Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

260 results about "Fibrous corn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

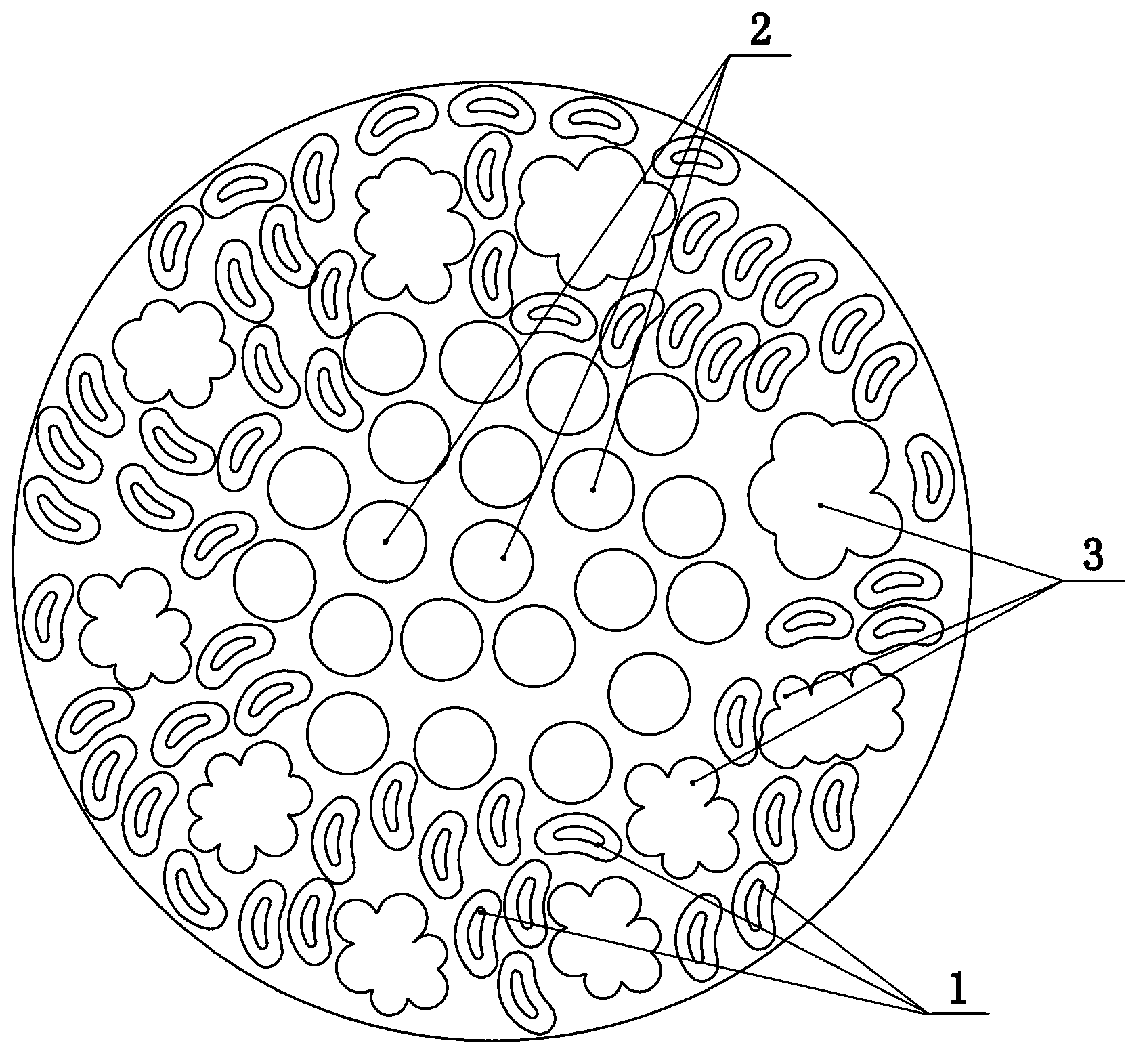

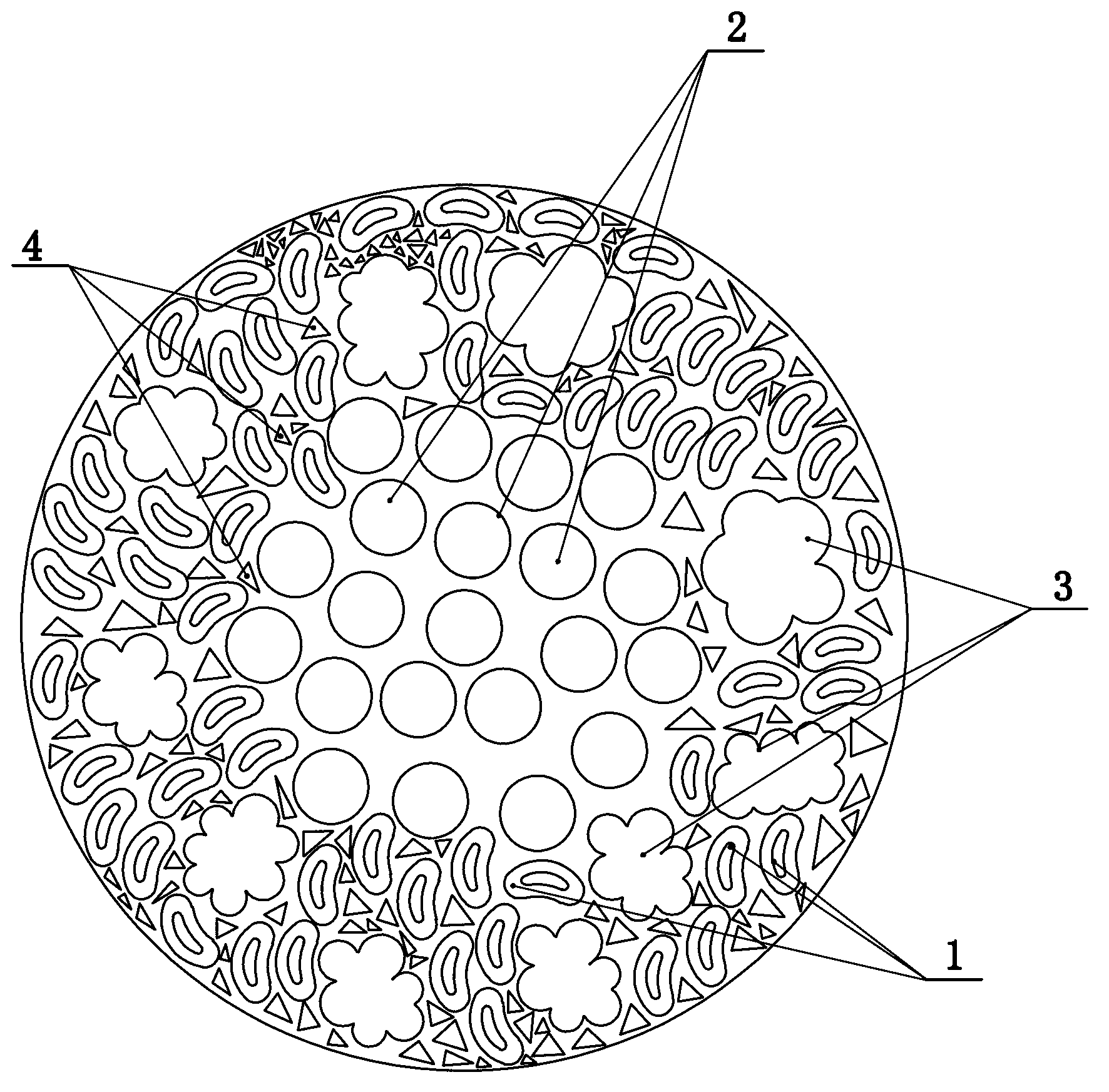

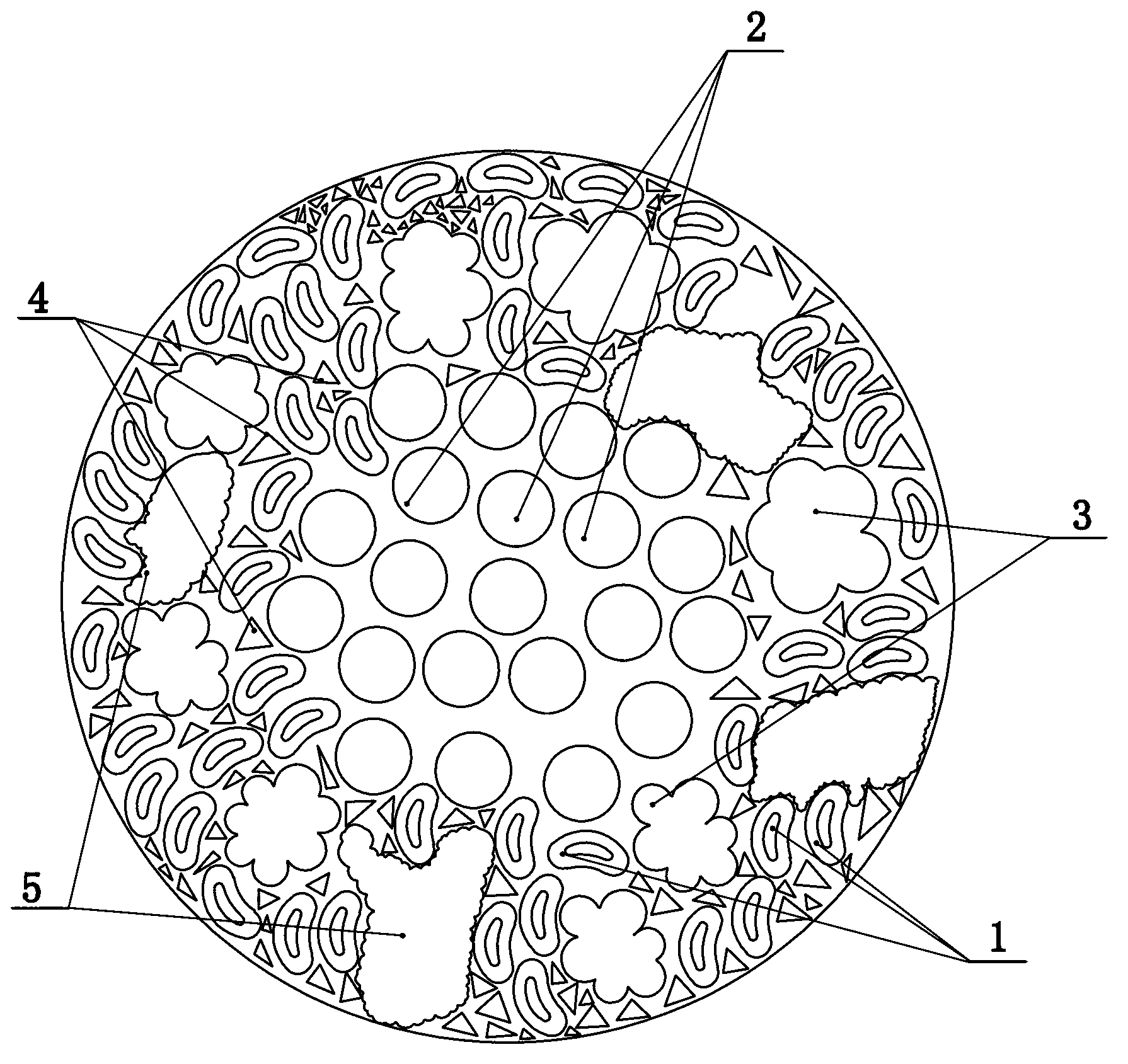

The structural composite is prepared by mixing the fibrous corn component with a polymer matrix, laminating the mixture, and applying heat and pressure.

Fermented feed additive, preparation method and application

ActiveCN102550815ASlow down digestionPromote digestion and decompositionFood processingAnimal feeding stuffMonosodium glutamateBacillus licheniformis

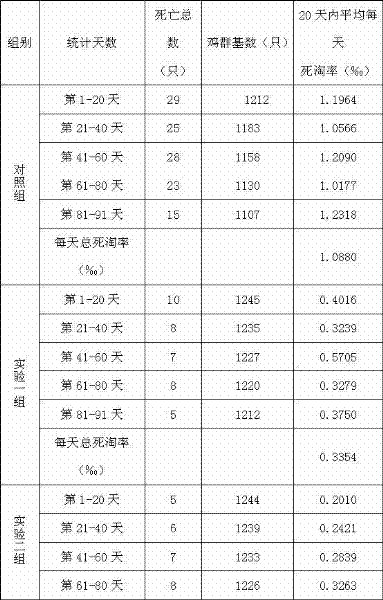

The invention discloses a fermented feed additive, a preparation method and application thereof. The fermented feed additive is prepared by fermenting mixed strains and mixed auxiliary materials consisting of monosodium glutamate protein, bean pulp, bran, cottonseed meal, corn fibers, rice bran and powdered rice hulls, wherein the mixed strains are obtained by mixing activated strains of lactobacillus acidophilus, lactobacillus planetarium, lactobacillus casei, saccharomyces cerevisiae, bacillus subtilis and bacillus licheniformis in a proportion of (1-5): (1-5): (1-5): (1-5): (1-5): (1-5); and the dosage of the fermented feed additive is 5 to 100 percent of the weight of the animal feed when used for the animal feed. According to the fermented feed additive, the bean pulp, the bran, the cottonseed meal and other raw auxiliary materials are sufficiently utilized, so that the food consumption in the animal feeding process is reduced; the fermented feed additive can be used to partiallyor completely replace the animal feed, and antibiotic medicaments can be reduced or prevented from being used; and no medicament is left, so that the feeding cost of farmers is reduced.

Owner:WEIFANG ZHONGKEJIAYI BIO FODDER TECH

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

Production method of corn fiber, bamboo fiber and cotton fiber blending pant fabric

InactiveCN101775686AEasy to weaveHas natural elasticityBiochemical fibre treatmentSingeingYarnBreaking strength

The invention relates to a corn fiber, bamboo fiber and cotton fiber blending pant fabric and a production method thereof. The pant fabric belongs to a woven fabric which is characterized by a yarn material and is produced by blending and weaving the following raw material fibers by weight percent: 20 to 30 percent of corn fiber, 40-51 percent of bamboo fiber and 20-30 percent of cotton fiber. The production method comprises three production process steps of spinning, weaving and dyeing and finishing. The invention provides the ideal corn fiber, bamboo fiber and cotton fiber blending pant fabric which also has natural elasticity and does not deform on the premise of keeping all natural ecological functions and good properties of the corn fiber, the bamboo fiber and the cotton fiber and is easy to weave and the production method thereof. The invention solves the problem that corn fiber weaving process has strict requirements, broken ends are increased because the single-fiber breaking strength of the bamboo fiber is lower and the cotton fiber has lower rebound resilience, and fabrics are easy to crinkle and do not resist mycete. The invention is especially suitable for pant fabric. Resources can be recycled, and thereby the pant fabric is beneficial to ecological environment protection.

Owner:青岛奈琦尔生物科技有限公司

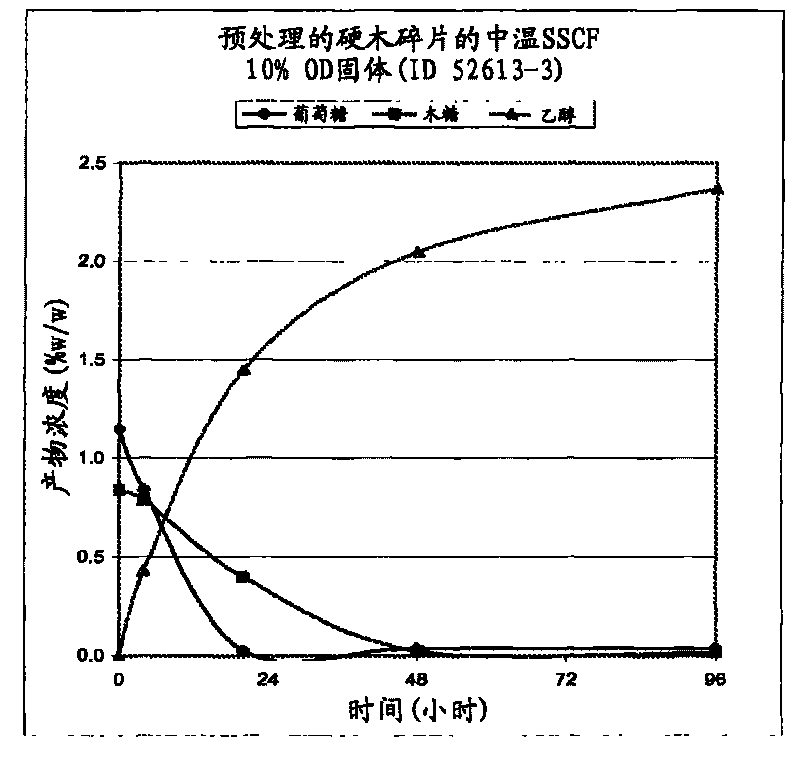

Combined thermochemical pretreatment and refining of lignocellulosic biomass

InactiveUS20100285534A1Increased ethanol yieldReduce the amount requiredPretreatment with water/steamBiofuelsCelluloseFiber

One aspect of the present invention relates to a method of processing lignocellulosic material, comprising initial steam pretreatment to give pretreated lignocellulosic material with an average particle size, followed by refining to give refined lignocellulosic material with an average particle size, wherein the average particle of the pretreated lignocellulosic material is greater than the average particle size of the refined lignocellulosic material. In certain embodiments, the lignocellulosic material is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugar cane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp fiber, sawdust, hardwood, and softwood.

Owner:MASCOMA CORPORATION

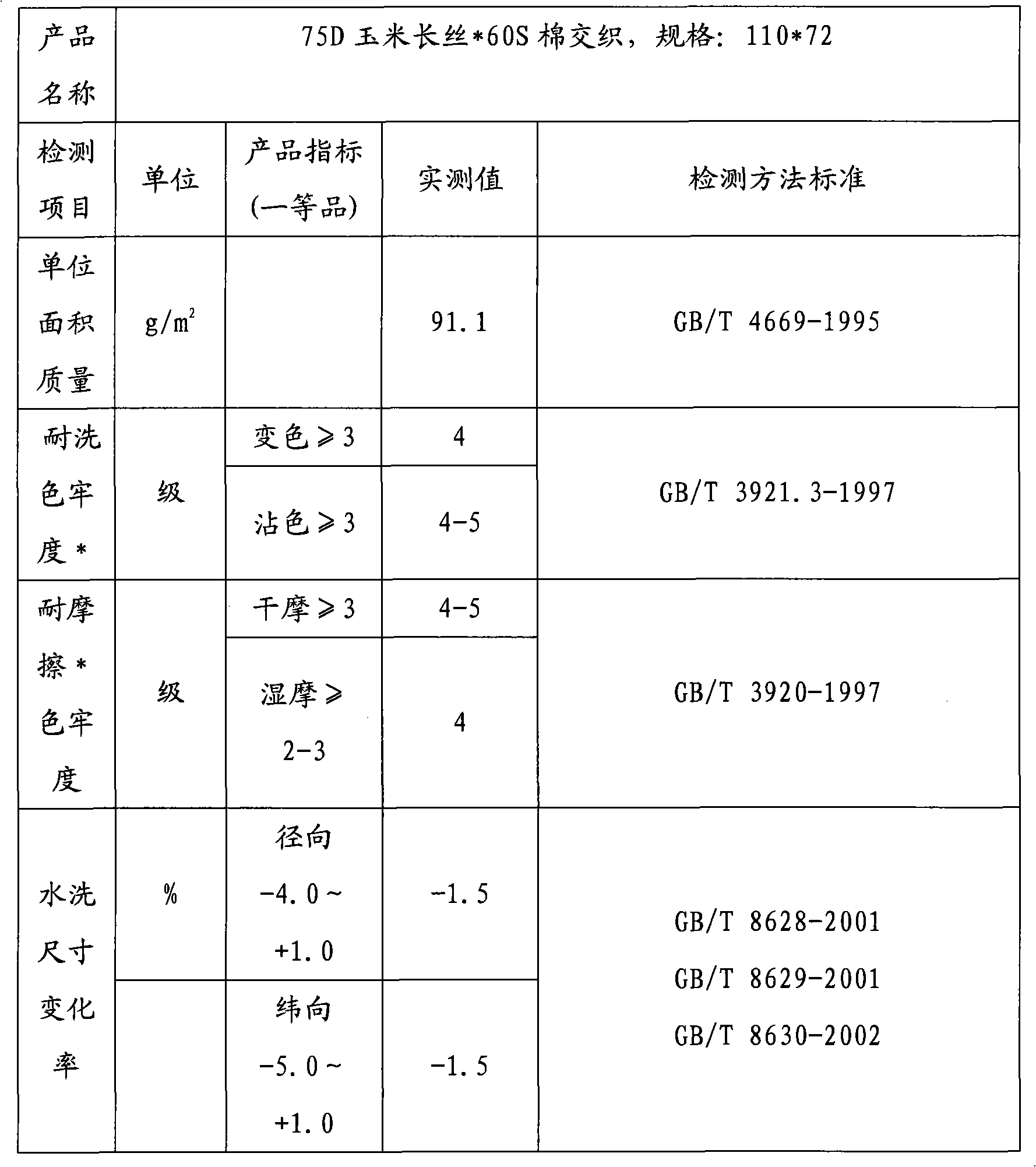

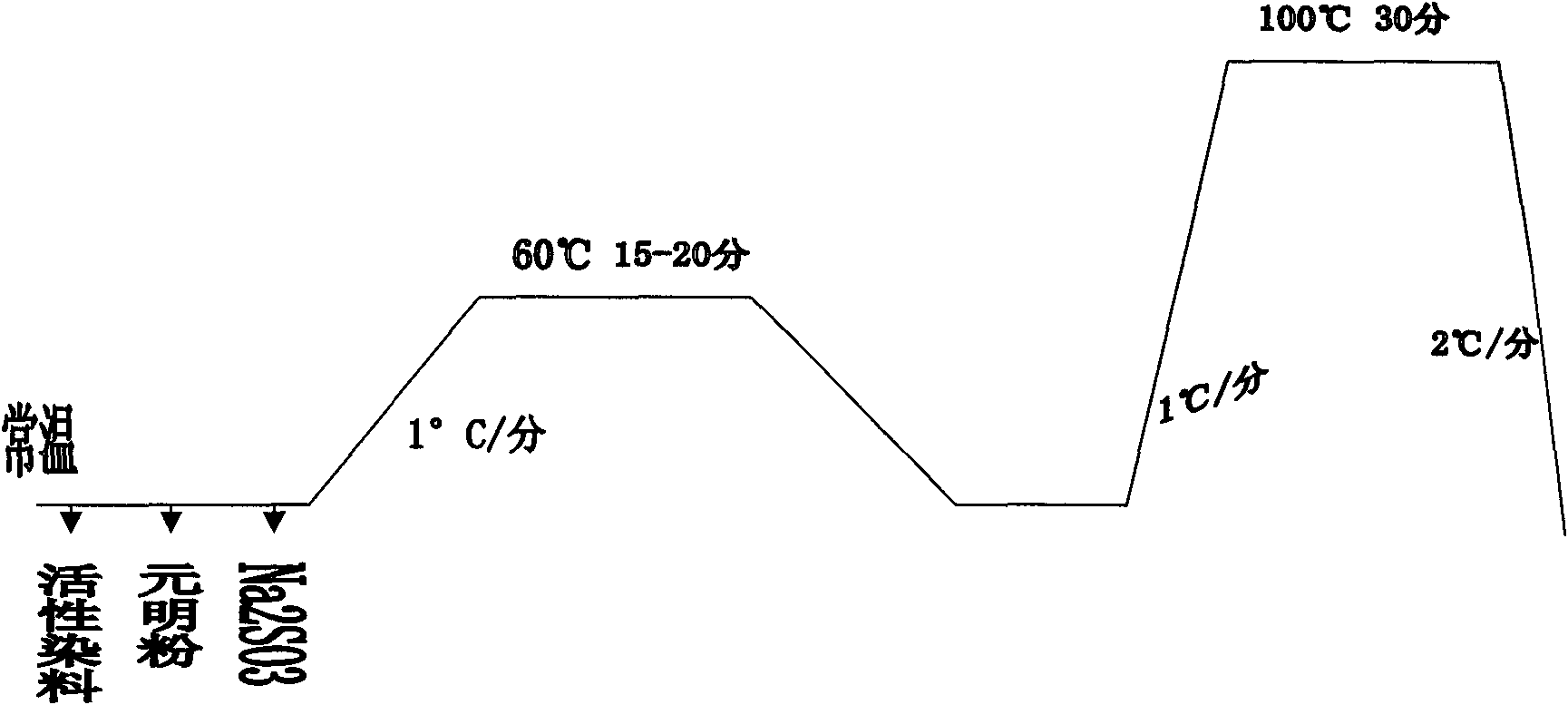

Dyeing and finishing process of corn fibers and cotton blending and mixed fabrics

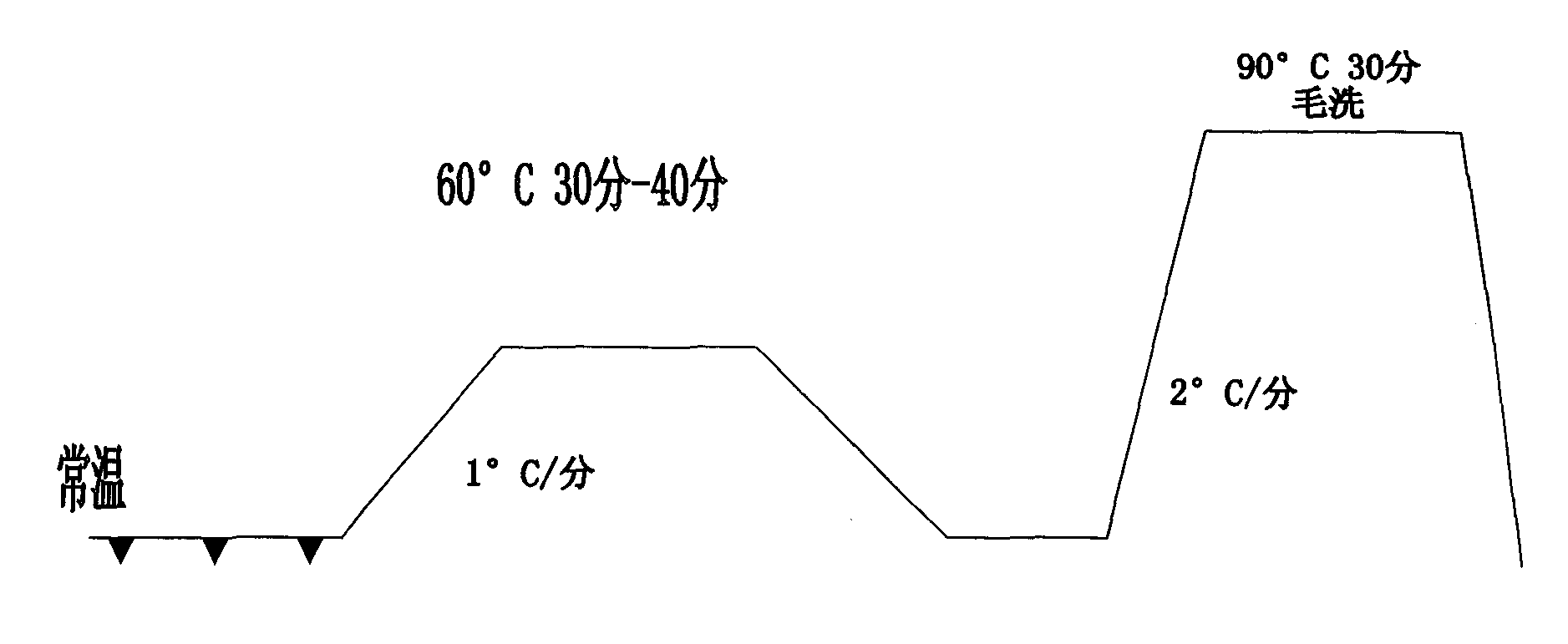

ActiveCN101671947ASufficient sourceNo need for petrochemical resourcesBiochemical fibre treatmentHeating/cooling textile fabricsDisperse dyeDying processes

The invention discloses a dyeing and finishing process of corn fibers and cotton blending and mixed fabrics, comprising the following steps: end stitching of greige cloth, pre-setting, pre-treatment,dyeing, dehydration, post finishing, and warehouse entry inspection. In the pre-setting process, the temperature is 120-130 DEG C and the time is 30-45 minutes; in the pre-setting process, the presetfabrics are placed in an overflow dying machine to conduct desizing and remove the hairiness on the surface of the fabrics; in the dying process, the corn fibers adopt middle temperature type and lowtemperature type dispersing dyes to conduct dying; and in the post finishing process, the dyed fabrics are placed in a 8-12g / L of hydrophilic amino-silicone softener for padding, and then the padded fabrics are dried and stentered and set at 100-120 DEG C. The dyeing and finishing process of corn fibers and cotton blending and mixed fabrics has good coloring rate, ensures the strength and feel ofcorn fibers, and also has significant impact on the industrial development of the textile industry.

Owner:安徽三宝棉纺针织投资有限公司

Corn fibre and polynosic fibre blended fabric and manufacturing technique thereof

The invention relates to a zein fiber and Richcel fiber blended fabric and a manufacturing technique thereof, wherein, the fabric adopts zein fiber and Richcel fiber blended yarns for weaving; blended proportion of the blended yarns is that: zein fiber to Richcel fiber is equal to 30-70 to 70-30; weave structure of the fabric is any one among plain weave, satin, twill or jacquard weave. The technique of the invention adopts special technological methods in procedures like spinning, slashing, denting, weaving and so on. The invention has the advantages that: firstly, two environment friendly fibers are reasonably utilized, and the fabric integrates advantages of good elasticity, antipilling, easy dyeing, non-inflammability and good luster and drapability of the two fibers; secondly, serviceability of the fabric is good, and the fabric has the characteristics of inability of stimulating human skin, good ventilation property, good wrinkle resistance and easy-care property, and uvioresistant property; thirdly, the manufacturing technique is improved and innovated; effective technique is provided for blended weaving of the two fibers; an ideal high grade product is provided for the society; the fabric has good social benefit and economic benefit.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Medium capable of cultivating aquatic benthon and proliferation water grass and its application method

ActiveCN102550879AImprove the cultivation standardPromote reproductionClimate change adaptationAgricultural fishingCelluloseAquatic animal

Owner:张家港鸿卿生物科技有限公司

Method for processing multi-fibre spun yarn and multi-fiber spun yarn processed through method

The invention relates to a method for processing a multi-fibre spun yarn. The method comprises the procedures of carding-blowing, drawing, roving, fine spinning and spooling, wherein the carding-blowing procedure comprises the step of binning cotton fibre, polyester fibre, viscose fibre and other functional fibre on a cotton set, wherein the content of the cotton fibre accounts for 10-75 percent of the total mass; the content of the polyester fibre accounts for 25-90 percent of the total mass; the contents of the polyester fibre and the viscose fibre are greater than 0; the content of the other functional fibre is greater than or equal to 0; the other functional fibre is one or more of nandina fibre, soybean fibre, zein fibre, wheat fibre, aloe fibre, pearl fibre and milk fibre; the linear density of the cotton fibre is 1.56-1.67 dtex, and the length of the cotton fibre is 28-30 mm; the linear density of the polyester fibre is 0.9-1.33 dtex, and the length of the polyester fibre is 38 mm; the linear density of the viscose fibre is 1.56-1.67 dtex, and the length of the viscose fibre is 35-38 mm; and the linear density of the other functional fibre is 1.56-1.67 dtex, and the length of the other functional fibre is 35-38 mm. The multi-fibre spun yarn manufactured according to the technical scheme provided by the invention has the effect of fusing all kinds of functional fibre to give a play to the advantages of the functional fibre.

Owner:浙江重盛家纺科技有限公司

Combined thermochemical pretreatment and refining of lignocellulosic biomass

One aspect of the present invention relates to a method of processing lignocellulosic material, comprising initial steam pretreatment to give pretreated lignocellulosic material with an average particle size, followed by refining to give refined lignocellulosic material with an average particle size, wherein the average particle of the pretreated lignocellulosic material is greater than the average particle size of the refined lignocellulosic material. In ceratin embodiments, the lignocellulosic material is selected from the group consisting of grass, switch grass, cord grass, rye grass, reedcanary grass, miscanthus, sugar-processing residues, sugar cane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp fiber, sawdust, hardwood, and softwoo.

Owner:MASCOMA CORPORATION

Multi-fiber blended fabrics

InactiveCN105780249AImprove comfortImprove practicalityWoven fabricsYarnPolyamideMoisture absorption

The present invention discloses multi-fiber blended fabrics, which comprise Nathan silk, bamboo fiber, acetate fiber, cuprammonium fiber, corn fiber, cotton fiber, conductive fiber, mercerising wool, terylene cotton, polypropylene fiber, polyamide, tencel, cashmere, plush and camel lint. The fabrics prepared thereby have the advantages of improved comfortableness and practicality because of the advantages of the multiple fibers. Excellent performance like antibiosis, deodorizing, moisture absorption, ventilating, health care, stable size, uniform color and soft feeling are provided. The fabrics are benefit for promoting blood circulation, accelerating metabolism, enhancing immunity, benefiting health and are comfortable for wearing.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

Green multifilament blended fabric

InactiveCN101275328AMeet the requirements of the yarn standardGood moisture absorption and air permeabilityWeft knittingWarp knittingFiberWrinkle skin

The inventive green multifilament blended facing material is formed by blended spinning of zein fibre, bamboo fibre and flaxrichce fibre, wherein, the chaine is same with the weft yarn, and the weight proportion of spinning raw material is 35-45 percent of zein fibre, 35-45 percent of bamboo fibre and 15-25 percent of flaxrichce fibre. The invention adopts a plurality of green fibres for blended spinning and interweaving, which sufficiently exerts the moisture absorption ventilating, peculiar silk like brightness, favorable reversion performance, wrinkle resistance, and pilling resistance of the zein fibre, and the favorable hydroscopicity , dyeability, soft comfortable hand feeling, and good drapability of the wood fiber, thereby the performance of various fibres is ascendency complementary, the spinning perfromance of fibre is increased, the brute force and quality of the yarns is improved; meanwhile the facing material is provided with features of favorable moisture absorption ventilating, comfort of wear, sliding feel well hand feeling, pendant dynamic, non electrostatic puzzle, good reversion perfromance and wrinkle resistance, etc.

Owner:SHANDONG QISAI TEXTILE

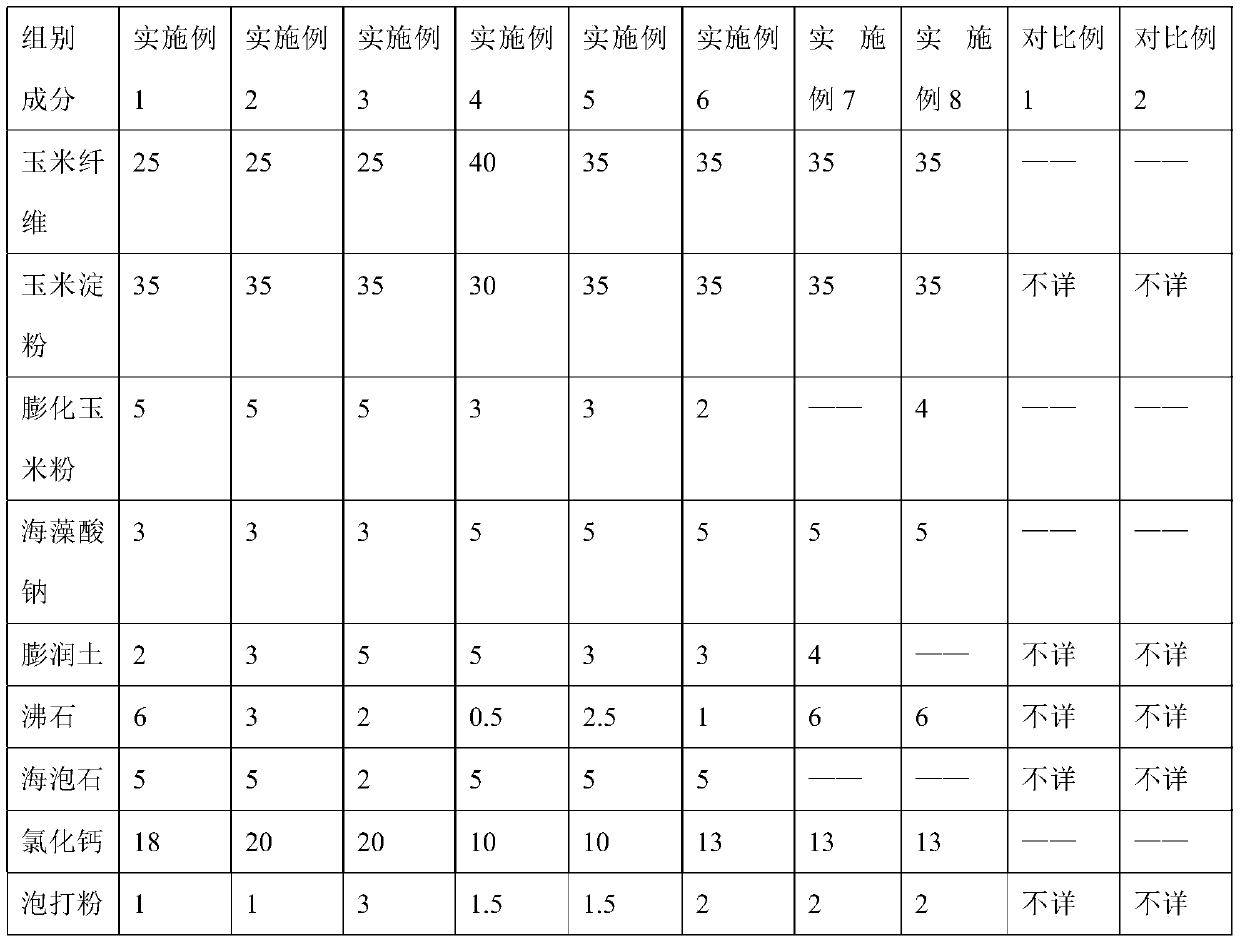

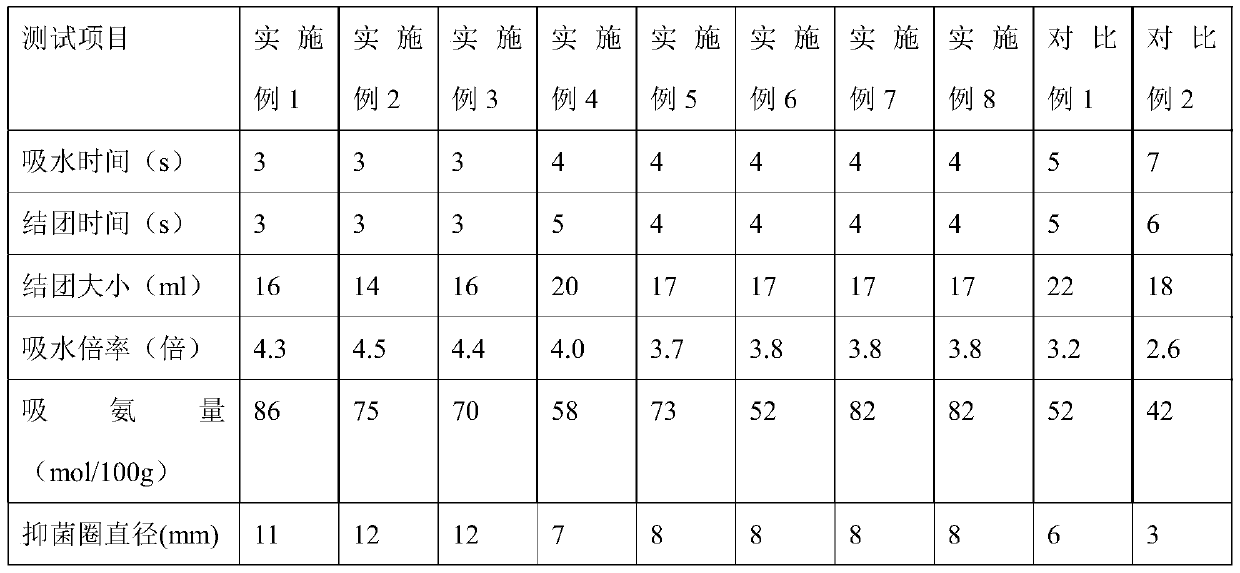

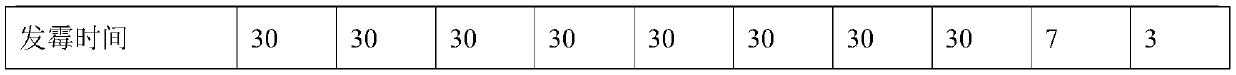

Natural plant fiber cat litter and preparation method thereof

The invention provides a natural plant fiber cat litter and a preparation method thereof and belongs to the field of pet products. The natural plant fiber cat litter is characterized by including, byweight part, 15-99 parts of corn fiber or sugarcane fiber, 0.000015-10 parts of zeolite, 0-60 parts of starch, 0-5 parts of extruded corn flour, 0-20 parts of sodium alginate, 0-3 parts of baking powder, 0-10 parts of sepiolite, 0-25 parts of calcium chloride and 0-10 parts of sodium bentonite. The natural plant fiber cat litter is mainly composed of the corn fiber or sugarcane fiber, which is lower in cost than pea fiber or soybean fiber required in conventional tofu cat litters, thereby saving cat keeping costs for consumers.

Owner:南京咕噜材料科技有限公司

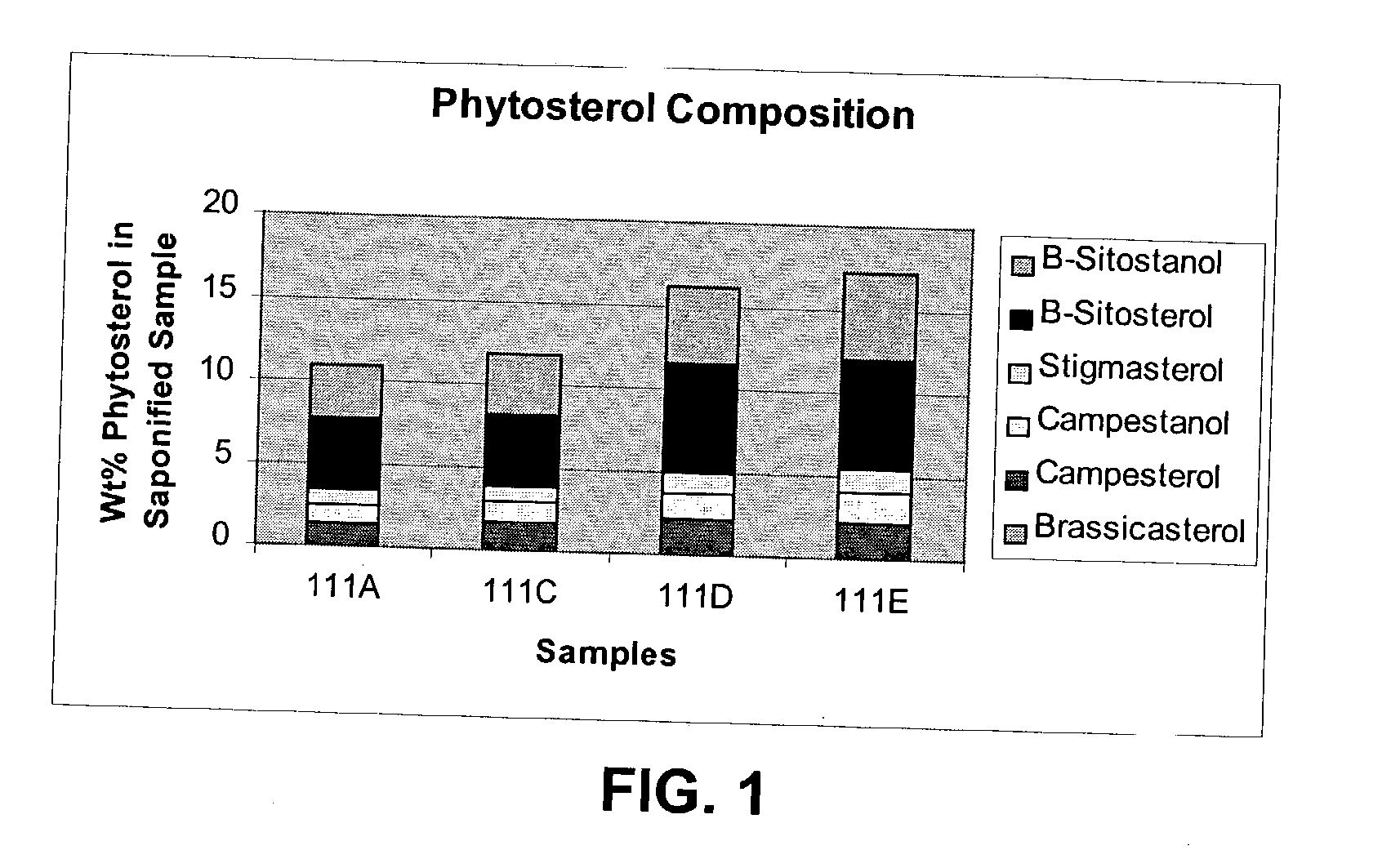

Extraction of phytosterols from corn fiber using green solvents

ActiveUS20030235633A1Reduce in quantitySave energyBiocideOrganic active ingredientsPlant sterolEthyl acetate

The present invention relates to the use of "green" or relatively benign solvents such as ethanol, ethanol / water, isopropyl alcohol, isopropyl alcohol / water, ethyl lactate, acetone, butanol, isoamyl alcohol, or ethyl acetate to extract phytosterols from wet corn fiber. The resulting oil product contains free phytosterols and free fatty acids.

Owner:ARCHER DANIELS MIDLAND CO

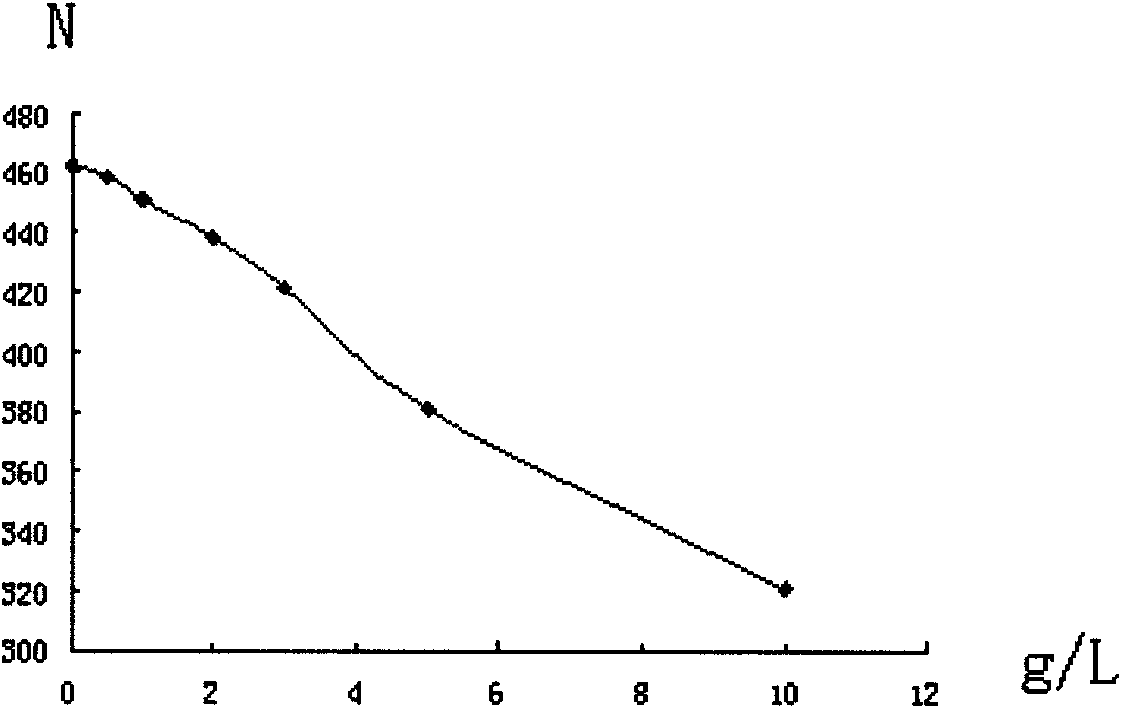

Corn fiber and regenerative hemp fiber blended antibacterial composite yarn and producing method thereof

InactiveCN101054747AGood moisture absorption and air permeabilityMoisture absorption and breathable retentionYarnYarnEngineering

The invention discloses a blended spinning antibacterial composite yarn of corn fiber and regeneration hemp fiber and manufacturing method thereof, which relates to spinning technique. According to technique scheme provided by the invention, the antibacterial composite yarn includes 30-60 quotient of corn fiber and 40-70 quotient of regeneration hemp fiber. The manufacturing method includes steps: a) treating the corn fiber by scotching, combing and pre-combining; b) treating the regeneration hemp fiber by scotching, combing and pre-combining; c) treating the pre-combined corn fiber and regeneration hemp fiber by strip combining, roving, spun yarn, drum winding and obtaining the blended spinning antibacterial composite yarn. The invention combines excellent characters of high strength and good shape keeping property of corn fabric, recuperates defects of bad overhanging property and bad shape keeping property of hemp fiber and regeneration hemp fabric, and captures problem of that hemp fiber can not be spun to thin yarn.

Owner:JIANGSU FUTENG TEXTILE +1

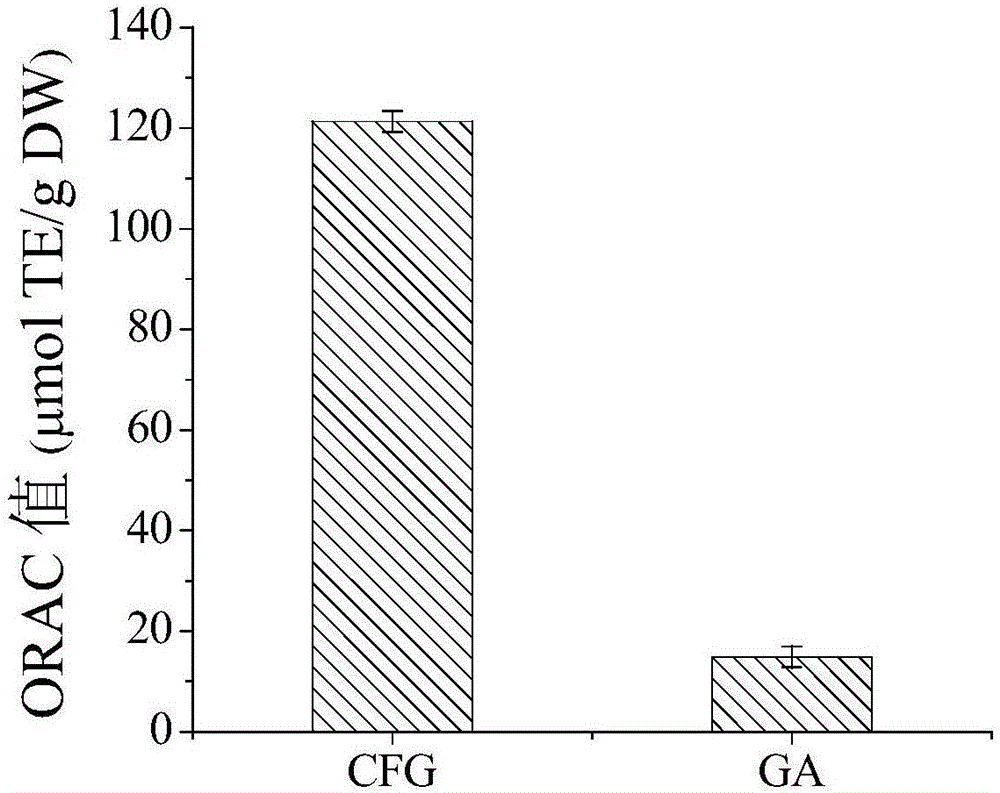

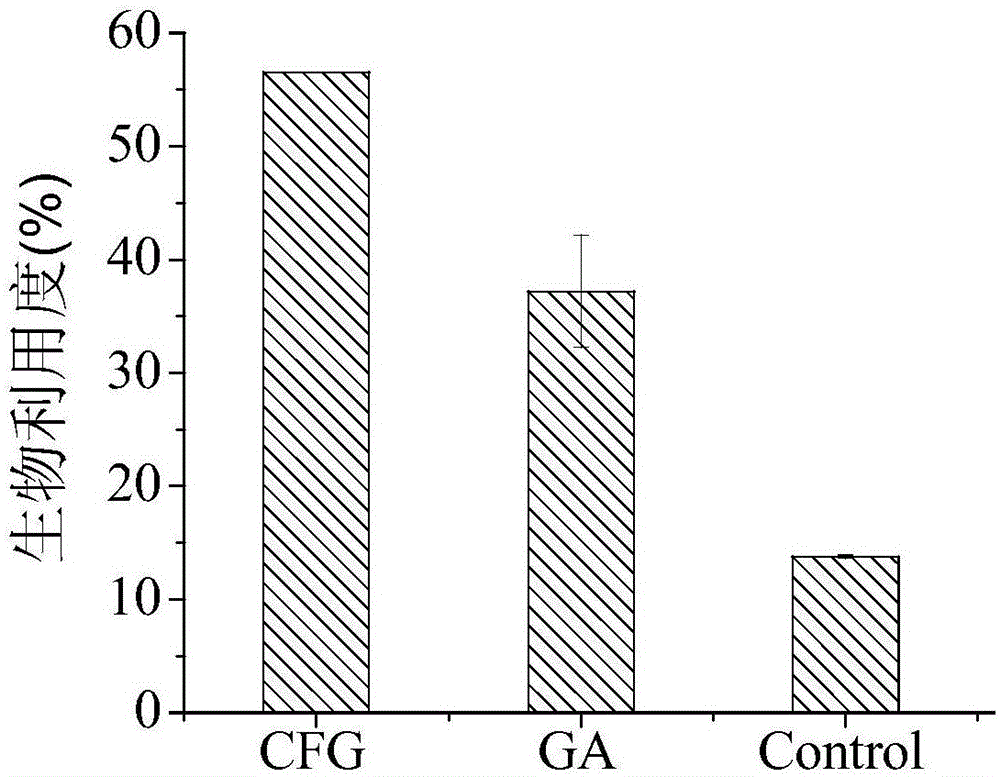

Preparation method of nano emulsion for improving bioavailability of xanthophyll

InactiveCN106690271AImprove stabilityImprove bioavailabilitySenses disorderHydroxy compound active ingredientsFiberOil phase

The invention discloses a preparation method of a nano emulsion for improving the bioavailability of xanthophyll. The method comprises the steps: firstly, preparing a corn fiber gum CFG, then dissolving the corn fiber gum CFG, citric acid and sodium benzoate in deionized water, and stirring slowly for 2-3 h, to obtain an aqueous phase; then adding xanthophyll to corn oil, and carrying out ultrasonic treatment to make the xanthophyll completely dissolved, to obtain an oil phase; mixing the oil phase and the aqueous phase, adding deionized water to quantify to 100%, homogenizing by a high-speed shear homogenizer, to prepare a crude emulsion, and carrying out high-pressure homogenization, to prepare the stable xanthophyll nano emulsion. The nano emulsion prepared by the method has the particle size in the range of 100-200 nm, has good storage stability, and has the xanthophyll embedding rate reaching 86%; the bioavailability of the xanthophyll in the emulsion is increased from 10% to 55%, and the efficacy of the xanthophyll in functional health food can be significantly improved.

Owner:SOUTH CHINA UNIV OF TECH

Environmental-friendly fiber cotton and preparation process thereof

InactiveCN102425037ANo pollutionMeet natureNon-woven fabricsAdhesivesEnvironmental resistanceCooking & baking

The invention discloses environmental-friendly fiber cotton and a preparation process thereof, in particular to a method for preparing the fiber cotton by mixing fiber with low melting point with corn fiber and soybean fiber and performing heat treatment and a product. The preparation process comprises the following steps of: preparing raw materials from 10%-30% of the fiber with low melting point and 90%-70% of one or two of corn fiber and soybean fiber through mixing; carrying out cutting, cotton carding, forming and hot baking adhesion on the prepared raw materials in sequence; carrying out pressing, rolling, rapid cooling and shaping simultaneously when the raw materials are still hot; and then cutting and packaging according to the requirements, wherein the temperature for hot baking shaping is 110-130 DEG C, and the adoption of air-laying and rapid cooling shaping technologies has an important significance in improving the quality of the fiber cotton. The corn and soybean fiber cotton disclosed by the invention can be biodegraded completely and comprehensively improve a fiber air-laid structure simultaneously, and the product can be naturally degraded under the action of microbes after being disused and is further different from chemical fiber cotton which needs to consume a large number of non-renewable petroleum resources and is still difficult to degrade, so that the fiber cotton disclosed by the invention is an ecological raw material with great development potentiality.

Owner:黄显飚

Benthic bait biological culture medium for breeding tubificidae and using method thereof

InactiveCN102524191AImprove the cultivation standardIncrease productionAnimal husbandryAquaculture industryCellulose

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Anti-wrinkle treatment process of wool and linen yarns

InactiveCN104695203AStrong water absorptionGood sweat absorptionVegetal fibresAnimal fibresPolymer scienceEthylic acid

The invention discloses an anti-wrinkle treatment process of wool and linen yarns. The anti-wrinkle treatment process comprises the following specific steps that 1, selected warp and weft yarns include, by mass, 32-38 parts of wool fiber, 24-34 parts of linen fiber, 9-11 parts of viscose, 7-13 parts of cotton fiber, 6-10 parts of chitosan fiber and the balance corn fiber, and the wool and linen yarns are dipped in a hydrogen peroxide solution to be treated; 2, the wool and linen yarns are dipped in a potassium permanganate solution to be treated; 3, the wool and linen yarns are treated in a solution comprising 0.3% of acetic acid and 0.2% of chitosan; 4, the wool and linen yarns are dipped in an organosilicon quaternary ammonium salt solution to be treated. The anti-wrinkle treatment process is easy to operate, low in treatment cost, good in anti-wrinkle effect, free of corrosion damage, and safe and environmentally friendly in the treatment process.

Owner:SUZHOU CHENHENG WEAVING

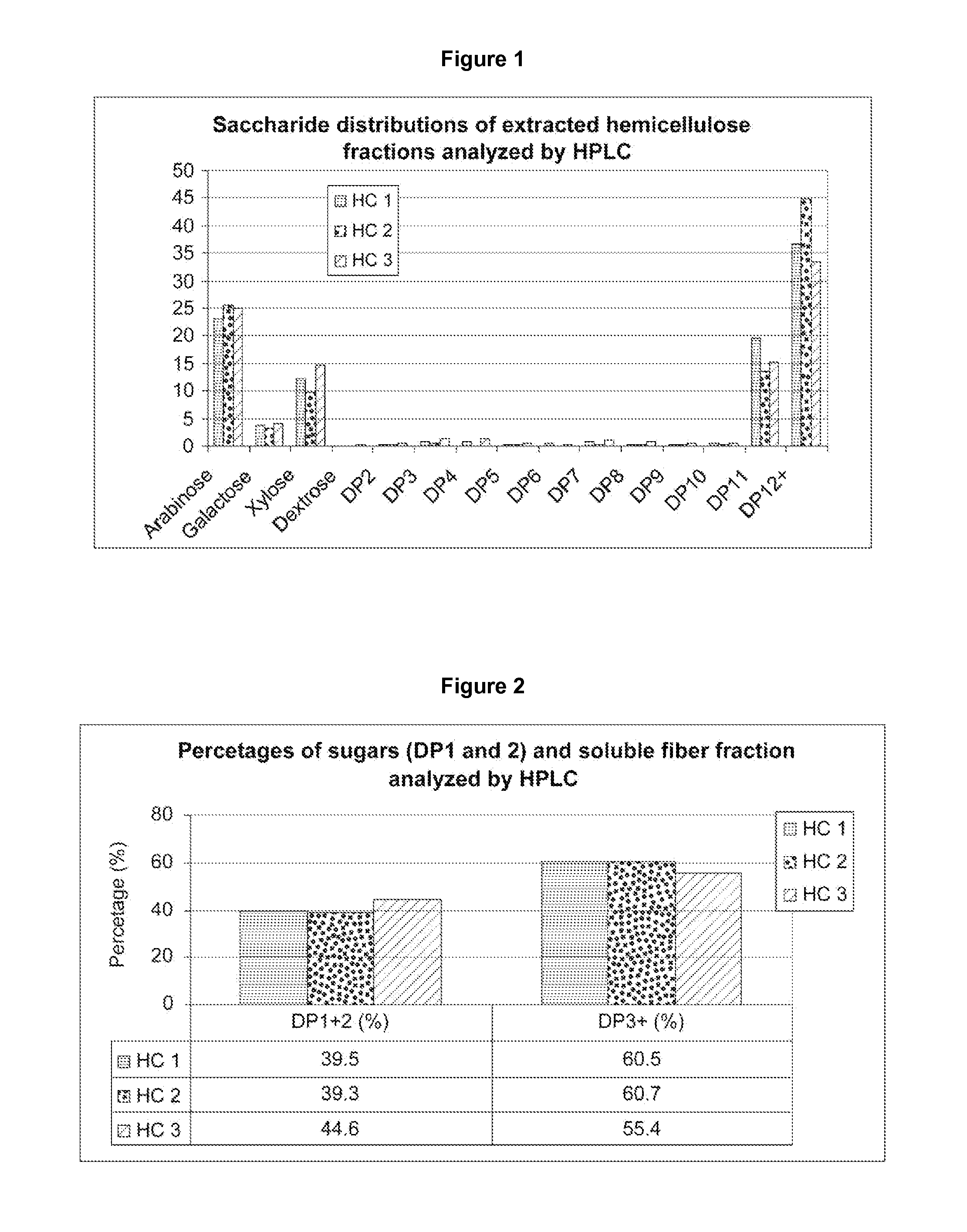

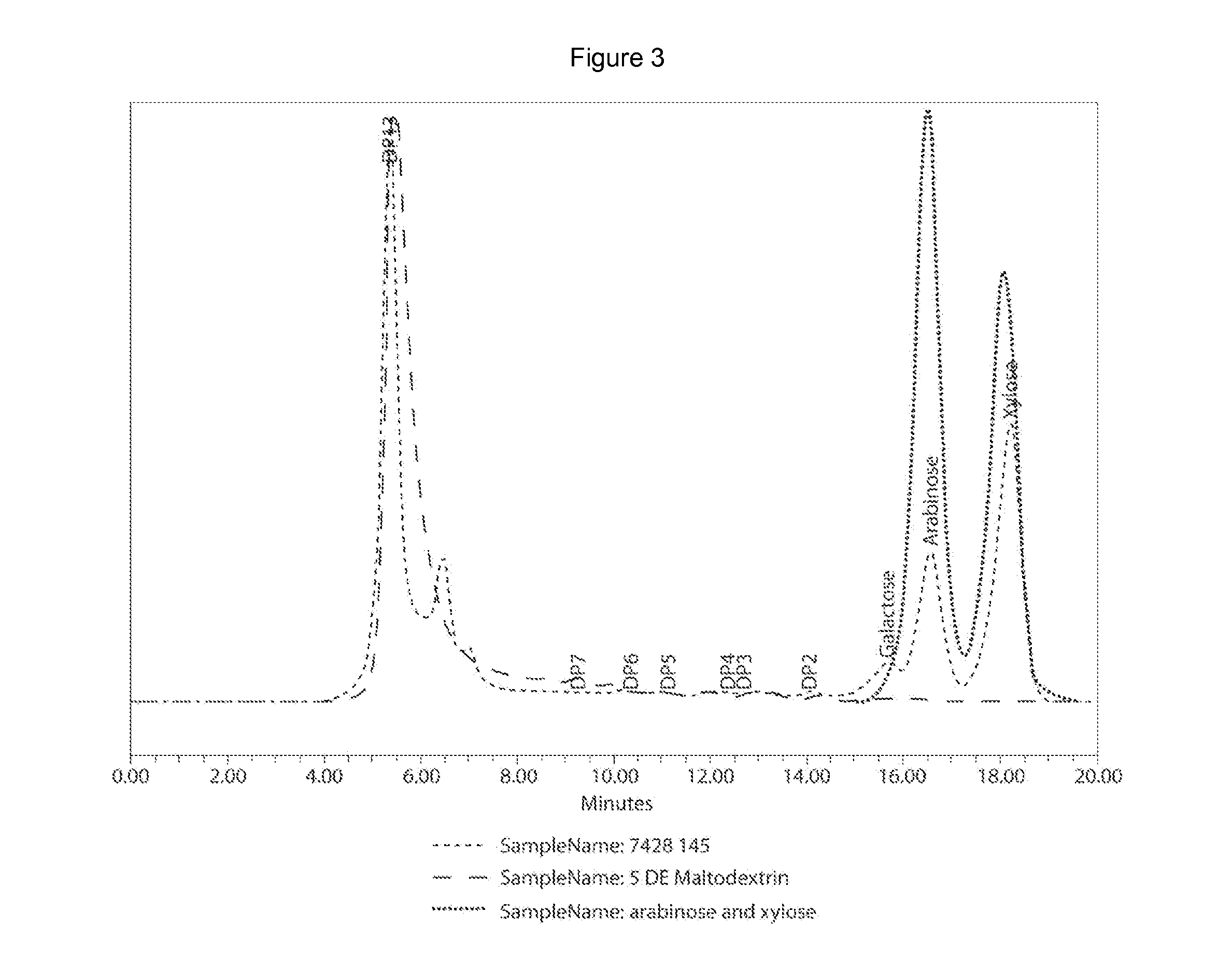

Process of extraction of hemicellulose from corn fiber

A process of separating one or more components of corn fiber that comprises contacting the corn fiber with an extraction fluid that comprises at least one weak acid, increasing the temperature of the resulting mixture of fiber and fluid to solubilize hemicellulose of the corn fiber into the fluid, cooling the mixture, and separating the cooled extraction mixture into a soluble fraction comprising dissolved hemicellulose and an insoluble fraction comprising cellulose.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

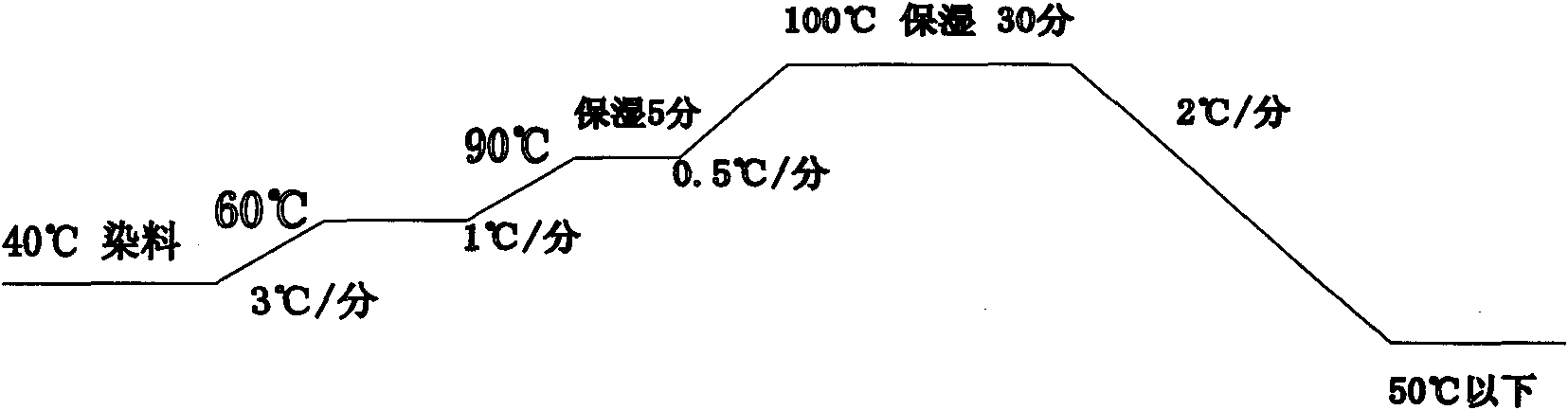

Zein fiber and bamboo fiber blended knitted fabric

InactiveCN101818405AEasy to weaveHas natural elasticityWeft knittingWarp knittingBreaking strengthEcological environment

The invention discloses a zein fiber and bamboo fiber blended knitted fabric, which is woven by blending zein fibers and bamboo fibers and is characterized in that: the knitted fabric comprises the following two fibers in percentage by weight: 40 to 45 percent of zein fibers and 60 to 55 percent of bamboo fibers; and the production method for the knitted fabric comprises three main production technical steps, namely spinning, weaving, and dyeing and finishing. The invention provides the zein fiber and bamboo fiber blended knitted fabric which has natural elasticity and good shaping performance and is easily woven on the premise of maintaining all the natural ecological functions and excellent performance of the zein fibers and the bamboo fibers, and the production method thereof. The problem of zein fiber weaving demanding process is solved; the defects that the strength of the bamboo fibers after moisture absorption is obviously reduced, the bamboo fibers easily have plastic deformation, the elasticity of the bamboo fibers is reduced and broken ends of the bamboo fibers are increased because of low single-fiber breaking strength, are overcome; and because of the recycling of resources, ecological environment is protected.

Owner:山东奈琦尔海洋科技有限公司

Uvioresistant short fiber manufacturing method

ActiveCN104372443AGood compatibilityStrong impact lowMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterPolymer science

A uvioresistant short fiber manufacturing method mainly includes that corn starch and polyesters are used as basic materials, and nano titanium dioxide is added to serve as a uvioresistant agent to make short fibers by melt spinning. The short fibers manufactured according to the method integrate advantages of corn fibers and polyester fibers and are excellent in uvioresistant effect.

Owner:NANTONG ANHENG CHEM FIBER CO LTD

Corn fiber extraction technology

The invention discloses a corn fiber extraction technology comprising the following steps: 1) dried and cleaned corn husk is chosen, and flyspeck and scaphium scaphigerum yinqu are added; 2) neutral water with pH at 7 is used for soaking to totally flood the corn husk; 3) the hard root base of powder corn husk is added, the hard root base is dipped to be totally soft, the corn husk adsorbs water to expand, and then the expanded corn husk is taken out to drain 50% of water; 4) the corn husk obtained in step 3 is put in a sealed container to ferment for 3-5 days (alcohol can be extracted in the process) at the normal temperature of 25-39 DEG C; and 5) the product obtained in step 4 is taken out to be cleaned with water to obtain high-quality corn fiber yarn. After dried, the corn fiber yarn can be produced into various daily necessities and other fiber substitutes, and extraction ratio is 90%; water used for cleaning corn fiber can be repeatedly used, and can provide rich water for farming industry and plant industry.

Owner:张洪溧

Maize fabric union cloth

Disclosed a corn fiber interwoven textile, which is interwoven by the gripper shuttle loom using cotton, wood, viscose, polyester fiber, warp made of blended yarn, and weft yarn made of PLA corn fiber filament or staple fiber. The corn fiber interwoven textile has fashions as plain weave, twill, and satin, wherein; the satin structure is the best. The warp can use 80S / 2í½120S / 2 polyester cotton, while the weft yarn can use 120d-150d filament and the fautness of woven is better set in upper range. The main advantages of corn fiber woven are that the front-back surface are obvious in two-color, the cloth is tight, and lustered.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

Bio-based nylon fabric and preparation process thereof

InactiveCN107880543AWith water absorptionSoftArtifical filament manufactureMonocomponent polyamides artificial filamentNylon materialFiber

The invention discloses a bio-based nylon fabric and relates to the textile field. The bio-based nylon fabric is prepared from the following components in parts by weight: 105-120 parts of bio-basednylon particles, 25-35 parts of bamboo fiber powder, 35-45 parts of corn fiber powder, 5-8 parts of an environment-friendly anti-oxidant agent and 10-15 parts of an environment-friendly flame retardant; the bio-based nylon particles are polymerized from bio-based pentamethylene diamine and petroleum-based adipic acid; the bamboo fiber powder is powder with a grain size of 5-15 mu m, formed by grinding bamboo fibers; and the corn fiber powder is powder with a grain size of 15-20 mu m, formed by grinding corn fibers. The bio-based nylon fabric has performances such as water absorption, softnessand wear resistance. The bio-based nylon fabric can be used for producing knitted underwear and clothing fabric. The bio-based nylon fabric takes bio-based nylon as a raw material, can be regenerated,is environment-friendly, is rich in raw material resource, and has many excellent performances.

Owner:苏州天亦辰针织有限公司

Process for dyeing fabric woven of bluish dogbane, corn fibers and soybean protein fibers

The invention discloses a process for dyeing a fabric woven of bluish dogbane, corn fibers and soybean protein fibers. The process includes selecting an interwoven fabric of bluish dogbane, corn fibers and soybean protein fibers, and specific dyeing steps include: turn-sewing, singeing, desizing, boil-bleaching, dyeing and post-finishing. By the process, dyeing effect is improved, and the fabric is less prone to shading, attractive and elegant in appearance, highly comfortable and fine in physical and mechanical properties. The fabric meets specifications of GB 18401-2003 National General Safety Technical Code for Textile Products, and has the effects of environment friendliness and health caring.

Owner:SUZHOU CHUANGYU WEAVING

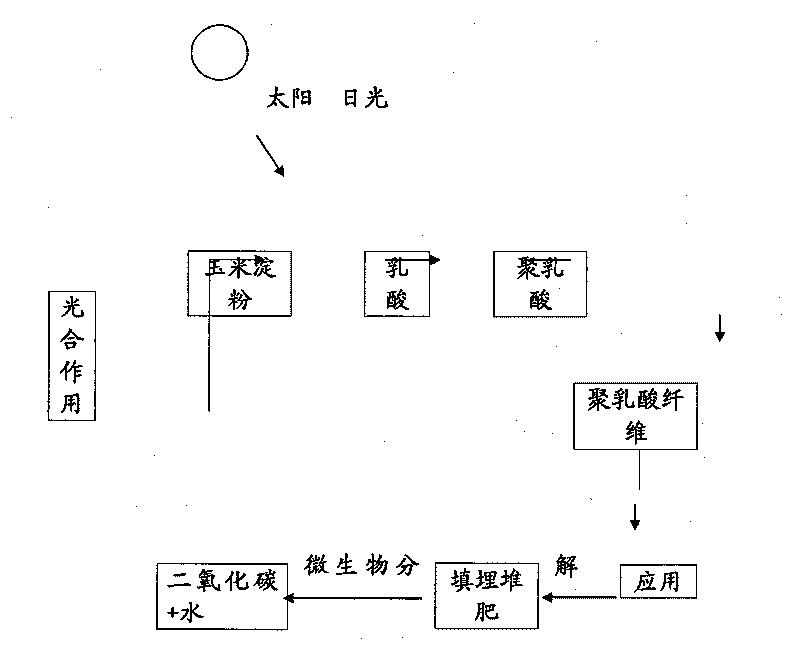

Naturally-degradable environmentally-friendly fiber fabric and processing technology thereof

The invention relates to a naturally-degradable environmentally-friendly fiber fabric which is characterized by comprising, by weight percent, 30-40 % of corn fiber, 20-30 % of bamboo charcoal fiber, 10-20 % of Lyocell fiber, and 10-15 % of polylactic acid fiber. The selected fiber materials are all easy to degrade, thereby being capable of reducing pollution to the environment. Furthermore, the fabric is relatively soft, relatively comfortable if wore, high in fabric strength, good in extensibility, soft in touch, good in drapability, and good in resilience, and can be applied in clothes, home textiles articles, sport articles, and healthcare fabric.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Dyeing and finishing process of corn fiber fabric

ActiveCN103290707AGood drapabilityIncrease elasticityDry-cleaning apparatus for textilesBleaching apparatusFiberPolymer science

The invention discloses a dyeing and finishing process of a corn fiber fabric. The dyeing and finishing process comprises the following procedures of: desizing, bleaching by oxygen, singeing, mercerizing, dyeing, softening and tentering, and pre-shrinking. The corn fiber fabric prepared by the dyeing and finishing process disclosed by the invention is a novel environment-friendly fiber; the fiber has very good draping, elasticity, hygroscopicity and air permeability, is comfortable to wear and is more and more favored by people.

Owner:RUGAO XIEHE PRINTING & DYEING

Method for preparing corn fiber non-woven fabric

The invention discloses a method for preparing corn fiber non-woven fabric, which comprises the following steps: 1, mixing 80 percent of corn fiber (PTT) and 20 percent of nylon fiber (PA6) in proportion, then manually spreading the mixture layer by layer, spraying water containing antistatic agent onto every spread layer for mixing, sealing the mixture by using a plastic film, and keeping a constant temperature for a period of time; 2, feeding the moisture-keeping corn mixed fiber after mixing into a weighing cotton box of a cotton hopper, and opening the corn mixed fiber by a bale opener to loosen the corn fiber; 3, adjusting the feeding amount of the corn mixed fiber by adjusting the photoelectric switching frequency of the weighing cotton box according to the fixed amount of a product; 4, delivering the corn mixed fiber fed by the weighing cotton box into a carding machine through an air suction device to carry out pre-carding and then fine carding; 5, evenly distributing the corn mixed fiber subjected to fine carding by three doffer carding machines onto a curtain of a lapping machine; 6, delivering the corn mixed fiber evenly distributed on the curtain of the lapping machine to a hot rolling mill to carry out heating and molding; and 7, using a lap former to lap the corn fiber non-woven fabric subjected to the heating and molding by the hot rolling mill.

Owner:侯玉生

Insulation cotton made of corn fibers and production method thereof

InactiveCN101691680ASolve the problem of stereotypes technologyHeat-wickingEster polymer adhesivesNon-woven fabricsPolymer scienceCarding

The invention relates to insulation cotton made of pure short corn fibers and a production method thereof. The cotton is made of 100% corn fibers. The method comprises the steps of opening, blending, carding, web forming, gel spraying, drying, shape setting, splitting and finished product rolling. The drying and shape setting temperatures range between 110 DEG C and 130 DEG C and the drying and shape setting time is 3-9min. The invention solves the problems of process temperature and drying and shape setting time during web forming of the corn fibers and also solves the problems caused by that the corn fibers are difficult to form webs due to brittleness, hardness and easy breakage.

Owner:浙江中超新材料股份有限公司

Green multi-fiber blended fabric

InactiveCN102719968AGood moisture absorption and air permeabilityFeel smoothWoven fabricsYarnYarnMoisture

The invention discloses a green multi-fiber blended fabric. The blended fabric is formed by blending corn fibers, bamboo fibers and bamboo charcoal fibers according to a certain proportion. The green multi-fiber blended fabric overcomes the defects that cotton fibers are not breathable, slow in wicking away moisture, easily breeds bacteria and produces mildew, etc. The green multi-fiber blended fabric takes full advantage of the characteristics of the corn fibers, the bamboo fibers and the bamboo charcoal fibers, and allows a plurality of the fibers to fuse together finely. The green multi-fiber blended fabric enables a plurality of the raw materials to complement each other with advantages, improves the strength of the yarns, and is characterized by a combination of health, fashion, quality, functions and environmental protection.

Owner:NANTONG DEBEIER IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com