Biomass low-nitrogen combustion boiler based on local gasification technology

A low-nitrogen combustion and biomass technology, applied in the direction of controlled combustion, combustion methods, combustion equipment, etc., can solve the problems of low combustion efficiency of small biomass boilers and high emission of nitrogen oxides in flue gas, so as to reduce black smoke and improve combustion degree, the effect of promoting NOx content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

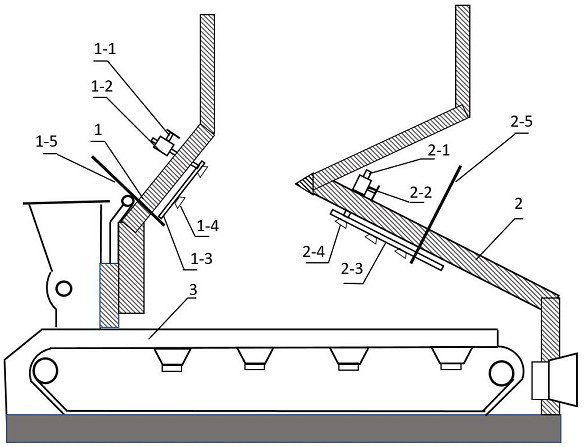

[0023] The present invention provides a biomass low-nitrogen combustion boiler based on partial gasification technology, including a front steam spray system and a rear steam spray system: wherein, the front steam spray system is located at the front arch 1 of the boiler, and the rear steam spray system is located at Boiler rear arch 2, both of which are connected to the heat exchange tube bundle / steam drum of the boiler. The front steam spray system is equipped with front valve 1-1, front air guide pipe 1-2, front distribution air pipe 1-3, front nozzle 1-4 and thermocouple 1-5; the rear steam spray system is equipped with rear valve 2-1 , rear air guide pipe 2-2, rear distribution air pipe 2-3, rear nozzle 2-4 and thermocouple B2-5.

[0024] The front arch 1 is equipped with 1 front nozzle 1-4, and the rear arch is equipped with 2 rear nozzles 2-4. The angle between the front nozzle 1-4 and the grate 3 is 70°; the angle between the rear arch nozzle and the horizontal grate ...

Embodiment 2

[0032] The invention provides a biomass low-nitrogen combustion boiler based on partial gasification technology, the difference is that the front arch 1 is provided with two front nozzles 1-4, the rear arch is provided with three rear nozzles 2-4, and the front nozzles 1-4 The included angle with the fire grate 3 is 85°; the included angle between the rear arch nozzle and the horizontal fire grate is 110°.

[0033] The working process includes the following steps:

[0034] (1) Thermocouple A1-5 and thermocouple B2-5 monitor the flue gas temperature in the furnace in real time;

[0035] (2) When the detected temperature in the furnace is 1000°C higher than the set temperature of the front arch 1, the front valve 1-1 of the front steam spray system is opened, and the water vapor passes through the front air guide pipe 1-2, the front air distribution pipe 1-3, and Spray atomized water vapor to the combustion area in the furnace through the front nozzle 1-4; when the detected tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com