Method for processing multi-fibre spun yarn and multi-fiber spun yarn processed through method

A processing method, technology of spinning yarn, applied in the direction of yarn, textile and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

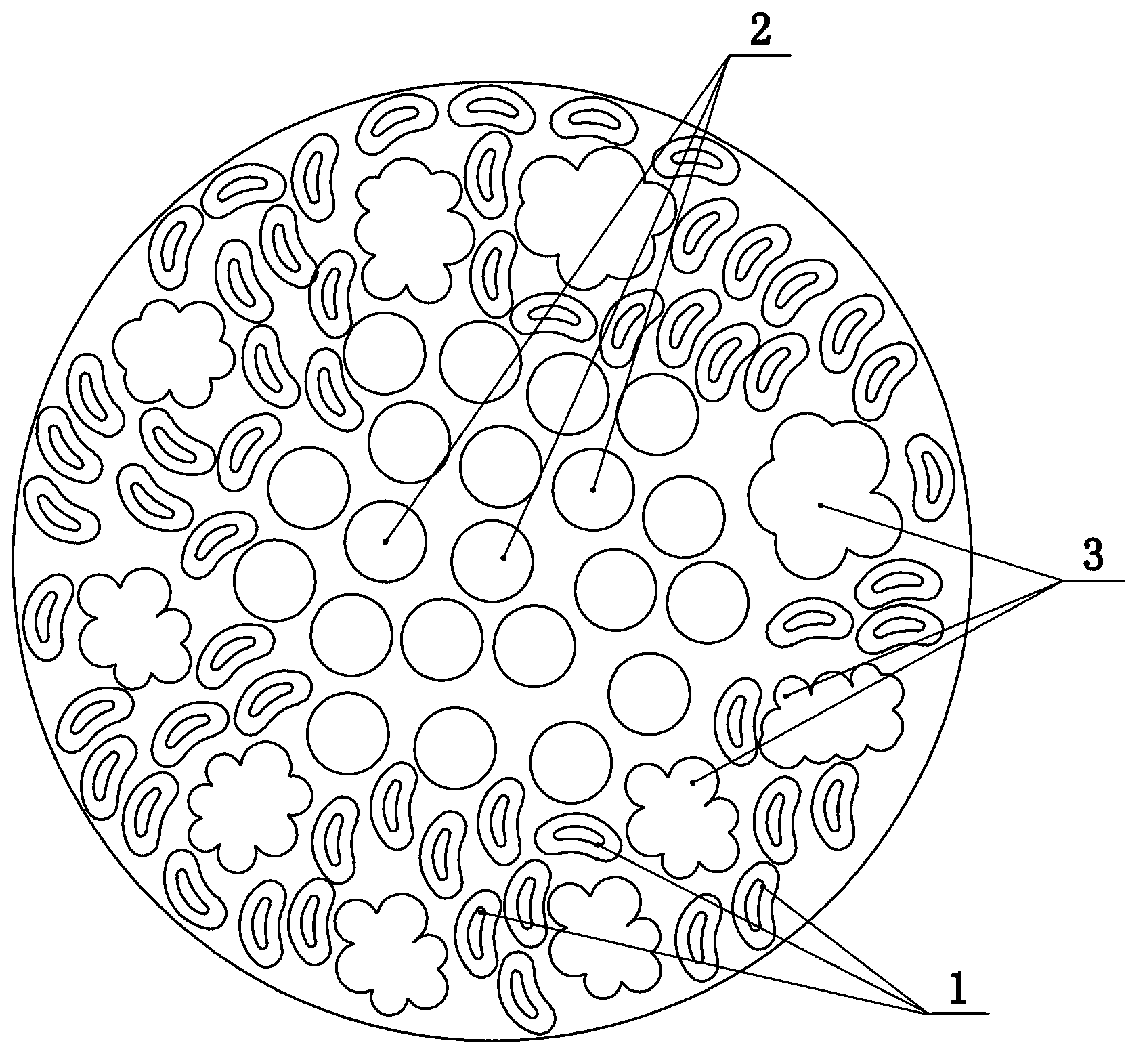

[0017] Example 1 Cotton fiber 1, polyester fiber 2, viscose fiber 3 blended yarn:

[0018] Textile material selection: cotton fiber 1: grade 3, linear density 1.67dtex, length 29mm; polyester fiber: linear density 1.33dtex, length 38mm; viscose fiber: linear density, 1.67dtex, length 38mm.

[0019] Blending ratio: cotton fiber, polyester fiber and viscose fiber are stored on the cotton table according to the mass ratio of 70:20:10, and the height and upper, middle and lower layer components are the same during the storage.

[0020] Specific spinning process:

[0021] Blowing and carding unit: JWF1012 cotton grabber→FA126 heavy object separator→FA113A single-axis opener→FA028 multi-bin cotton blender→FA1124 cleaning machine→FA151 dust removal machine→JWF1172 cotton feeding box→FA221E carding machine →FA306A draw frame→FA322B draw frame→FA457 roving frame→DTM129 spinning frame→AC X5 automatic winder→packing.

[0022] The cotton grabbing machine adopts the technology of less grabbing and ...

example 2

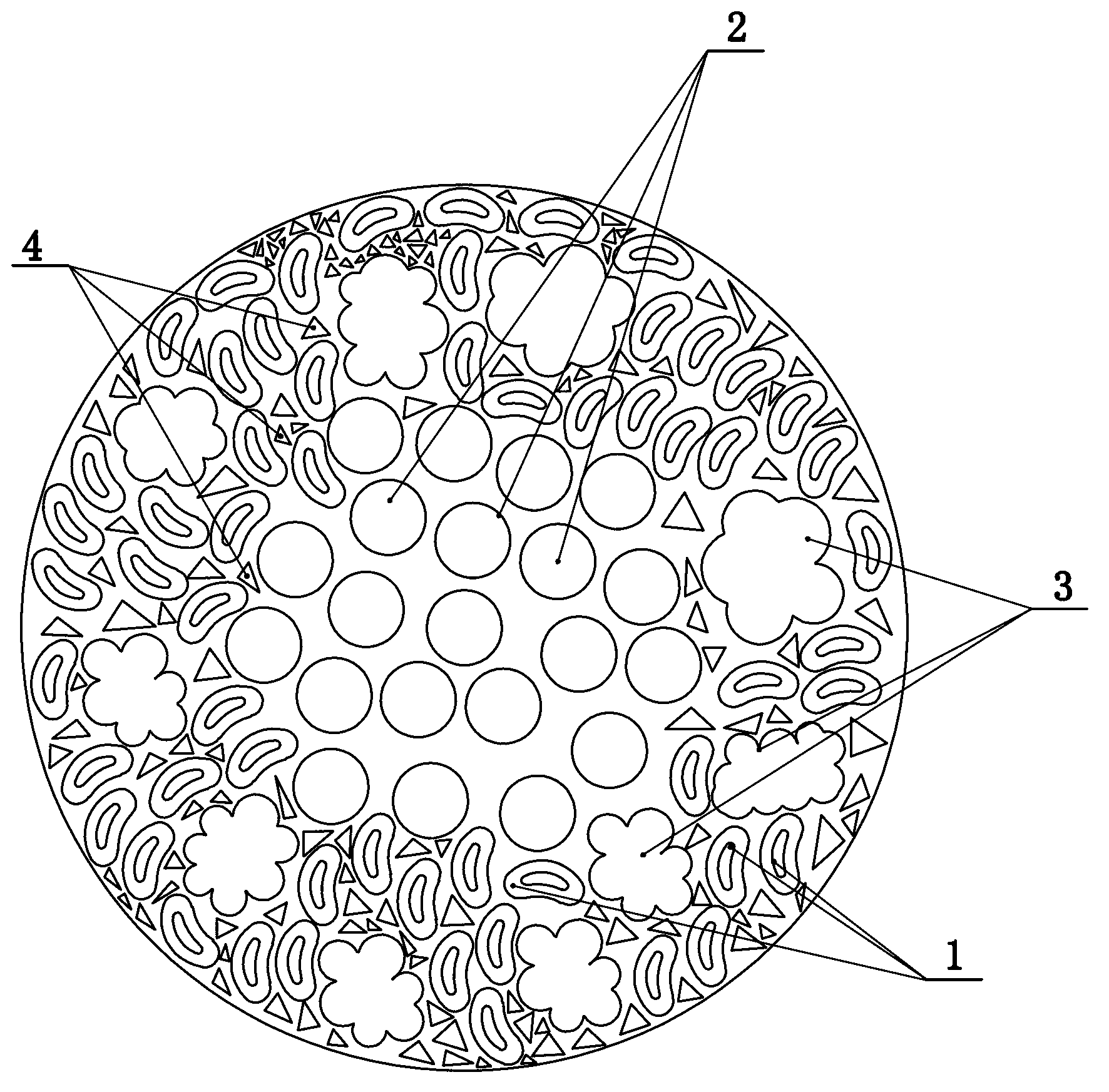

[0030] Example 2 Spinning cotton fiber 1, polyester fiber 2, viscose fiber 3, sky bamboo fiber 4 blended yarn:

[0031] Selection of textile materials: cotton fiber 1: grade 3, linear density 1.67dtex, length 29mm; polyester fiber 2: linear density 1.33dtex, length 38mm; viscose fiber 3: linear density, 1.67dtex, length 38mm; sky bamboo Fiber 4: Linear density, 1.67 dtex, length 38mm.

[0032] Blending ratio: cotton fiber 1, polyester fiber 2, viscose fiber 3, and sky bamboo fiber 4 are stored on the cotton platform at a mass ratio of 40:40:10:10. The height and composition of the upper, middle and lower layers are the same.

[0033] Specific spinning process: Same as Example 1.

[0034] The blowing-carding and drawing process are the same as in Example 1.

[0035] Roving twist coefficient 78.

[0036] In the spinning process, the twist factor is 341, the traveler specification is 6903 10 / 0#, and the others are the same as in Example 1.

[0037] The winding process is the same as in Exam...

example 3

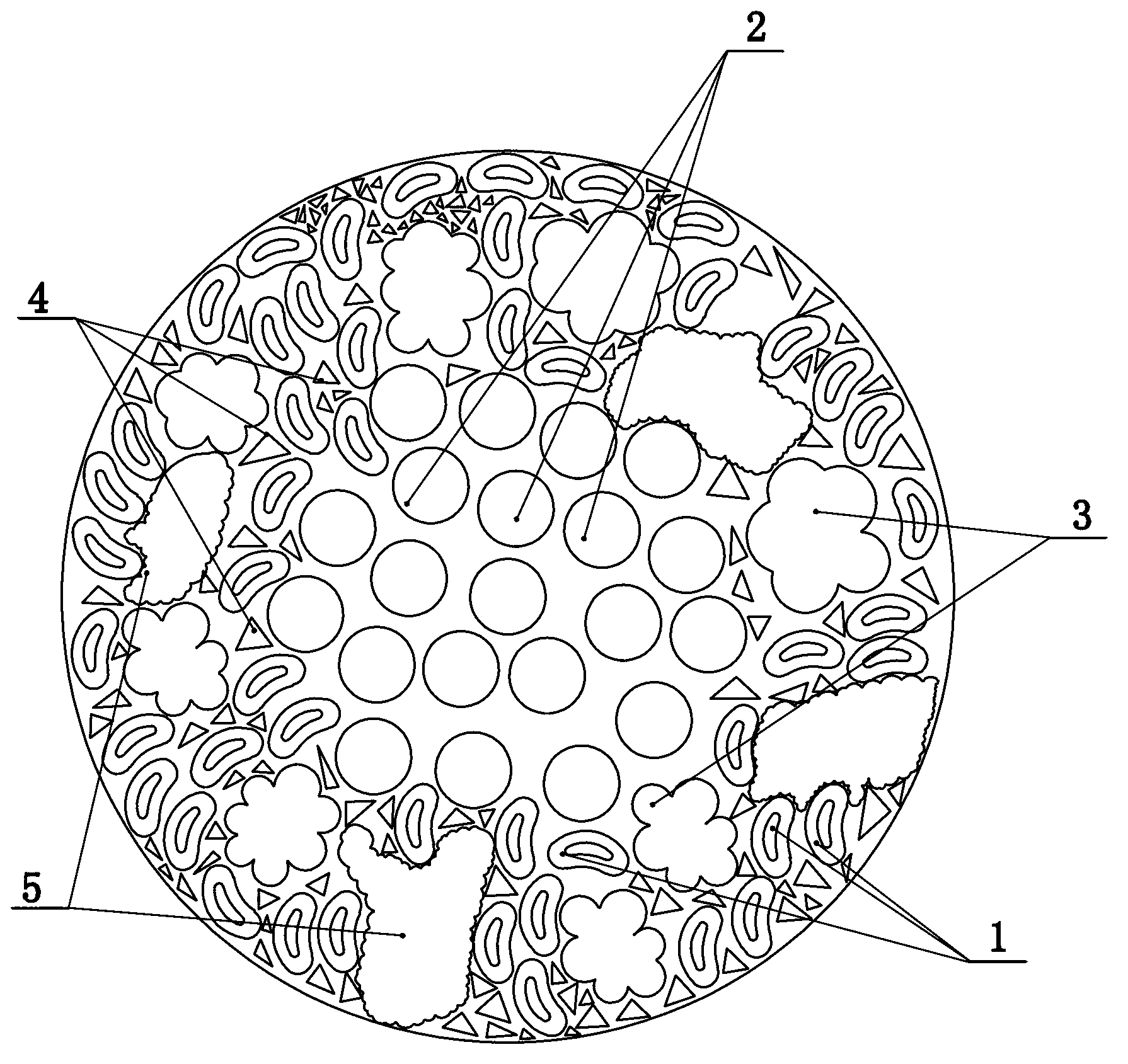

[0041] Example 3 Blended yarn of cotton fiber 1, corn fiber 5, polyester fiber 2, viscose fiber 3, and bamboo fiber 4:

[0042] Selection of textile materials: cotton fiber 1: grade 3, linear density 1.67dtex, length 29mm; corn fiber 5: fineness 1.1D, average length 35mm; polyester fiber 2: linear density 1.33dtex, length 38mm; viscose fiber 3 : Linear density, 1.67dtex, length 38mm; Sky bamboo fiber 4: Linear density, 1.67dtex, length 38mm.

[0043] The corn fiber 5 is pulled loose, humidified (moisture regain is controlled at 9%) into a bale, and the cotton fiber 1, corn fiber 5, polyester fiber 2, viscose fiber 3, and sky bamboo fiber 4 are in a mass ratio of 25:25:30:10 :10 Put the warehouse on the cotton table, the height and composition of the upper, middle and lower layers are the same.

[0044] Process flow: same as example 1

[0045] Blowing-carding unit: FA221E carding machine, the gauge from the feeding board to the licker roller is 0.50mm, and the gauge from the licker ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com