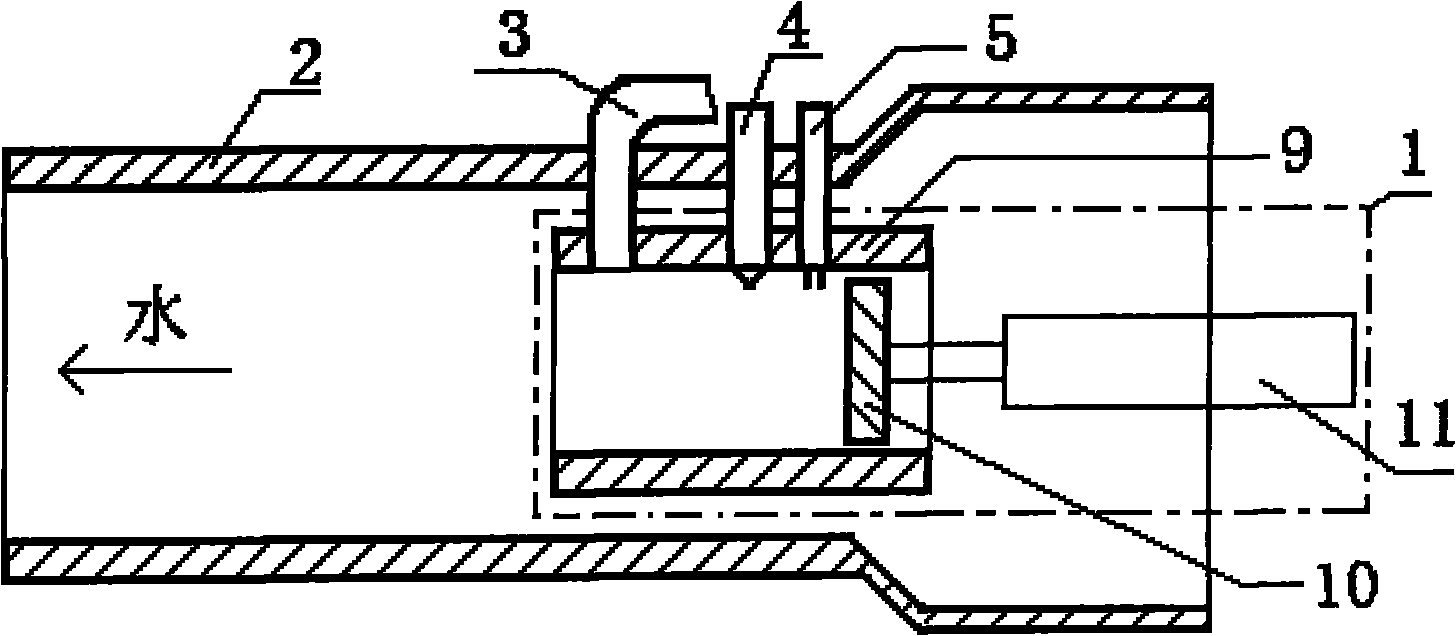

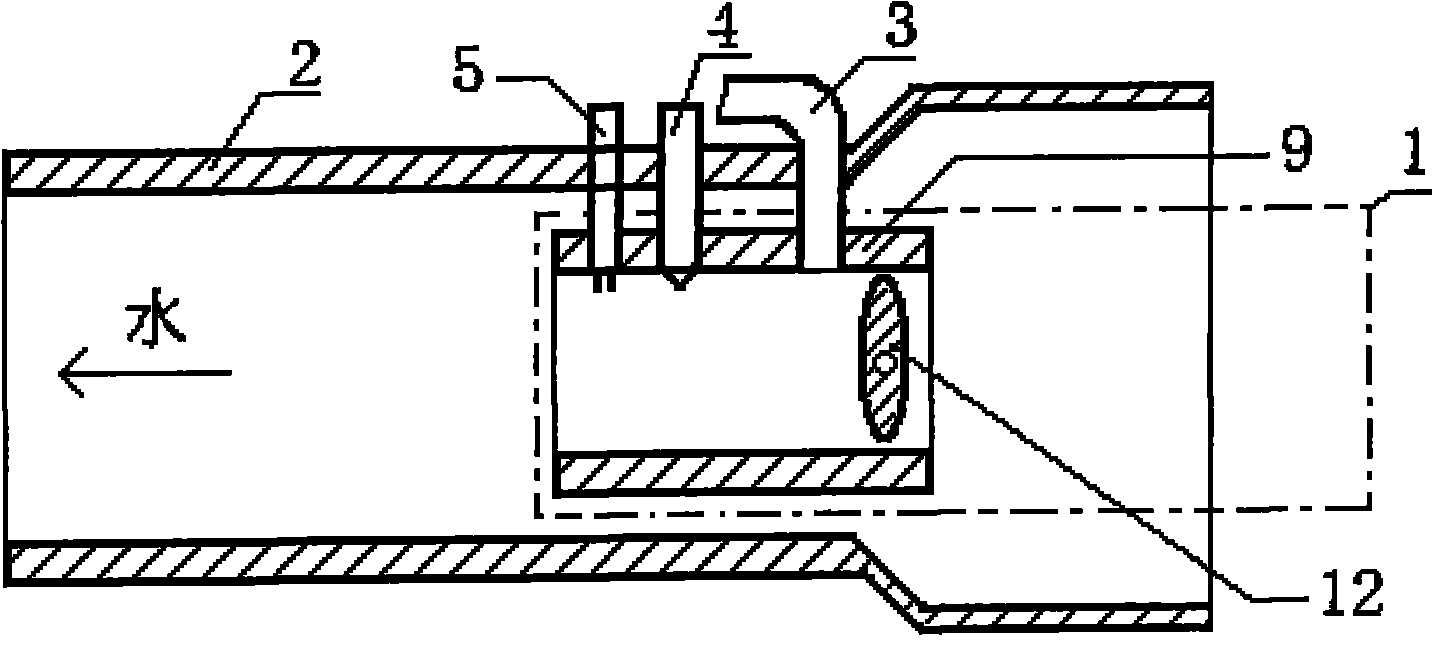

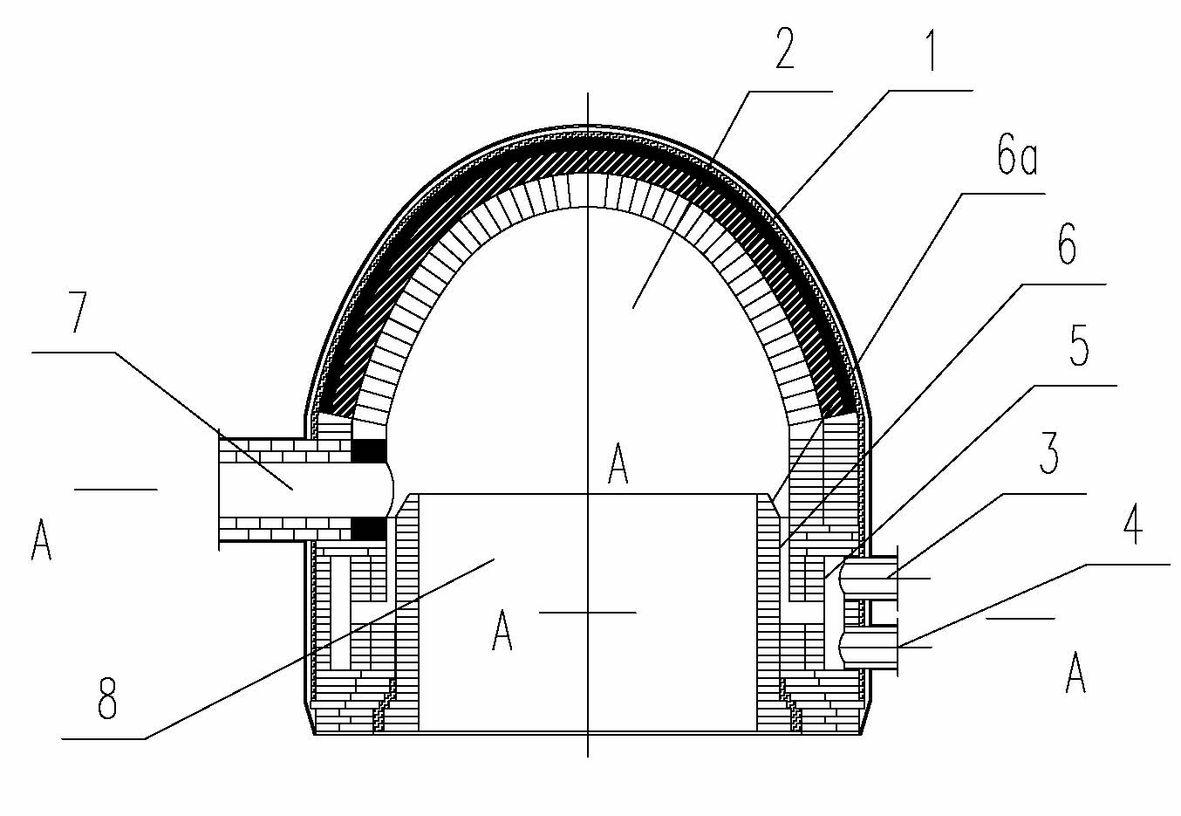

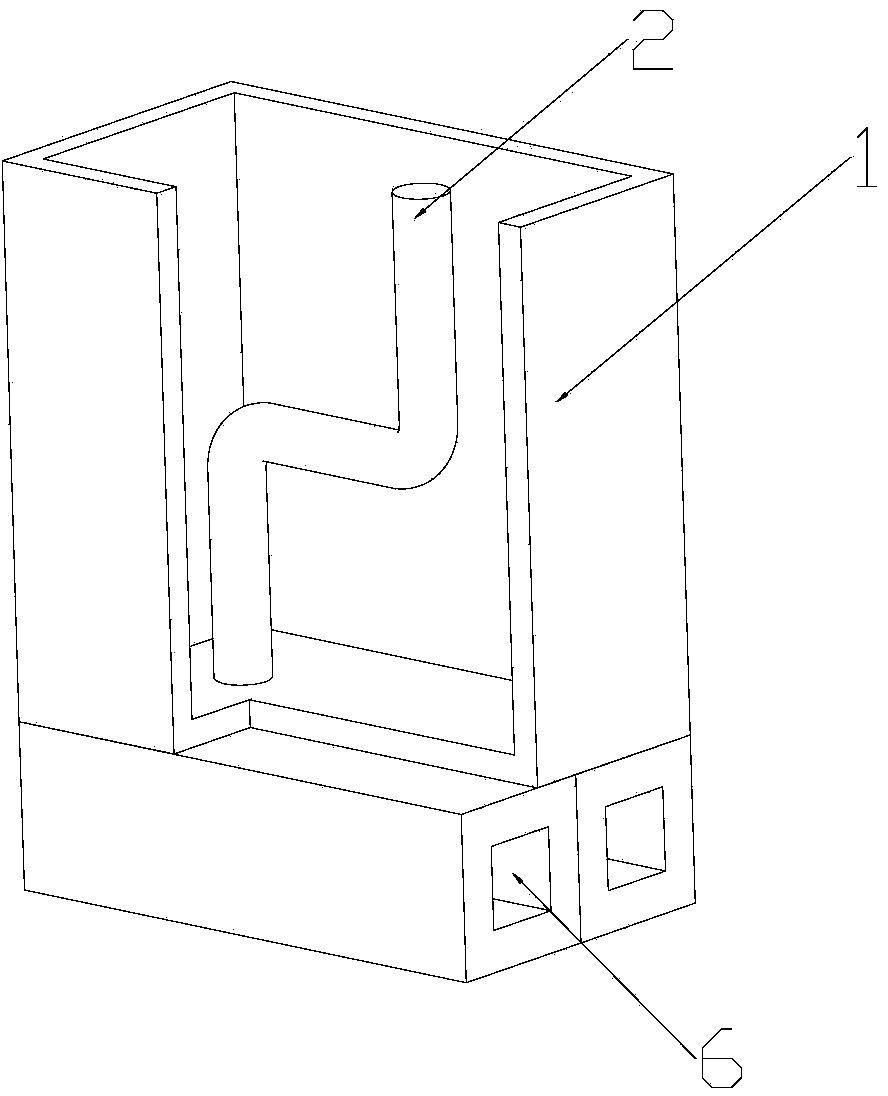

Ship propeller

InactiveCN101927823ALess heat lossRealize integrationPropulsive elementsModular compositionHigh energy

The invention discloses a ship propeller which mainly comprises a cylinder and a jet pipe, wherein the cylinder is provided with a compressed air inlet, a fuel nozzle and an ignition unit. The ship propeller is characterized in that both the cylinder (1) and the jet pipe (2) of the propeller work in water, compressed air and fuel are respectively introduced into the cylinder through the compressed air inlet (3) and the fuel nozzle (4) and are subject to burning explosion under the action of an ignition unit (5), and burning explosion products directly jet out a water column in the jet pipe (2) so as to generate a thrust force based on the reactive force. Compared with the known ship propelling system, the propeller uses the cylinder part as the power unit, uses the jet pipe part as the propelling unit and realizes the integration of the power unit and the propelling unit, thereby having the advantages of high propelling efficiency, high energy utilization efficiency, high economical efficiency, simple structure and high operational reliability. The invention includes multiple implementation schemes, can realize the ultra high-power propulsion by modular combination and is applicable to various ships.

Owner:李江平 +1

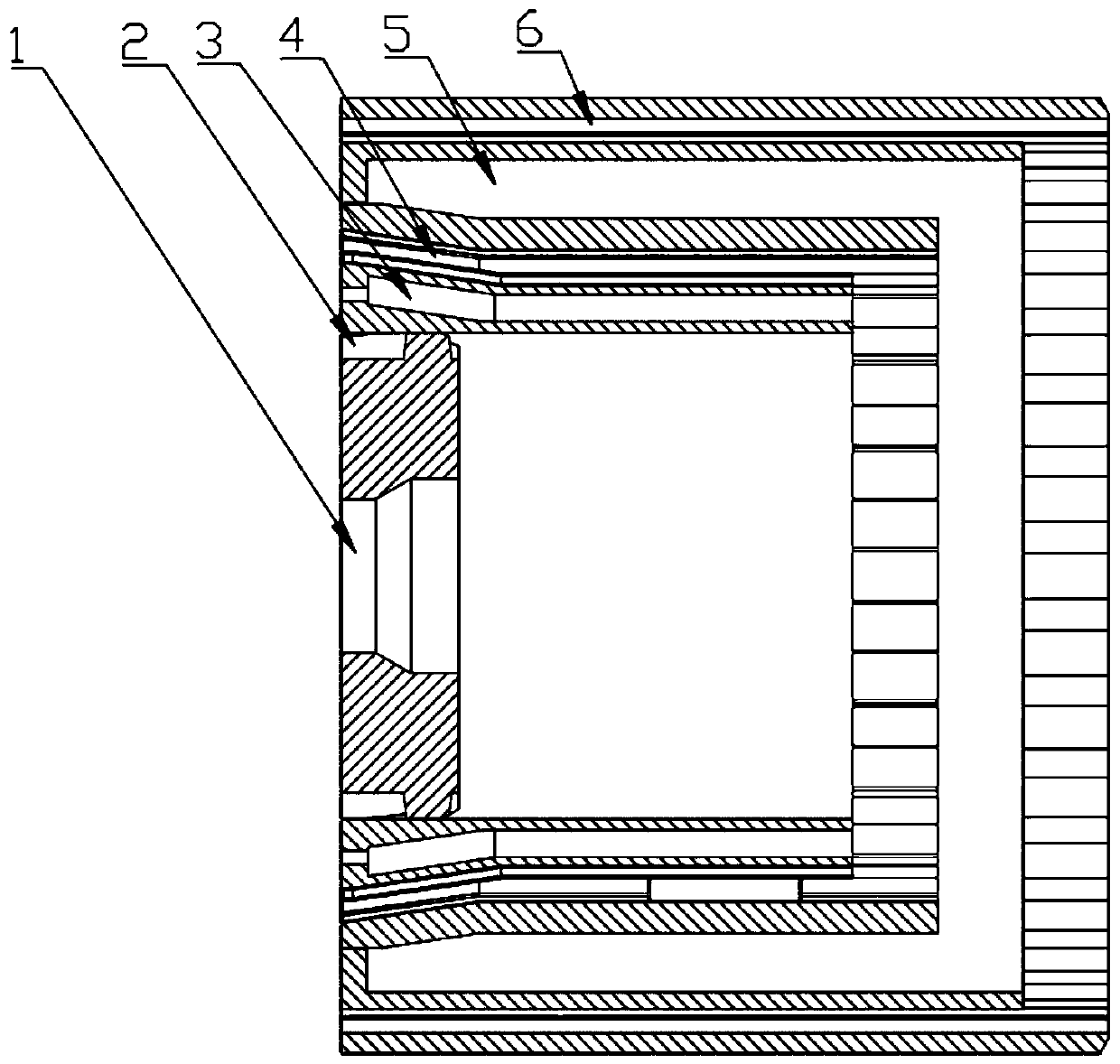

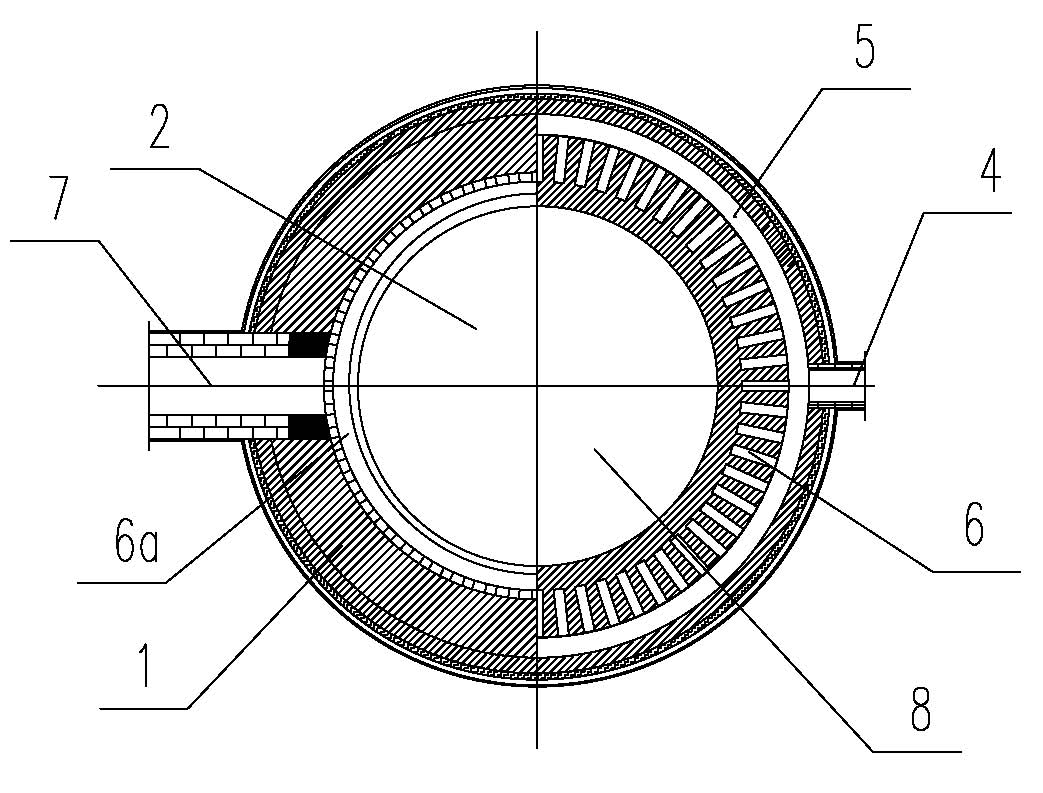

Intensive-classification low-NOx pulverized coal burner

ActiveCN103759259AIncrease swirl intensityIncrease combustionPulverulent fuel combustion burnersCombustion apparatusSlagNitric oxide

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

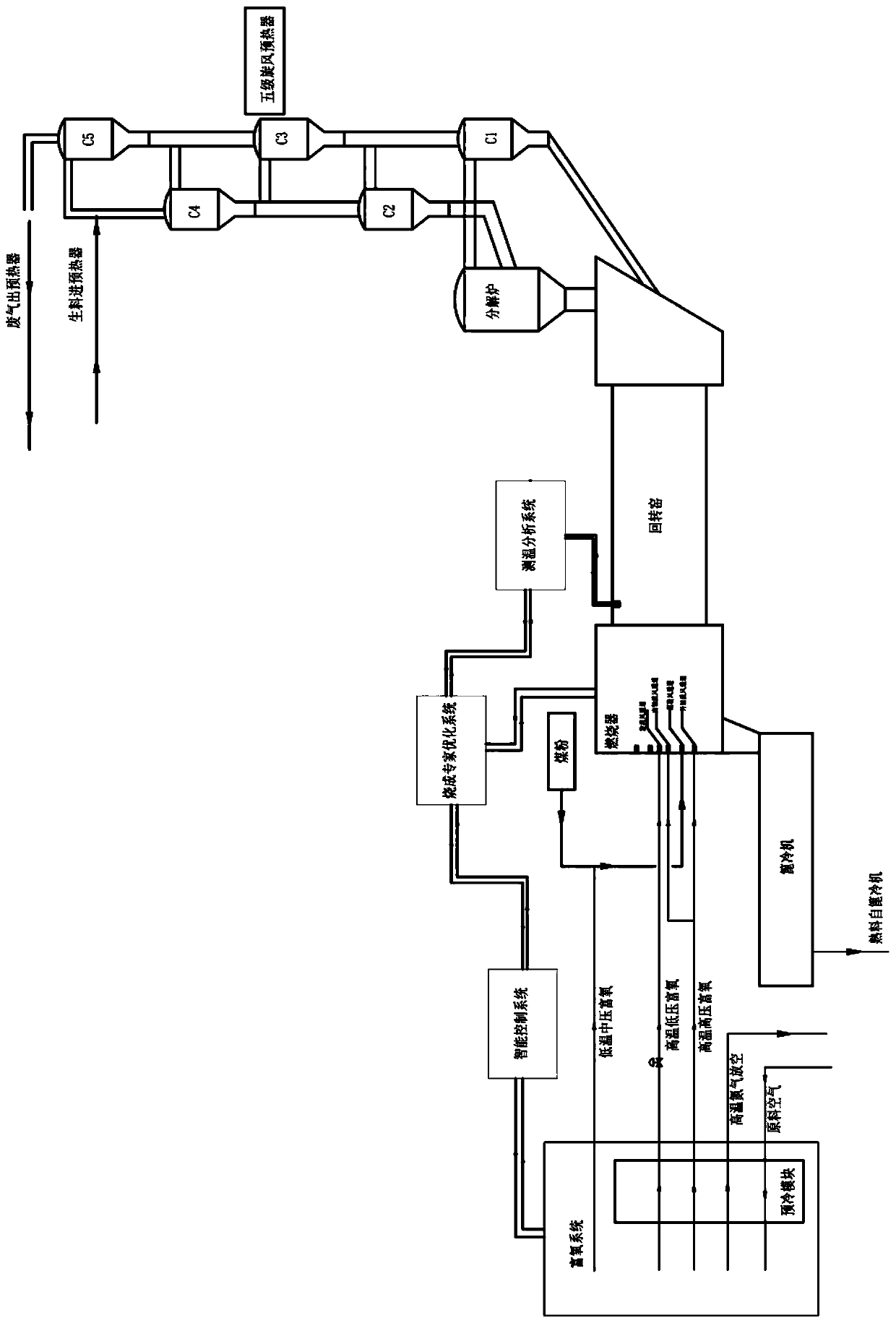

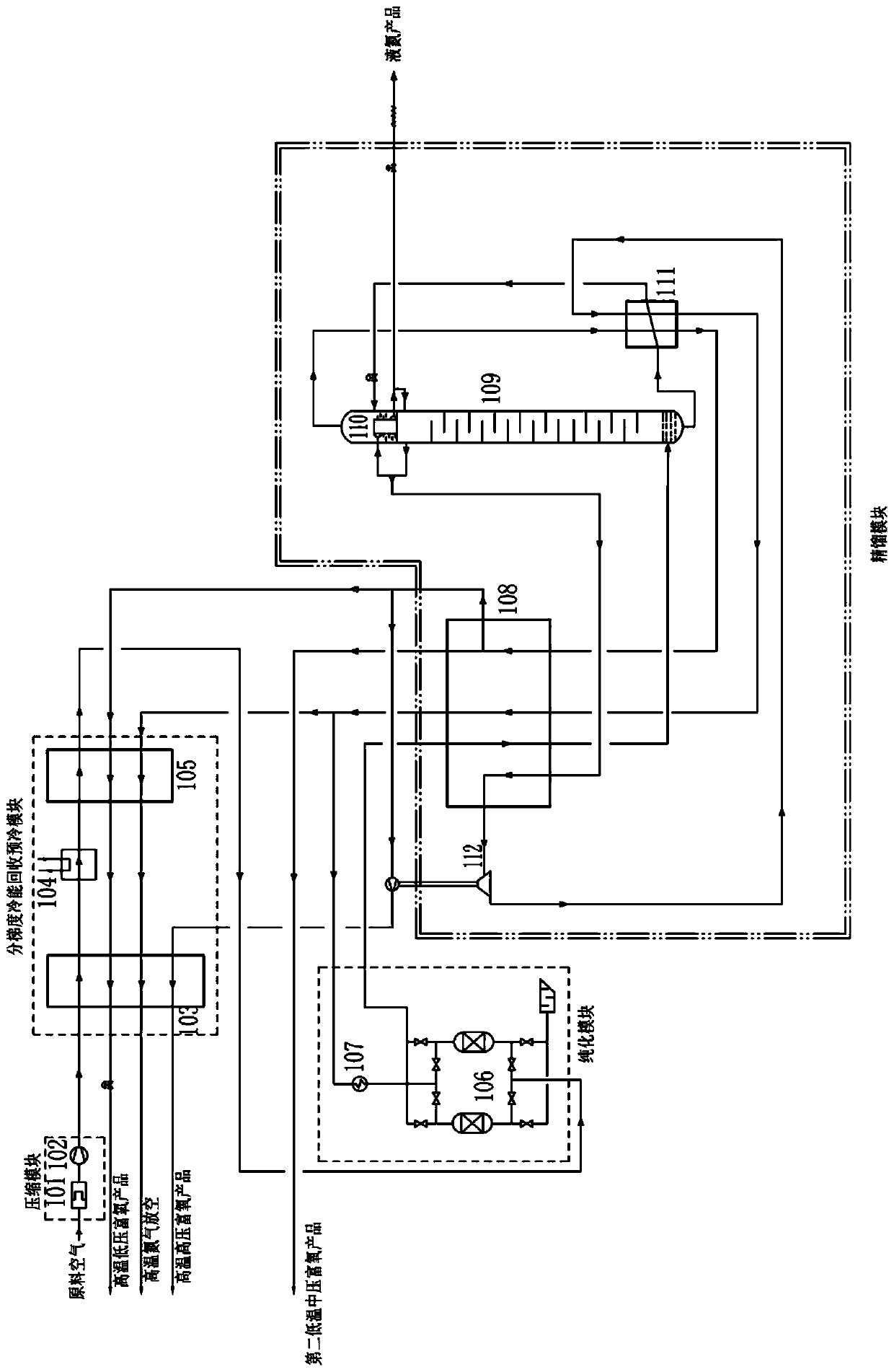

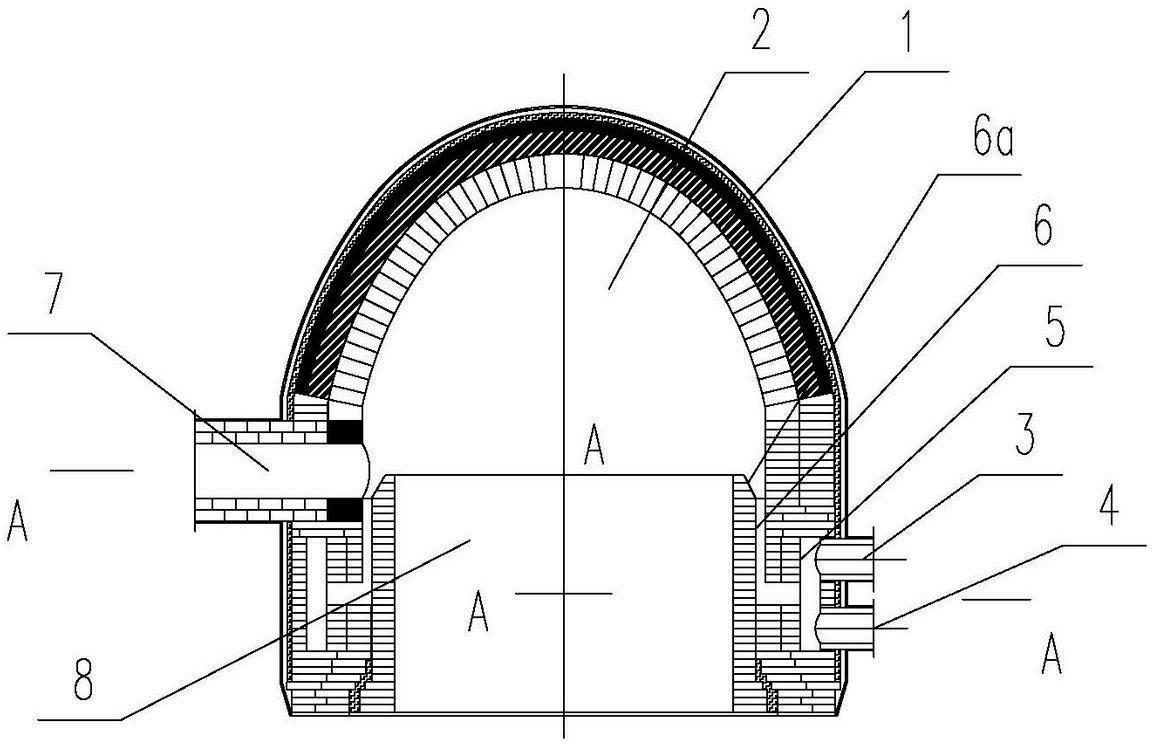

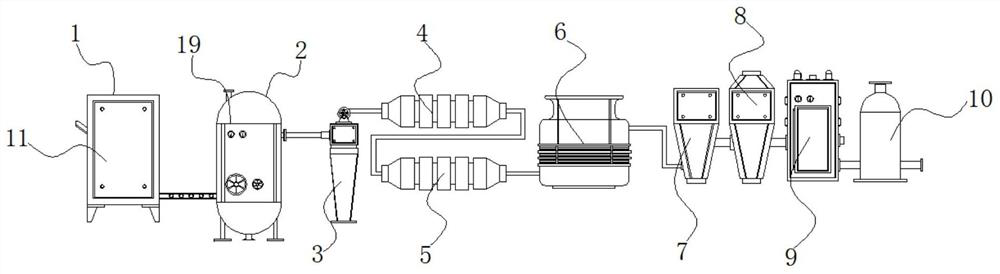

Intelligent control oxygen-enriched firing system and method for kiln

ActiveCN111521003ASmall fluctuationReduce dosageSolidificationLiquefactionThermodynamicsProcess engineering

The invention discloses an intelligent control oxygen-enriched firing system for a kiln. The intelligent control oxygen-enriched firing system for the kiln comprises an oxygen-enriched system, an oxygen-enriched burner, a temperature measurement and analysis system, a firing expert optimization system and an intelligent control system. According to the intelligent control oxygen-enriched firing system for the kiln, the oxygen enrichment is produced and provided by a special oxygen-enriched system; the novel oxygen-enriched burner is adopted; according to different coal powder types, coal powder amount and grinding granularity of a kiln system, the shapes and temperature distribution of flames are obtained by the accurate temperature measurement and analysis system, all on-site actual thermal parameters and on-site states of the kiln are combined, the system analysis and the prediction and judgment are carried out by the firing expert optimization system, and the intelligent regulationand dynamic matching of the special oxygen-enriched system are controlled by the intelligent control system, so that the optimal operation state of the firing system of the kiln is kept, the efficientand stable burning of coal powder in the oxygen-enriched burner is realized, the consumption of the coal powder is reduced, the quality of burned materials is improved, the generation and emission ofNOx are effectively reduced, meanwhile, the fluctuation of the kiln system caused by the debugging experience and level difference of operators is reduced, and the normal and stable operation of thekiln system is guaranteed.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

Pot calciner thermoregulation control device and method

ActiveCN106044746ARealize precise automatic controlHigh degree of automationCrucible furnacesElectricityCombustion

The invention discloses a pot calciner thermoregulation control device and method. The device comprises a photoelectric temperature sensor installed on a flame channel of a pot calciner, air conditioners installed on inlets of air channels of the pot calciner and a negative pressure regulator installed on an outlet of a gathering flue of the pot calciner, the photoelectric temperature sensor, the air conditioners and the negative pressure regulator are electrically connected with a control unit of the pot calciner, and the control unit of the pot calciner is in communication with a remote client side. When real-time temperature, detected by the photoelectric temperature sensor, of the flame channel is not within the target temperature range, the control unit of the pot calciner directly sends an instruction, or the remote client side sends an instruction to the control unit of the pot calciner, then the control unit of the pot calciner sends the instruction to the air conditioners and the negative pressure regulator to regulate respective opening degrees and then regulate the combustion degree of volatile matter in the flame channel, the real-time temperature of the flame channel is automatically and accurately regulated to be within the target temperature range, and the automation degree of the pot calciner is improved.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

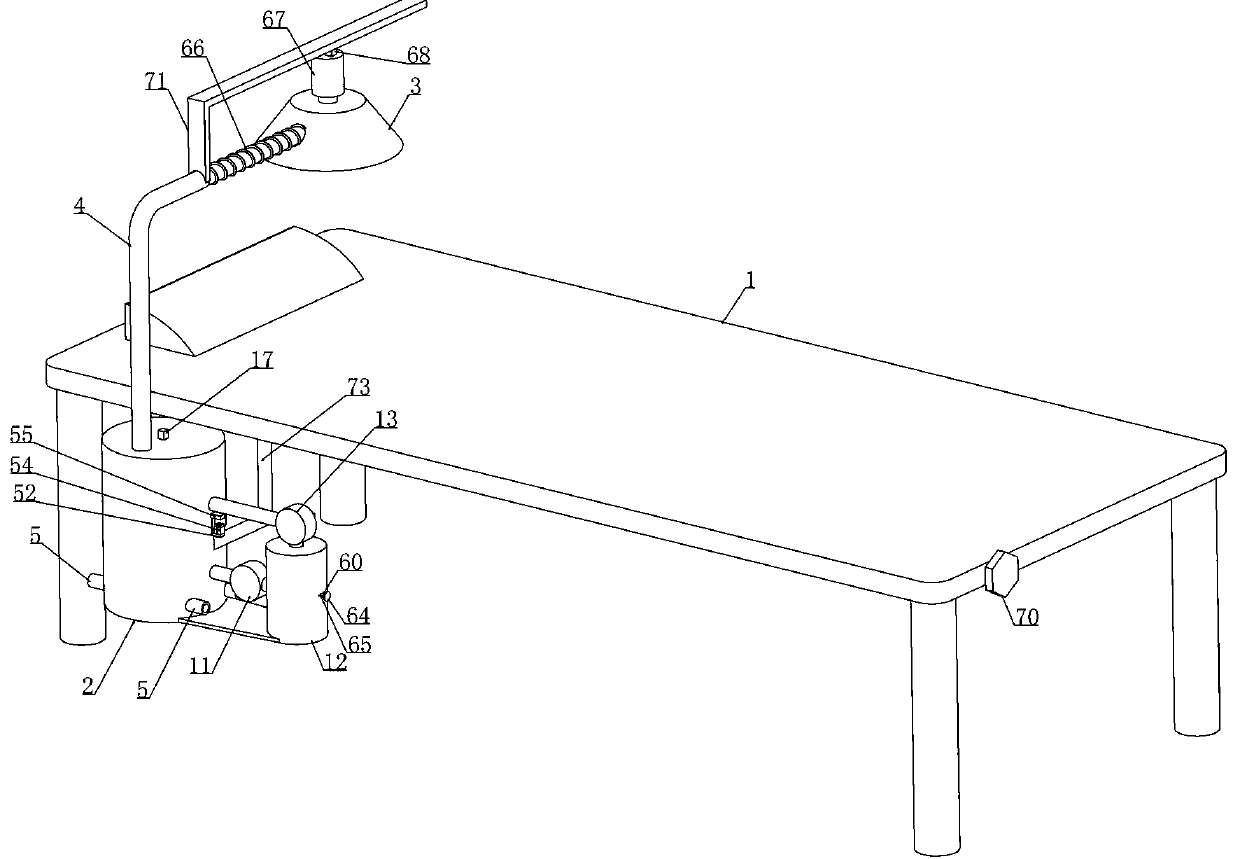

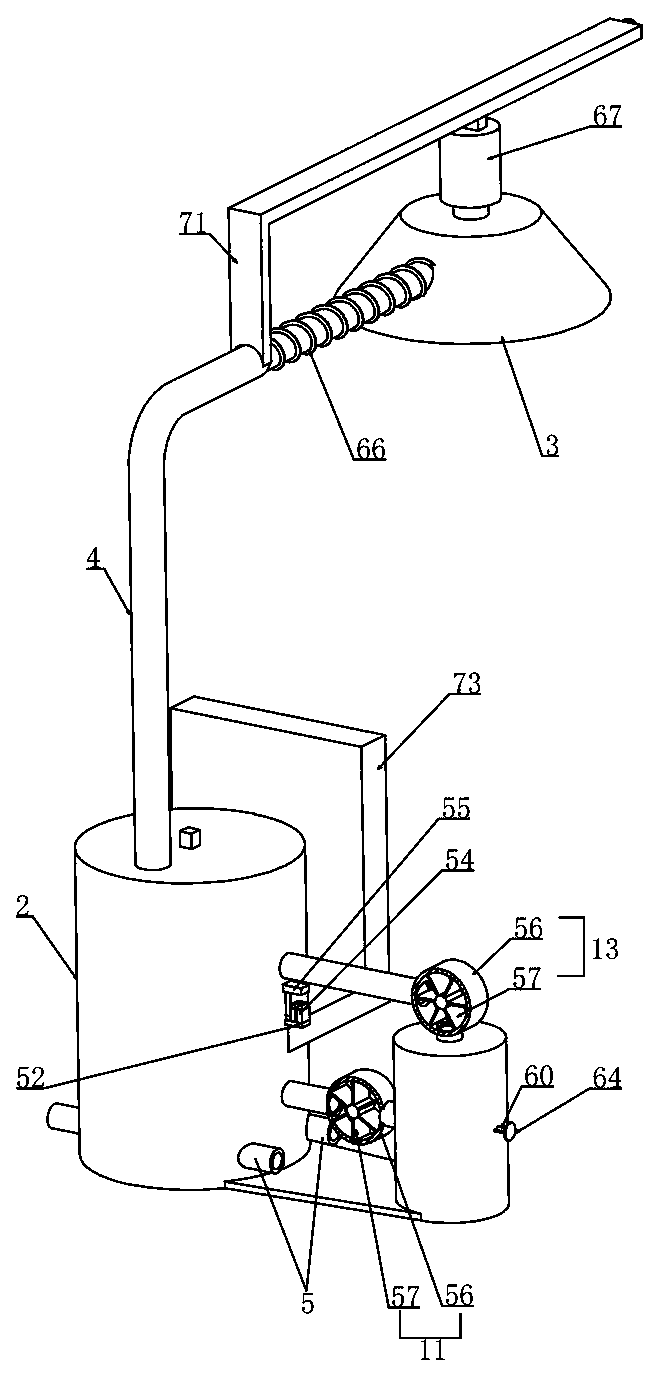

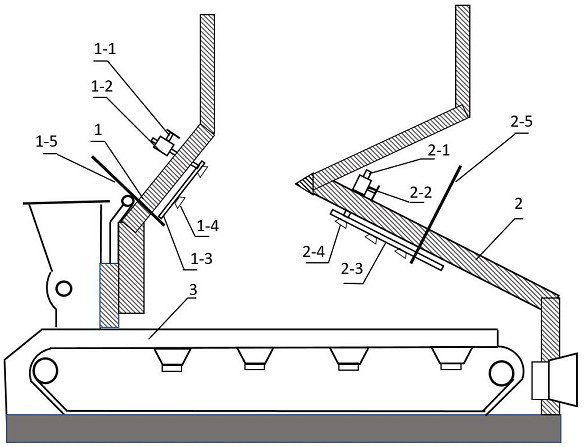

Needle warming moxibustion therapeutic instrument for internal medicine

ActiveCN110897878AAvoid burnsInhibition of combustionDevices for heating/cooling reflex pointsMedicineEngineering

The invention relates to a needle warming moxibustion therapeutic instrument for internal medicine. The needle warming moxibustion therapeutic instrument effectively solves the problem that an existing needle warming moxibustion device cannot correspondingly adjust the combustion degree of moxa sticks according to the change of moxibustion therapy temperature. According to the technical scheme, the needle warming moxibustion therapeutic instrument for the internal medicine can automatically control the combustion degree of moxa sticks according to the temperature of moxibustion therapy, when the moxibustion therapy temperature is too high, the air inflow of a combustion cylinder is reduced, therefore, the combustion of moxa sticks is inhibited, when the moxibustion therapy temperature is too low, an air supply device is started and the air inflow of a combustion box is increased, in addition, a storage transfer box used for storing moxa hot gas is further arranged in the scheme and used for guiding heat generated by combustion of the moxa sticks into the transfer box when the moxibustion therapy temperature is too high, and when the moxibustion therapy temperature is too low, the moxa hot gas in the transfer box is guided to the moxibustion therapy part of the patient in time.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

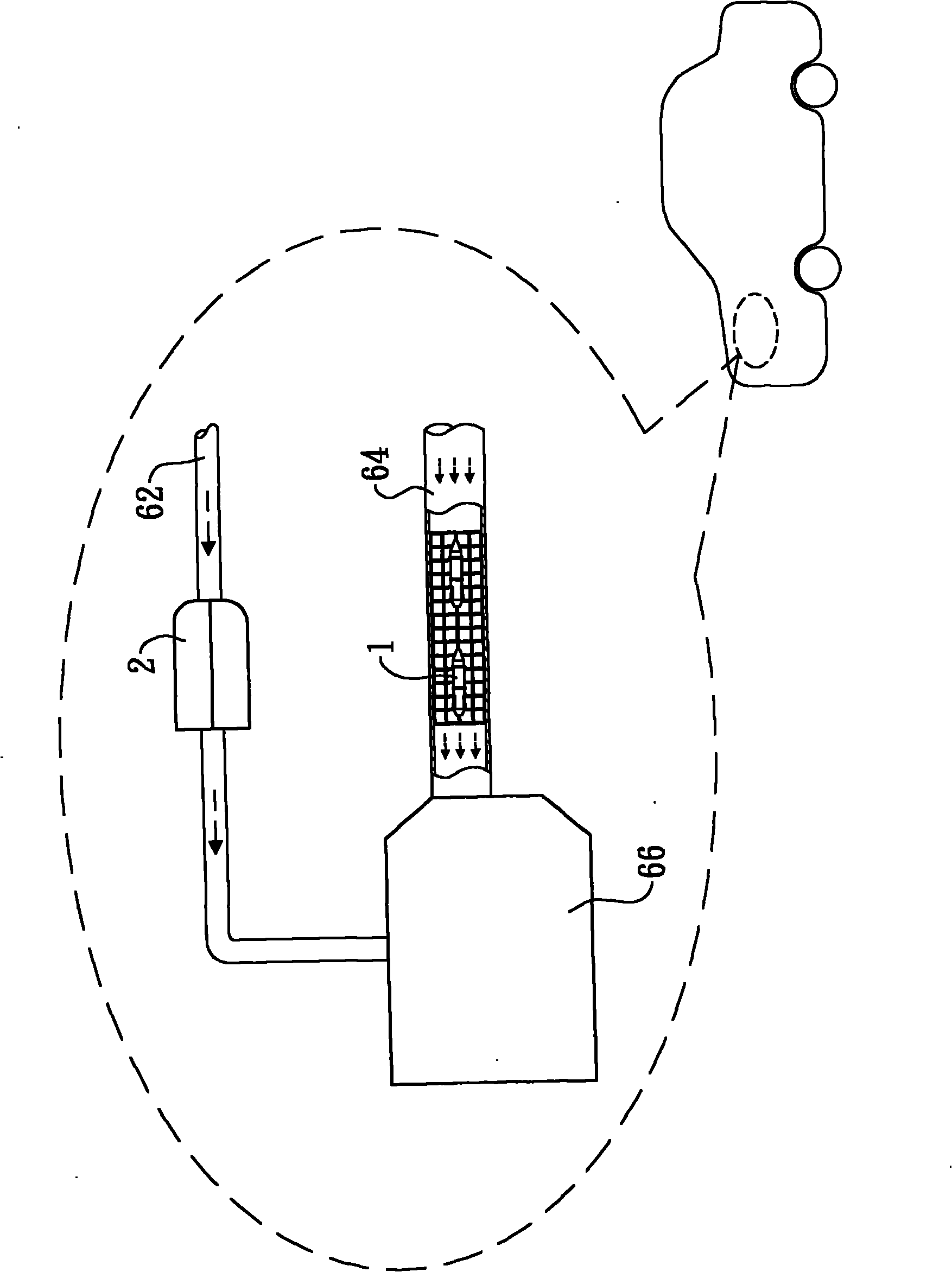

Far infrared composite material and vehicle power promoting system using same

InactiveCN101886591AIncrease combustionIncrease oxygen contentInternal combustion piston enginesCombustion-air/fuel-air treatmentFuel oilElectric generator

The invention discloses a far infrared composite material and a vehicle power promoting system using the same. The far infrared composite material consists of a far infrared substance and a compound substance coating the far infrared substance. The vehicle power promoting system comprises at least one oxygen content increasing element fixed in an intake pipeline of a vehicle engine, at least one first reduction element fixed outside an oil inlet pipeline of the vehicle engine, at least one second reduction element attached to a shock absorber, and a voltage stabilizing element electrically connected with a vehicle battery and a generator. Therefore, the vehicle power promoting system can increase the oxygen content of the intake of the engine and reduce oxidized fuel oil in the oil inlet pipeline to further improve the utilization efficiency of the fuel oil in the engine and reduce exhaust emission.

Owner:陈俊源 +2

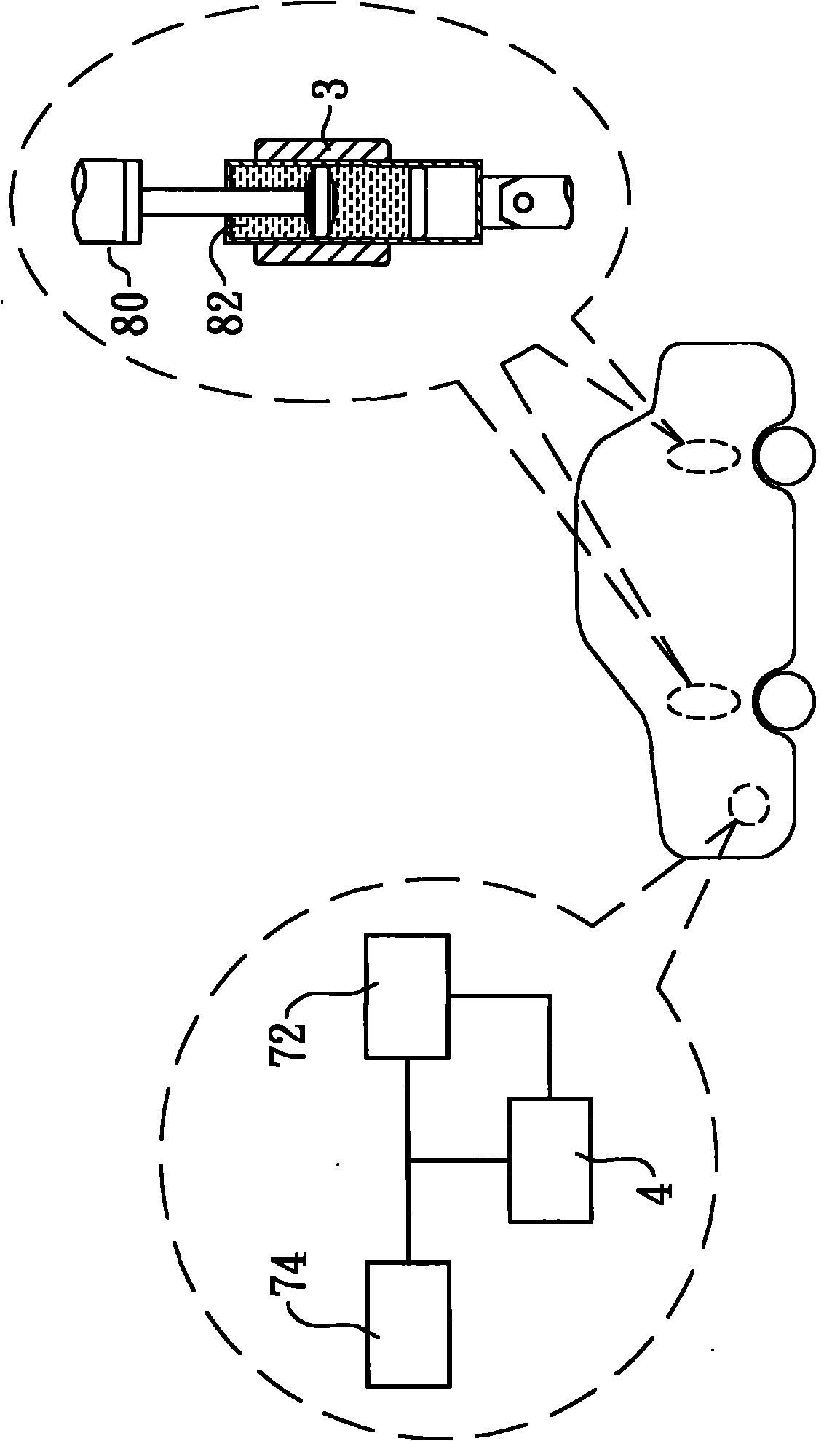

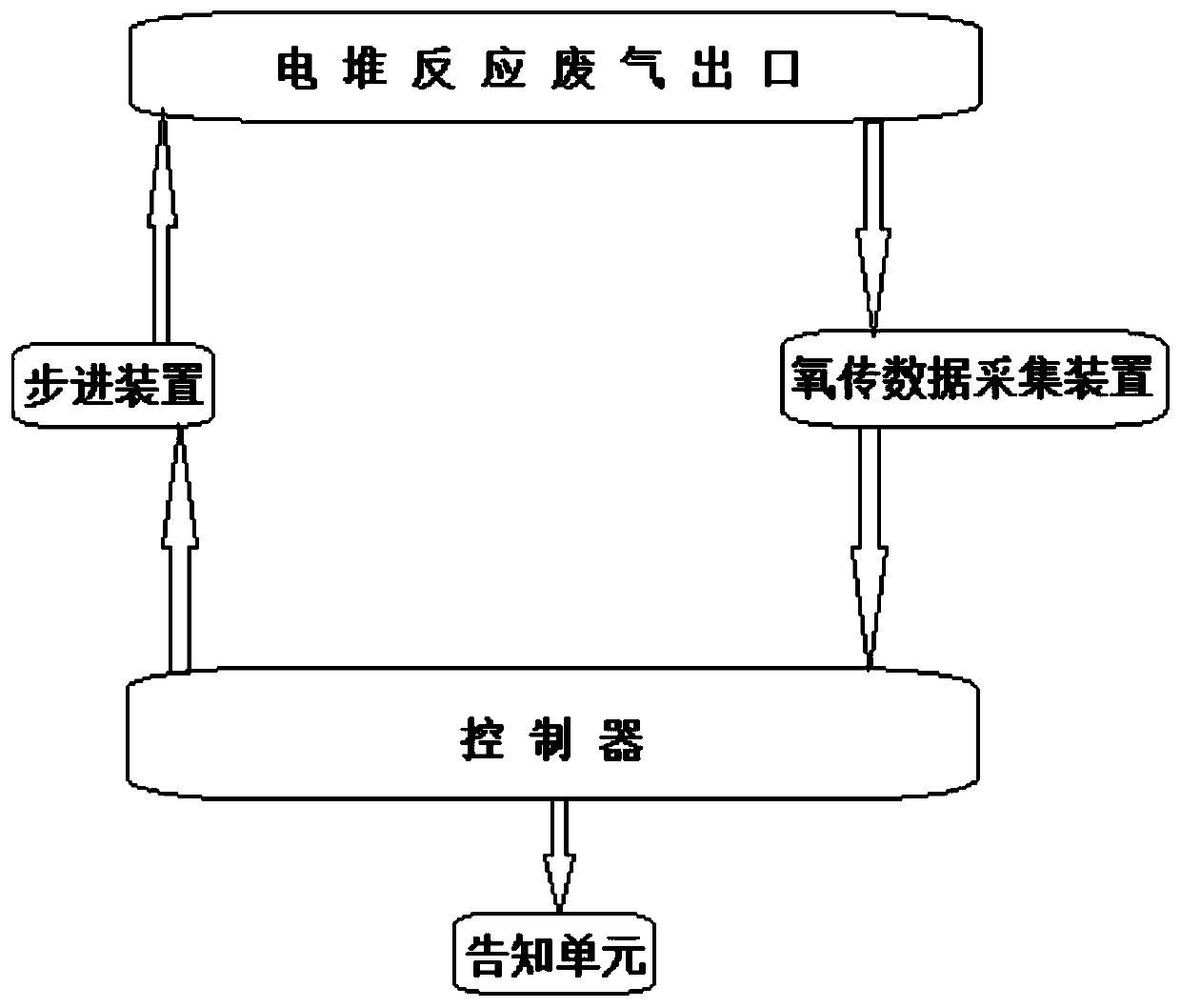

System and method for controlling exhaust valve angle of methanol fuel cell

The invention relates to the technical field of angle control systems and methods, in particular to a system and a method for controlling an exhaust valve angle of a methanol fuel cell. The control system comprises a controller, a stepping device, an electric reactor reaction waste gas outlet and an oxygen transmission data acquisition device; the controller controls a displacement of the steppingdevice through data obtained by the oxygen transmission data acquisition device; the stepping device is in contact with the electric reactor reaction waste gas outlet; and the difference of exhaust valve angles affects an oxygen content value E of tail gas emission in the electric reactor reaction waste gas outlet, wherein the oxygen content value E of the tail gas emission is collected through the oxygen transmission data acquisition device. The control method comprises the steps that the oxygen content value E is controlled to be in a range defined in the description. According to the control system provided by the invention, the controller can be used for controlling the stepping device through the data of the oxygen content value E in an oxygen sensor so as to control the valve angleof tail gas of the methanol fuel cell.

Owner:CHINA HYDROGEN NEW ENERGY TECH CO

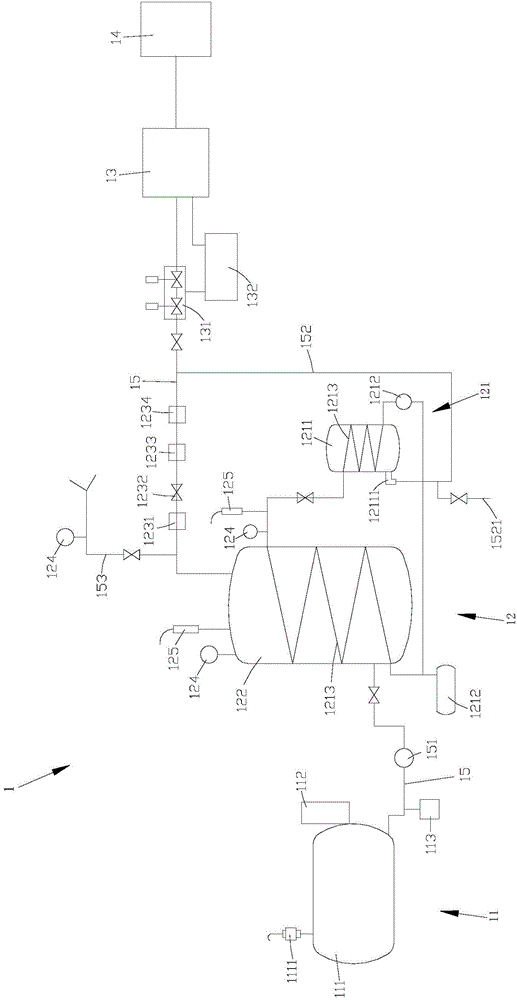

Methanol heating device

The invention relates to the technical field of chemical engineering, discloses a methanol heating device which comprises a material storage device for storage and output of methanol, a gasification device for methanol gasification and a combustion device for gas heating, wherein the material storage device, the gasification device and the combustion device are communicated in sequence through a main pipeline; the gasification device comprises a reaction pot for reacting and gasifying methanol and a heat circulation device for combusting methanol gasified in the reaction pot to supply heat to the reaction pot. According to the methanol heating device provided by the invention, the reaction pot can provide a stable high-pressure and high-temperature environment in the case of heat supply of the heat circulation device, so that methanol and impurities are gasified into a mixed gas and then are conveyed into the combustion device for combustion to supply heat; in the way, the requirements for the purity of methanol are low, and the gaseous methanol is high in combustion degree, does not generate formaldehyde gas after combustion, is more environment-friendly.

Owner:李飞

Application of renewable plant fiber, cigarette paper with hole forming function through thermal cracking, and preparation method and application of cigarette paper

InactiveCN105064120AEnhanced dilutionReduced CO and tar emissionsInorganic compound additionNon-woody plant/crop pulpTarFibrous corn

The invention discloses application of renewable plant fiber, cigarette paper with a hole forming function through thermal cracking, and a preparation method and application of the cigarette paper. Renewable plant fiber such as corn fiber is applied to preparation of the cigarette paper with the hole forming function through thermal cracking firstly; the cigarette paper has the hole forming function through thermal cracking due to the hole forming function through thermal cracking of the renewable plant fiber such as corn fiber; after the cigarette paper is prepared to cigarette, the pore volume and the micropore number of the cigarette paper around a cigarette carbonized thread in the cigarette combustion process are increased, and the effects of diffusion of CO in mainstream smoke through the cigarette paper and the dilution of air to the mainstream smoke are improved, so that the purpose of reducing the emission of CO and tar oil in the mainstream smoke is realized, and the sensory quality of the cigarette is free of influence; through the adoption of the cigarette paper, the emission of the CO in the mainstream smoke can be reduced by 15% or above, and the tar oil emission can be reduced by 5-9%. The cigarette paper is simple in preparation method and low in cost, and industrialized production can be realized.

Owner:CHINA TOBACCO HUNAN INDAL CORP

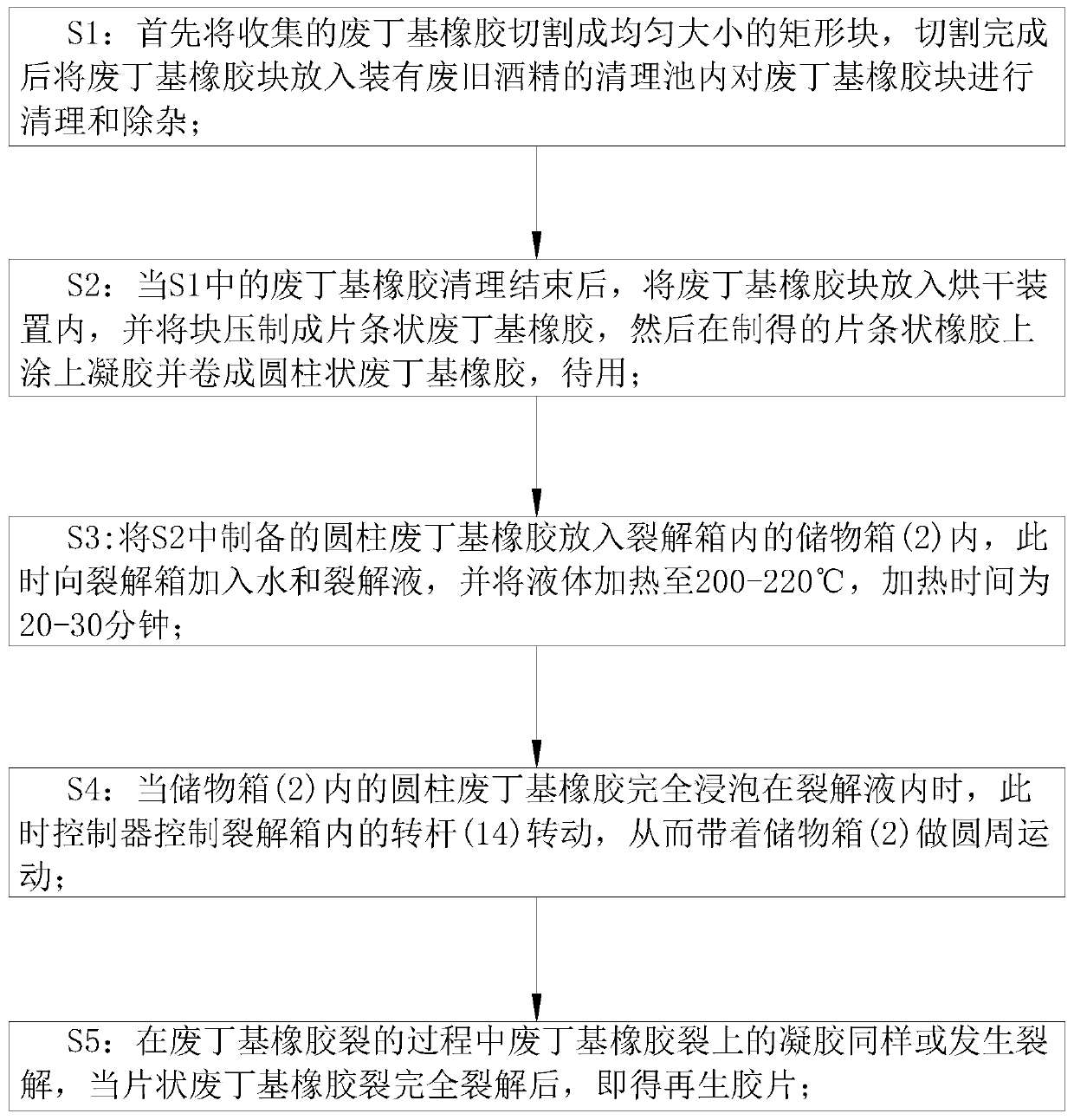

Cracking process of waste butyl rubber

InactiveCN111548530AAvoid accumulationDoesn't over crack the problemPlastic recyclingButyl rubberChemistry

The invention belongs to the technical field of cracking of waste butyl rubber, and particularly relates to a cracking process of waste butyl rubber. The cracking box comprises a box body; wherein a driving rod is rotationally connected into the inner wall of the box body through a motor; a circular groove is formed in the inner wall of the driving rod, and first through holes are uniformly formedin the inner wall of the circular groove; the outer surface of the driving rod is fixedly connected with rotating rods which are uniformly arranged, and the two rotating rods correspond to each other; the outer surface of each rotating rod is fixedly connected with a dorsal fin. According to the invention, the method is mainly used for solving the problems that during the pyrolysis process of waste butyl rubber in the prior art, the waste butyl rubber is usually directly put into a lysis solution, which may cause accumulation of the waste butyl rubber in the lysis solution, the cracking liquid can also precipitate and accumulate, so that the problems of partial excessive cracking and partial incomplete cracking of the waste butyl rubber are caused, and meanwhile, excessive cracking of thewaste butyl rubber can generate a large amount of harmful gas, so that the atmosphere and a water source can be polluted are solved.

Owner:陈一帆

Multifunctional coal burning additive and application thereof

InactiveCN106867622AStrong combustion-supporting and energy-saving functionsStrong desulfurization and emission reduction functionsSolid fuelsFuel additivesAluminateCarrier system

The invention provides a multifunctional coal burning additive and an application thereof. The additive is prepared by compounding a natural macromolecular organic compound and natural ore rich in aluminate and silicate and having sponge-shaped structural pores as a carrier and a multi-element compound. The additive is of a double-carrier system, and meanwhile has functions such as burning assistance, sulfur fixation, smoke elimination, dust removal, decoking, corrosion inhibition; moreover, the using dosage is small and accounts for 0.1 to 0.15 percent of the coal burning amount, the multifunctional coal burning additive is easy to add, simple in process and low in cost, a cost-benefit ratio reaches 1: 6 or higher, the production cost is low, the economic benefit is good, and the market advantage is high.

Owner:谭坚忠

Beam-type burner

InactiveCN104006387AMeet heating process requirementsImprove the heating effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorAlloy

The invention relates to a beam-type burner. A gas pipe, an air pipe and an ever-burning fire tube are arranged in a square beam, the air pipe is located on the outer side of the gas pipe, a gas and air mixing structure is formed between the inner wall of the air pipe and an air branch port and a gas branch port, and the ever-burning fire tube is arranged on the outer side of a whirlwind flaming port. Cooling media enters the burner from the inlet of a cooling pipe and flows out from the outlet of the cooling pipe after passing a cooling cavity. The bottom of the beam is connected with a short tube to from the whirlwind flaming port, and the front end of the air branch port extends out of the beam. The gas branch port is located in the air branch port to form the single burner. The burner is of a beam-type structure and can be directly arranged on the lower portion of the inside of an alloy furnace, the occupied space is small, and burning efficiency is improved. The beam-type burner has the advantages of enabling alloy materials to be evenly heated, meeting the requirements of the alloy heating process, being high in burning efficiency, small in occupied space, high in adaptability and long in service life, fully using energy resources and saving energy, and flames do not need to be adjusted.

Owner:LUOYANG YUXIN ENG TECH

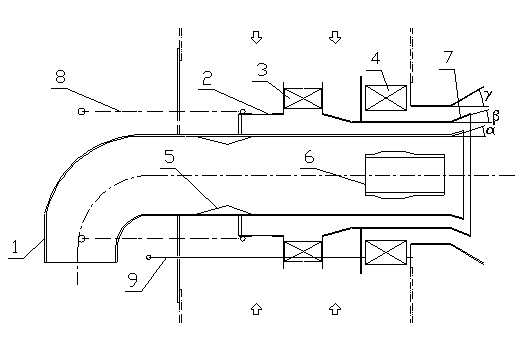

Combustion device for preheating and combusting sprayed-up backflow on nozzle with uniform mixing and distribution of coal gas and air

InactiveCN102563620AReduce manufacturing costRaise the combustion temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

The invention relates to a combustion device for preheating and combusting sprayed-up backflow on a nozzle with uniform mixing and distribution of coal gas and air. The combustion device effectively solves the problems such as low mixing speed, non-uniform mixing, low combustion intensity, incomplete combustion, complex space of a combustion chamber and complex structure of a combustor, The combustion device is characterized in that the upper space of a wall body of the combustion chamber is a backflow combustion chamber; a coal-air inlet pipe on the wall body of the combustion chamber is connected with a premixing ring road; a premixed gas nozzle at the middle part of the premixing ring road is connected with a premixed gas guiding ring groove which is arranged at the bottom part of the backflow combustion chamber; a gas flow outlet pipe is arranged on the ring wall of the side surface of the wall body of the combustion chamber or the top part of a sphere-shaped arch; and the lower part of the backflow combustion chamber is provided with a gas flow outflow section. The combustion device effectively solves the key problems such as instable combustion, weak combustion intensity and low combustion temperature at low calorific value, improves the thermo-engineering property of a hot-air furnace and an industrial kiln, and plays a decisive role in realizing high efficiency, high air temperature, energy conservation and environmental protection of the hot-air furnace and the industrial kiln.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Method for ignition and combustion-supporting treatment of flame-retardant petrochemical residual oil by using Brown gas

PendingCN111336528AIncrease combustionImprove combustion efficiencyBurnersAir/fuel supply for combustionThermodynamicsCombustion chamber

The invention discloses a method for ignition and combustion-supporting treatment of flame-retardant petrochemical residual oil by using Brown gas. The method of igniting and supporting combustion ofresidual oil comprises following steps that S1, residual oil is stored in a preheating device, and the preheating device preheats the residual oil; S2, the preheated residual oil is conveyed into a residual oil atomization device by a residual oil conveying pump, and the residual oil atomization device is positioned in a high-temperature mixing ignition chamber; S3, an air blower and the residualoil atomization device are matched to atomize the residual oil, and the atomized residual oil is sprayed into the high-temperature mixing ignition chamber and a combustion chamber; S4, ignition devices in the high-temperature mixing ignition chamber and Brown gas ignition nozzles work cooperatively to ignite the atomized residual oil; and S5, the ignition devices arranged inside the combustion chamber and the Brown gas ignition nozzles are used for supporting combustion of the atomized residual oil which is not sufficiently combusted. In the method, the ignited and atomized residual oil and enough air are further fully combusted when passing through the high-temperature combustion-supporting area, so that the combustion degree and efficiency of the residual oil are improved.

Owner:上海甘吉环保科技有限公司

Bio-oil combustion furnace capable of clearing away ash conveniently and good in combustion degree

PendingCN110836385AEasy to clean furnace ashGood burningDomestic stoves or rangesLighting and heating apparatusFlueProcess engineering

The invention relates to the technical field of bio-oil combustion furnaces, and discloses a bio-oil combustion furnace capable of clearing away ash conveniently and good in combustion degree. The bio-oil combustion furnace comprises a furnace body. The top of the furnace body is fixedly connected with a flue. One side of the furnace body is fixedly connected with a feeding opening. One end of thefeeding opening is fixedly connected with a combustion chamber. The bottom of the combustion chamber is fixedly connected with an interlayer plate. Ash leaking holes are formed in the interlayer plate. An ash accumulation chamber is fixedly connected to the bottom of the interlayer plate. A through hole is formed in one side of the furnace body, the upper side and the lower side of the inner wallof the through hole are fixedly connected with sliding blocks, the outer sides of the sliding blocks are in sliding connection with a sliding groove, the sliding blocks are in sliding connection withan ash removal rod through the sliding groove, the left side of the ash removal rod is fixedly connected with a handle, and the right side of the ash removal rod is fixedly connected with an ash removal plate. Through cooperative use of the handle, the ash removal rod, the ash removal plate, the sliding blocks and the sliding groove, the effect that ash can be cleared away conveniently is achieved.

Owner:怀化腾辉新能源科技有限公司

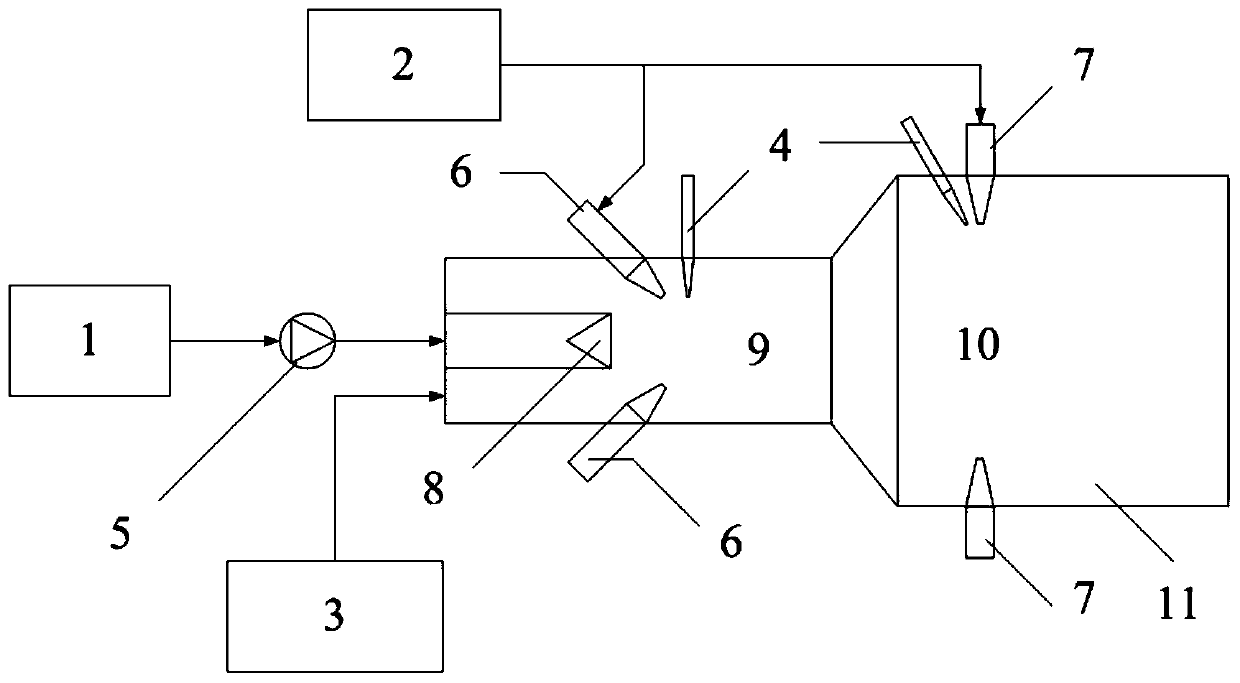

Oxygen enrichment intensifying roasting method of nonferrous metal mineral resource

The invention relates to an oxygen enrichment intensifying roasting method of a nonferrous metal mineral resource, and belongs to the technical field of energy conservation and emission reduction andintensifying. The oxygen enrichment intensifying roasting method comprises the steps that firstly, the nonferrous metal mineral resource and fuel are mixed to be even after being smashed, oxygen enrichment intensifying roasting is conducted by igniting in an oxygen enrichment environment, roasting gas phase composition is monitored in the oxygen enrichment intensifying roasting process, and timelyadjustment is conducted on the oxygen enrichment concentration; when Co vol% in a high temperature flue gas phase is larger than 80%, the oxygen enrichment concentration is controlled to be larger than 50% and less than 100%; and when CO vol% in the high temperature flue gas phase is larger than 40% and less than or equal to 80%, the oxygen enrichment concentration is controlled to be larger than21% and less than or equal to 50%, and high temperature flue gas generated in the roasting process is exhausted into the air after being subjected to dust collecting, waste heat utilization and desulfuration treatment. The oxygen enrichment intensifying roasting method utilizes a strong thermodynamic advantage of the oxygen enrichment environment, oxygen enrichment intensifying roasting is conducted on the nonferrous metal mineral resource in an oxygen enrichment atmosphere, the fuel utilization rate is sharply improved while the temperature field, the chemical potential and the dynamics conditions of a roasting system are evened and enhanced, and the problems that the fuel utilization rate is low, the reaction efficiency is limited and the environmental negative influence is large existing in a traditional roasting technology are solved.

Owner:KUNMING UNIV OF SCI & TECH

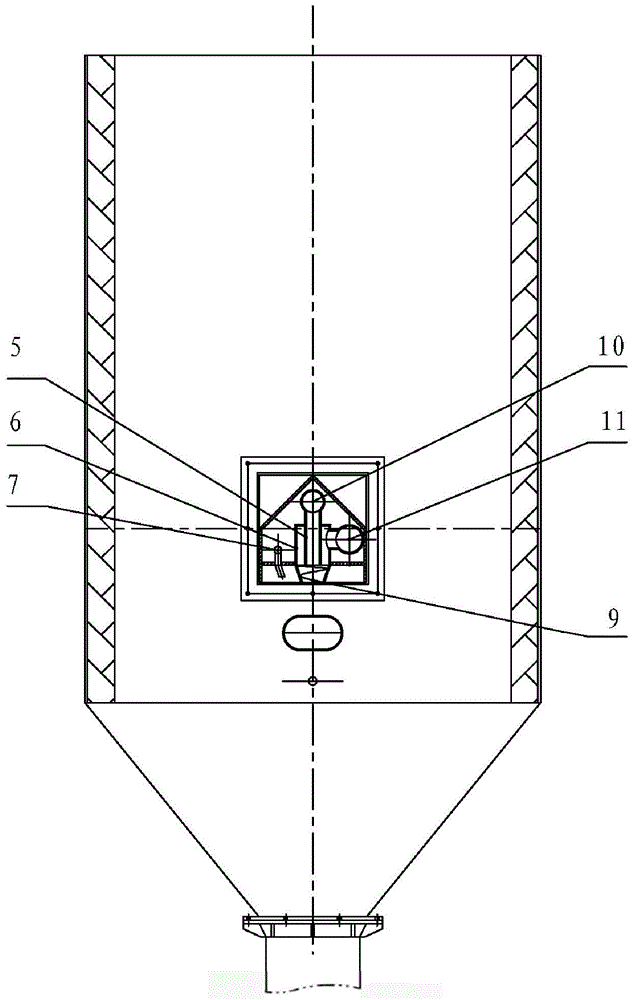

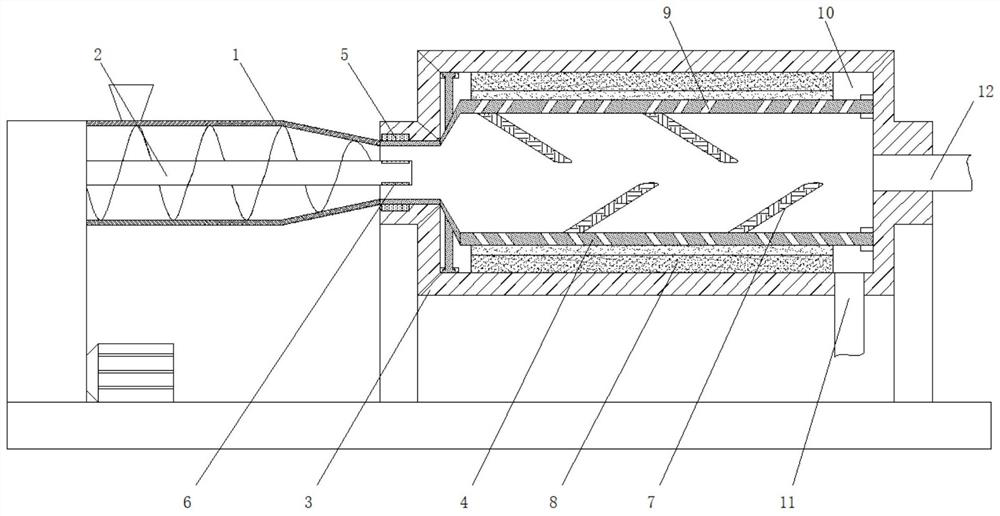

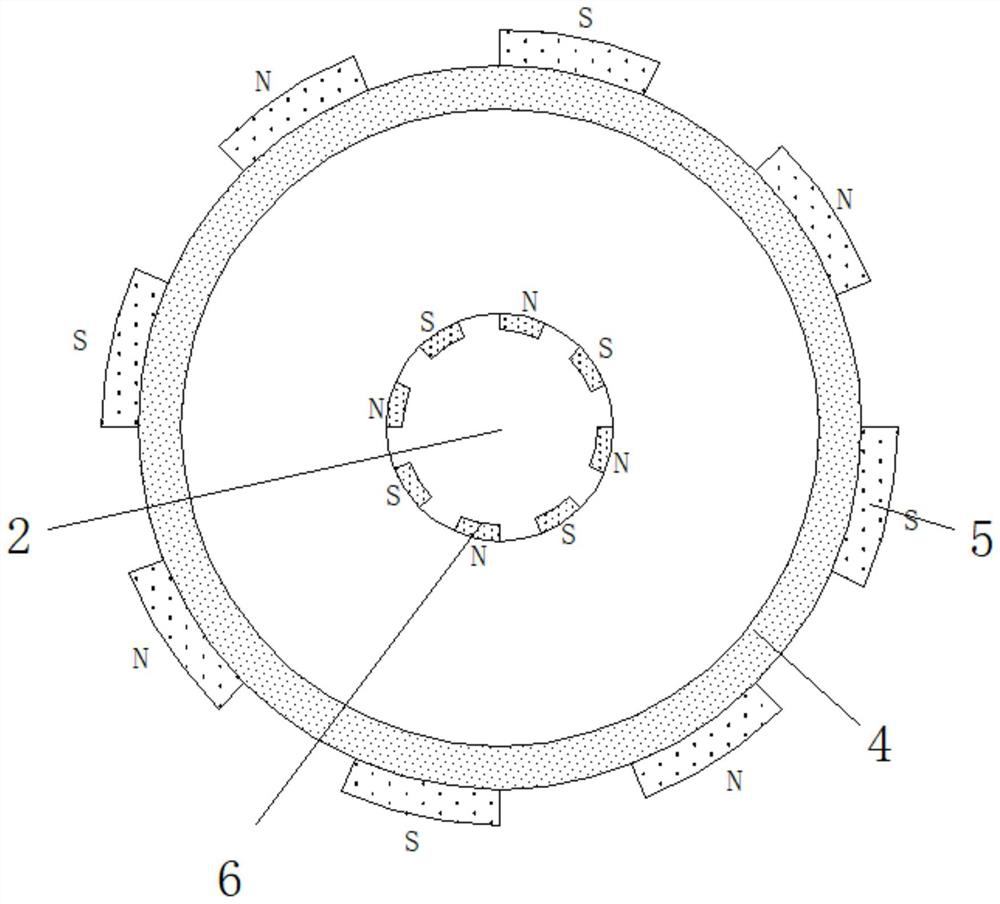

Biomass raw material pyrolyzing furnace

ActiveCN113462414AImprove liquidityAvoid wrapping normal raw materialsProductsReagentsMetallurgyMaterials science

The invention relates to the technical field of biomass pyrolyzing furnaces, and discloses a biomass raw material pyrolyzing furnace, which comprises a feeding pipeline, a center shaft is mounted in the feeding pipeline, a pyrolyzing furnace body is mounted at the outlet end of the feeding pipeline, and an inner furnace is movably mounted in the pyrolyzing furnace body. The inner furnace capable of movably rotating is arranged in the pyrolyzing furnace, the center shaft drives the inner furnace to rotate through magnetic force between the strong magnets, biomass raw materials in the inner furnace can be driven to rotate when the inner furnace rotates, and the softened biomass raw materials can be thrown out of the inner furnace from flowing holes under the action of centrifugal force due to the fact that the mobility of the softened biomass raw materials is good, the softened raw materials and normal raw materials are combusted separately, the situation that the normal raw materials are wrapped by the softened raw materials can be effectively avoided, the combustion degree of the normal raw materials is improved, meanwhile, the stirring rod is arranged inside, the combustion degree of the raw materials in the inner furnace can be effectively improved, and sufficient combustion of the raw materials is guaranteed.

Owner:辽宁昌盛节能锅炉有限公司

Biomass low-nitrogen combustion boiler based on local gasification technology

PendingCN113028445AImprove combustion efficiencyBurn fullyNon-combustible gases/liquids supplyCombustion regulationPollutant emissionsProcess engineering

The invention discloses a biomass low-nitrogen combustion boiler based on a local gasification technology. According to the boiler, a front steam spraying system and a rear steam spraying system are arranged on a front arch and a rear arch correspondingly, and each steam spraying system is provided with a valve, a gas guide pipe, a gas distribution pipe, a spray head and a thermocouple. According to the biomass low-nitrogen combustion boiler, water vapor atomizing nozzles are arranged on the front arch and the rear arch, and atomized steam is sprayed to a high-temperature oxidation area in the boiler, so that biomass particles which are combusted are locally gasified, reducing gas is generated, NOx is reduced and removed in the combustion process, and the problem of emission of pollutants such as the NOx in a small biomass boiler is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

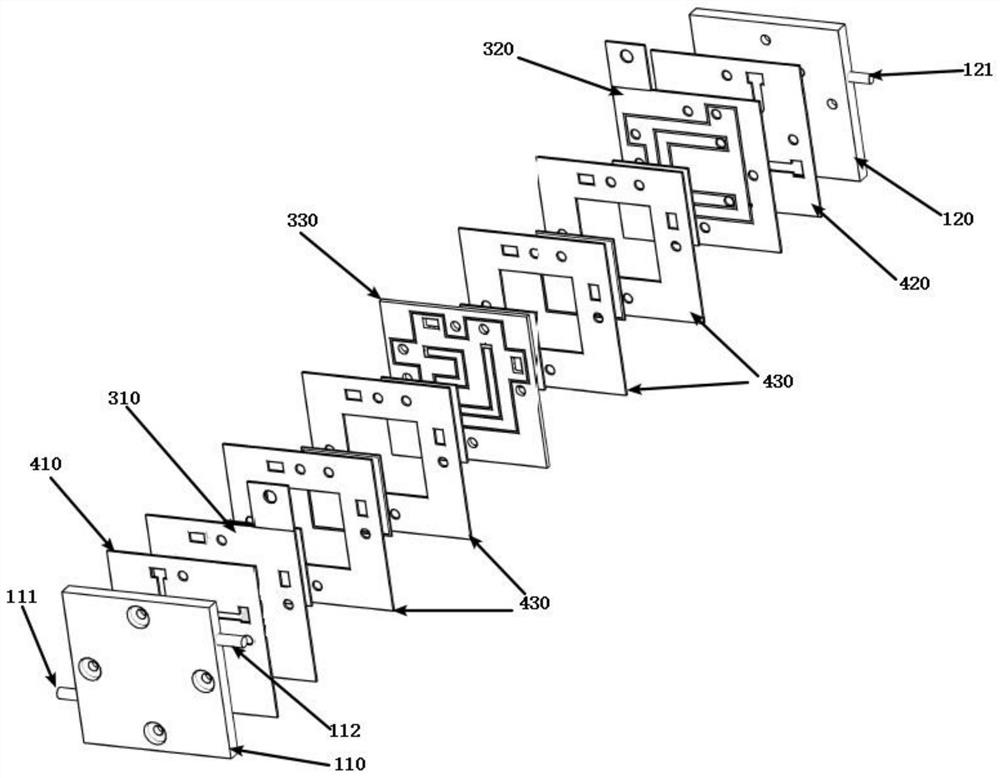

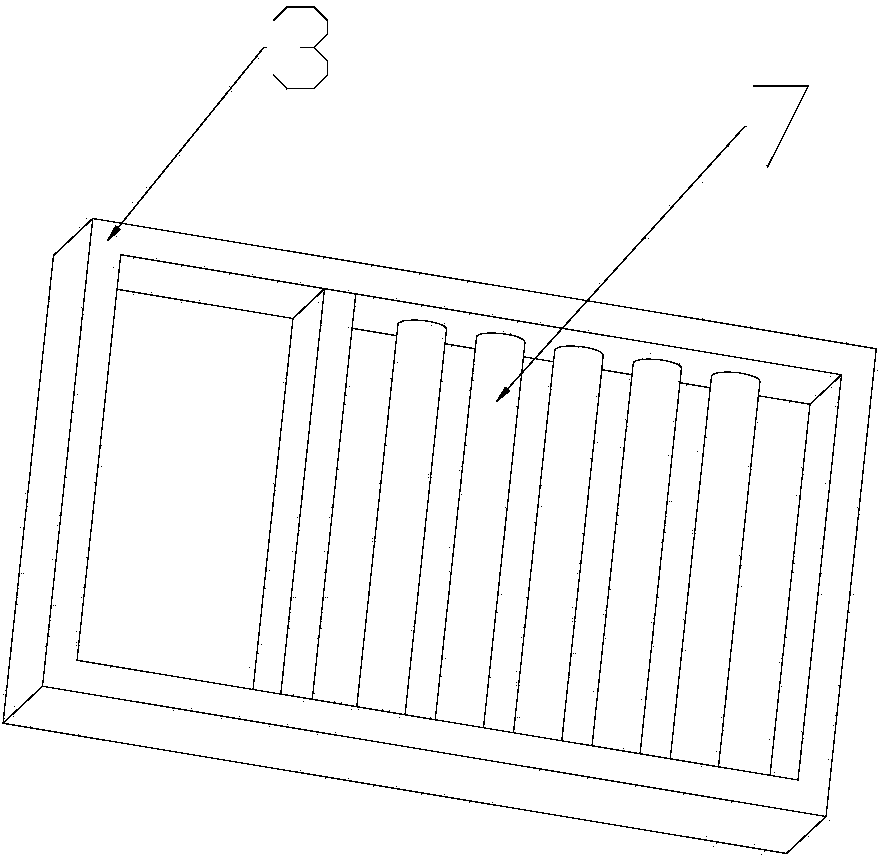

Water electrolysis device and automobile auxiliary air inlet device

PendingCN113106478AElectrolytic realizationIncrease contact areaCellsInternal combustion piston enginesElectrolysed waterMicrowell Plate

The invention relates to the technical field of automobiles, and in particular, relates to a water electrolysis device and an automobile auxiliary air inlet device. The water electrolysis device comprises a first shell and a second shell which are oppositely arranged; the first shell is provided with a water inlet and a water outlet; the second shell is provided with an air outlet; an anode plate and a cathode plate are arranged between the first shell and the second shell, and one or more neutral plates are arranged between the anode plate and the cathode plate; an electrolysis unit is formed between the anode plate and the neutral plates or between two neutral plates or between the neutral plates and the cathode plate; and the electrolysis unit comprises a first micro-pore plate and a second micro-pore plate, and an ion exchange membrane is arranged between the first micro-pore plate and the second micro-pore plate. The voltage required by electrolysis is low, the combustion degree of gasoline can be improved favourably, and the content of harmful gas in tail gas is further reduced.

Owner:智达盛世(广州)氢能与环境科技有限公司

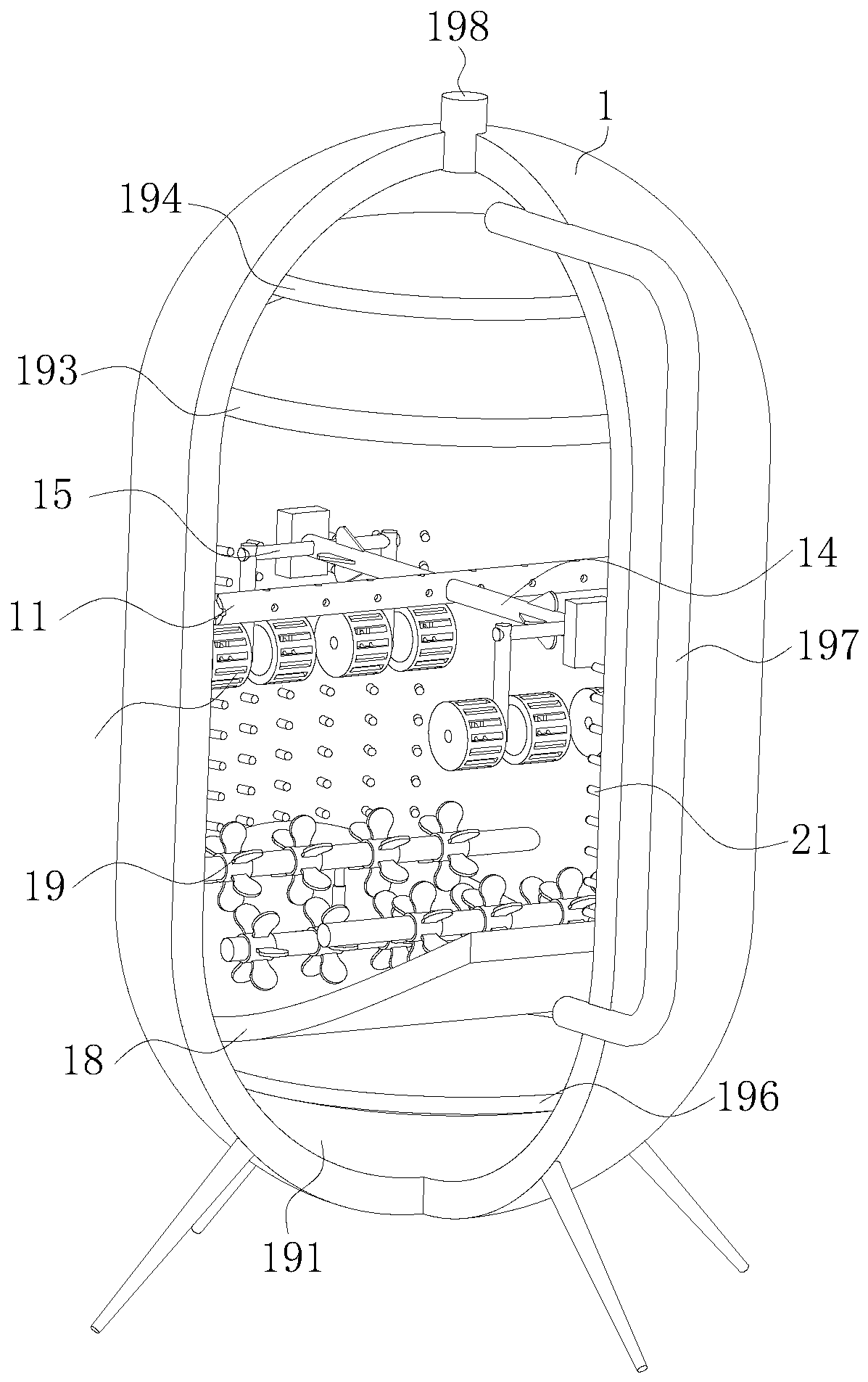

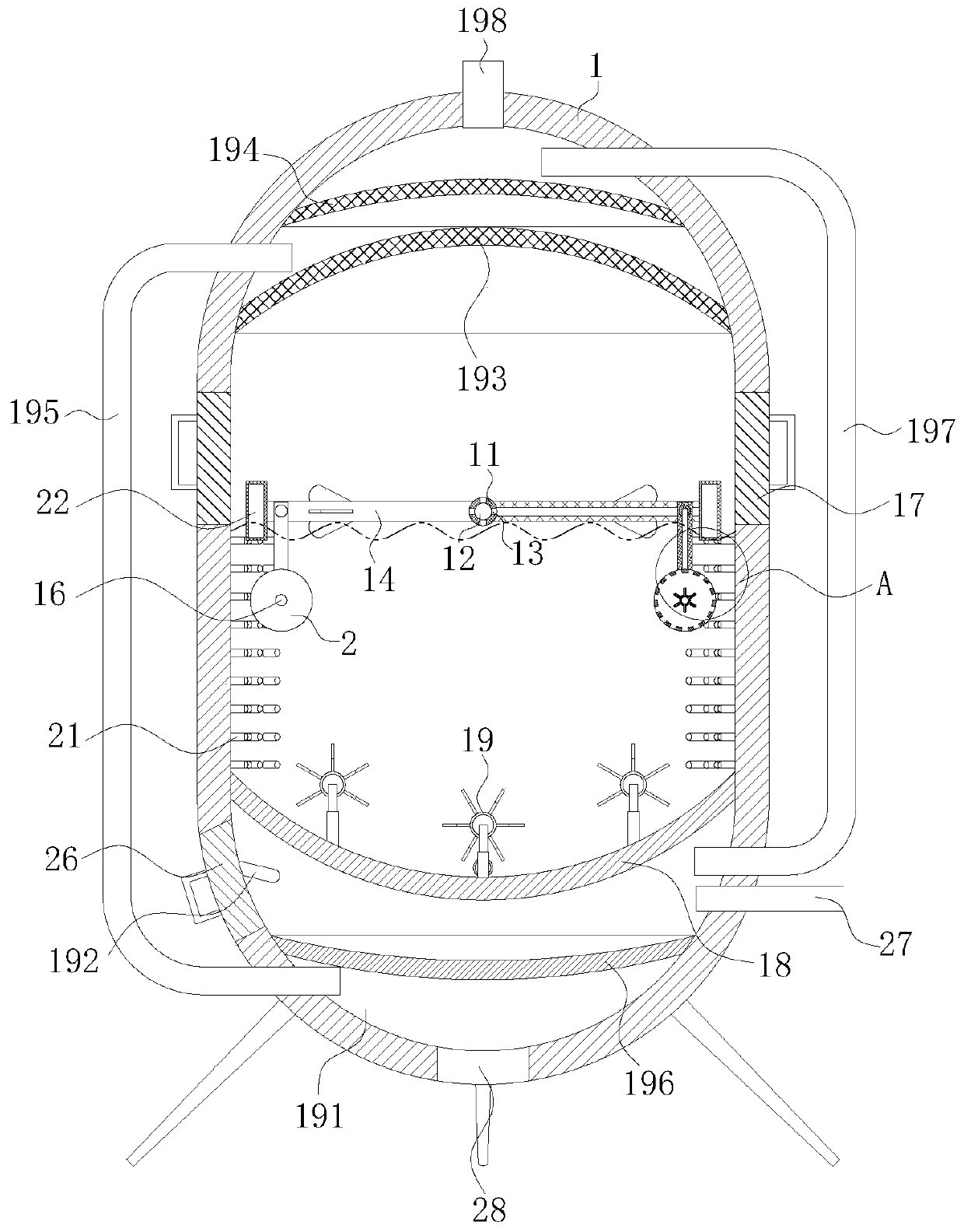

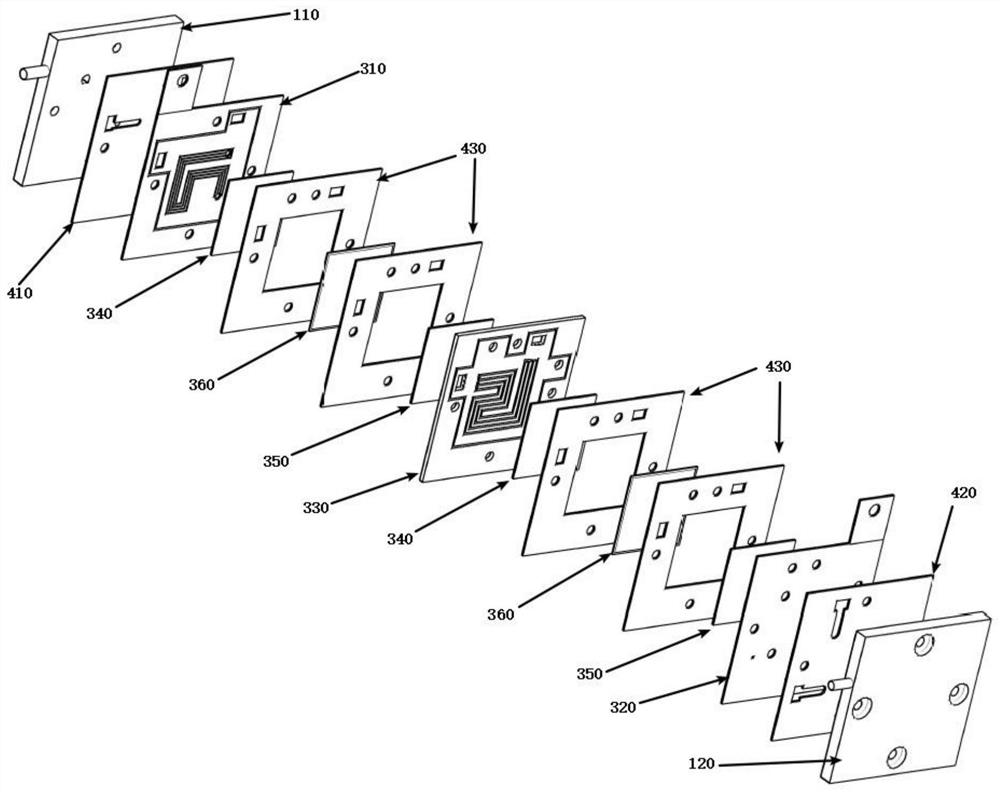

A coal chemical industry solid slag recycling system

ActiveCN109185889BIncrease combustionAchieve reuseChemical industryIncinerator apparatusCombustionSlag

The invention relates to the field of coal chemical industry solid treatment, in particular to a coal chemical industry solid slag recycling system. The coal chemical industry solid slag recycling system comprises a smashing furnace, a middle furnace and an incineration furnace; the smashing furnace is arranged above the middle furnace, the incineration furnace is arranged below the middle furnace, the smashing furnace comprises a spiral conveyor, a grinding roller, a rotating mechanism, a bearing, a damping spring II and a smashing furnace shell, the middle furnace comprises a shaking plate,a spring I, an air bag, a spring II, a gas conveying pipe, an elastic ring support and a storage wheel, and the incineration furnace comprises a water tank, a steam conveying pipe, a hydrargyrum sealbox I, an automatic water outlet device, a hydrargyrum seal box II and a safety valve. The coal chemical industry solid can be sufficiently combusted, heat generated by combustion can be used, large-scale waste heat recycling is achieved, and the system is an effective manner for repeatedly using coal chemical industry solid resources and improving the energy use rate.

Owner:兖矿煤化工程有限公司

Boiler with water inlet heat absorbing and water storage functions

The invention relates to a boiler with water inlet heat absorbing and water storage functions. The boiler comprises a boiler body, a water inlet pipe assembly, a boiler upper cover and a heat insulation water storage tank, wherein the water inlet pipe assembly comprises a plurality of water inlet pipes, each water inlet pipe transversely penetrates through a containing space in the boiler upper cover, the boiler body comprises a fire pipe and a heating boiler, the fire pipe is arranged in the heating boiler, the fire pipe is of a zigzag structure and is arranged in the heating boiler, the length of the fire pipe guarantees that flame can sufficiently extend in the fire pipe and cannot leak at the tail end of the fire pipe, a fire delivery machine is arranged at the initial end of the fire pipe, a fire inducing fan is arranged at the tail end of the fire pipe, and the heating boiler is connected with the heat insulation water storage tank through a pipeline and a water suction pump. The boiler has the advantages that the heat recovery is completed by the boiler upper cover; by arranging the fire pipe as the zigzag structure, the combustion degree of biomass in the fire pipe is improved; by arranging the heat insulation water storage tank, excessive hot water produced by one-time heating can be stored.

Owner:ANHUI GUIHONG ENERGY SAVING BOILER

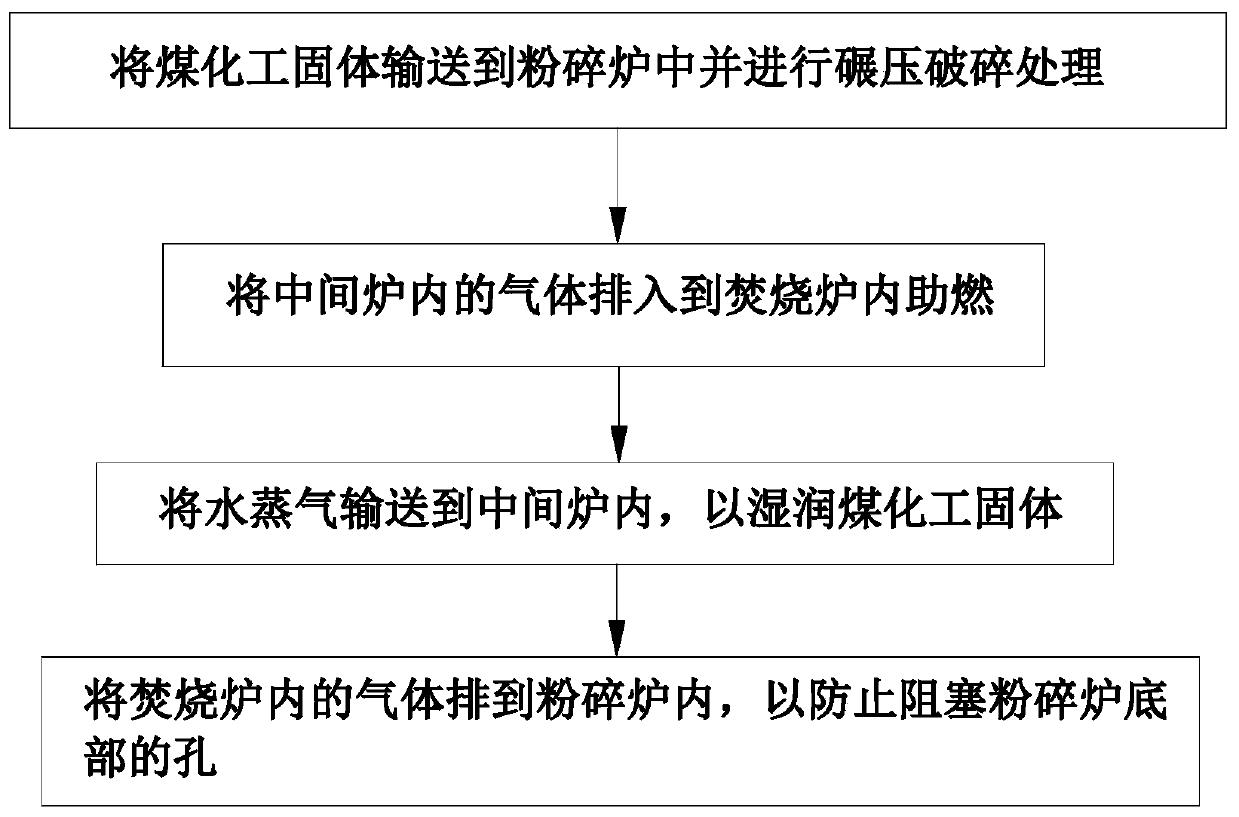

A kind of coal chemical industry solid slag reuse method

ActiveCN108895461BIncrease combustionAchieve reuseIncinerator apparatusCombined combustion mitigationCombustionWater vapor

The invention belongs to the field of coal chemical solid processing, and in particular relates to a coal chemical solid slag recycling method. The method includes step 1 of conveying coal chemical solids into a crushing furnace and performing crushing treatment; step 2 of discharging air in an intermediate furnace into an incinerator to assist combustion; step 3 of conveying vapor into the intermediate furnace to wet the coal chemical solids; and step 4 of discharging gas in the incinerator to prevent holes at the bottom of the incinerator from being blocked. According to the coal chemical solid slag recycling method, the coal chemical solids can be fully burned, heat generated by the combustion is utilized, and the method is an effective way to achieve the recycling of coal chemical solid resources and improve energy utilization rate.

Owner:绍兴绩家纺织有限公司

Biomass fuel combustion reaction box

PendingCN109297011AIncrease combustionEquilibrium Combustion Reaction ConditionsSolid fuel combustionCombustion apparatusTemperature controlCombustion

The invention discloses a biomass fuel combustion reaction box which comprises a combustion box body, a plurality of conveying pipes and an output pipe, wherein the conveying pipes and the output pipeare arranged on the combustion box body; the conveying pipes are distributed on the side wall of the combustion box body; and a temperature control valve is arranged on each conveying pipe. Through the arrangement of the conveying pipes on the side wall of the combustion box body, fuel can be in sufficient contact with combustion gas immediately after entering the combustion box body, and the combustion degree of the fuel can be improved; and the fuel is input as required according to the temperature of each point in the combustion box body, so that the combustion reaction conditions in the combustion box body can be balanced, the combustion gas in the combustion box body can be uniformly and stably distributed in the combustion box body, and the combustion sufficiency can be further guaranteed.

Owner:盐城项果科技有限公司

A system and method that uses industrial amateur heat associations to dispose of waste

ActiveCN114110608BIncrease combustionBurn fullyExhaust apparatusRotary drum furnacesFlue gasProcess engineering

The invention discloses a system and a method for co-processing waste by utilizing industrial waste heat, and belongs to the technical field of co-processing waste. It includes a pre-disposal furnace and a clinker calcination system for burning and disposing of waste. The tertiary air from the grate cooler is introduced into the pre-disposal furnace, and the top of the pre-disposal furnace is connected to the upper end of the calciner through a flue gas channel. The pretreatment furnace is provided with an oxygen-enriched air inlet; the oxygen-enriched air inlet faces the main combustion area of the pretreatment furnace and forms an included angle of 30°-45° with the level of the pretreatment furnace. The present invention adopts oxygen-enrichment to achieve an oxidative environment, allowing waste particles to be fully burned; and the excess oxygen-enriched gas is passed into the decomposition furnace through a flue gas pipeline, thereby providing favorable conditions for suppressing the production of sulfur dioxide in the decomposition furnace.

Owner:崇左南方水泥有限公司

Circulating combustion device of methanol automobile

InactiveCN107191247AIncrease combustionImprove utilization efficiencyHuman health protectionElectrical controlAir filtrationCombustion

The invention provides a circulating combustion device of a methanol automobile. The circulating combustion device comprises an engine, a methanol box, an air inlet pipe, an exhausted air filtering device, a methanol separating chamber, an air filtering device and a linkage mechanism; the engine is used for combusting methanol to supply energy; the methanol box is connected with a fuel air inlet of the engine and provided with a switch; the air inlet pipe is connected to an air inlet of the engine and provided with a switch; the exhausted air filtering device is used for filtering out solid particles in gas, connected to an exhaust outlet of the engine and provided with a switch; the methanol separating chamber is used for separating methanol from other gases, connected to the air inlet pipe and the exhausted air filtering device and provided with an exhaust outlet; the air filtering device is used for removing dust particles in air through filtering; the linkage mechanism is connected to all above-mentioned switches, driven by the engine and used for controlling the switches to be switched on or switched off according to the running condition of the engine. The circulating combustion device has the advantages of being high in energy resource utilization rate, free of pollution, clean and environmentally friendly.

Owner:苏州克莱尔环保科技有限公司

Gas-assisted atomizing nozzle of atomization hyperviscous fluid

The invention relates to a gas-assisted atomizing nozzle of atomization hyperviscous fluid. The gas-assisted atomizing nozzle of the atomization hyperviscous fluid comprises a nozzle, a current-limiting cone plate,a gas-liquid distributor and a locking nut. The gas-liquid distributor comprises an atomizing gas pipeline and a hyperviscous fluid pipeline, wherein the atomizing gas pipeline is placed at the center and the hyperviscous fluid pipeline is coated on the atomizing gas pipeline. The locking nut tightly compresses on the outlet end of the gas-liquid distributer in a sealing mode and the nozzle tightly compresses the current-limiting cone plate on the outlet end of the atomizing gas pipeline. A plurality of air holes are formed in the current-limiting cone plate. The gas-assisted atomizing nozzle of the atomization hyperviscous fluid provides a gas assisted atomizing nozzle, strengthens mix between the gas and the liquid and effectively improves atomizing quality. When the gas-assisted atomizing nozzle of the atomization hyperviscous fluid is used for burning atomizing hyperviscous combustible liquid of a combustion device, ignition time can be greatly shortened, and when matched with a common air regulator, combustion efficiency and after-combustion degree of the combustible liquid are greatly improved.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH +1

Selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy

A selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy distributes biomass fuel at the core part of a mixture before sintering by two-stage granulation to properly reduce the burning rate of the biomass fuel and improve the burning degree of the biomass fuel, so as to achieve the purpose of enhancing biomass energy sintering, wherein the two-stage granulation comprises the steps of: firstly preparing biomass fuel, iron ore and quicklime in a granulating disc into mother nuclide with the granularity of 3-5mm, then mixing with iron ore, limestone, dolomite, quicklime, sinter returns and coke powder (or coal), and carrying out second granulation for 3-6min in a granulating drum, so as to obtain the mixture before sintering with the biomass fuel wrapped at the core part. By selective distribution technology of the biomass fuel, the biomass fuel can be applied to iron ore sintering so as to successfully substitute for 10-60% of coke powder and not to influence the yield and quality indexes of the sintered ore.

Owner:CENT SOUTH UNIV

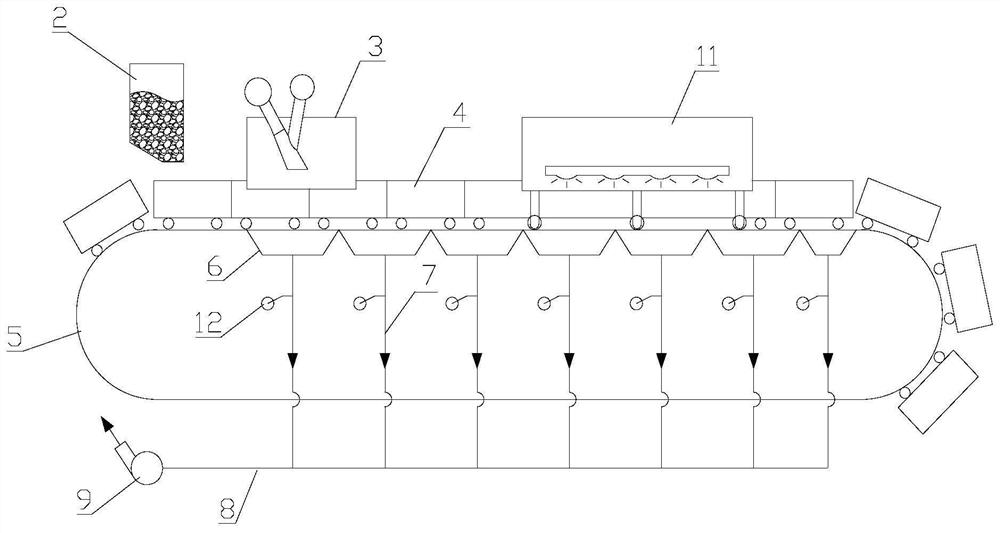

Oxygen-enriched and low-CO sintering method, oxygen-enriched and low-CO sintering machine and control method thereof

ActiveCN113251793BEmission reductionIncrease combustionMaintainance of heating chambersCharge treatment typeFlue gasFlue

The invention discloses an oxygen-enriched and low-CO sintering method, an oxygen-enriched and low-CO sintering machine and a control method thereof. The oxygen-enriched and low-CO sintering machine includes: rails, trolleys, distributing machines, and bellows, and further includes: a CO concentration detection device , located in each of the bellows or branch flues; the oxygen-enriched air spraying device, located above the sintered material surface of the trolley, is configured to be able to move back and forth and adjust the length of the oxygen-enriched injection section, so as to be located at its oxygen-enriched Oxygen is sprayed on the surface of the sintered material in the injection section; the control device is used to control the injection amount of the oxygen-enriched air spraying device and the position and length of the oxygen-enriched injection section. The sintering method and sintering machine aim at the problems of large amount of flue gas treatment and high cost in the removal of CO from the existing sintering flue gas end. By spraying oxygen-enriched air to different areas of the sintering material surface, the full combustion of fuel is promoted, and the sintering process is reduced. The generation of CO can be controlled to realize the treatment of CO pollutants in sintering flue gas.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Device and method for producing sodium metabisulfite from sulfur slag

ActiveCN112357935AImprove finenessIncrease combustionEnergy inputAlkali metal sulfite preparationCooling towerSodium metabisulfite

The invention discloses a device and method for producing sodium metabisulfite from sulfur slag, and relates to the technical field of pyrophorous chloride production.The device specifically comprisesa crusher and a cyclone separator, the output end of the crusher is connected with a rotary furnace through a metering type conveying belt, and the cyclone separator is connected with the output endof the rotary furnace through a pipeline; the output end of the secondary waste heat boiler is connected with a cooling tower through a pipeline, and the output end of the washing tower is connected with a drying tower through a pipeline. According to the device and method for producing sodium metabisulfite from sulfur residues, sulfur filter residues are processed to replace refined sulfur for sodium metabisulfite production, waste is turned into wealth, so that the sodium metabisulfite production cost is reduced, heat generated during sulfur filter residue production can be recycled throughthe first-stage waste boiler and the second-stage waste boiler, resource waste is avoided, and through the cooling tower, the washing tower, the drying tower electric demister and the compressor, theSO2 gas concentration can be stabilized, the gas yield can be increased, and SO2 flue gas impurities can be reduced, so that the quality during sodium metabisulfite production is improved.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com