Combustion device for preheating and combusting sprayed-up backflow on nozzle with uniform mixing and distribution of coal gas and air

A combustion device and a technology of returning a combustion chamber, which are applied in the combustion using lump fuel and gaseous fuel, the combustion using liquid fuel and gaseous fuel, the combustion using gaseous fuel and powder fuel, etc., can solve the problem of low combustion temperature and low heat. Problems such as unstable combustion of gas and weak combustion intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

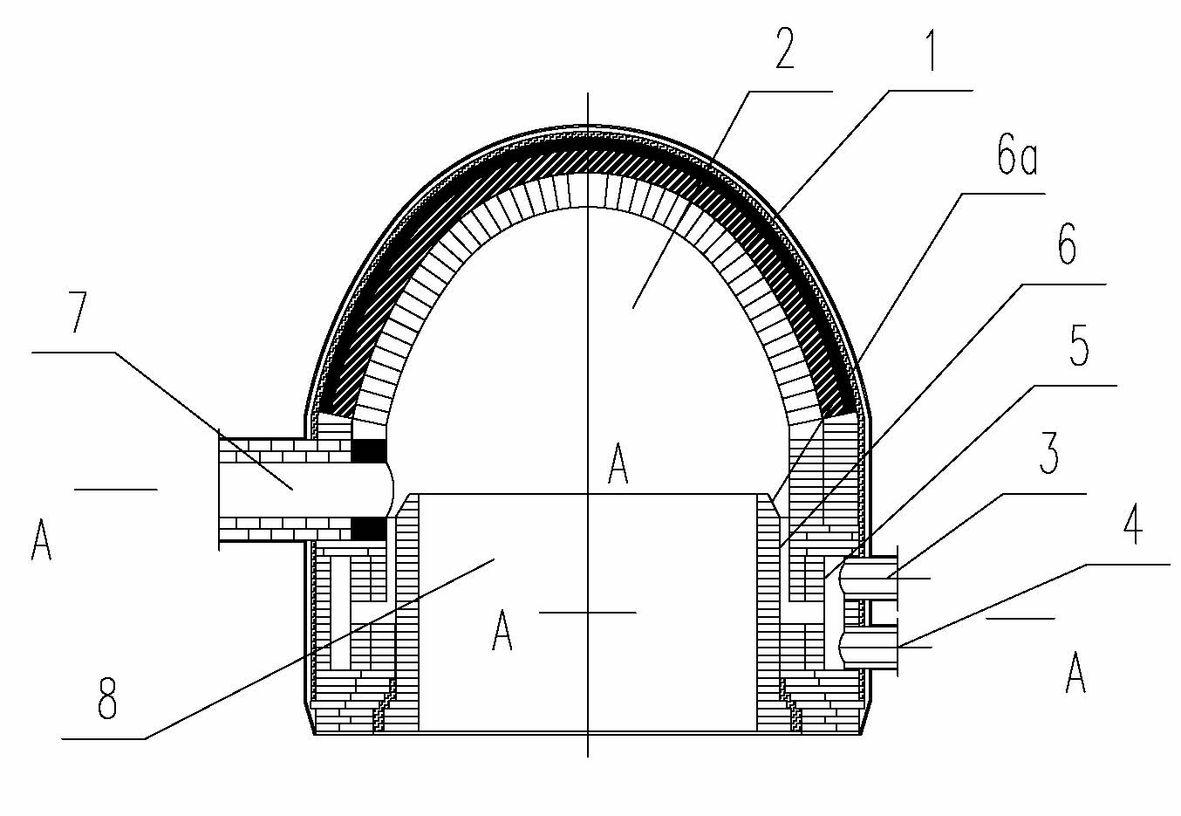

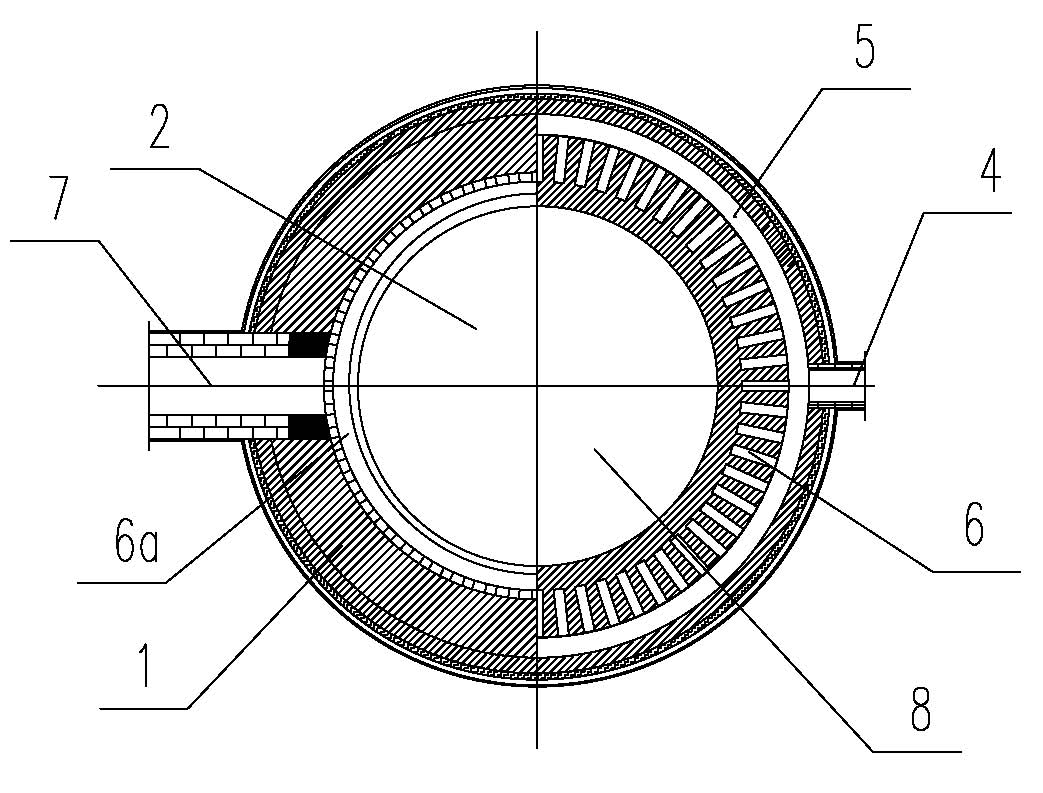

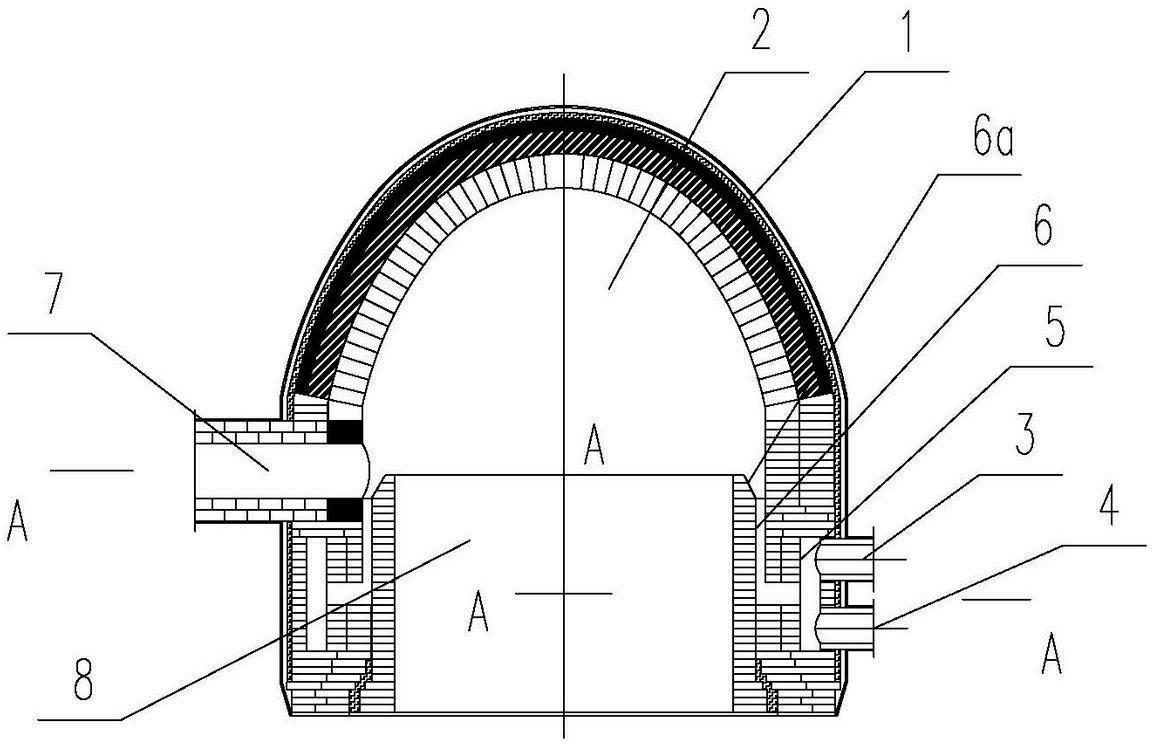

[0009] Such as figure 1 , figure 2 As shown, the present invention includes a combustion chamber wall 1, a recirculation combustion chamber 2, a gas intake pipe 3, an air intake pipe 4, a premixed ring 5 for gas and air, a premixed gas nozzle 6, and a premixed gas guide ring groove 6a , the airflow outlet pipe 7 and the combustion device airflow outflow section 8, the combustion chamber wall 1 is composed of the spherical vault above and the cylinder below, and the upper space of the combustion chamber wall is the backflow combustion chamber 2. A gas inlet pipe 3 and an air inlet pipe 4 are arranged perpendicular to the axis of the cylinder of the chamber wall 1, and the gas inlet pipe and the air inlet pipe are vertically or obliquely connected to the premixing ring 5 built in the combustion chamber wall 1 , the section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com