Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323results about "Fuel feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

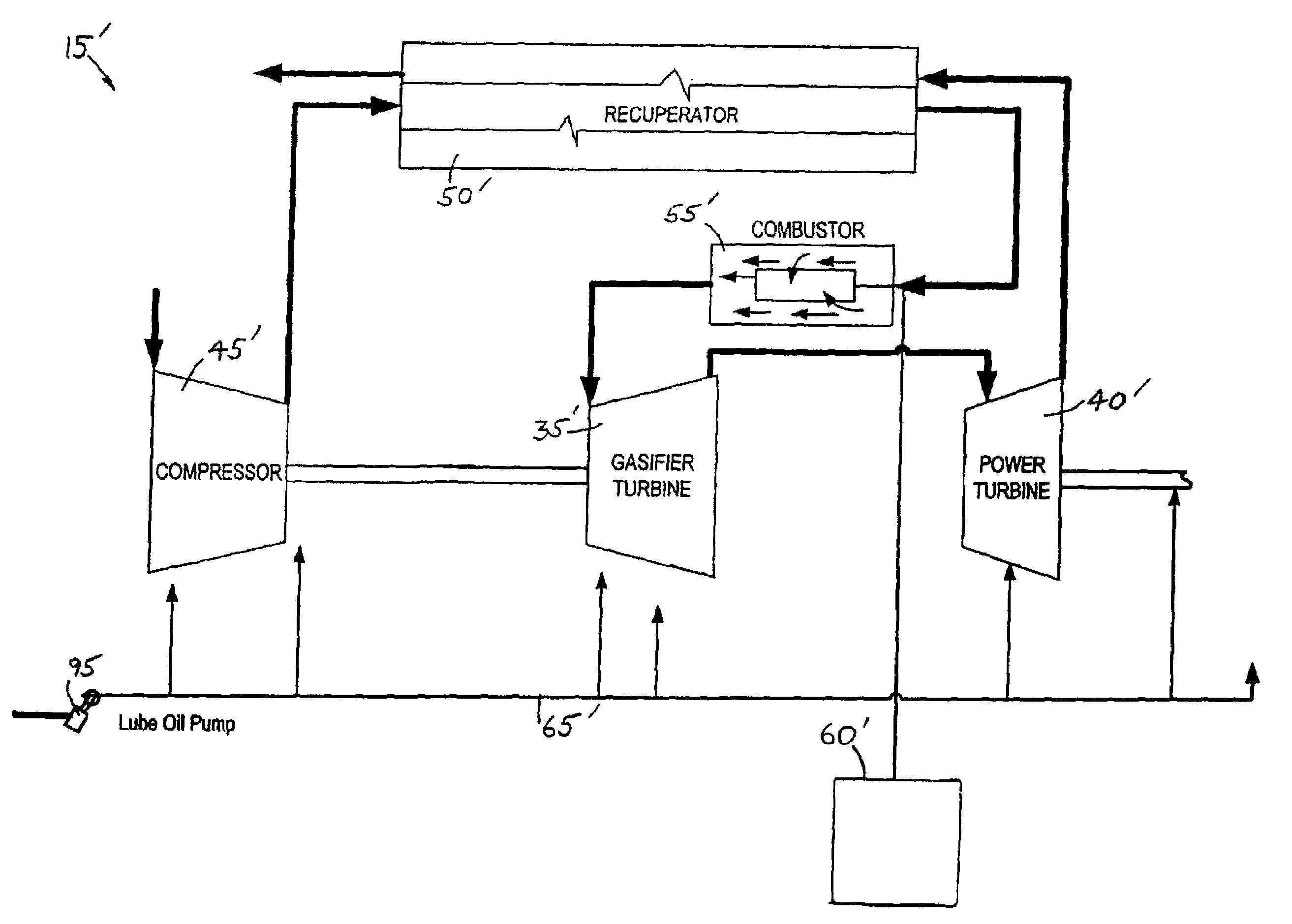

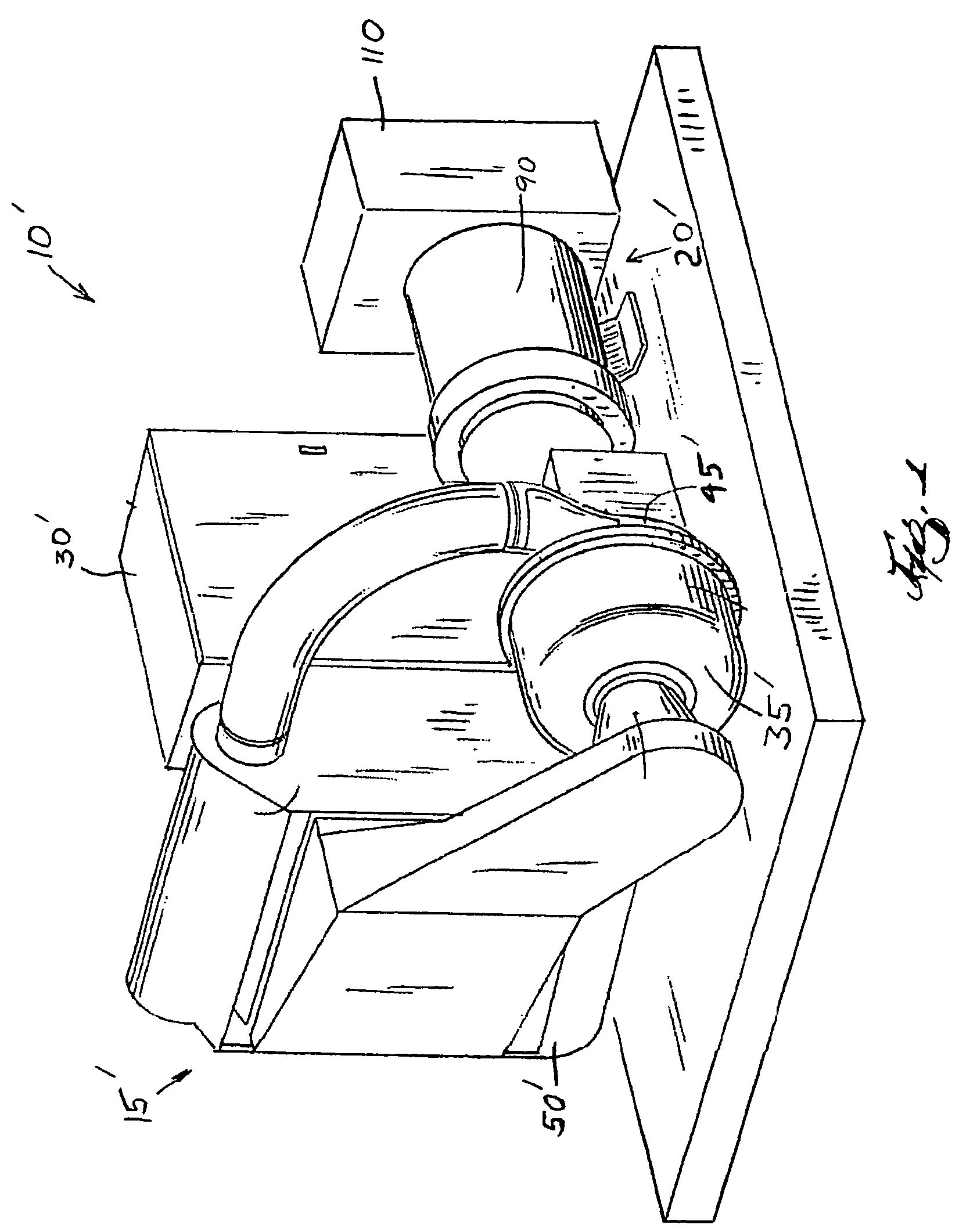

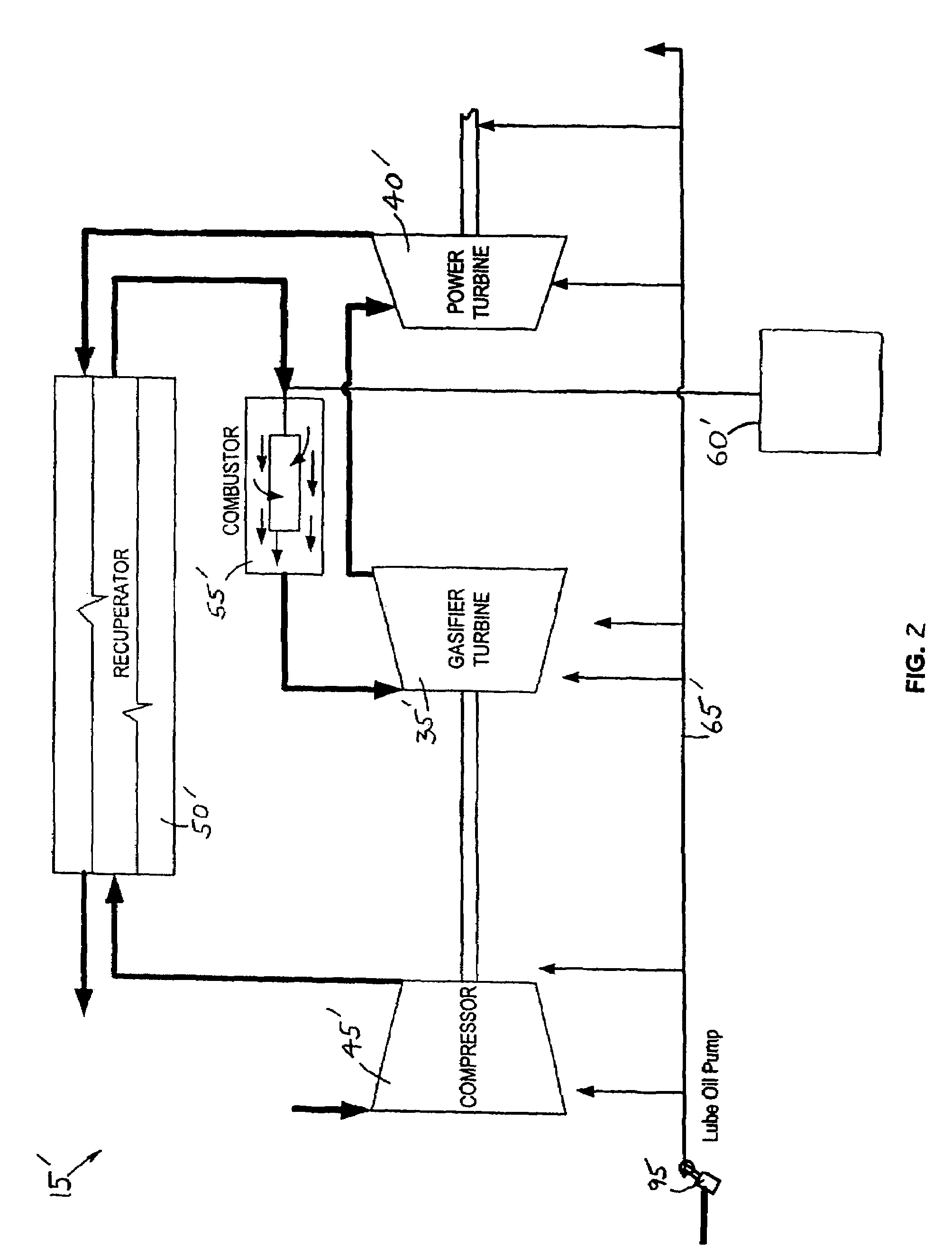

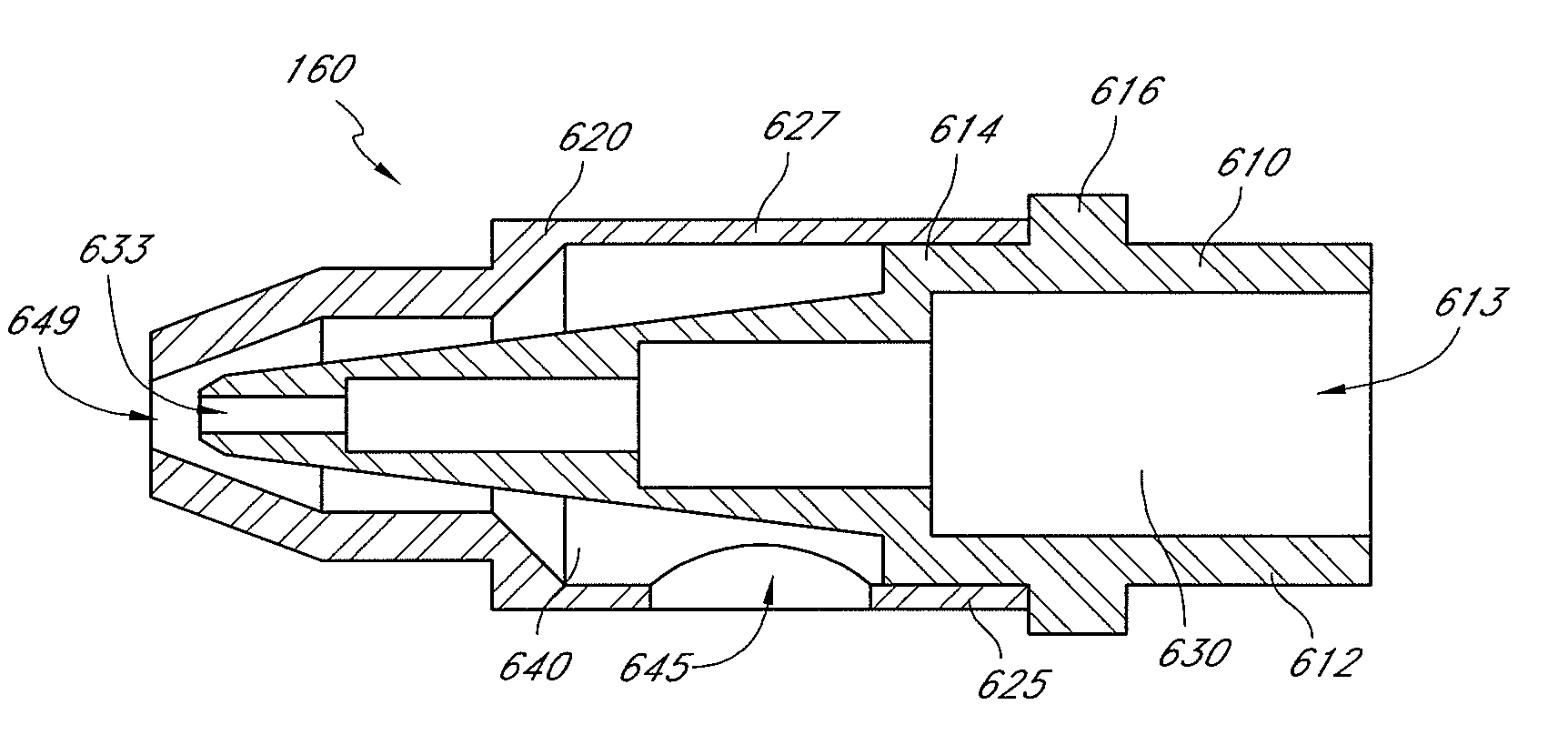

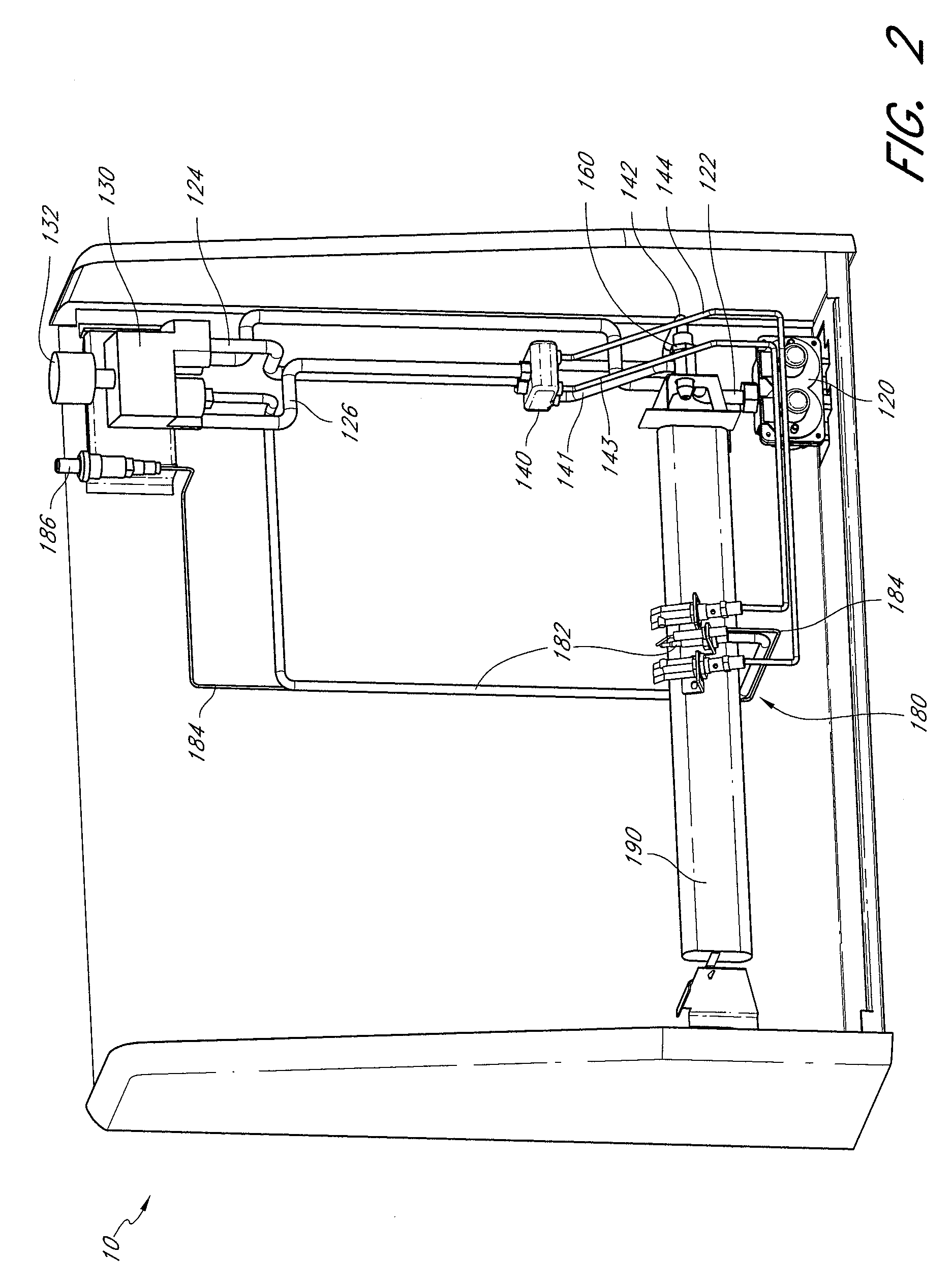

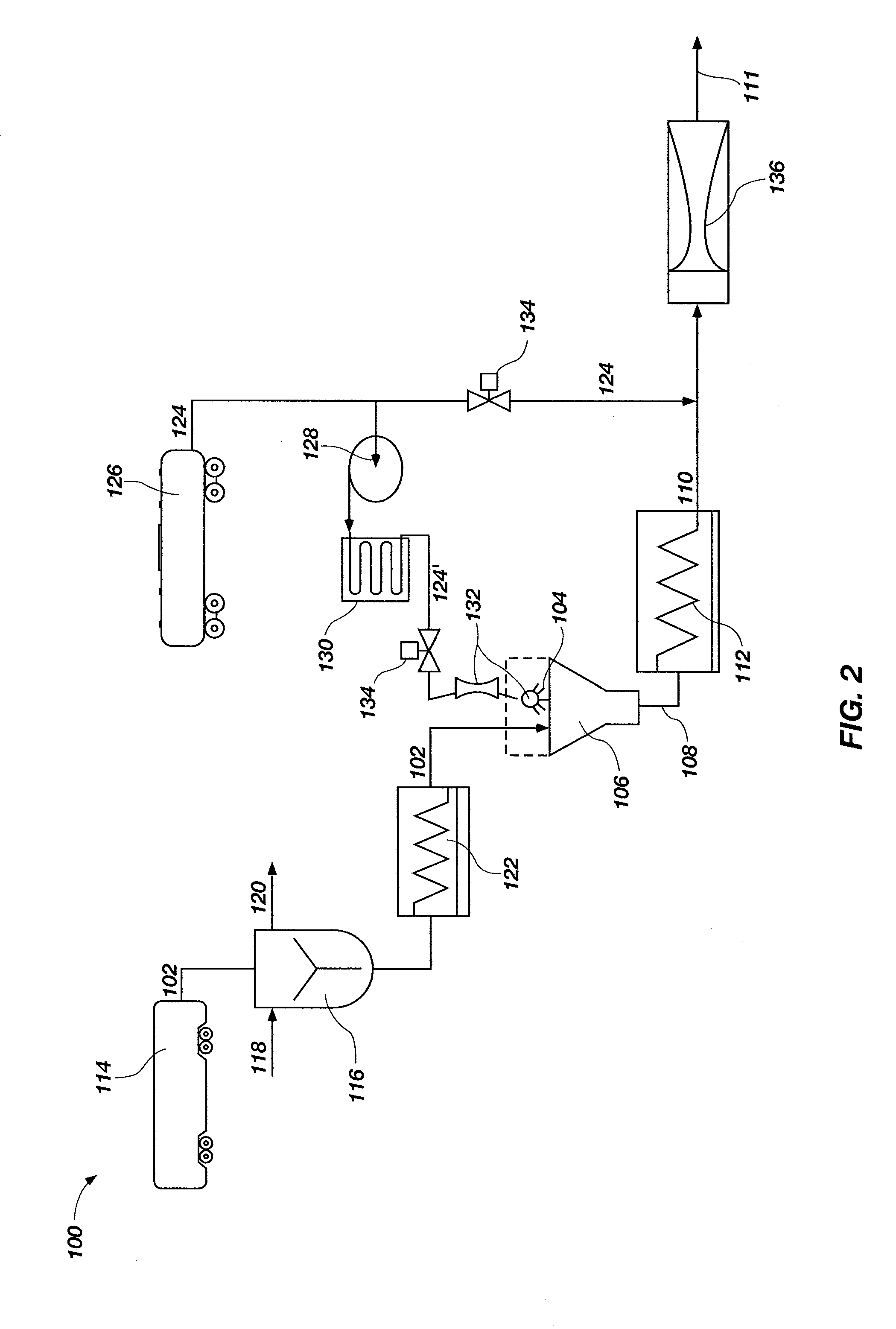

Fuel-conditioning skid

A fuel-conditioning skid for an engine. The fuel-conditioning skid includes an inlet that is connectable to a source to receive a flow of fuel containing undesirable compounds. An outlet is connectable to the engine to deliver a flow of fuel that is substantially free of undesirable compounds. An inlet cleaner is in fluid communication with the inlet and is operable to remove a portion of the undesirable compounds. A compressor is in fluid communication with the inlet cleaner to receive the flow of fuel at a first pressure and discharge the flow of fuel at a second pressure. The second pressure is greater than the first pressure. A purifier is in fluid communication with the inlet cleaner to receive the flow of fuel. The purifier is operable to remove substantially all of the remaining undesirable compounds from the flow of fuel.

Owner:FLEXENERGY ENERGY SYST

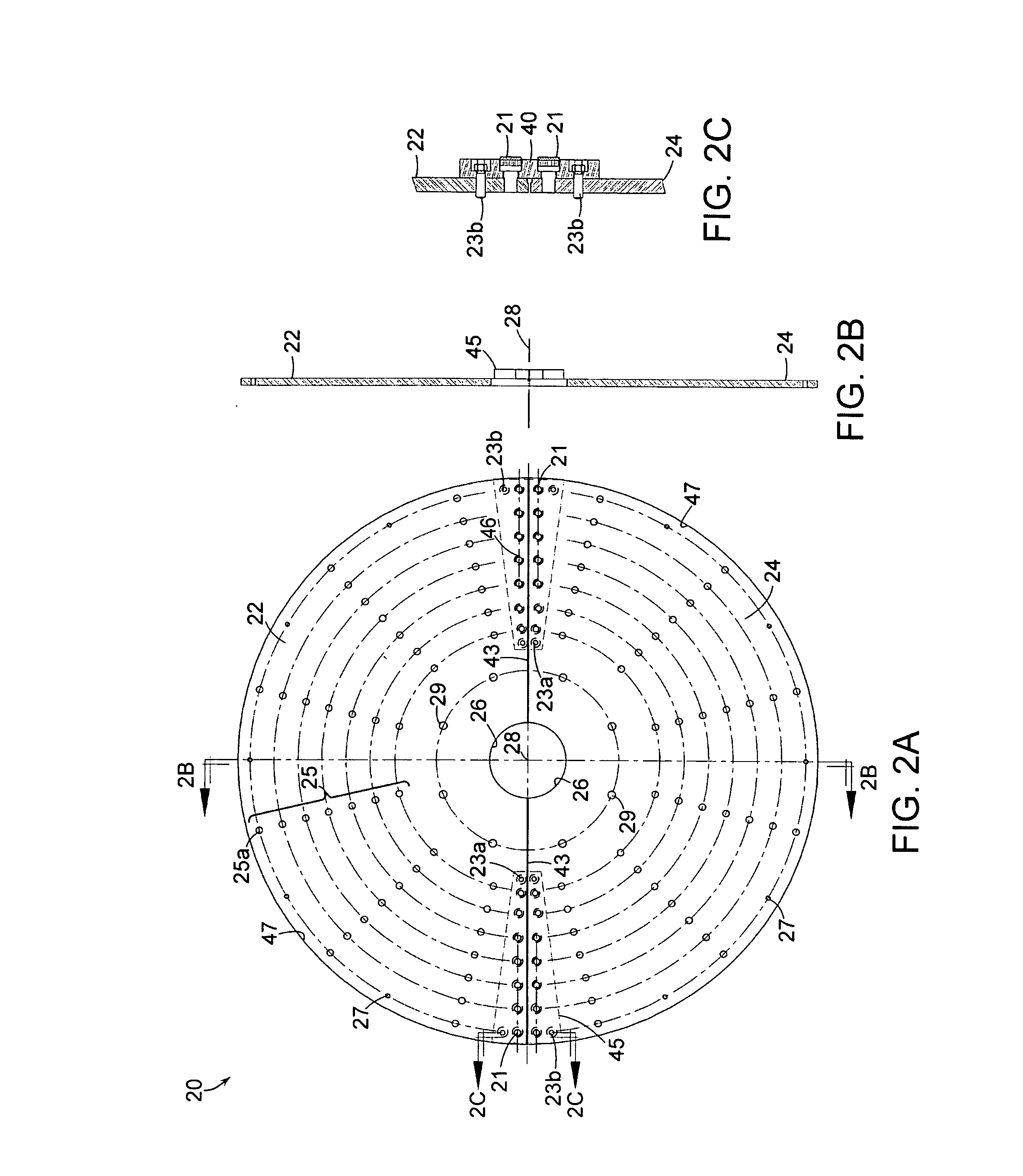

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

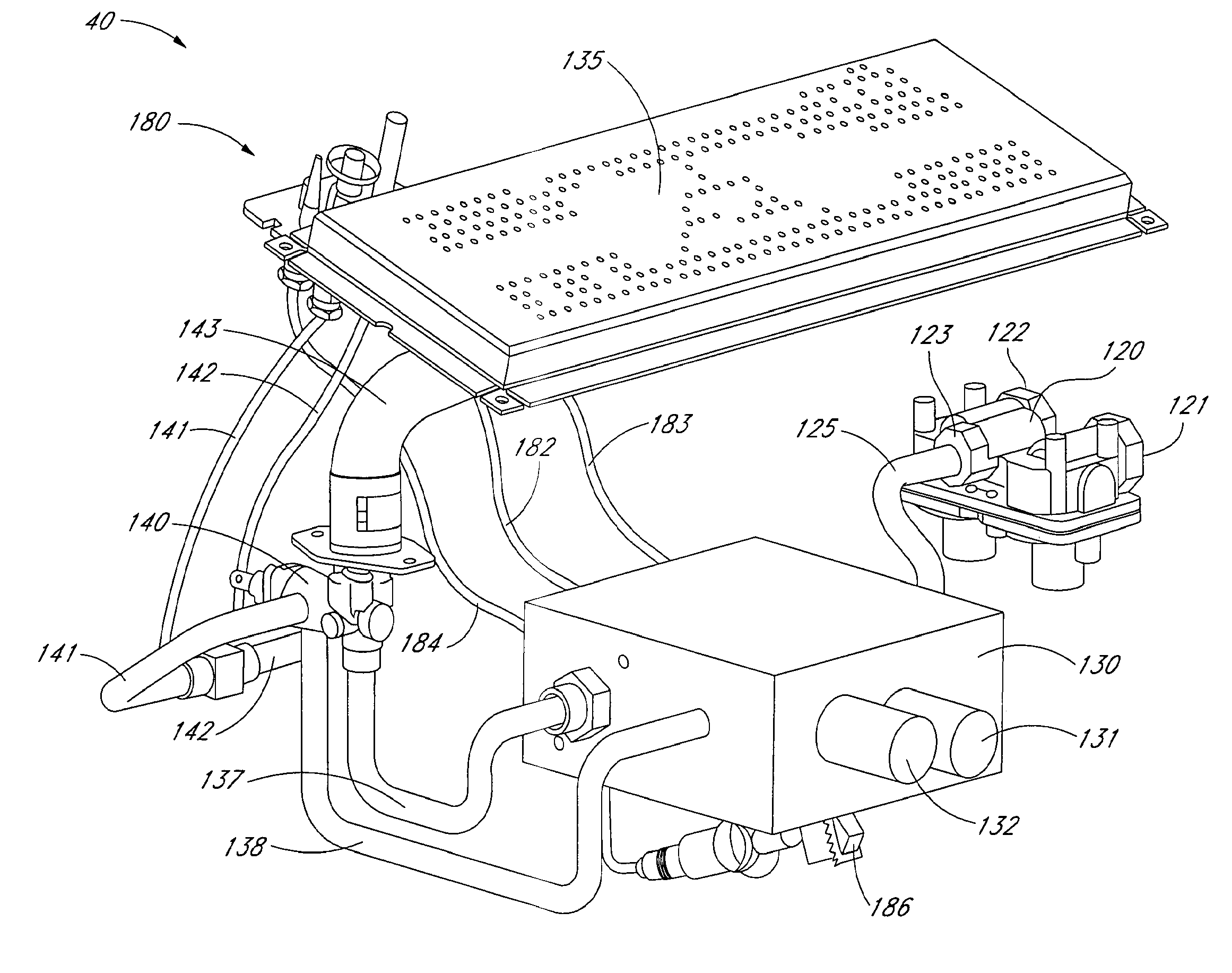

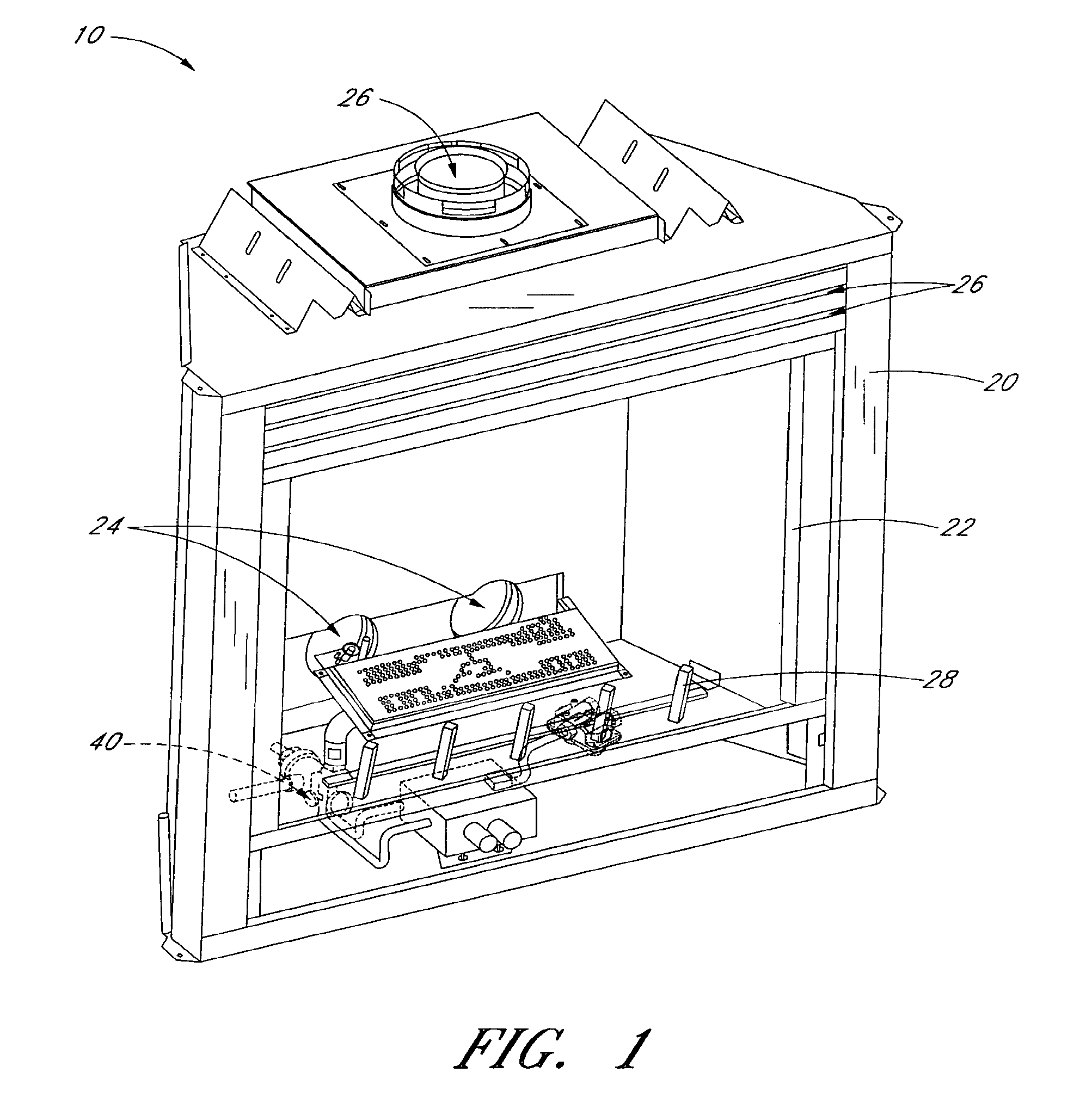

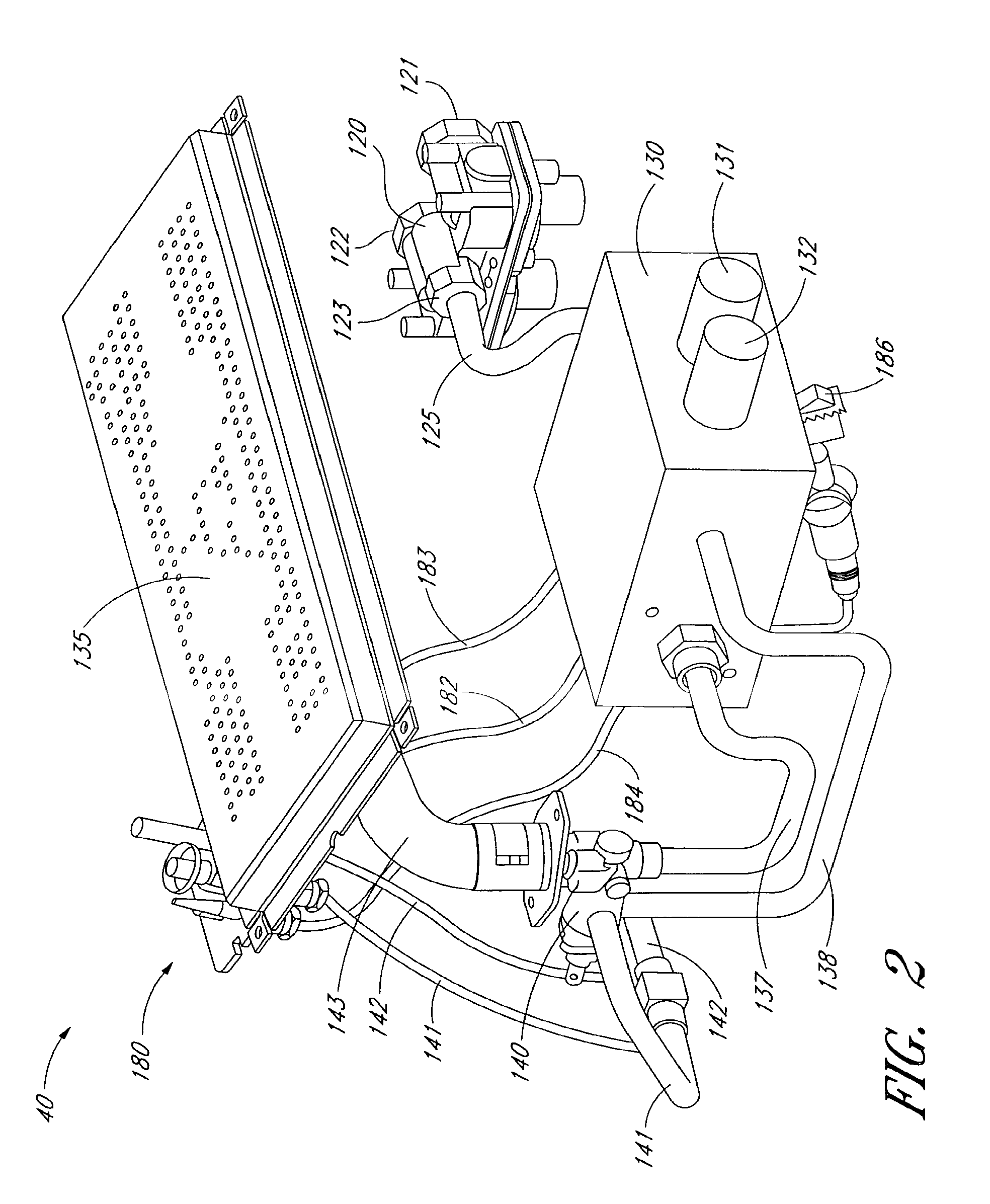

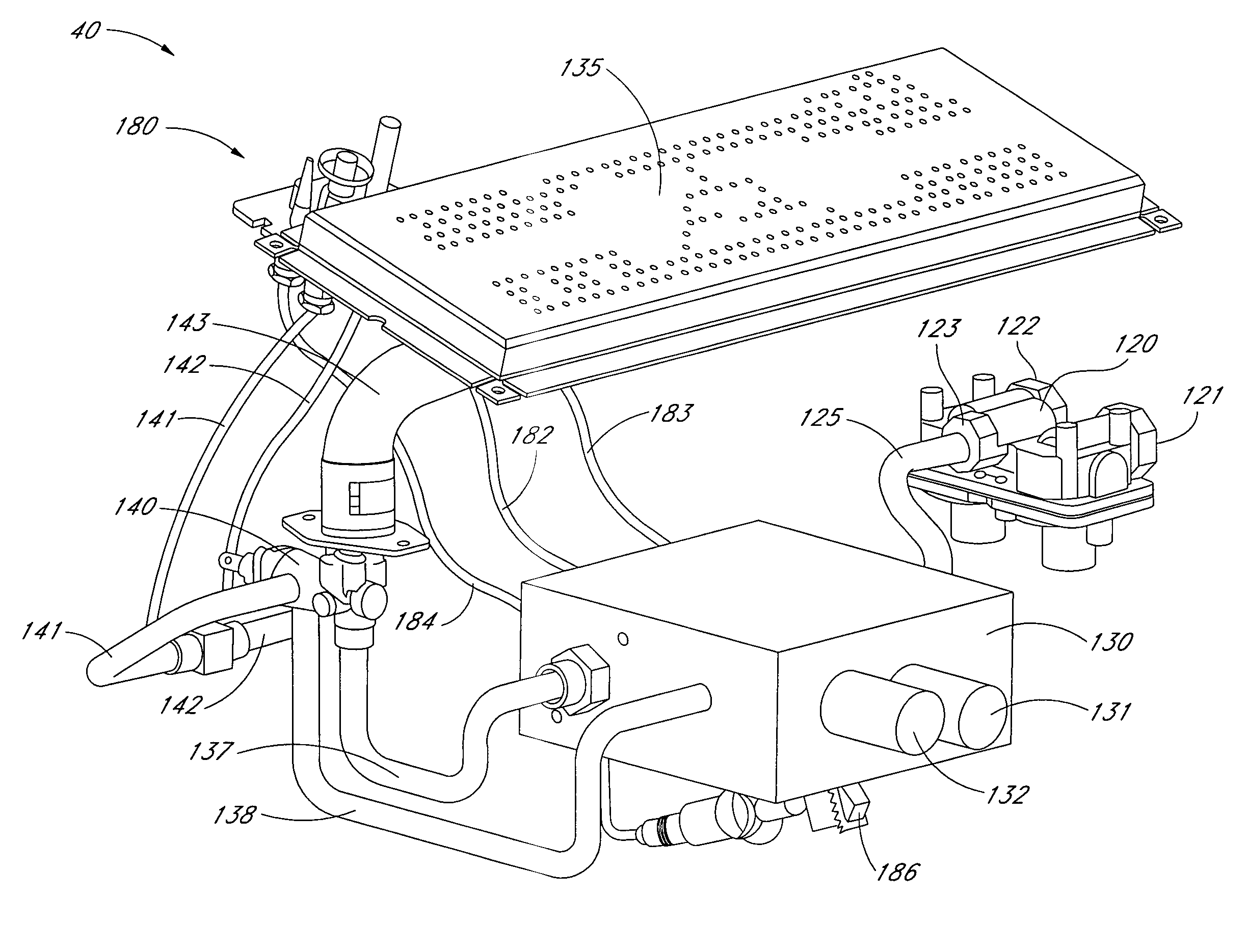

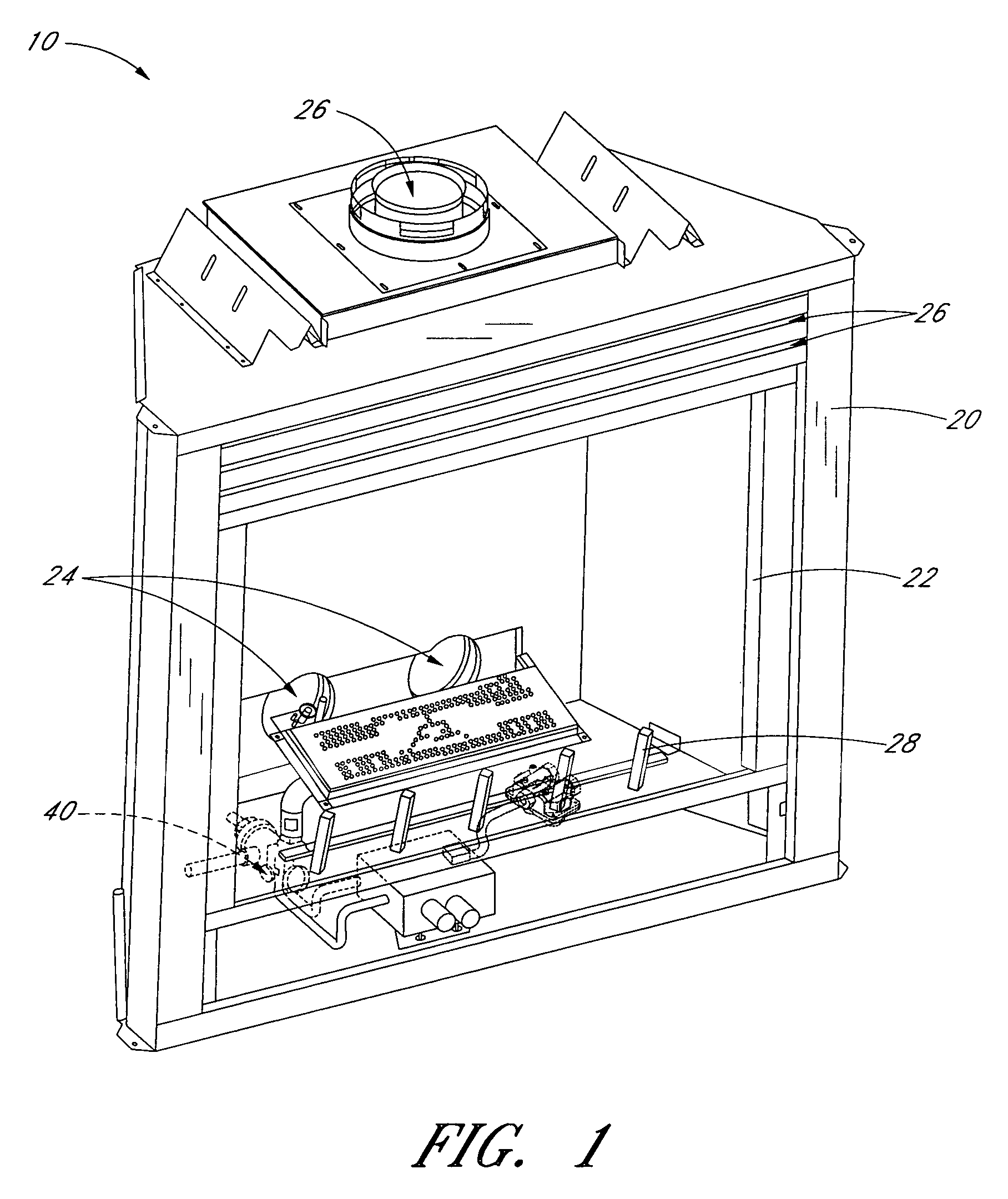

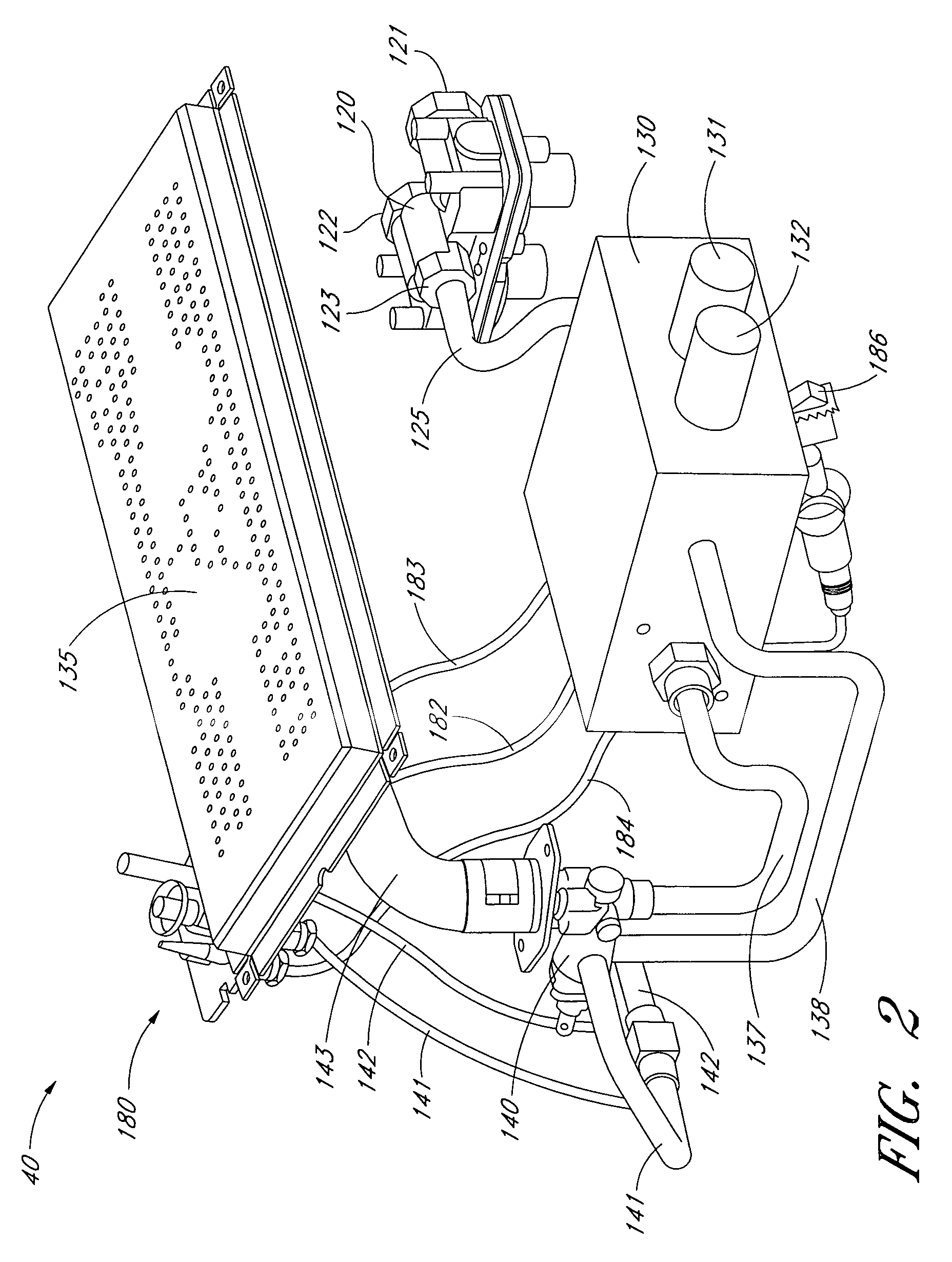

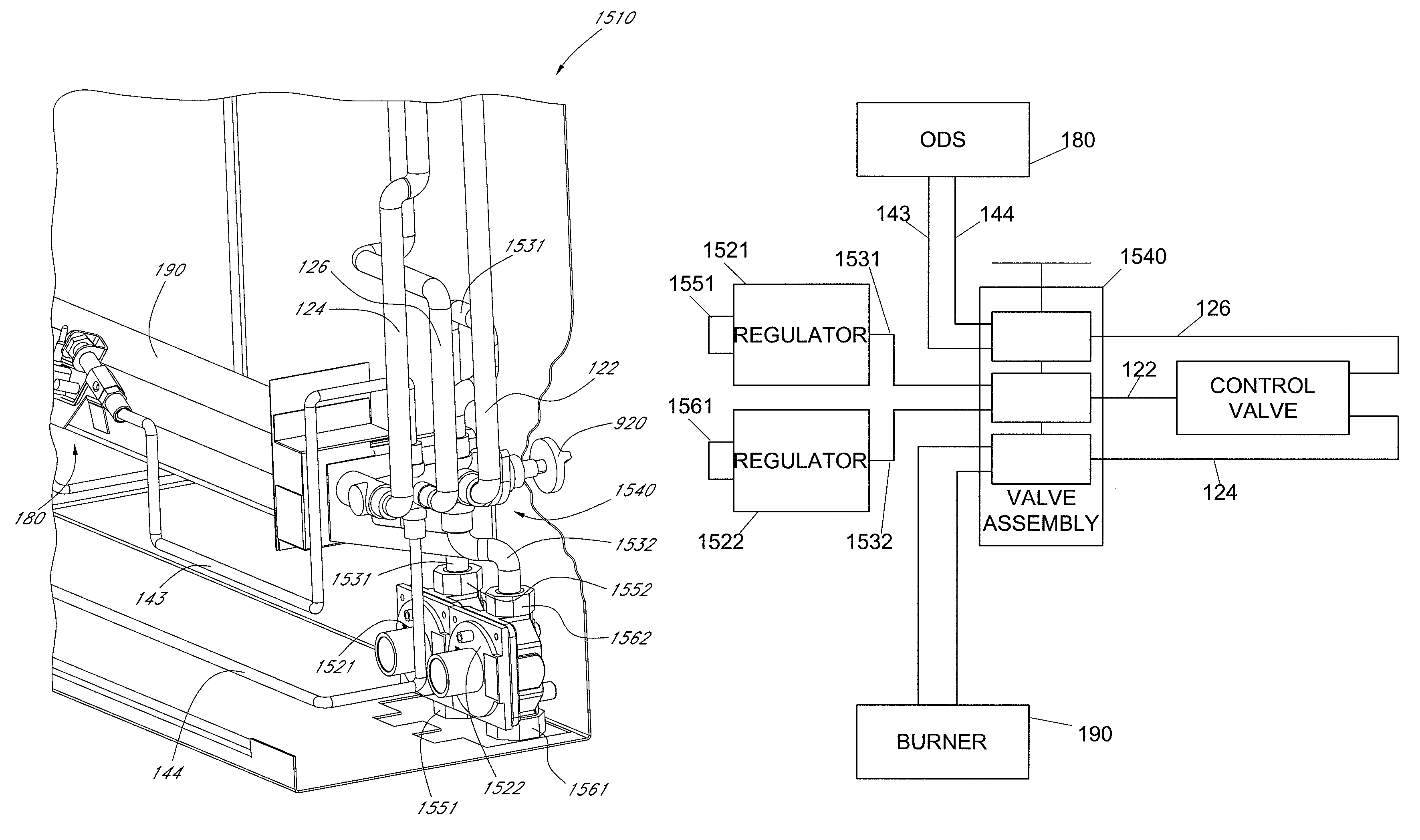

Fuel selection valve assemblies

In certain embodiments, an apparatus includes a control valve for regulating fuel flow. The apparatus can include a burner and a valve assembly. In some embodiments, the valve assembly includes a housing, which can define a first fuel input for receiving a first fuel from a first fuel source and a second fuel input for receiving a second fuel from a second fuel source. The housing can define a first fuel output for directing fuel toward the control valve, and can define a third fuel input for receiving a portion of either the first fuel or the second fuel from the control valve. The housing can define a first egress flow path and a second egress flow path, each for directing fuel to the burner. In certain embodiments, the apparatus includes a valve body configured to selectively permit fluid communication between the first and second inputs and the output and between the third input and the egress flow paths.

Owner:PROCOM HEATING

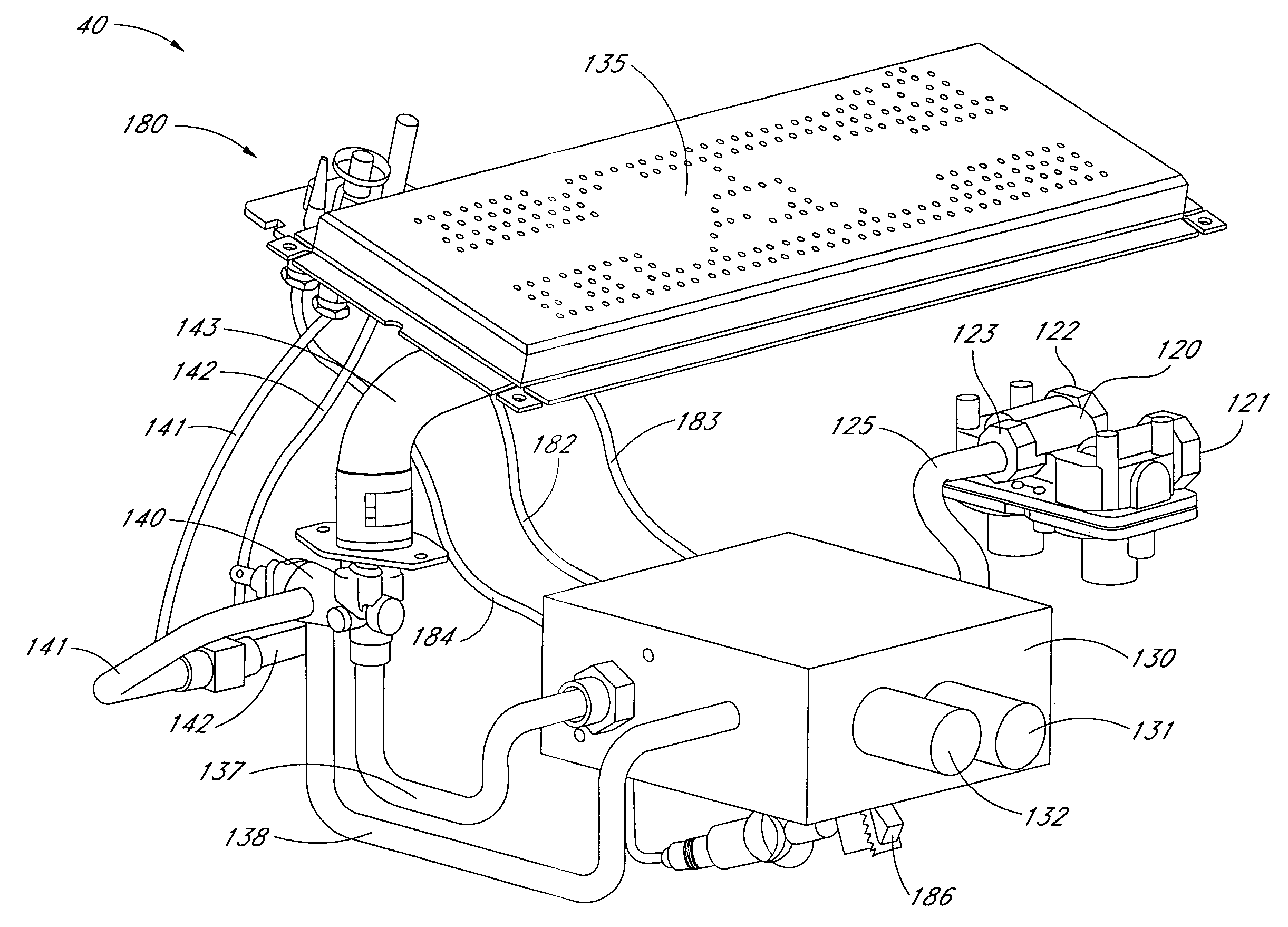

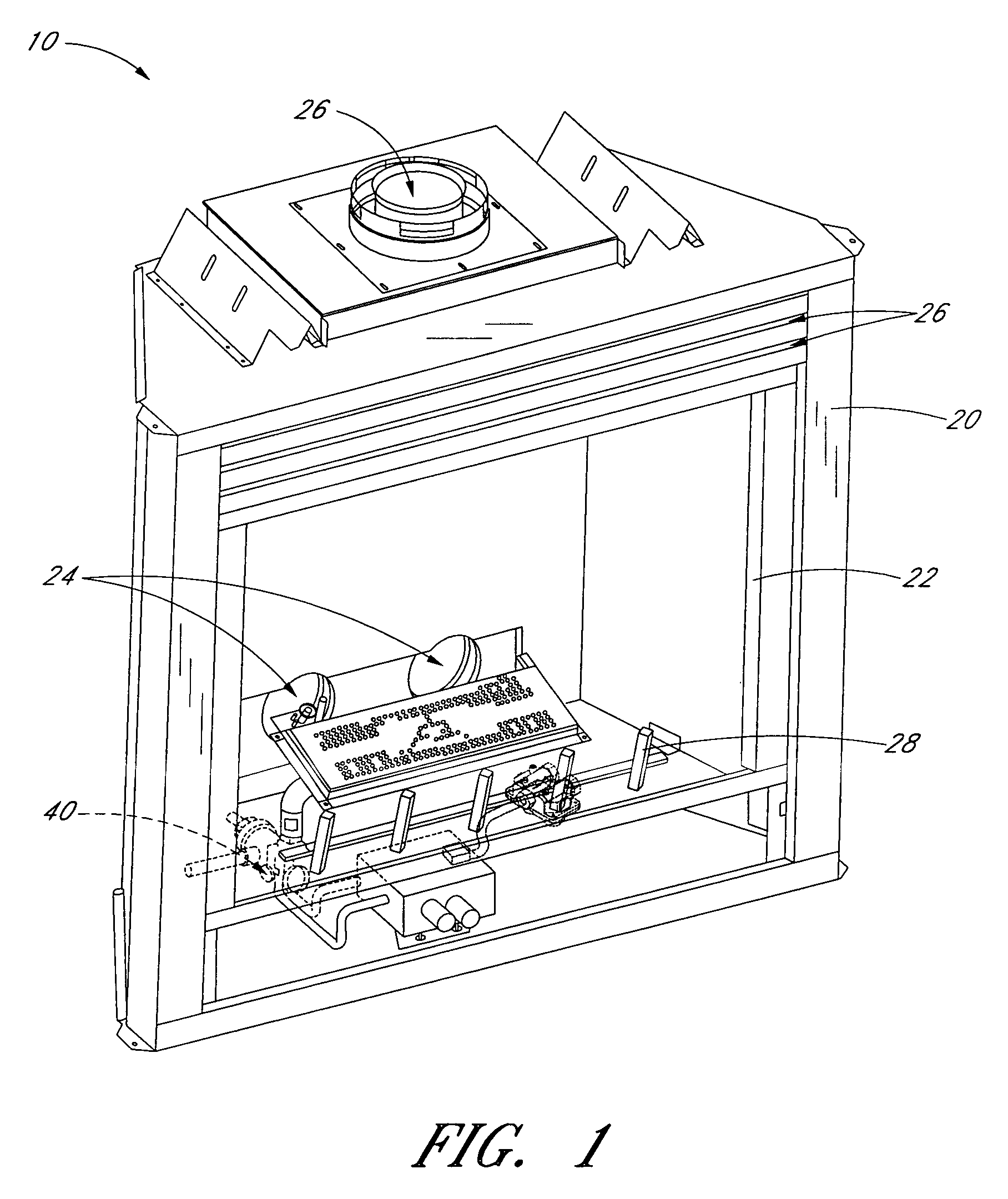

Pilot assemblies for heating devices

In certain embodiments, an apparatus can comprise a dual fuel pilot assembly. The pilot assembly can comprise a first fuel dispenser, a second fuel dispenser, an igniter and at least one of a thermocouple, and a thermopile. The pilot assembly can be configured to direct heat from combustion of one of either a first fuel or a second fuel to the at least one of the thermocouple and the thermopile.

Owner:PROCOM HEATING

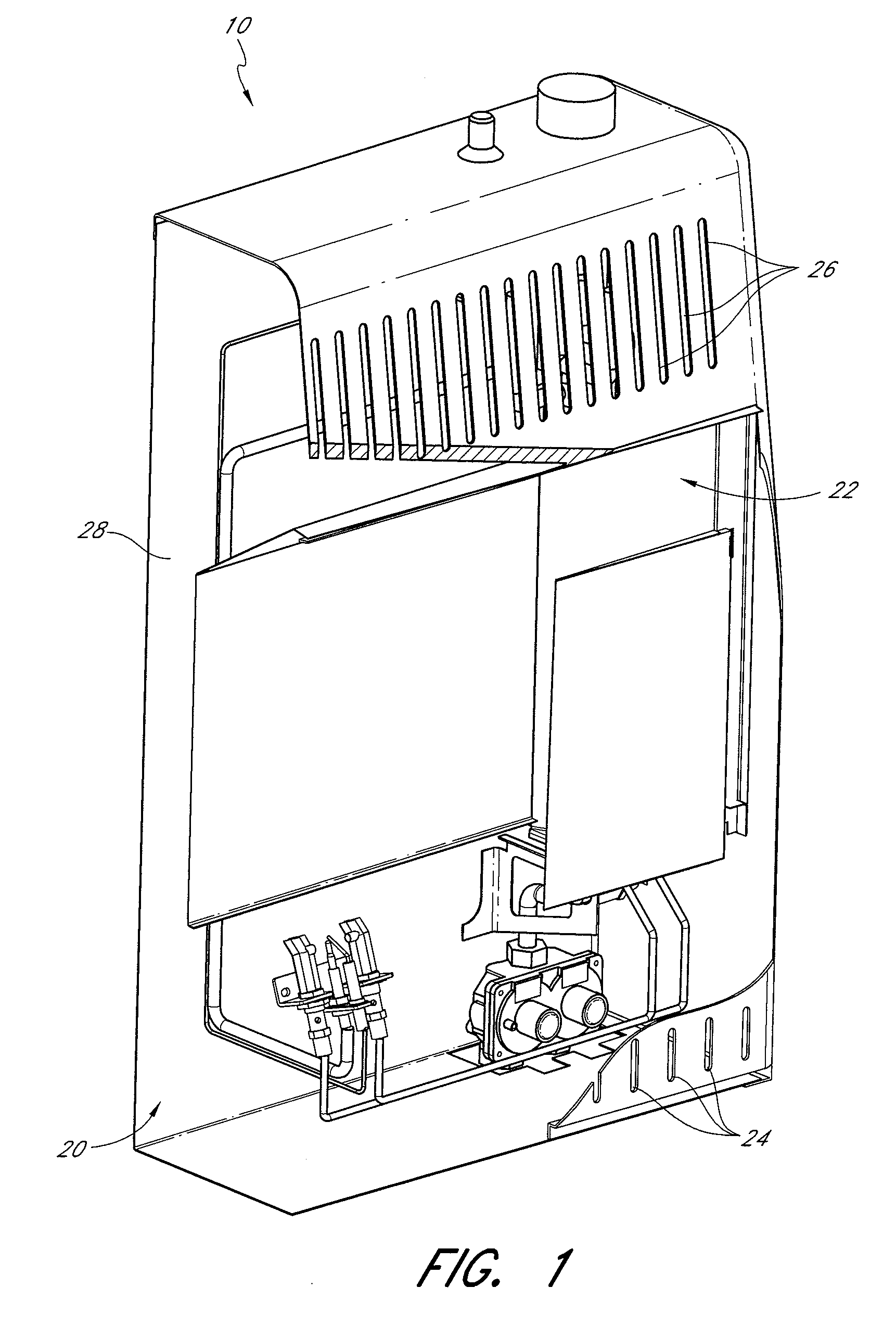

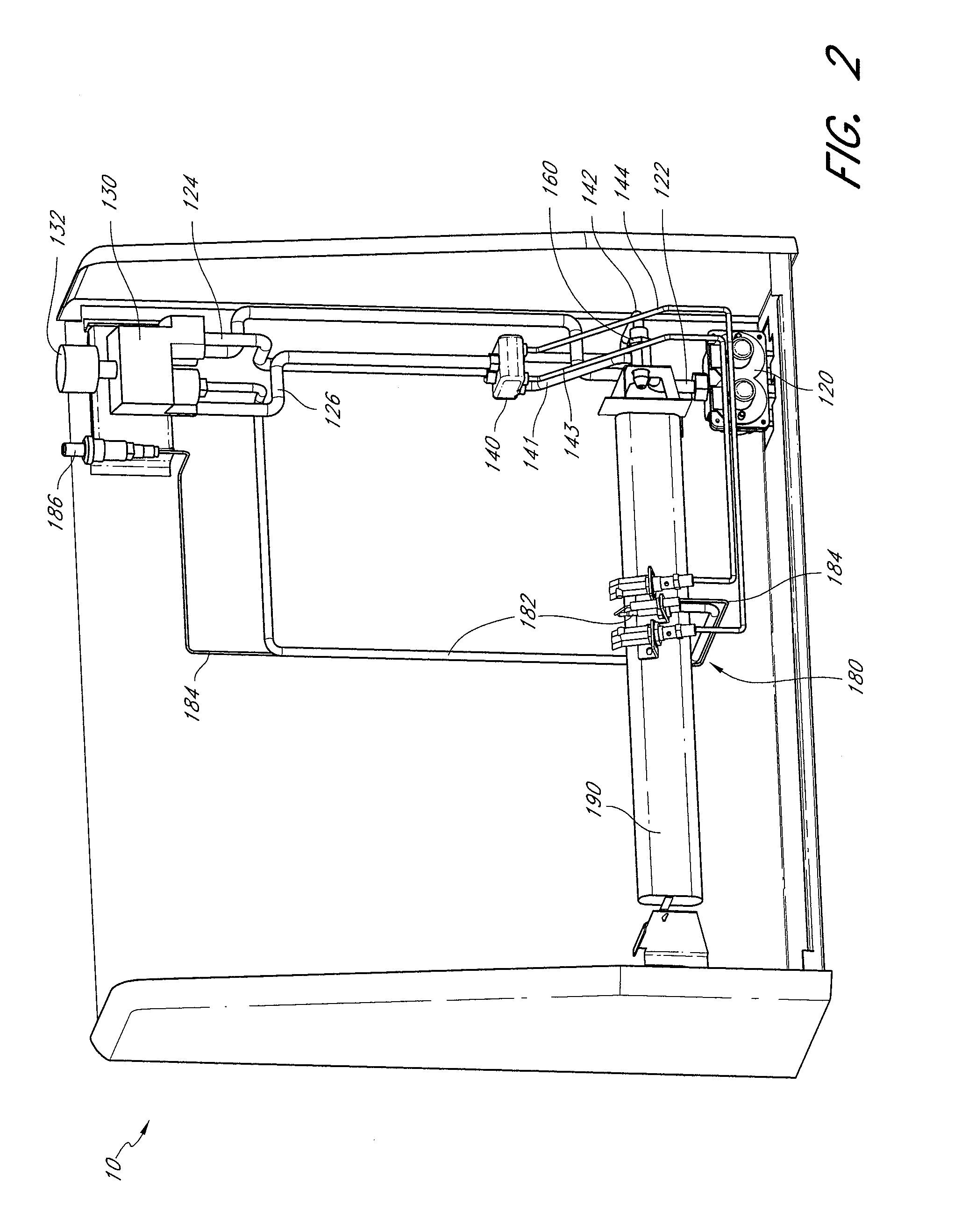

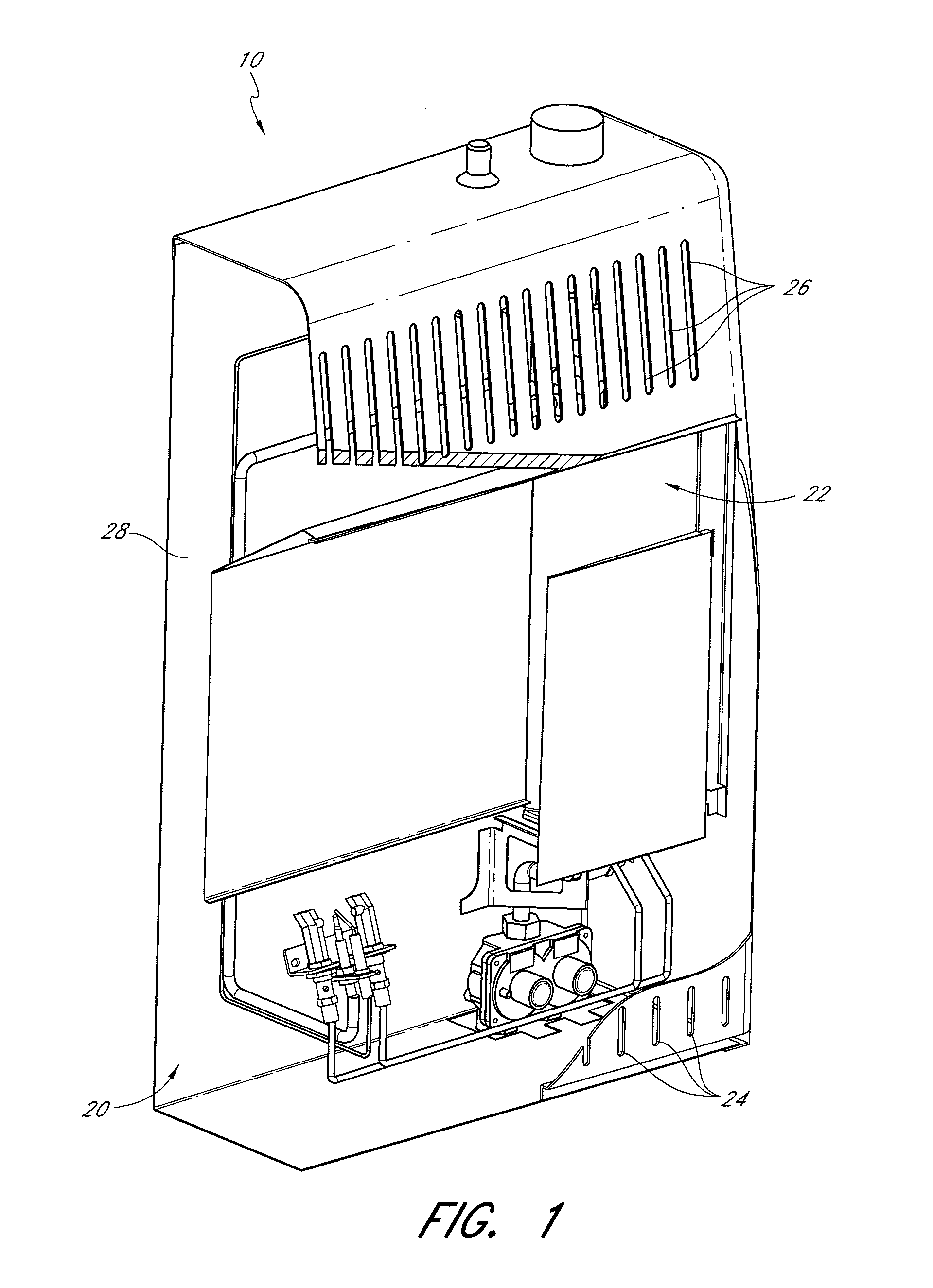

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel input and a second fuel input. The housing can further define a first flow path, a second flow path, a third flow path, and a fourth flow path. The assembly can include a fluid flow controller configured to selectively permit fluid communication between the first fuel input and either the first flow path or the second flow path, and configured to selectively permit fluid communication between the second fuel input and either the third flow path or the fourth flow path. The assembly can further include a first nozzle member defining an inlet and an outlet. The inlet of the first nozzle member can be in fluid communication with the first flow path. The assembly can further include a second nozzle member defining an inlet and an outlet. The inlet of the second nozzle member can be in fluid communication with the second flow path.

Owner:BLUEGRASS LIVING INC

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel input and a second fuel input. The housing can further define a first flow path, a second flow path, a third flow path, and a fourth flow path. The assembly can include a fluid flow controller configured to selectively permit fluid communication between the first fuel input and either the first flow path or the second flow path, and configured to selectively permit fluid communication between the second fuel input and either the third flow path or the fourth flow path. The assembly can further include a first nozzle member defining an inlet and an outlet. The inlet of the first nozzle member can be in fluid communication with the first flow path. The assembly can further include a second nozzle member defining an inlet and an outlet. The inlet of the second nozzle member can be in fluid communication with the second flow path.

Owner:PROCOM HEATING

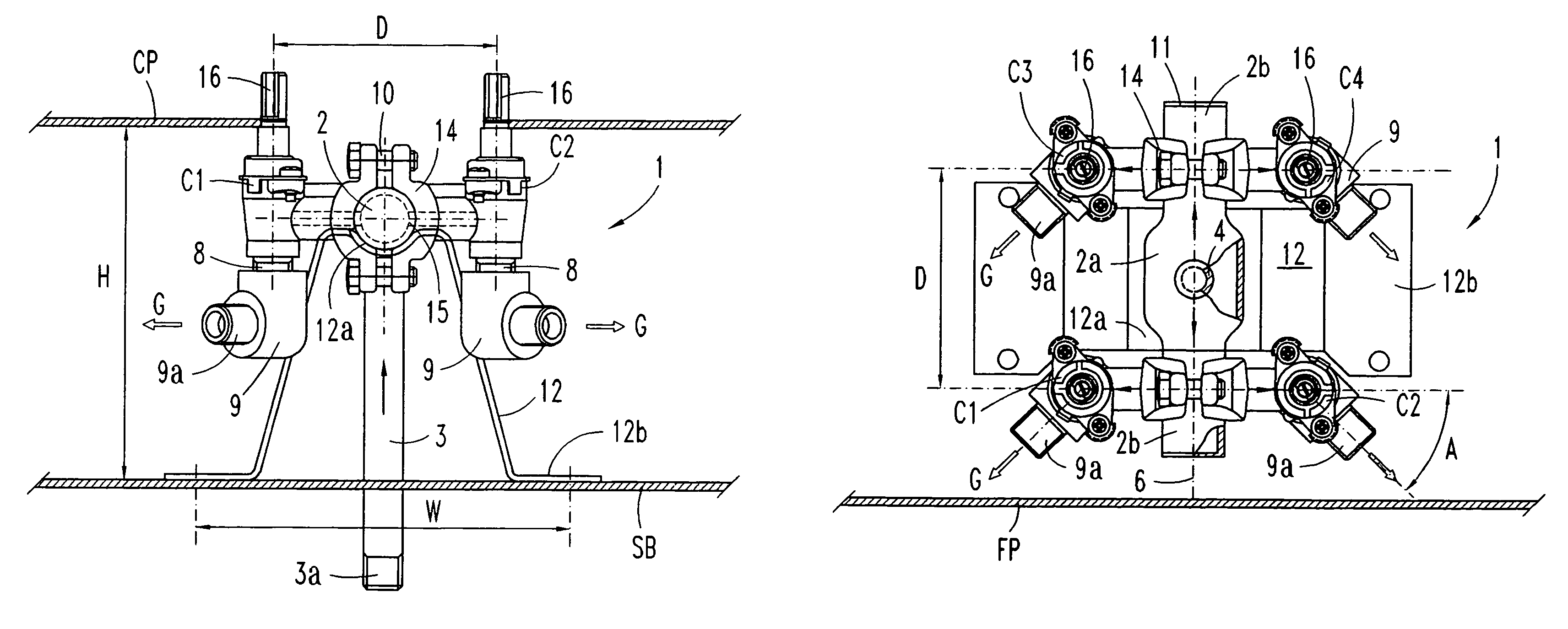

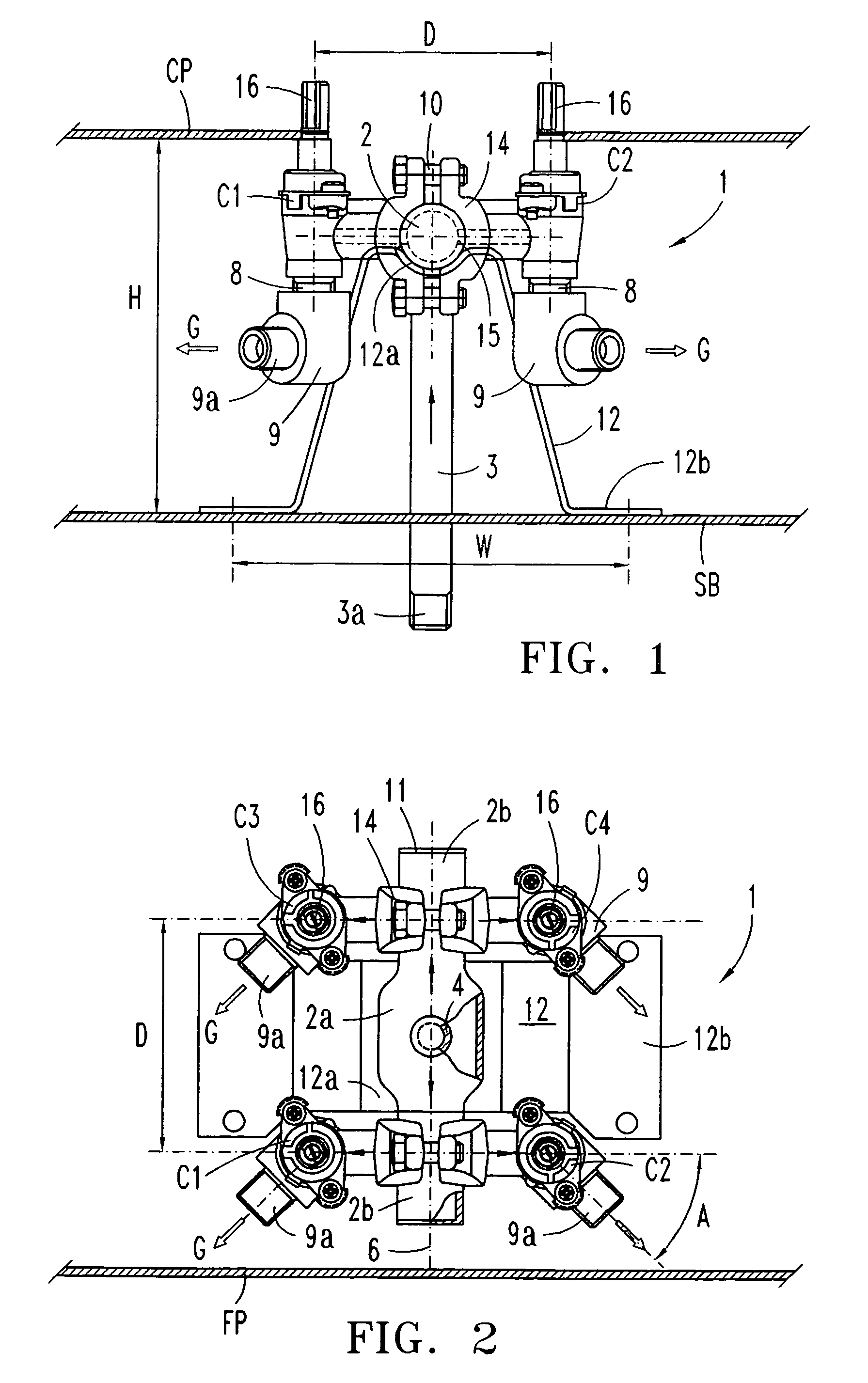

Gas distribution assembly with rotary taps for a cooking appliance

InactiveUS7048538B2Simple configurationCheap constructionDomestic stoves or rangesStoves/ranges topsCombustorDrive shaft

The gas distribution assembly (1) is adapted for the supply of a gas flow (G) to a cooking appliance with top burners, and comprises a straight tubular-shaped manifold conduit. (2) and various rotary taps (C1–C4) provided with an arched mounting base, which are superimposed in twos opposite to each other on a tubular part (2b) of the manifold, and fixed by means of common screws (10). The tap drive shafts (16) stand out from the horizontal cooking plane (CP) occupying a small-sized square geometric area (D×D) . A supporting leg (12) for the distribution assembly (1) is made of a plate folded and fixed on a horizontal structural base (SB), the gas feeder nipple (3) being connected to a central hollow part (2a) of the manifold, extended in a direction opposite to that of the drive shafts (16).

Owner:COPRECITEC

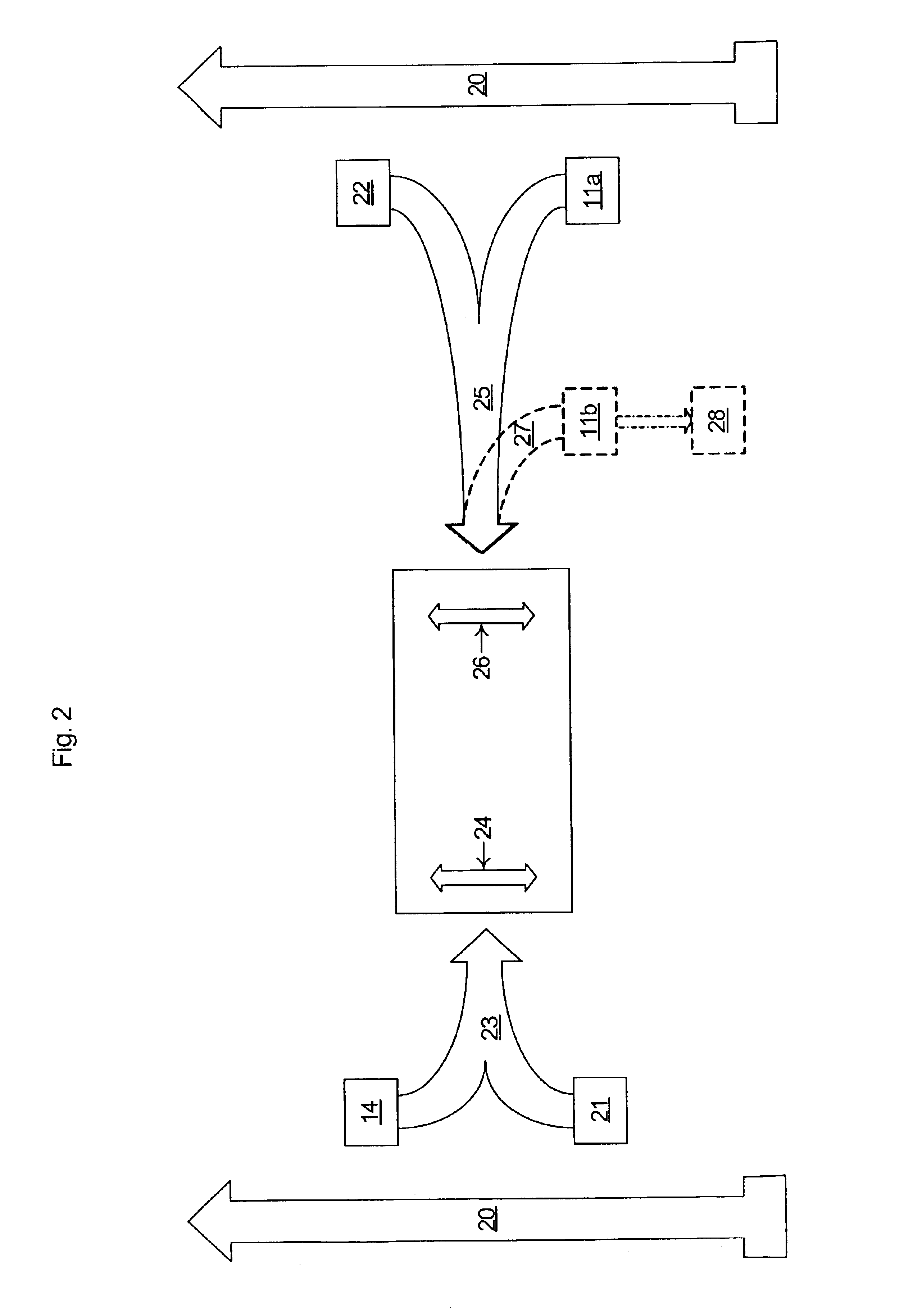

Methods of adjusting the Wobbe Index of a fuel and compositions thereof

Novel methods of providing fuels to a gas-to-liquids facility are disclosed. A gas-to-liquids facility typically operates in a remote location and therefore must supply its own energy needs. These facilities are often sustained by fuels having different heating values, and for smooth operation while transitioning from one fuel to another, (such as during startup, shut down, and emergencies) the Wobble Indices of the two fuels cannot greatly vary from one another. According to embodiments of the present invention, the Wobble Index of either or both of the fuels is adjusted such that their ratio is less than or equal to about 3. The fuel having the higher Wobble Index may be natural gas, and materials such as nitrogen, carbon dioxide and flue gas may be added to lower its Wobble Index. The fuel having the lower Wobble Index may be the tail gas of a Fischer-Tropsch synthesis, and materials such as methane, ethane, LPG, or natural gas may be added to raise its Wobble Index. Alternatively, carbon dioxide may be removed from the tail gas to raise its Wobble Index.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Split Control Unit

ActiveUS20130042920A1Functional valve typesTurbine/propulsion fuel supply systemsEngineeringControl unit

A split control unit in a distributed flow unit includes a flow inlet configured to receive a fuel flow, a first manifold having flow lines to supply fuel to one or more primary nozzles, and a second manifold having flow lines to supply fuel to one or more secondary nozzles. In an embodiment, the second manifold is in fluid communication with the flow inlet. A metering valve has a first port in fluid communication with the flow inlet and with the second manifold. The metering valve is configured to supply a metered fuel flow to the first manifold. A flow passage is in fluid communication with, and runs between, a flow line of the first manifold and a flow line of the second manifold to allow for a continuous cooling flow in the second manifold when all of the one or more secondary nozzles are closed.

Owner:WOODWARD GOVERNOR CO

Fuel selection valve assemblies

In certain embodiments, an apparatus includes a control valve for regulating fuel flow. The apparatus can include a burner and a valve assembly. In some embodiments, the valve assembly includes a housing, which can define a first fuel input for receiving a first fuel from a first fuel source and a second fuel input for receiving a second fuel from a second fuel source. The housing can define a first fuel output for directing fuel toward the control valve, and can define a third fuel input for receiving a portion of either the first fuel or the second fuel from the control valve. The housing can define a first egress flow path and a second egress flow path, each for directing fuel to the burner. In certain embodiments, the apparatus includes a valve body configured to selectively permit fluid communication between the first and second inputs and the output and between the third input and the egress flow paths.

Owner:PROCOM HEATING

Process for combustion of high viscosity low heating value liquid fuels

ActiveUS20080305445A1Easy to cleanHigh viscosityBurnersSpace heating and ventilationCombustion chamberGlycerol

The present invention is directed to a process for the clean and convenient combustion of high viscosity liquid fuels, such as glycerol, as well as an apparatus useful for carrying such processes. In certain embodiments, the invention provides a process for glycerol combustion comprising providing a combustion apparatus with a glycerol combustion chamber that facilitates reflective heating, pre-heating the glycerol combustion chamber, atomizing the reduced viscosity glycerol, and combining the atomized glycerol with air in the glycerol combustion chamber to thereby completely combust the glycerol. In one embodiment, such as when using a pressure-atomizing nozzle, the inventive method may further comprise treating the glycerol to reduce the glycerol viscosity.

Owner:NORTH CAROLINA STATE UNIV

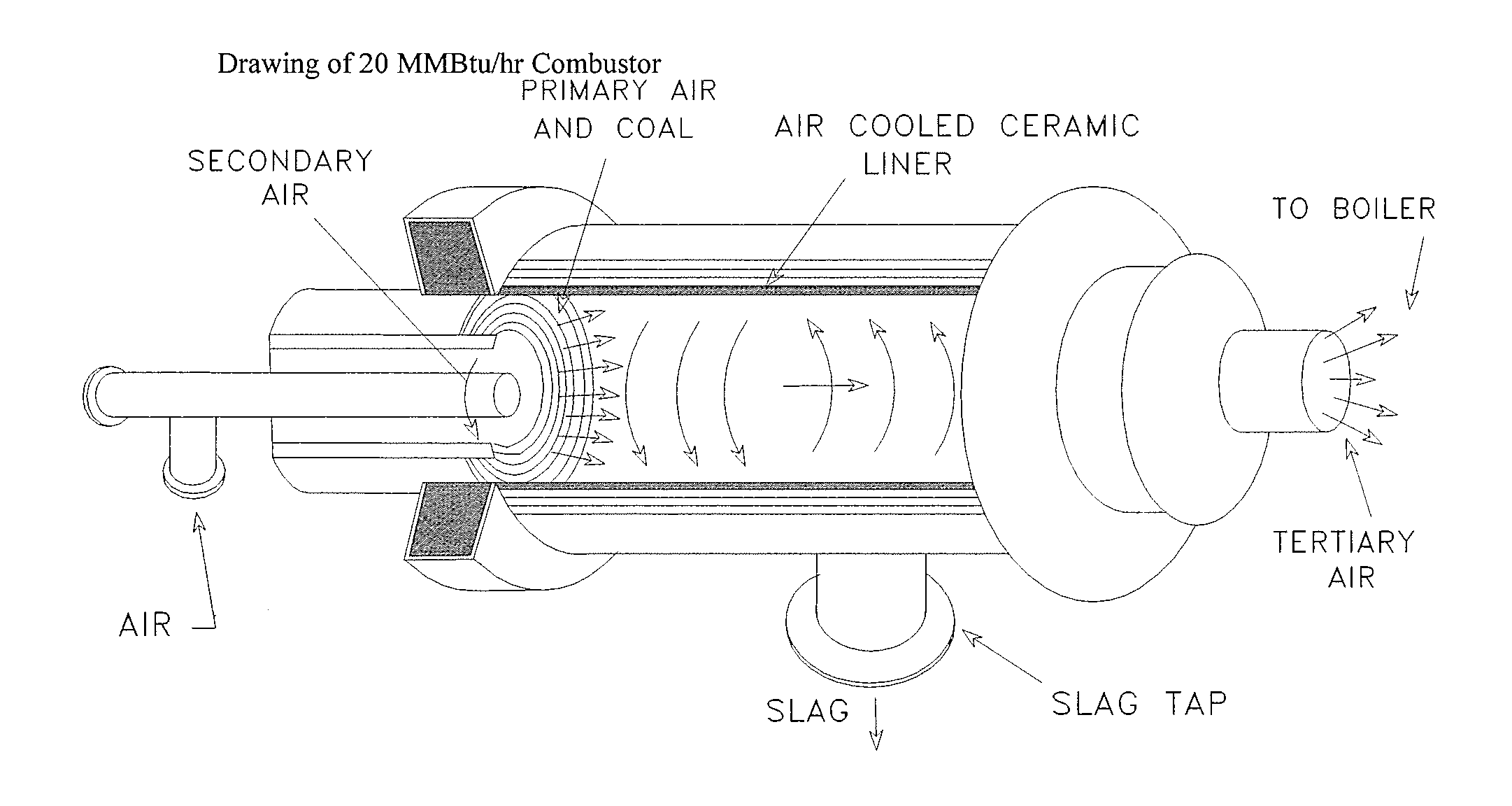

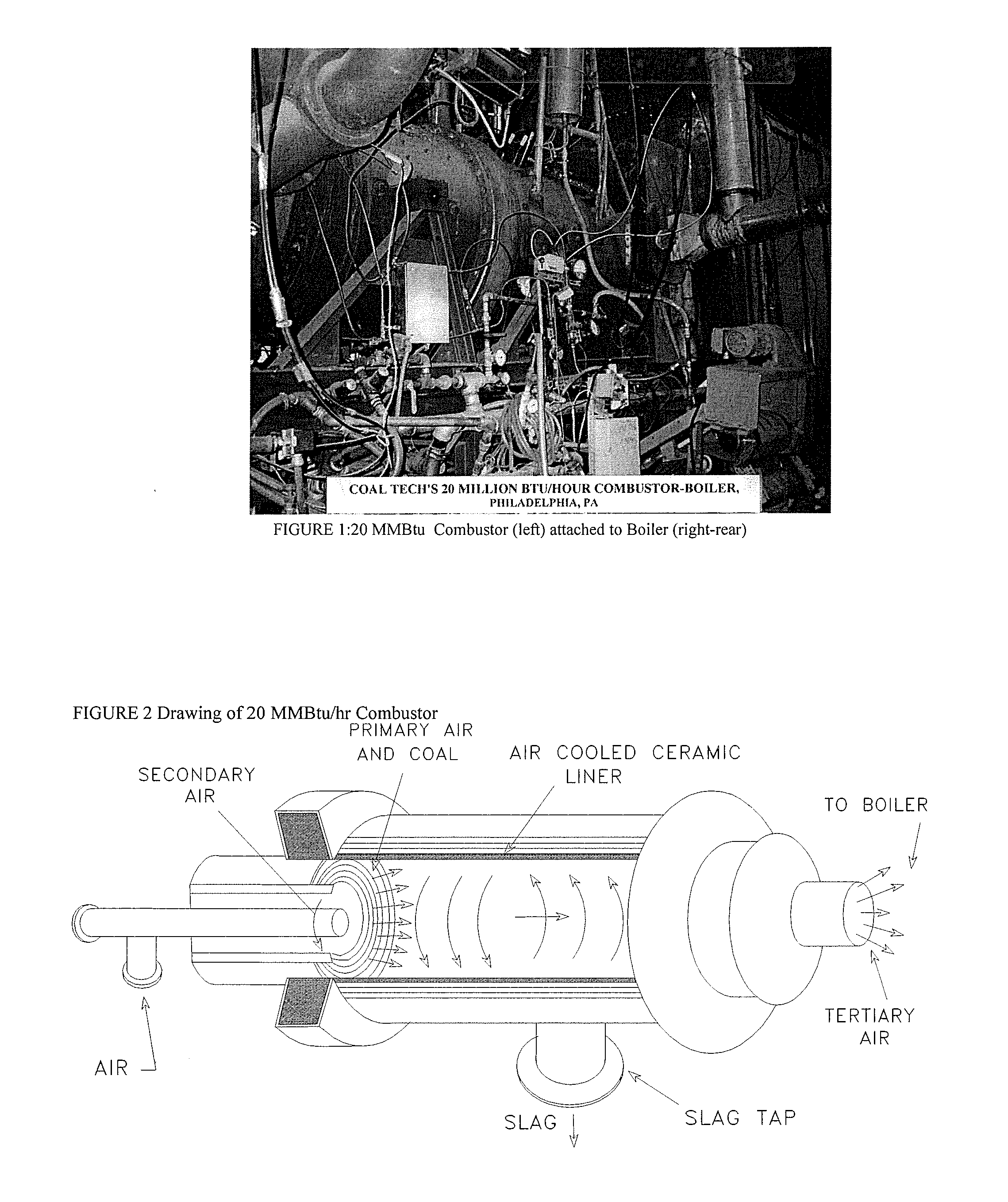

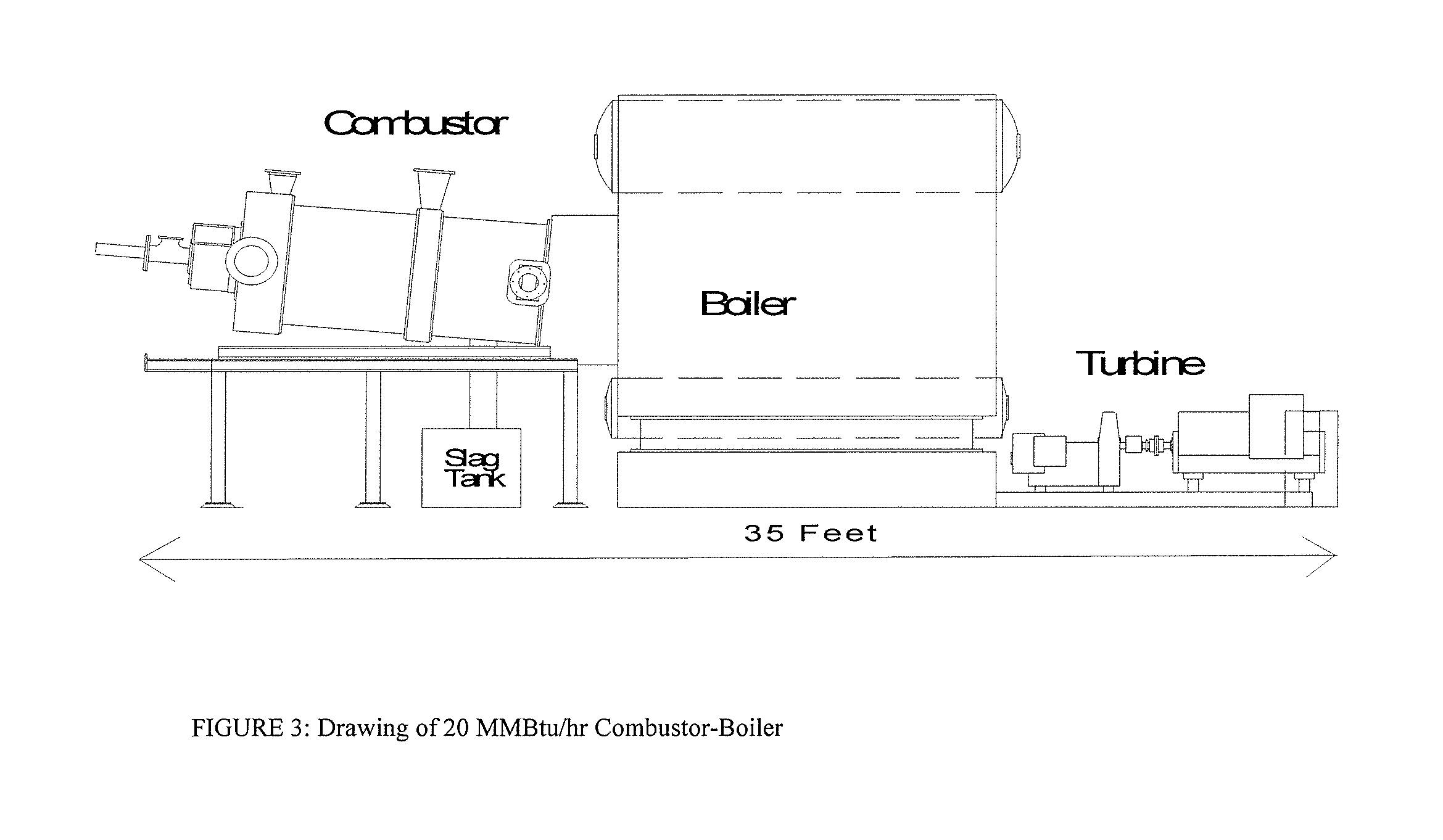

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and co2 sequestration

InactiveUS20110173139A1Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsMaterials scienceChar

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

Catalytic treatment of fuel to impart coking resistance

ActiveUS7744827B2Increase fuel capacityImprove rendering capabilitiesTurbine/propulsion fuel supply systemsCosmonautic vehiclesDecompositionEngineering

A fuel delivery system for a gas turbine engine includes a catalytic device for treating fuel to increase the usable cooling capability of an endothermic fuel. The catalytic device operates to treat and decompose components within in the fuel to render the fuel non-coking beyond 250° F. The catalytic device includes material that initiates reactions, and decomposition of coke forming components within the fuel to non-coke forming components within the fuel.

Owner:RTX CORP

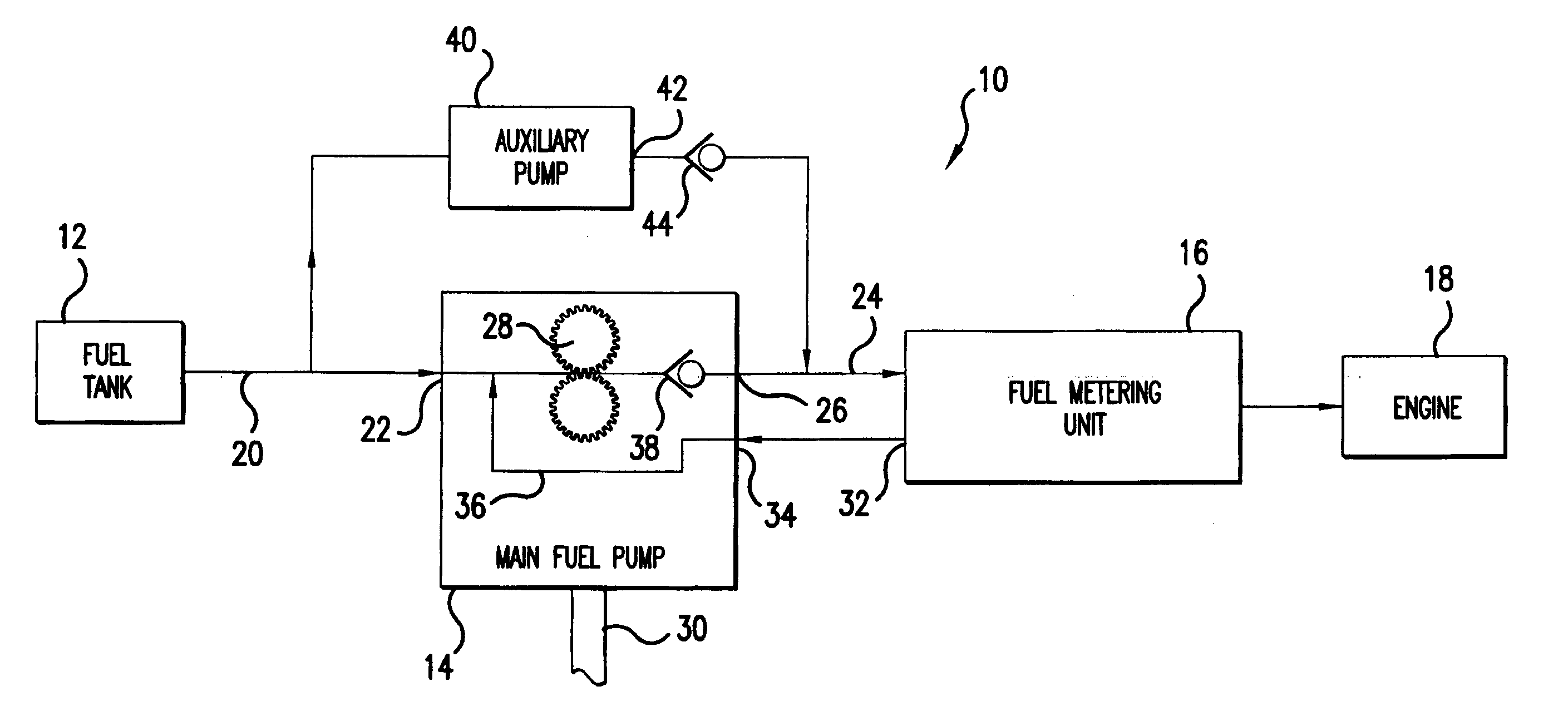

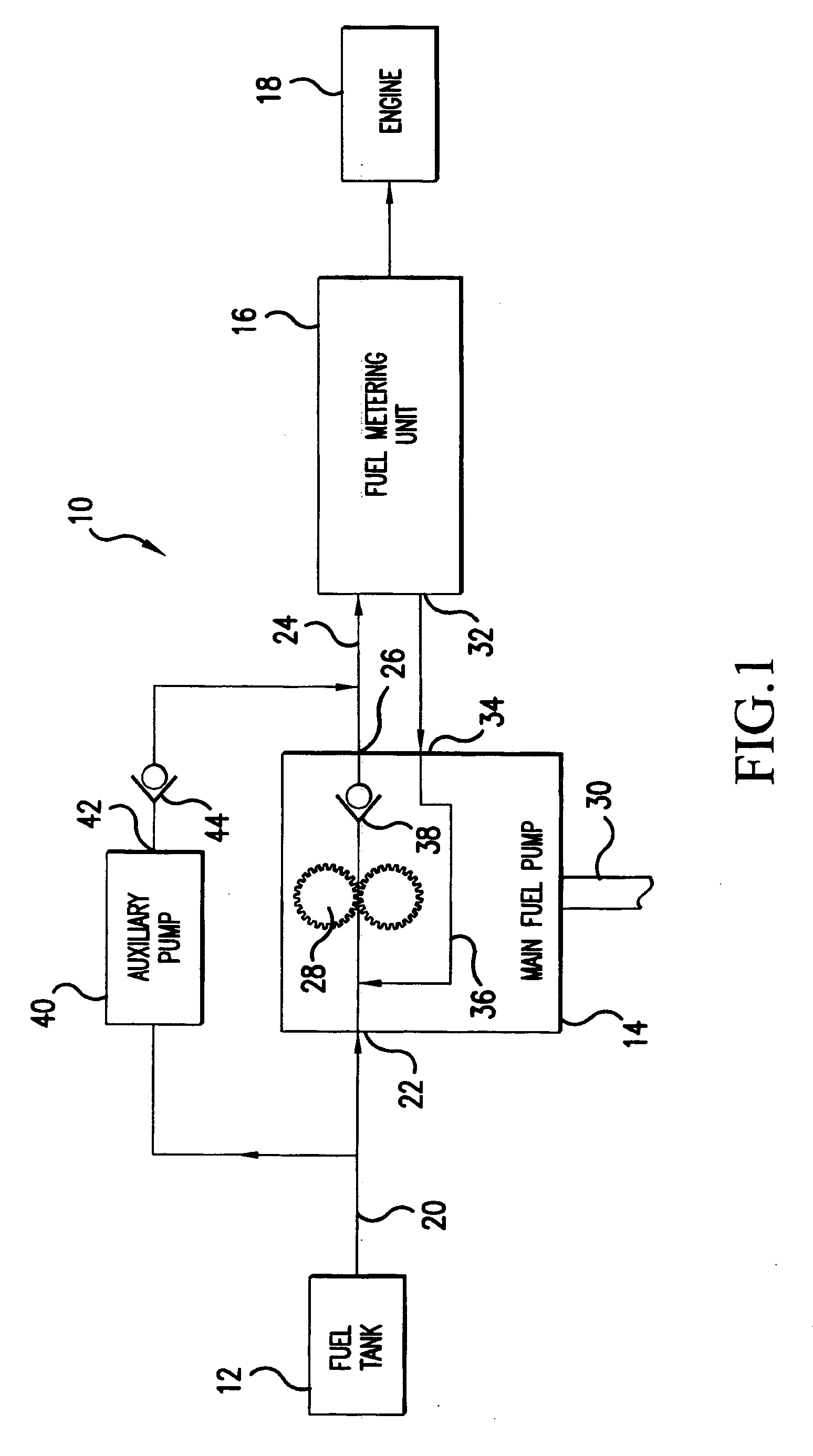

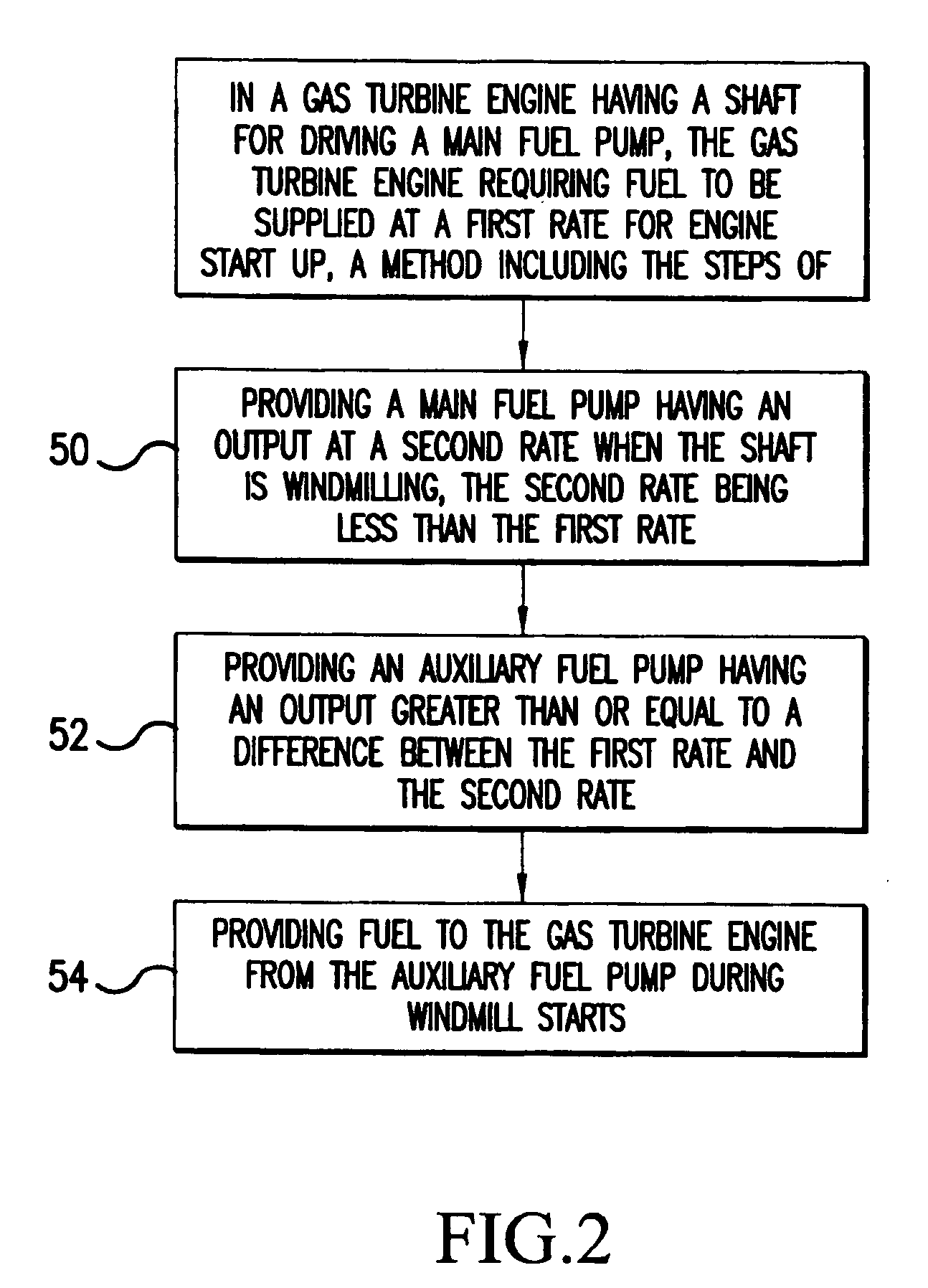

Reduced-weight fuel system for gas turbine engine, gas turbine engine having a reduced-weight fuel system, and method of providing fuel to a gas turbine engine using a reduced-weight fuel system

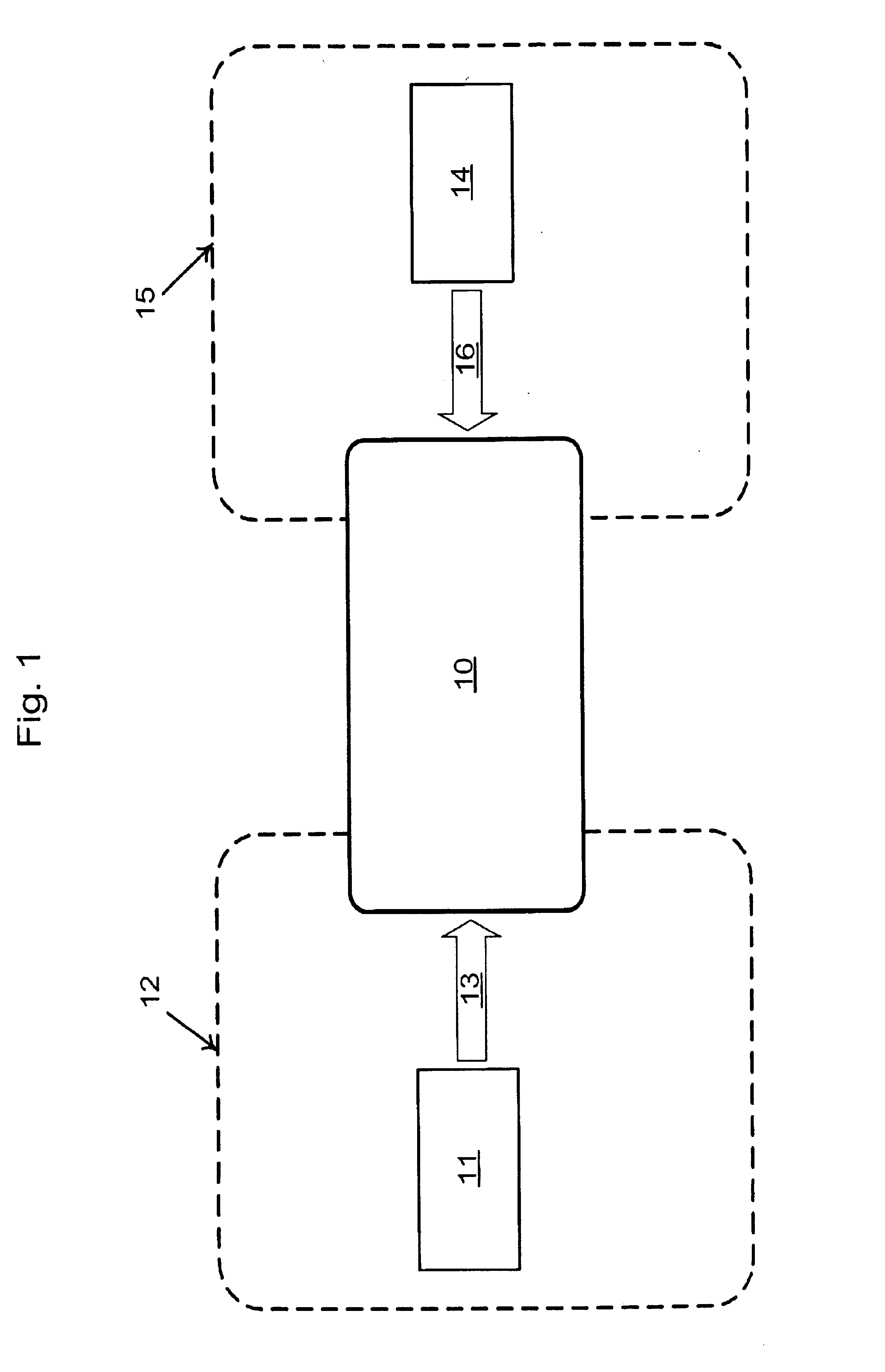

A fuel system (10) for a gas turbine engine (18) having a shaft (30) and requiring fuel to be supplied at a first rate for engine start up, the fuel system (10) including: a main fuel pump (14) for providing fuel to the gas turbine engine (18), the main fuel pump (14) having an output varying with shaft speed, the output being at a windmilling rate when the engine (18) is windmilling, the windmilling rate being less than the first rate; and an auxiliary fuel pump (40) for providing fuel to the gas turbine engine (18) and having an auxiliary output rate greater than or equal to the difference between the first rate and the windmilling rate. A method of operating such a fuel system (10) is also disclosed.

Owner:HONEYWELL INT INC

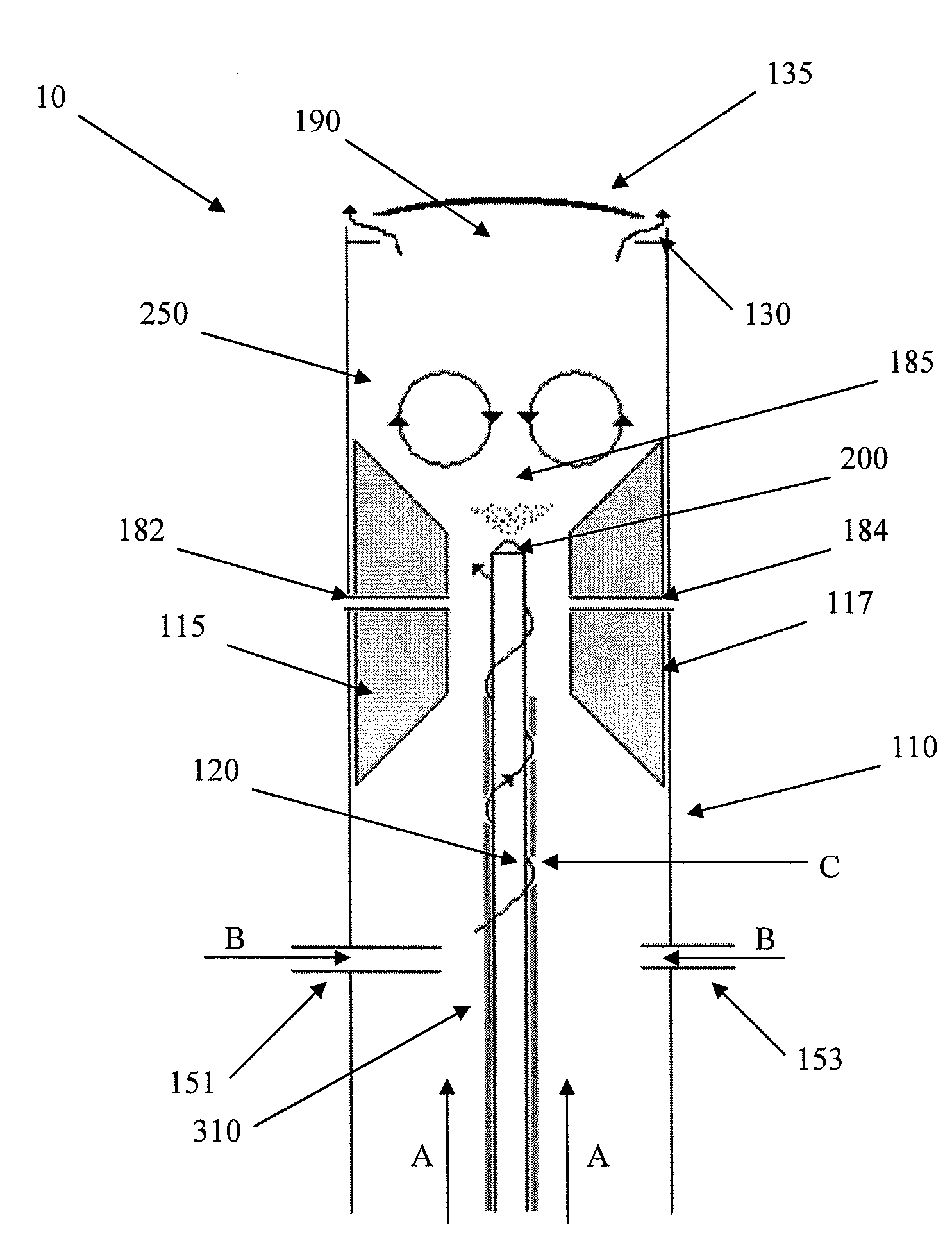

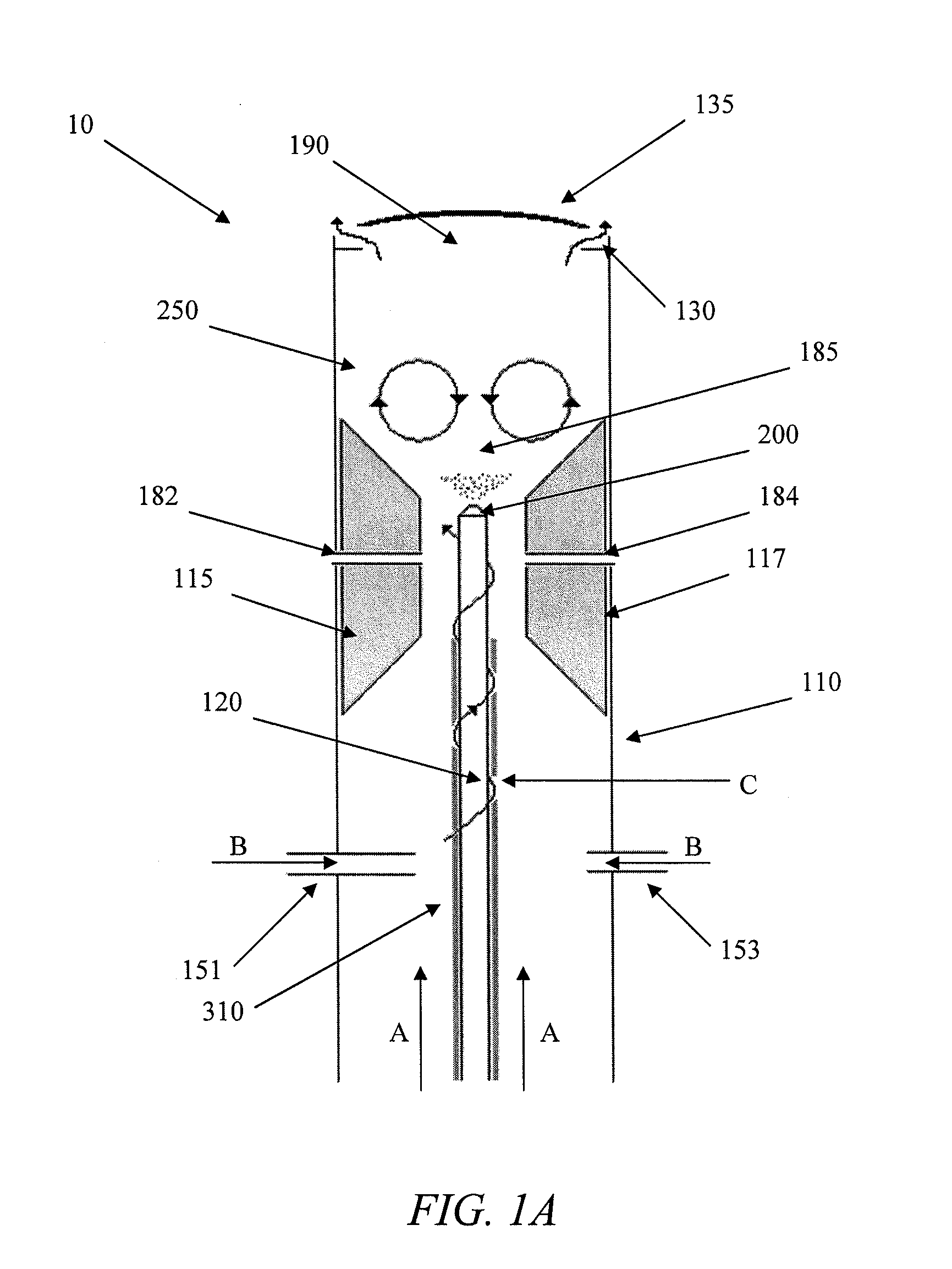

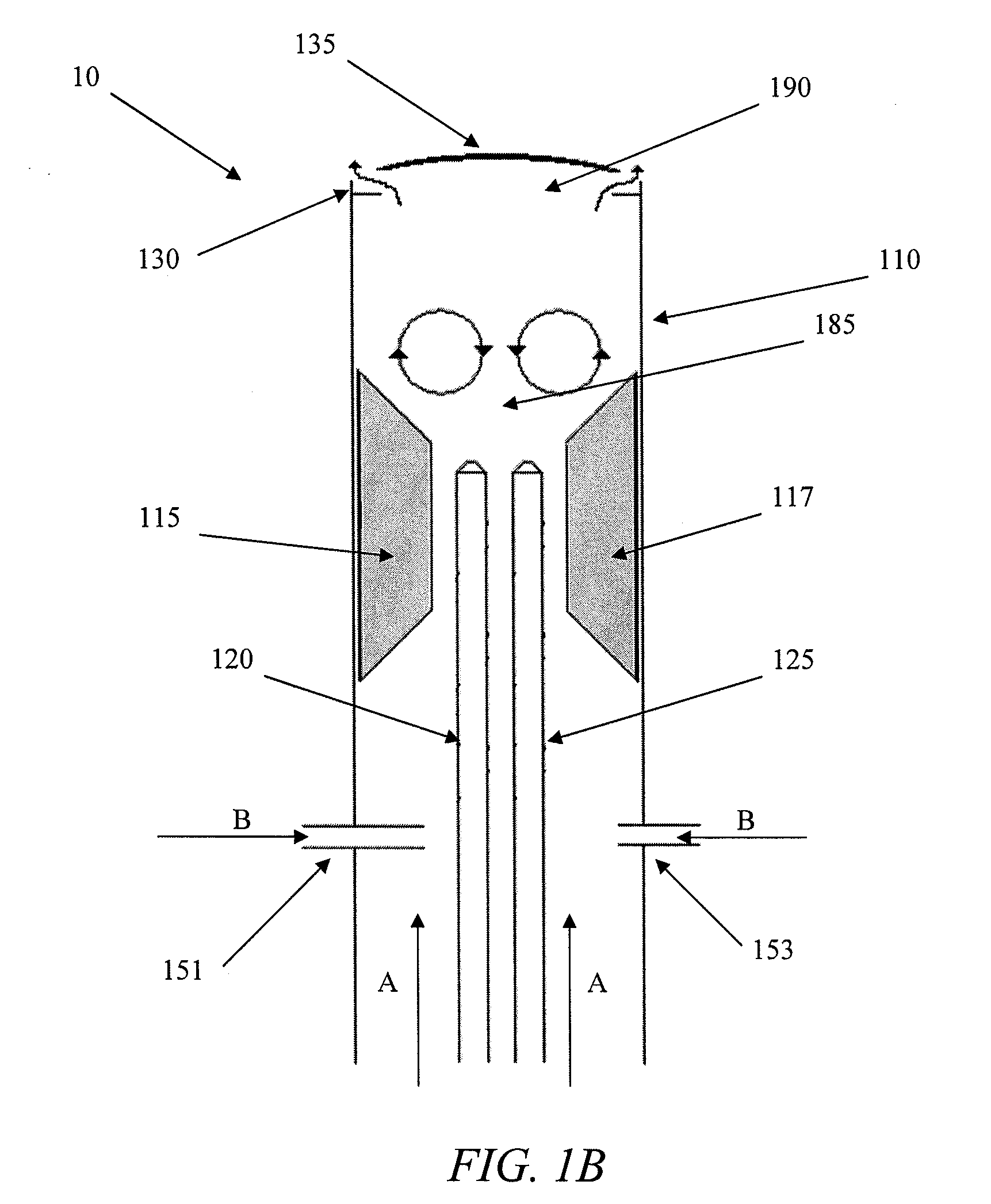

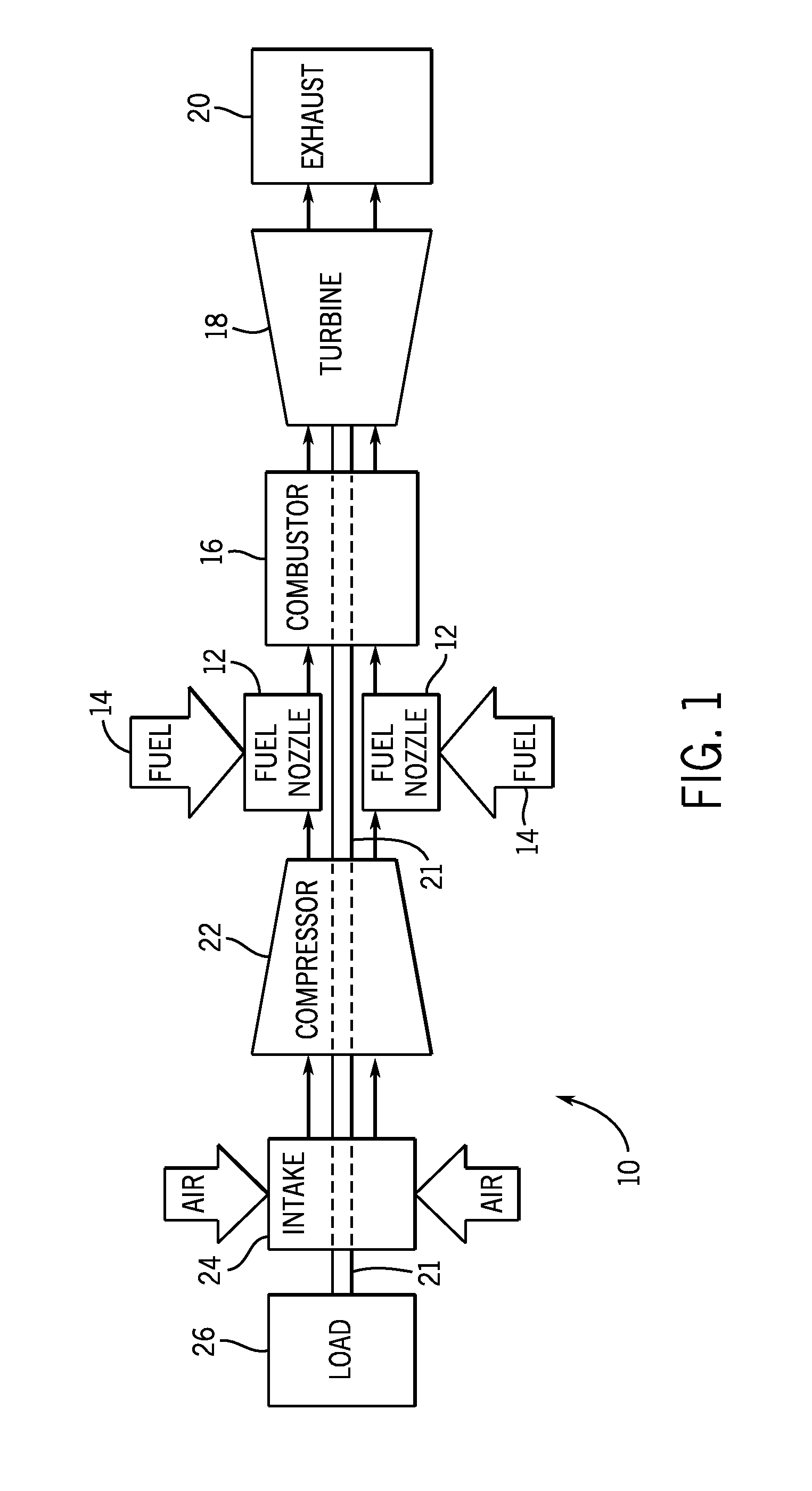

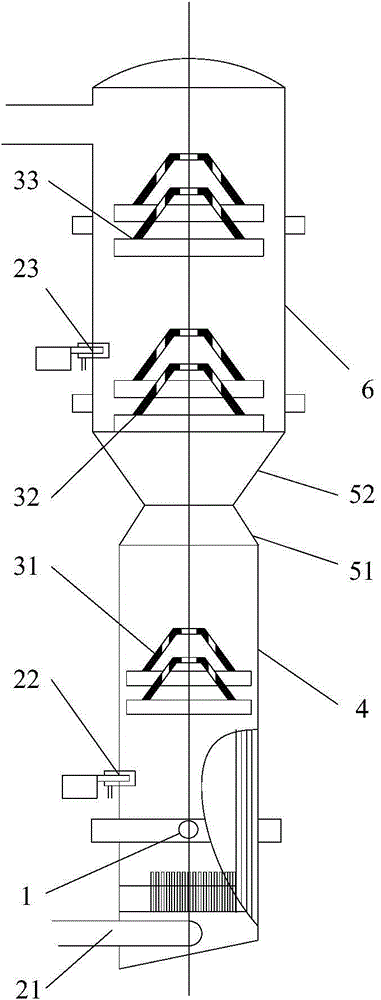

Multiple stage combustion process to maintain a controllable reformation temperature profile

InactiveUS20050048333A1Uniform exchangeGenerate uniformFuel cells groupingFuel cell auxillariesFuel cellsWorking fluid

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

System having layered structure and method of making the same

A system includes a layered structure. The layered structure includes first and second coalesced layers and an intermediate layer disposed between the first and second coalesced layers. The first and second coalesced layers have a higher degree of coalescence than the intermediate layer.

Owner:GENERAL ELECTRIC CO

Reduced-weight fuel system for gas turbine engine, gas turbine engine having a reduced-weight fuel system, and method of providing fuel to a gas turbine engine using a reduced-weight fuel system

A fuel system (10) for a gas turbine engine (18) having a shaft (30) and requiring fuel to be supplied at a first rate for engine start up, the fuel system (10) including: a main fuel pump (14) for providing fuel to the gas turbine engine (18), the main fuel pump (14) having an output varying with shaft speed, the output being at a windmilling rate when the engine (18) is windmilling, the windmilling rate being less than the first rate; and an auxiliary fuel pump (40) for providing fuel to the gas turbine engine (18) and having an auxiliary output rate greater than or equal to the difference between the first rate and the windmilling rate. A method of operating such a fuel system (10) is also disclosed.

Owner:HONEYWELL INT INC

Valve assembly for modulating fuel flow to a gas turbine engine

ActiveUS20090026398A1Rapid oscillatory movementReducing frictional surface contactFuel supply regulationOperating means/releasing devices for valvesTorsion springMagnetic flux

A valve assembly for modulating fuel flow is disclosed which includes a valve housing having an inlet section and an outlet section, at least one valve rotor disposed between the inlet section and the outlet section for modulating fuel flow through the valve housing, wherein the at least one valve rotor is formed from a ferritic magnetic flux permeable material and is mounted for rotational movement within the valve housing, under the influence of a torsion spring, between first and second magnetically latched positions, and a pair of electromagnets means for alternately latching the at least one valve rotor in the first and second magnetically latched positions.

Owner:DELAVAN

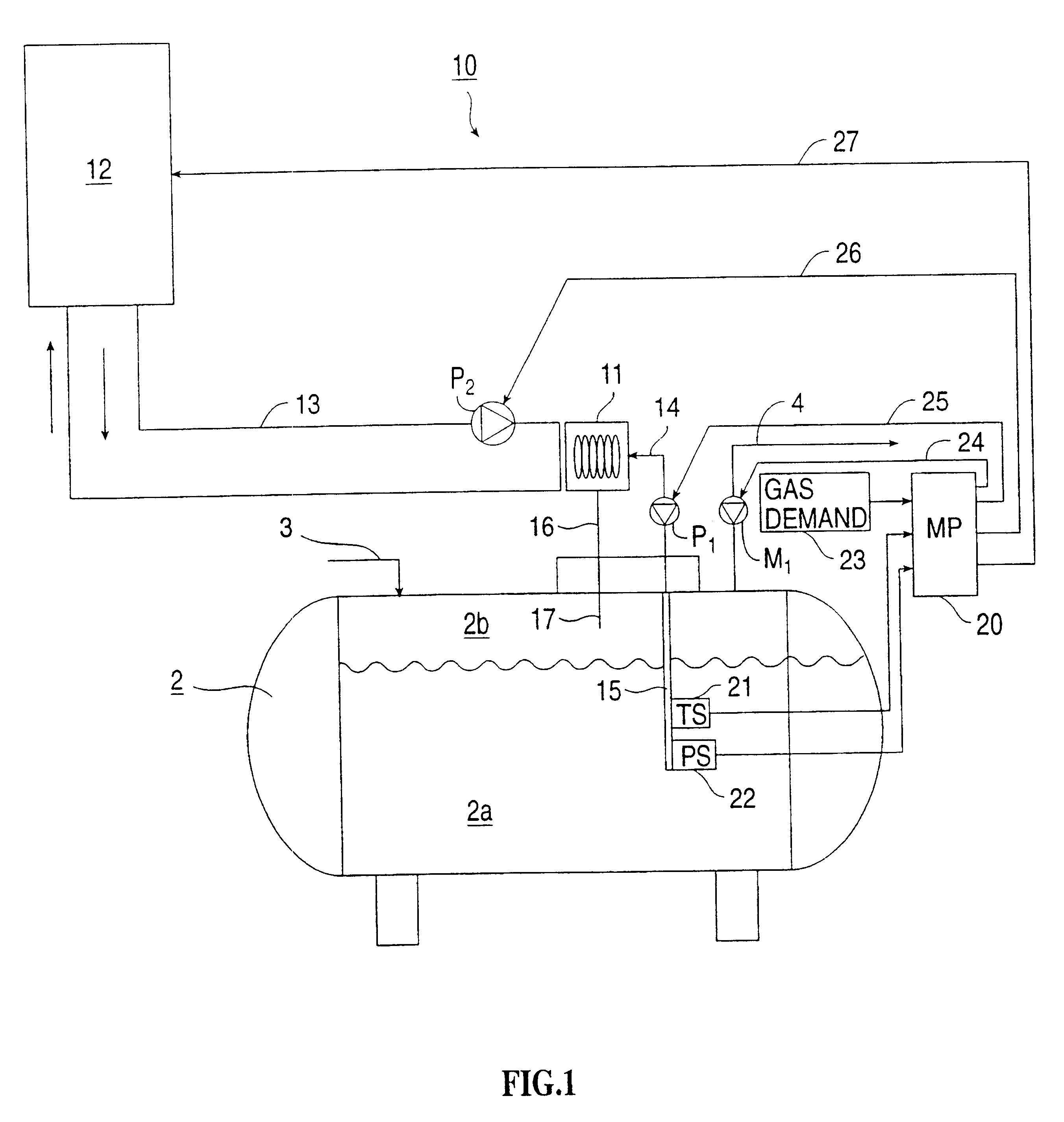

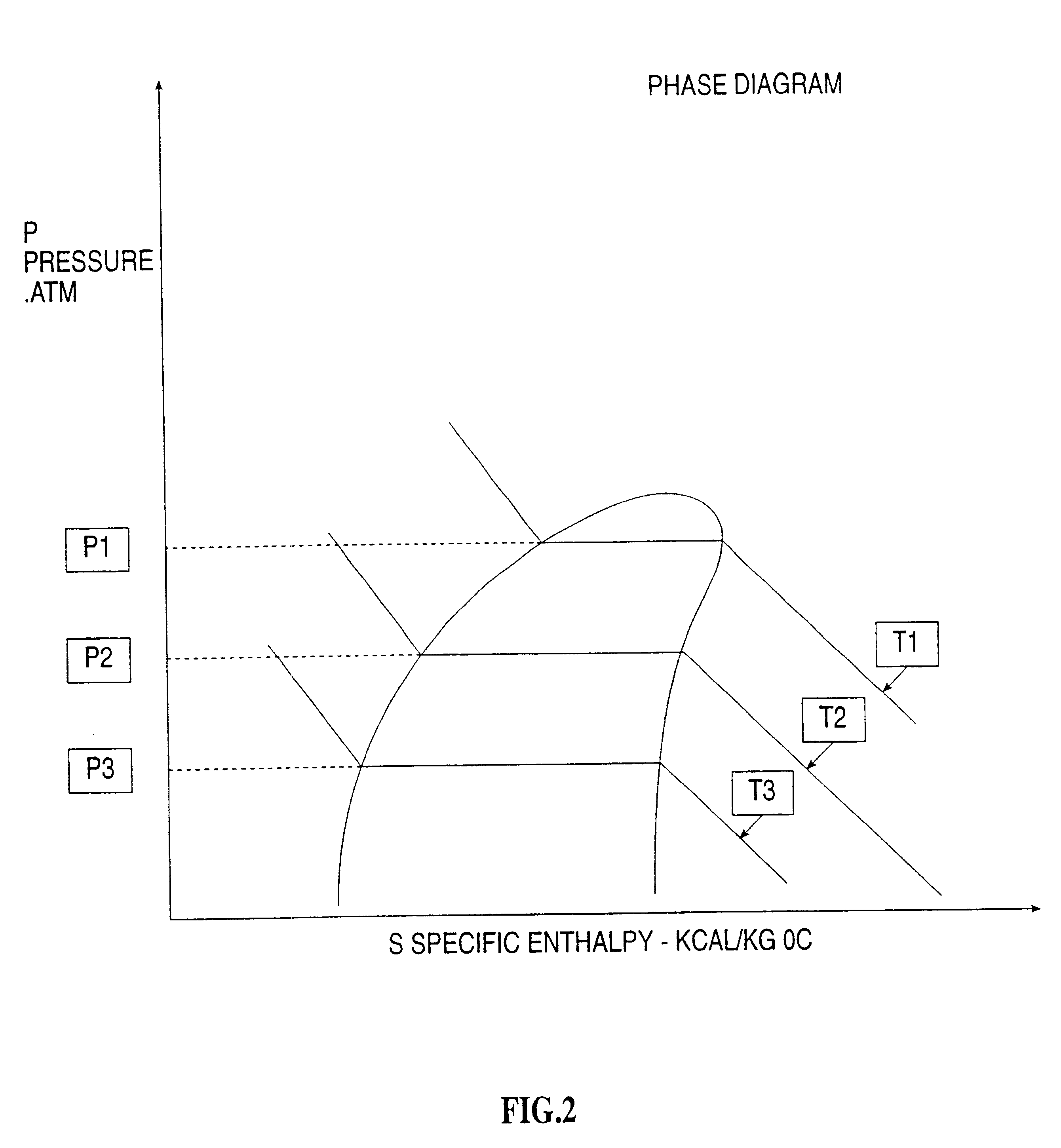

Method and apparatus for supplying vaporized gas on consumer demand

InactiveUS6470690B1Reduce heatCompact and inexpensive to installVessel mounting detailsVessel geometry/arrangement/sizeProcess engineeringProduct gas

A method of supplying vaporized gas from a storage tank storing the gas in liquified form in a lower liquid region and having a vapor region thereover, the method including employing an external source of heat to heat a heat exchange liquid to no more than about 35° C., bringing the heat exchange liquid into heat exchange relation with at least a portion of the liquified gas so as to transfer heat from the external source of heat to the liquified gas, and supplying vaporized gas to the consumer, according to the consumer demand, directly from the vapor region of the storage tank. The heat exchange relation is controlled such that the at least portion of the liquified gas which is heated remains mostly in a liquified state but that the temperature of the liquified gas is prevented from falling below a predefined minimum operational temperature.

Owner:EXTA EXCLUSIVE THERMODYNAMIC APPL

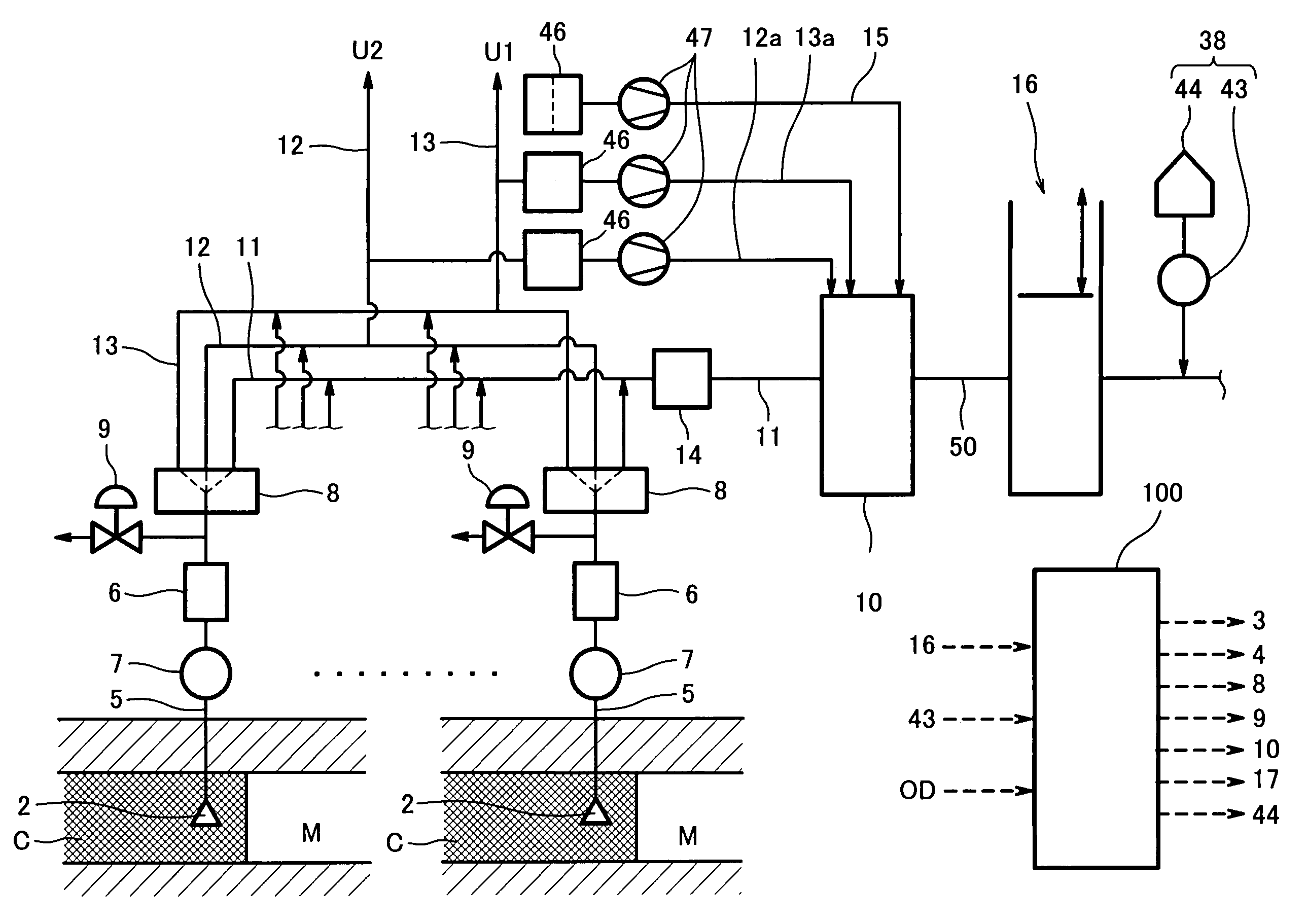

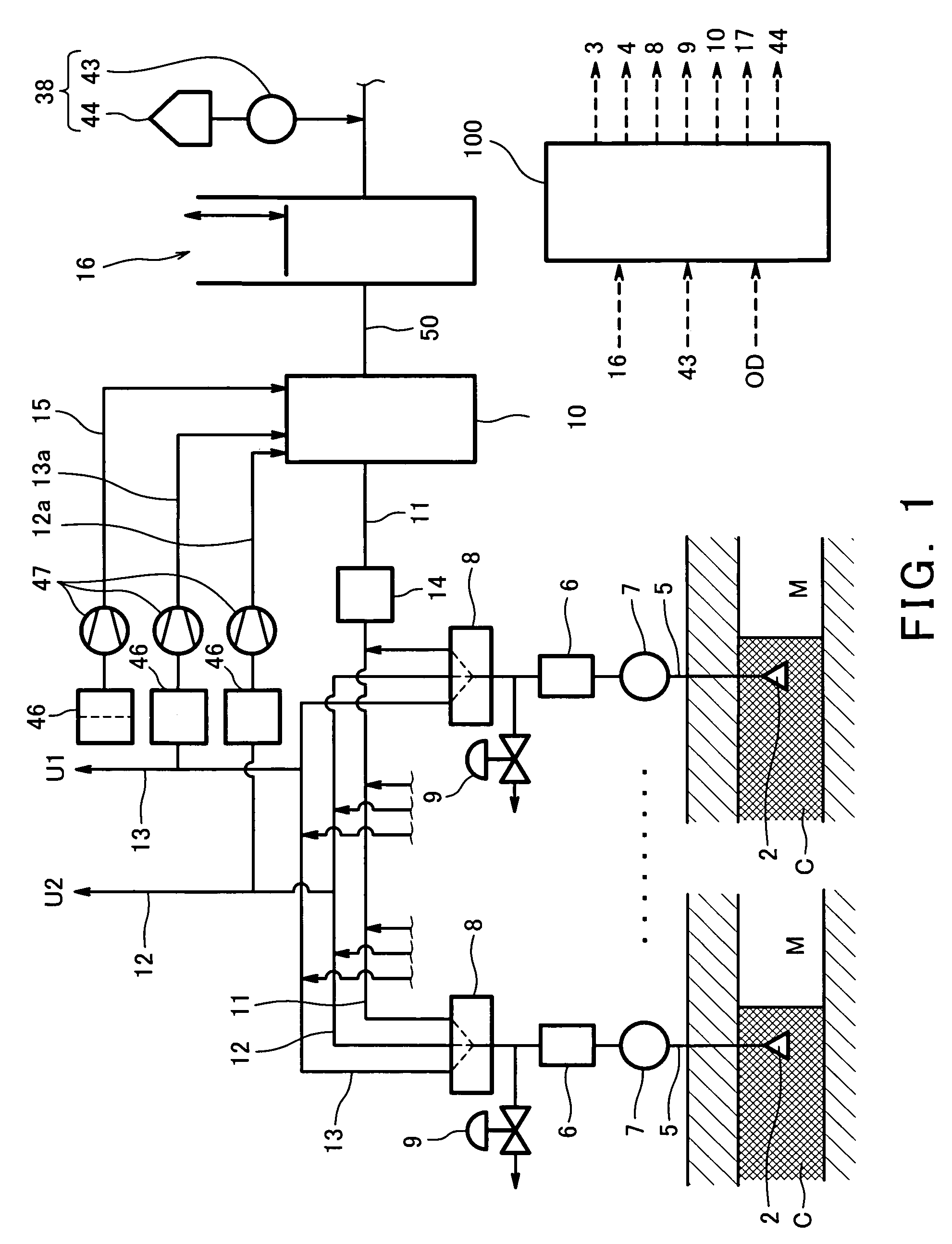

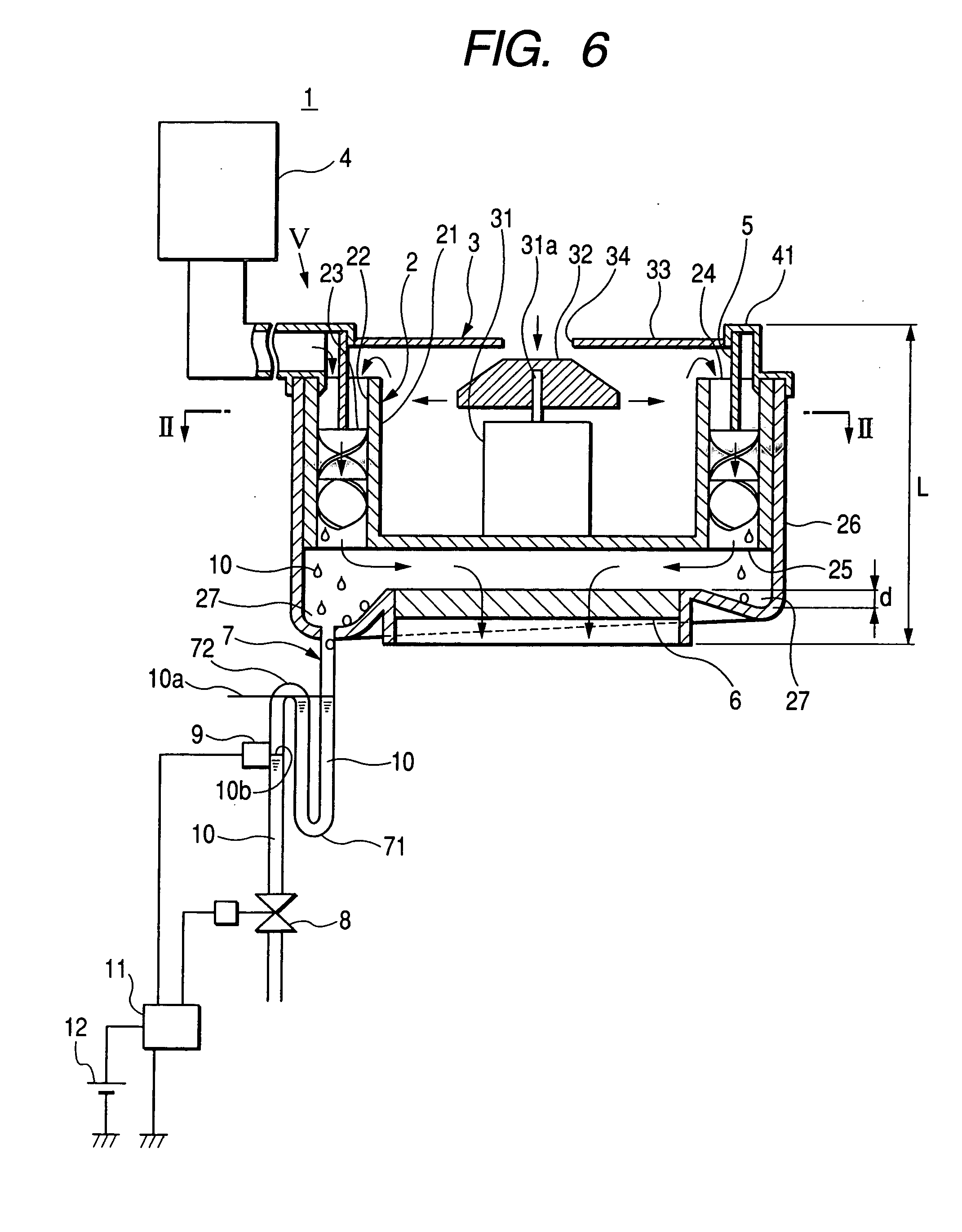

Motor-operated valve apparatus

InactiveUS7168677B2Short timeIncrease the number ofDomestic stoves or rangesOperating means/releasing devices for valvesMicrocomputerRange of motion

When a fluid flow channel is interrupted while an electronic circuit unit 50 including a microcomputer 51 and the like receives electric source power, a flow control valve is displaced to a predetermined position closer to a first end of both ends of a motion range of the flow control valve in the fluid flow channel by a stepping motor 29. When the supply of electric source power is restarted after the supply of electric source power to the electronic circuit unit 50 is stopped, a predetermined number of pulses capable of displacing the flow control valve from the first end to a home position are supplied to the stepping motor 29 to displace the flow control valve to the home position with a second end of both ends of the motion range of the flow control valve being the home position of the flow control valve. Thus, the flow control valve is shifted to the home position while preventing occurrence of a disorder of the stepping motor, abnormal sounds and vibrations, in a simple configuration, without requiring means for detecting arrival of the flow control valve at the home position.

Owner:RINNAI CORP

Fuel supply system

InactiveCN102777285AReduce pollutionFuel diversificationElectrolysis componentsNon-fuel substance addition to fuelLow noiseCombustion chamber

The invention discloses a fuel supply system which comprises a pure hydrogen storage container, a pure oxygen storage container, a first pressure regulator, a second pressure regulator, an engine combustion chamber, a power generator, a storage battery, a hydrogen / oxygen fuel battery, a water storage tank, an electrolytic bath, an exchange film, a first pressurizer and a second pressurizer, wherein the pure hydrogen storage container is used for storing and supplementing pure hydrogen; the pure oxygen storage container is used for storing and supplementing pure oxygen; the first pressure regulator is used for regulating the pressure and the flow of output pure hydrogen and pure oxygen; the second pressure regulator is used for regulating the pressure and the flow of output pure hydrogen and pure oxygen; the engine combustion chamber is used for receiving pure hydrogen and pure oxygen and igniting so as to combust to generate the power; the hydrogen / oxygen fuel battery is used for receiving pure hydrogen and pure oxygen so as to generate chemical reaction to generate the power; the exchange film is used for separating and purifying hydrogen and oxygen generated by the electrolytic bath into pure hydrogen and pure oxygen; the first pressurizer is used for conveying separated and purified pure oxygen to the pure oxygen storage container to be stored up; and the second pressurizer is used for conveying separated and purified pure hydrogen to the pure hydrogen storage container to be stored up. The fuel supply system has the advantages of diverse fuel, clean gas discharge, low noise, little environment pollution, high reliability and the like, and is easy to maintain.

Owner:陈温乐

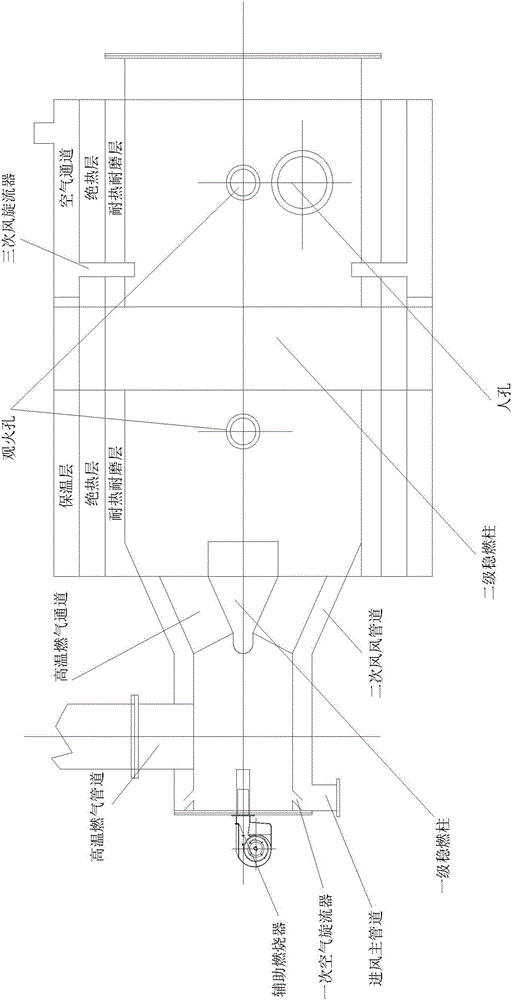

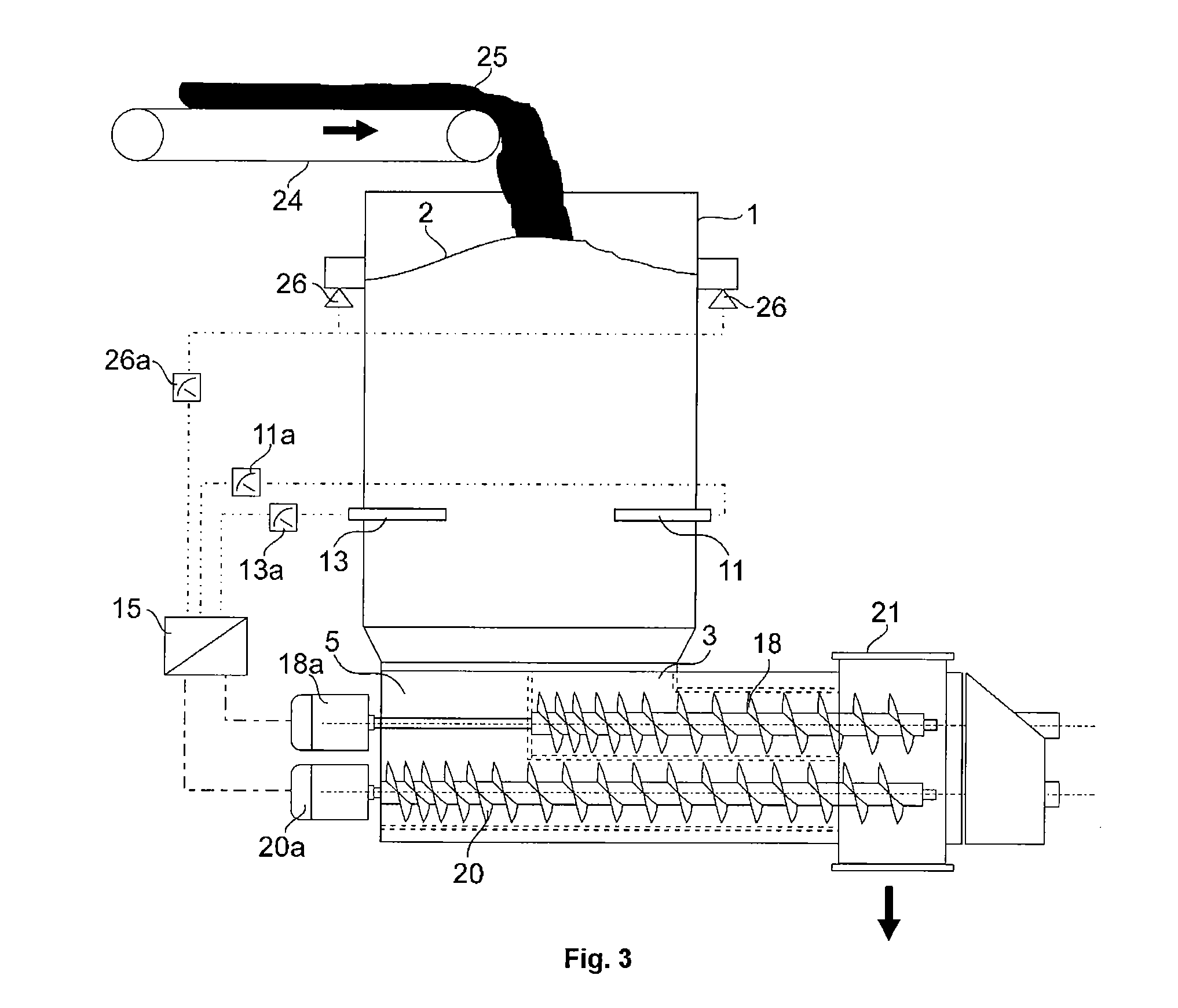

Biomass solid waste and hazardous waste combustion gas production system

ActiveCN104819472AEmission reductionImprove carbon conversionFuel feedersIncinerator apparatusCycloneCombustion chamber

The invention discloses a biomass solid waste and hazardous waste combustion gas production system. The air is sent into a combustion furnace through different positions in three times to facilitate staged combustion of combustion gas to further enable the combustion gas to achieve full combustion in the combustion furnace, so that the emission of nitrogen oxide is reduced effectively, and the carbon conversion of materials is increased. Furthermore, a gas cyclone and an air cyclone are used, the gas cyclone is composed of a gas chamber and a plurality of branches tangentially and uniformly distributed in the circumferential direction of the combustion chamber from the outside of a primary combustion chamber to the inside, and the branches are circumferentially and uniformly distributed from a main gas inlet and is characterized in that the diameters of the branches gradually decrease from the main gas inlet to the position away from the main gas inlet to ensure the consistent intake rate. The turbulent flow combustion stabilization is performed on the gas in the combustion furnace to form a recirculation zone for heat storage and maintaining the temperature of stable combustion.

Owner:山东百川同创能源有限公司

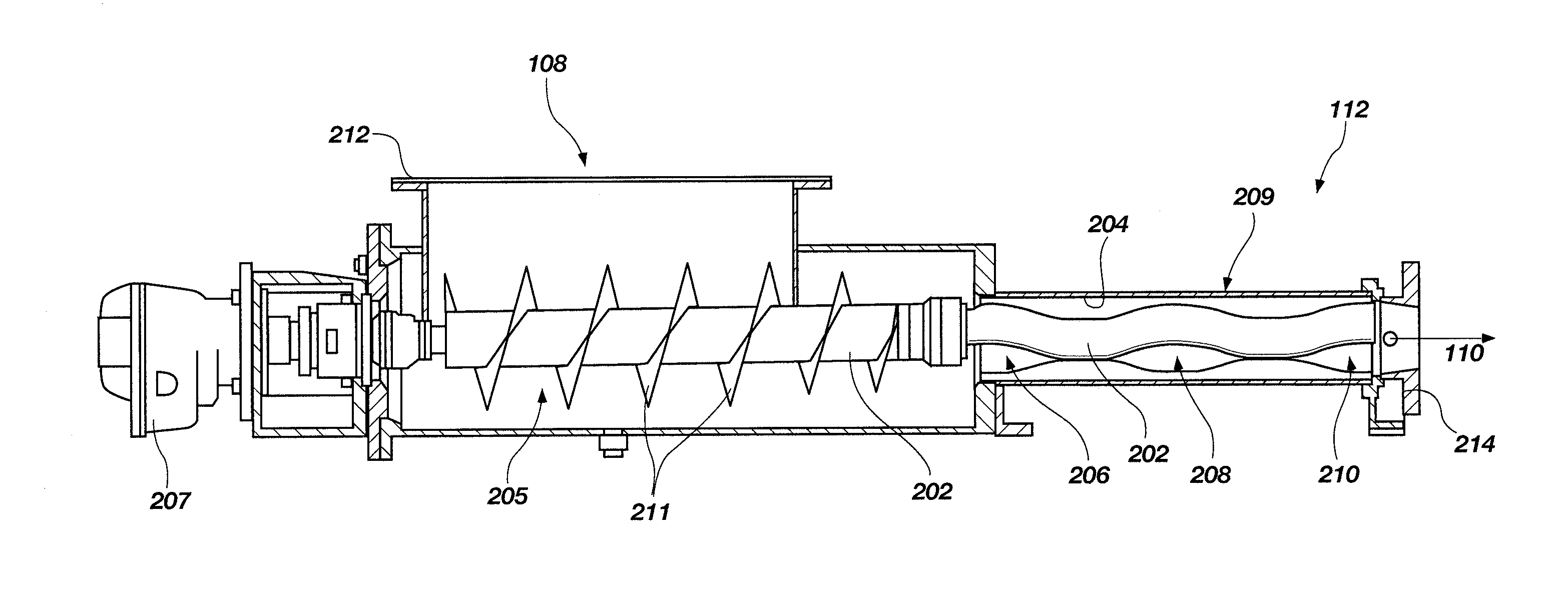

Method and Apparatus for the Continuous Controlled Discharge of Solids

InactiveUS20080244986A1ConveyorsPower operated devicesElectrical resistance and conductanceSolid mass

It is known that poorly-flowing solid materials can lead to an inhomogeneous mass flow of the solid across the discharge cross-section of a silo. If the solid in the silo is also heated or cooled the uneven mass flow can lead, for example, to local variations in temperature and / or hence to varying product properties. According to the invention, the above problem may be resolved, whereby a method and a discharge device for a solids silo and a solids silo are disclosed, permitting a controllable solids discharge evenly across the cross-section of the silo. The cross-section of the silo discharge is divided into several, preferably equivalent, partial cross-sections to which a continuously controllable discharge device is connected. The solid flow discharged from the controllable discharge devices can be collected on a continuous conveyor arranged therebelow and removed. The even solid mass discharge from the continuous discharge devices is controlled, depending on measured signals from several equivalent sensors, recording the local mass flow in the corresponding partial sections of the silo, by means of the conveyor power of the discharge device, relating to each sensor. Where electrically-conducting solids are used which are to be heated in the silo using electrodes by means of resistance heating, the control of the discharge devices is achieved with the measured current at the electrodes.

Owner:MASCHFAB GUSTAV EIRICH

System and method for safe removal/oxidative decomposition of fuel from a fuel container

A system and method for removal or oxidative decomposition of fuel from a fuel storage container for use in a direct oxidation fuel cell and direct oxidation fuel cell system wherein the fuel permeates through a material and can be exposed to a catalyst / enzyme which oxidizes the fuel as it leaves the storage container. The system includes a fuel storage container provided with a catalyst-coated material. An airtight seal is provided over the catalyzed area, which seal is broken to allow oxygen access, and consequently the catalytic reaction. The airtight seal may be broken by simple manual methods or automatic methods on removal of the container from the fuel cell system.

Owner:DURACELL U S OPERATIONS

Method and System for Continuously Pumping a Solid Material and Method and System for Hydrogen Formation

A method of continuously providing a pressurized slurry of a solid material and liquid carbon dioxide is disclosed. The method comprises mixing particles of the solid material and particles of solid carbon dioxide in a mixing container and feeding the mixture of the solid material and the solid carbon dioxide to a pump to form a slurry of the solid material and liquified carbon dioxide. Within the pump, the solid carbon dioxide sublimates, forming a gaseous carbon dioxide which subsequently liquefies due to an increase in pressure. The liquid carbon dioxide and the solid material then mix to form the slurry of the solid material and the liquid carbon dioxide. In some embodiments, the pressurized slurry may be used for pipeline transportation of the solid material. A system of producing a continuous pressurized slurry of solid material and liquid carbon dioxide is also disclosed. A method of producing hydrogen is also disclosed.

Owner:JOHN P DOOHER TRUST +1

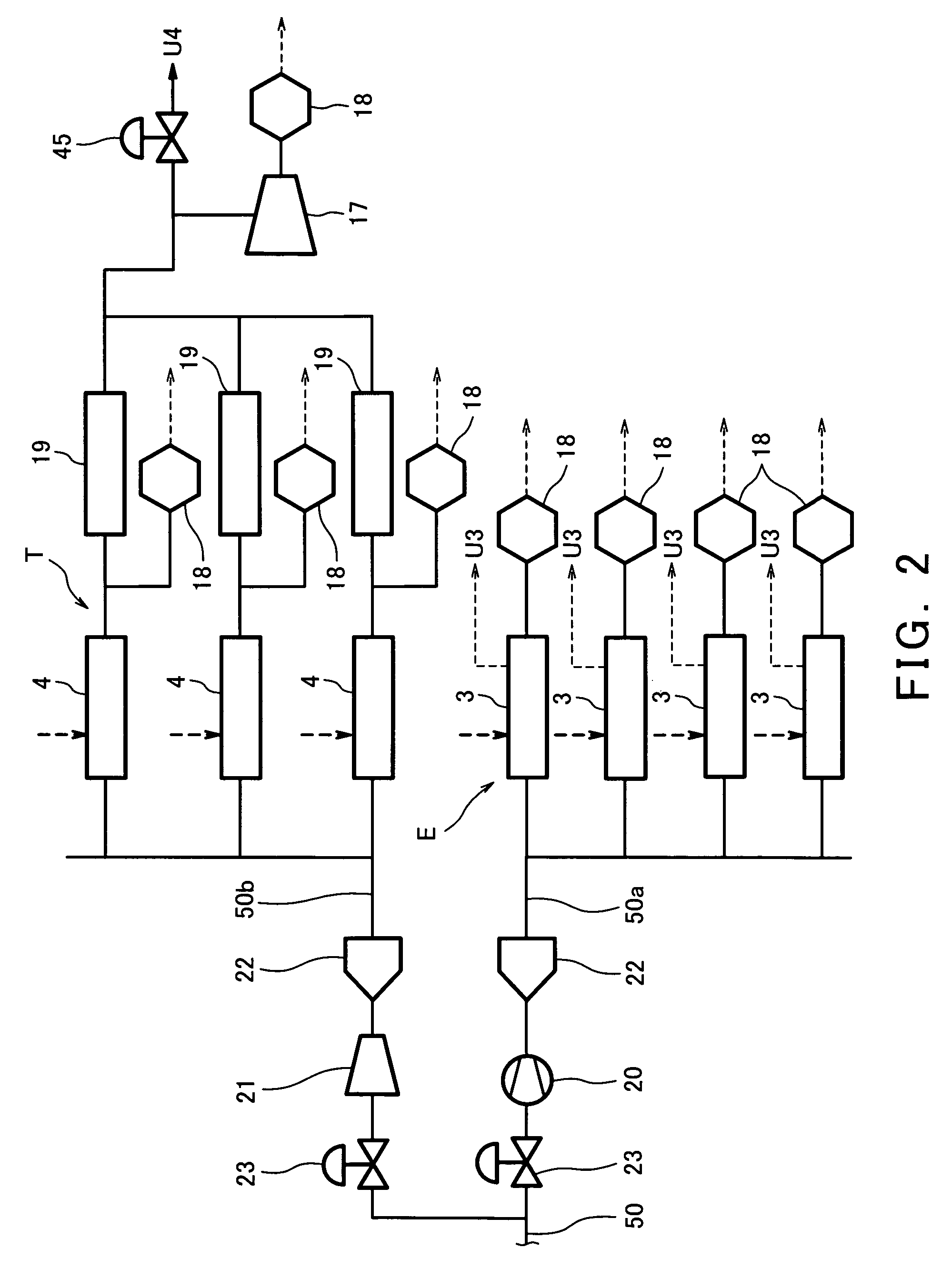

Electric power supply equipment

InactiveUS7334391B2Reduce power generation efficiencyAvoid wastingInternal combustion piston enginesGas turbine plantsProcess engineeringProduct gas

Owner:KAWASAKI HEAVY IND LTD

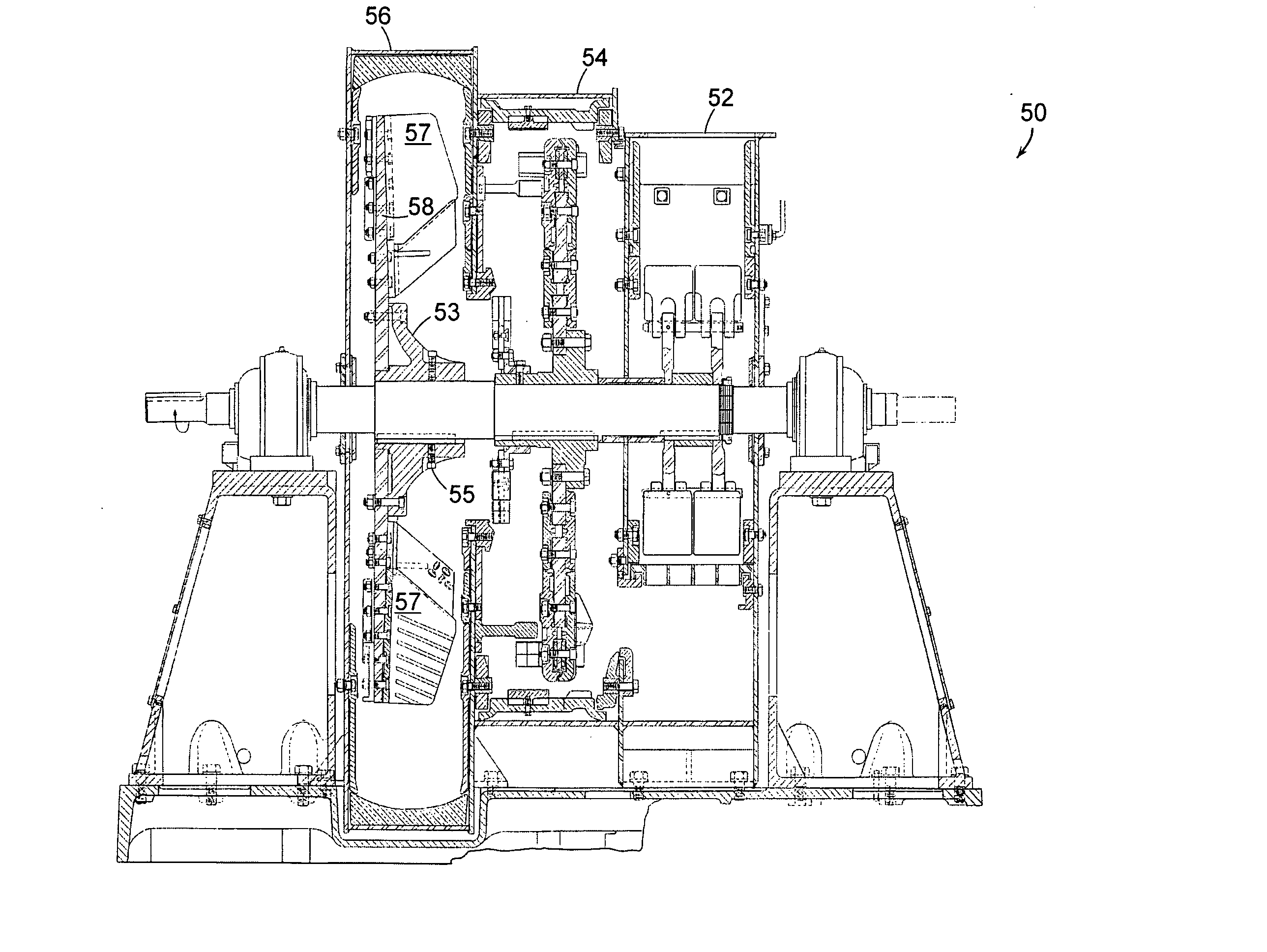

Split fan wheel and split shroud assemblies and methods of manufacturing and assembling the same

ActiveUS20070069052A1Removed and installedPrevent intrusionSpecific fluid pumpsPropellersImpellerEngineering

Devices and systems for transporting a material suspended in a fluid, e.g., pulverized coal, that can be assembled about a rotary element are disclosed. The devices and systems comprise a first portion or half of a fan wheel assembly, a second portion or half of a fan wheel assembly, and a plurality of splice plates for connecting the first portion of the fan wheel assembly to the second portion of the fan wheel assembly about the rotary element. Methods of manufacturing and assembling the sectionalized devices and systems are also provided.

Owner:RILEY STOKER

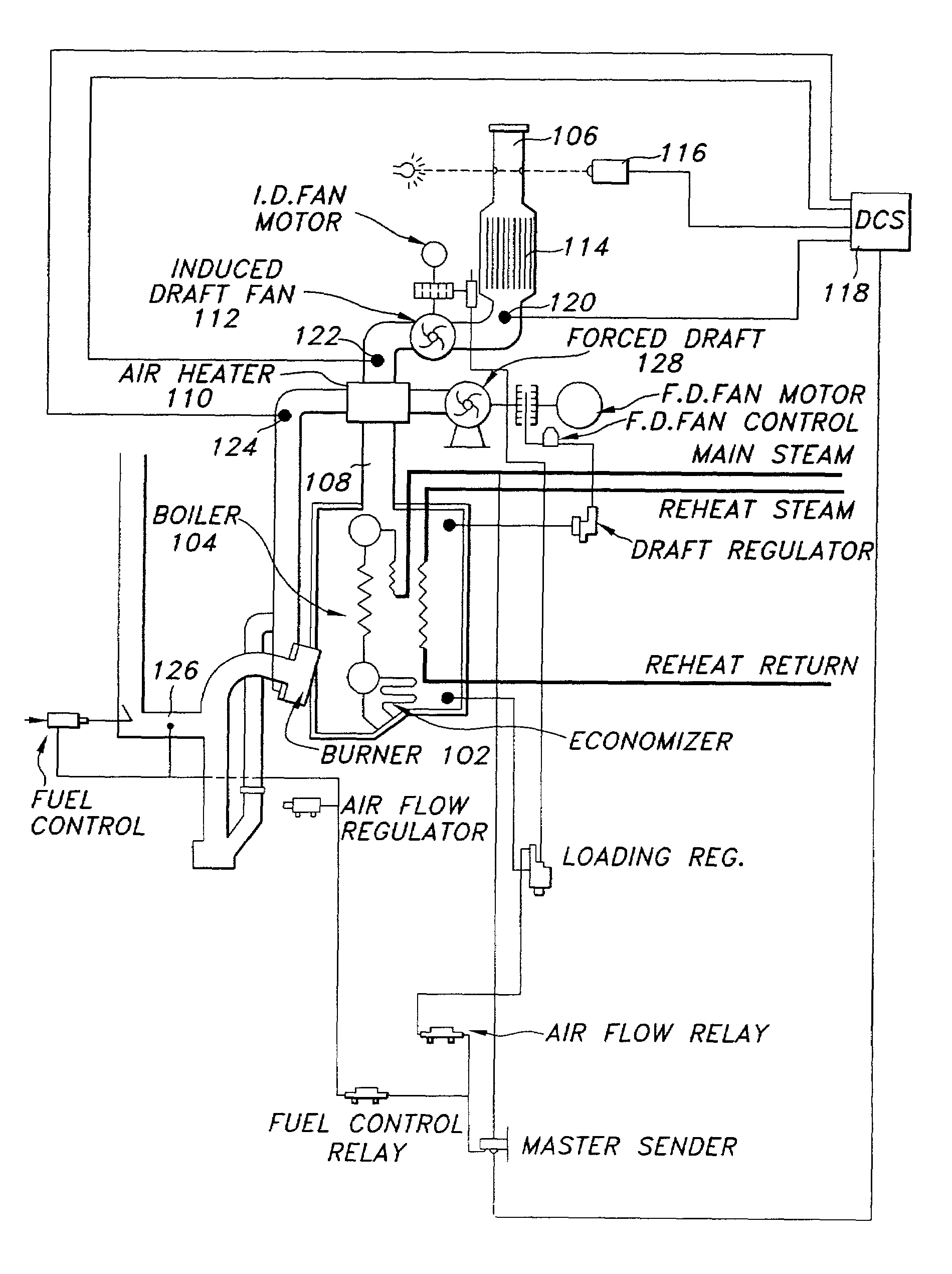

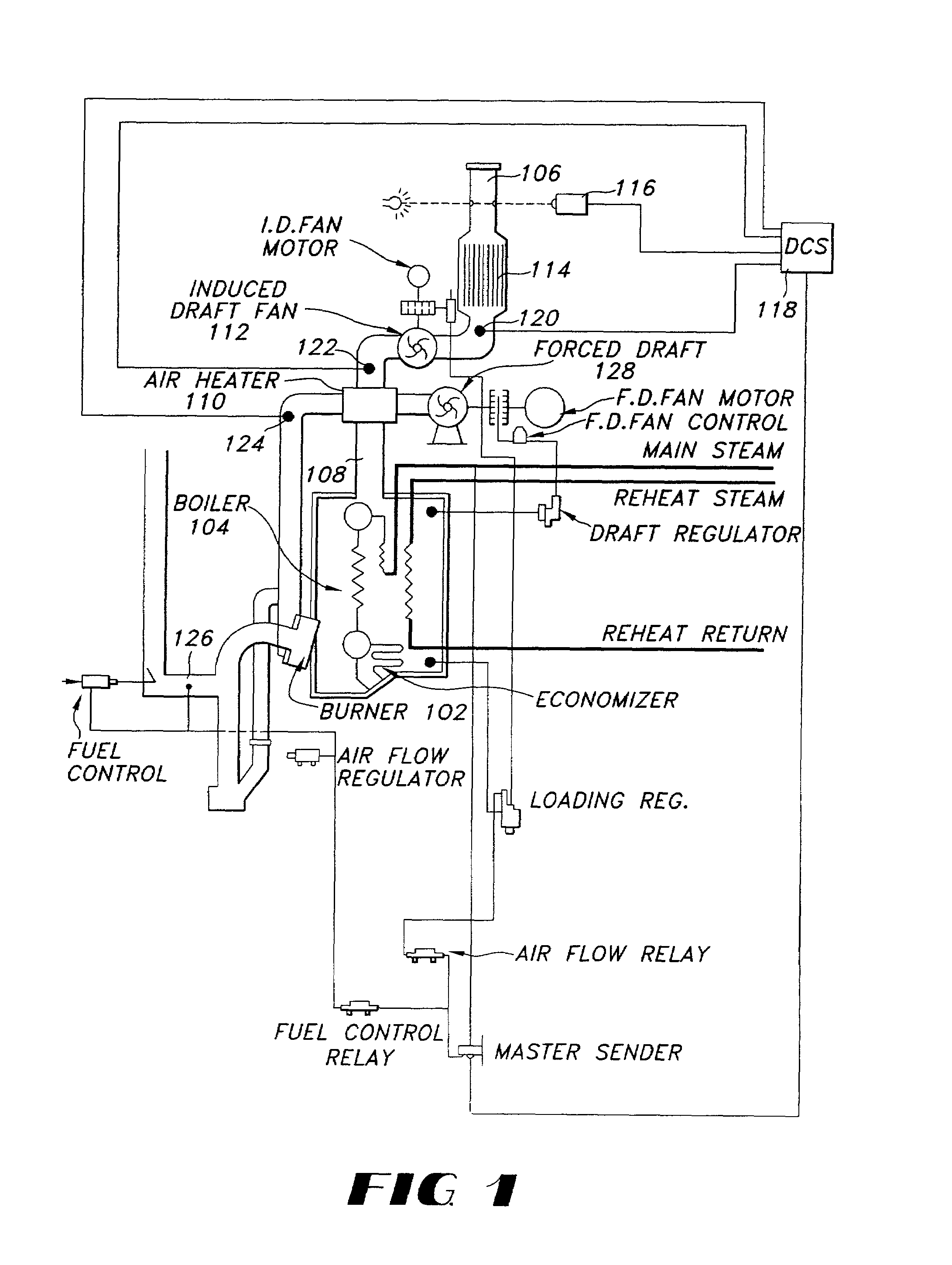

Systems and methods for determining the existence of a visible plume from the chimney of a facility burning carbon-based fuels

Excess oxygen in the combustion process of a facility that bums carbon-based fuels may cause a visible plume in the atmosphere at the stack of the facility. Traditional optical based opacity monitors may be unable to detect this plume or the plume may form at a location downstream from the opacity monitor toward the stack. The present invention discloses methods to utilize common combustion control variables to detect and signal the presence of a visible plume of exhaust gasses. Also disclosed are systems that detect the visible plume and provide a signal so that the combustion process may be manually or automatically adjusted to reduce or eliminate the visible plume.

Owner:FLORIDA POWER & LIGHT

Air and gas two-heat-accumulation heating furnace

ActiveCN103225018ASmooth heating operationQuality improvementFuel feedersFurnace typesCombustion chamberExhaust gas emissions

The invention relates to an air and gas two-heat-accumulation heating furnace. The air and gas two-heat-accumulation heating furnace comprises a heating furnace, 2-20 combustion gas heat accumulators, 2-20 air heat accumulators, combustion gas heat exchangers and air heat exchangers. Each of the combustion gas heat accumulators and the air heat accumulators is provided with a heat accumulation combustion chamber. The combustion gas heat accumulators are divided into two groups of combustion gas heat accumulators, each group of the combustion gas heat accumulators is connected with a combustion gas pipeline and an exhaust gas discharge system through triple valves respectively, the other side of each group of the combustion gas heat accumulators is connected with the combustion gas heat accumulation combustion chambers, and the combustion gas heat accumulation combustion chambers are connected to the combustion gas inlets of flat flame burners through cone valves. The air heat accumulators are divided into two groups, each group of the air heat accumulators is connected with an air pipeline and an exhaust gas discharge system through triple valves respectively, the other side of each group of the air heat accumulators is connected with the air heat accumulation combustion chambers, and the air heat accumulation combustion chambers are connected to the air inlets of the flat flame burners through cone valves. The air and gas two-heat-accumulation heating furnace realizes the stationary heating operation of the heating furnace, optimizes the heating effect and the operation stability and improves the qualities of heated products through the alternative heat ambulation of the two groups of the combustion gas heat accumulators and the two groups of the air heat accumulators and the preheating of air or the combustion gas.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Gas mixing apparatus

A static mixer includes a plurality of mixing elements disposed parallel to each other and arrayed annularly to define an inner cylindrical space surrounded by these mixing elements. Each mixing element has stationary vanes disposed in a circular passage. A blower supplying the air to the static mixer is entirely or partly accommodated and fixed in the inner cylindrical space of the static mixer. The static mixer and the blower are disposed parallel to each other. The overall length of the fuel mixture generating apparatus can be shortened.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com