Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

433results about "Vanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and apparatus for fabricating blades

A method for fabricating a blade using a mold having a shape corresponding to a predetermined finished shape of at least a portion of the blade. The method includes stacking a plurality of layers of a material in the mold, stacking at least one component with the stack of the plurality of layers, wherein the component is a composite comprising a cured resin and at least one layer of fiber, and laminating the stack of the plurality of layers and the component.

Owner:GENERAL ELECTRIC CO

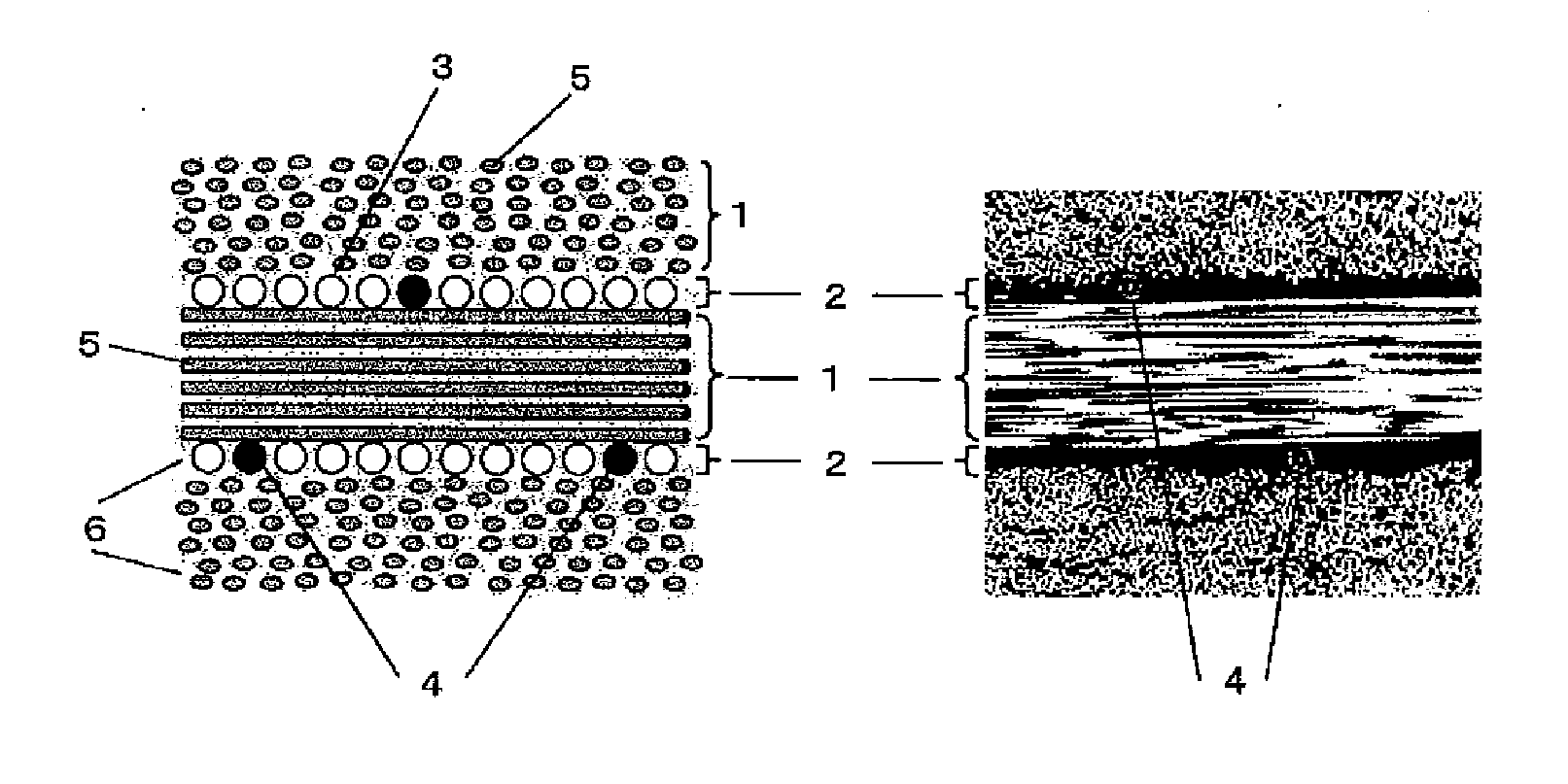

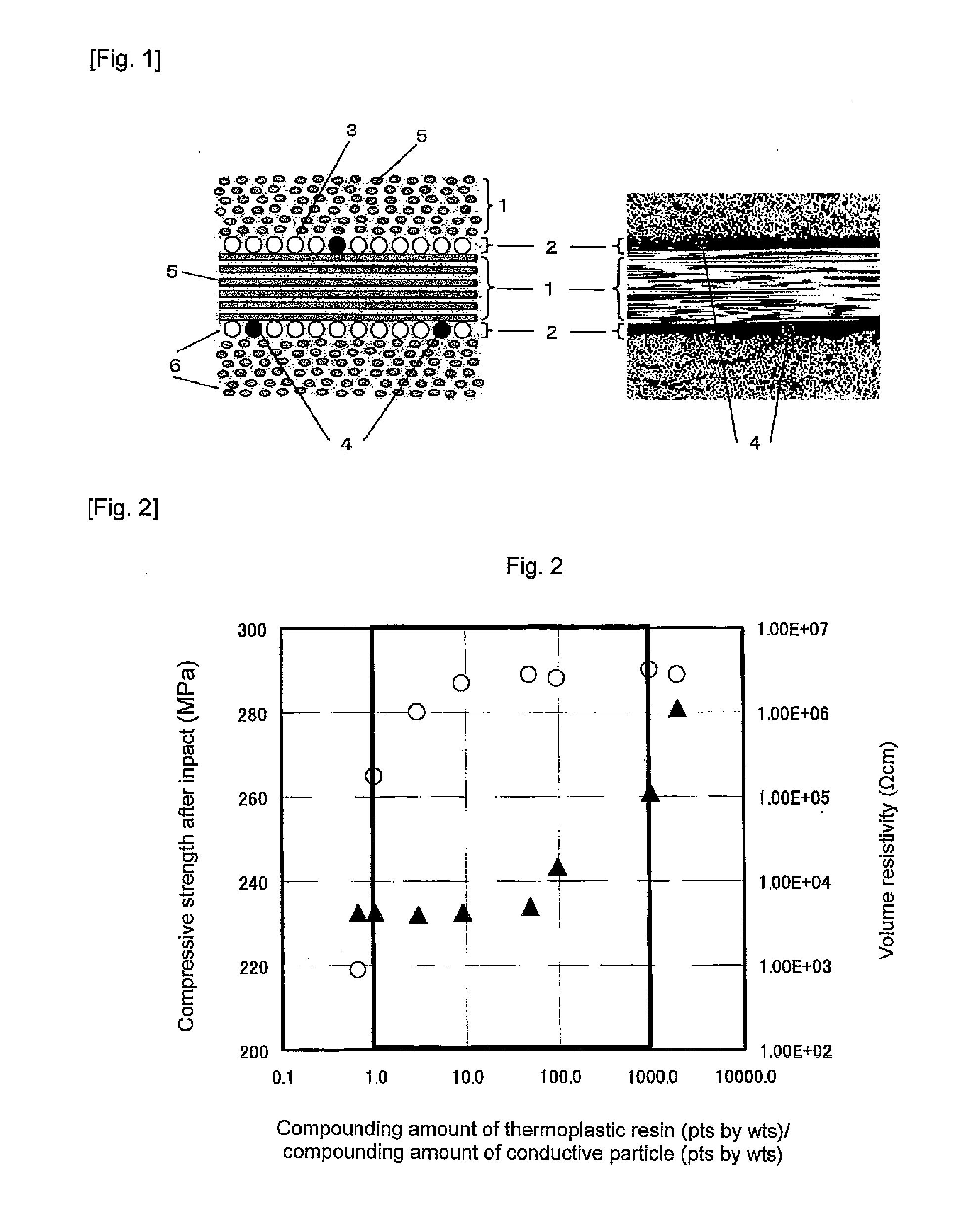

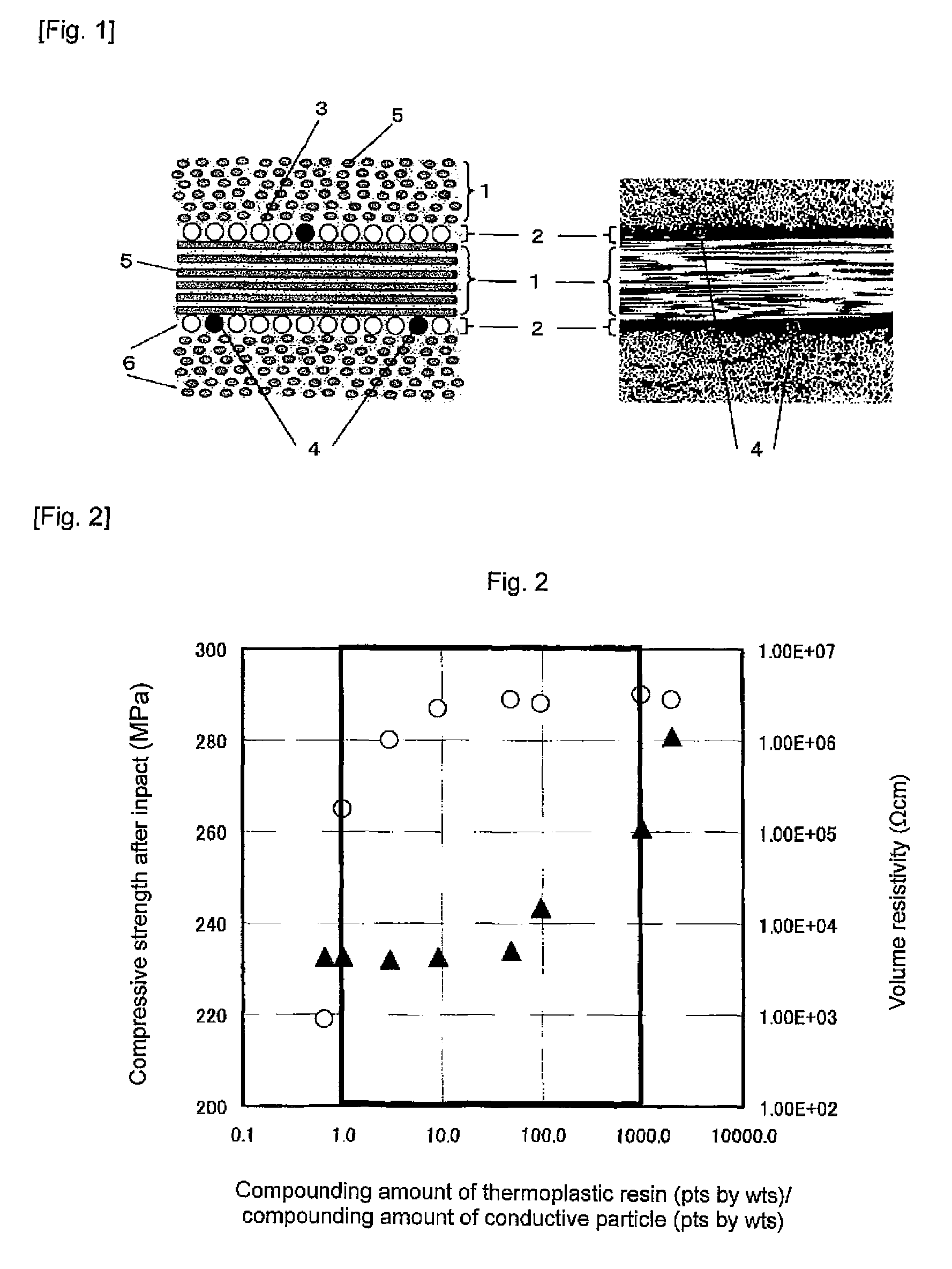

Prepreg and carbon fiber reinforced composite materials

ActiveUS20100178487A1Improve conductivityImprove impact resistanceNon-metal conductorsCarbon fibresCarbon fiber reinforced compositePre-preg

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

Protective Sheets, Articles, and Methods

ActiveUS20080286576A1ResistanceMinimize distortionSynthetic resin layered productsLaminationMechanical engineeringEngineering

Owner:PPG ADVANCED SURFACE TECH LLC

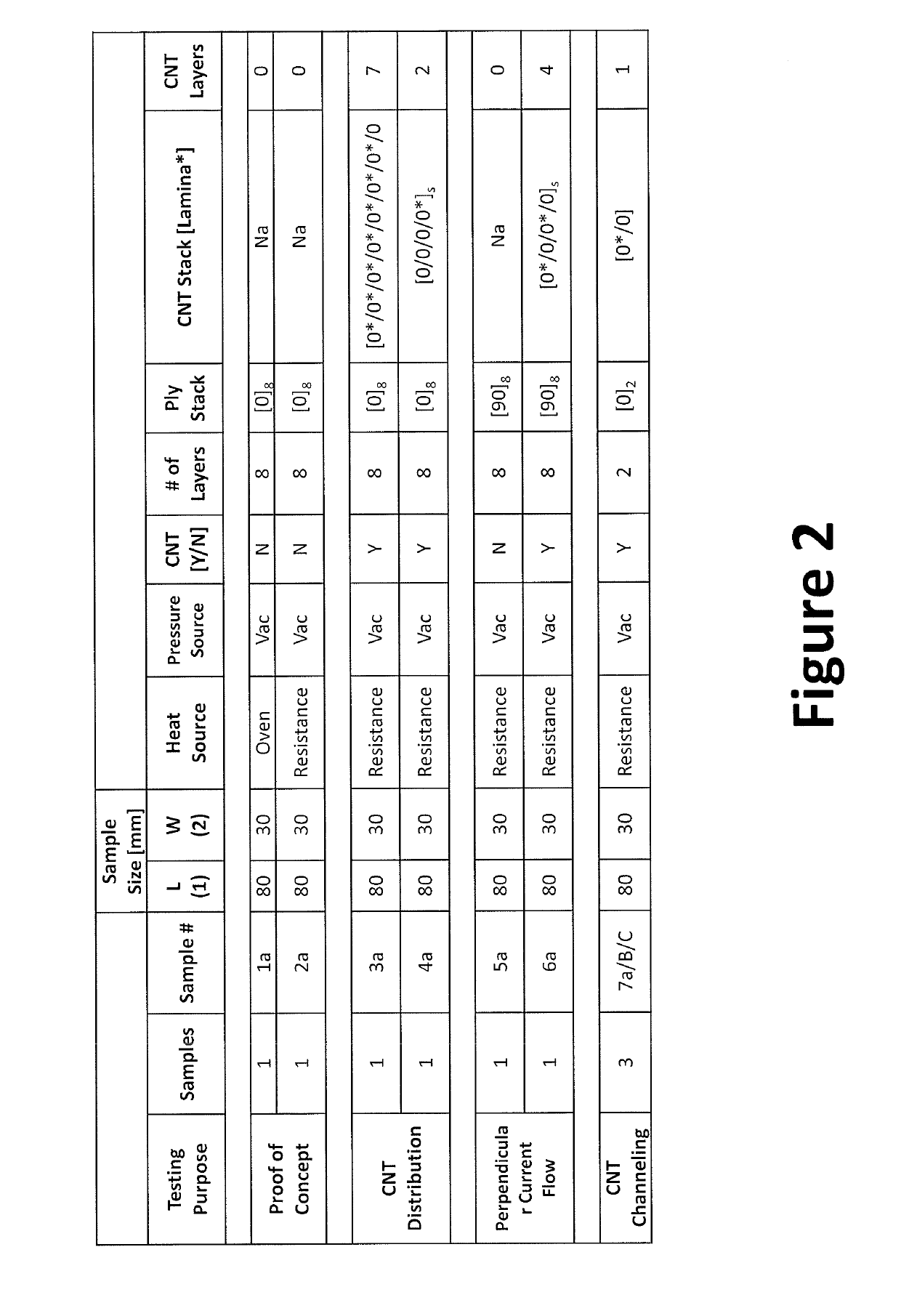

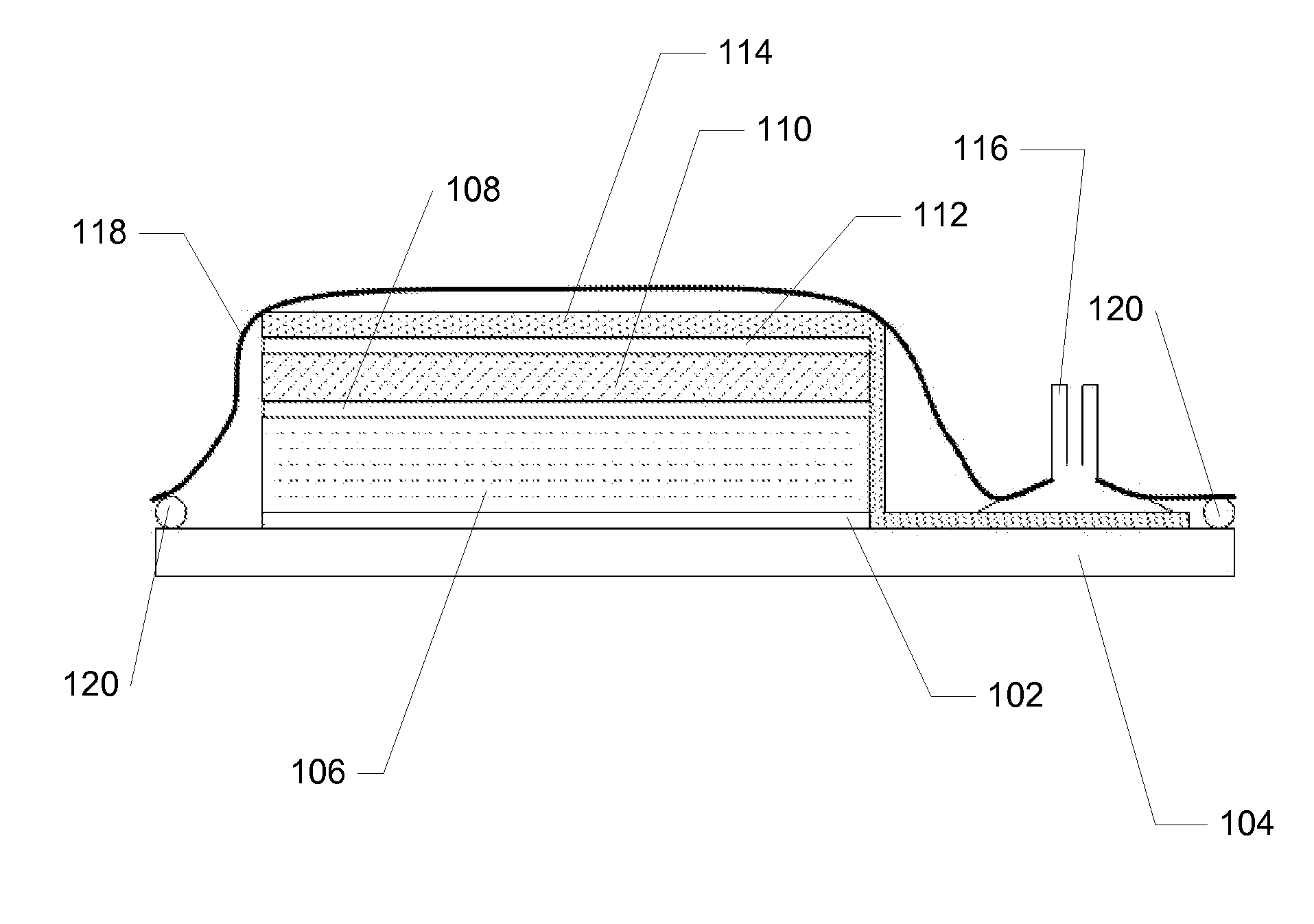

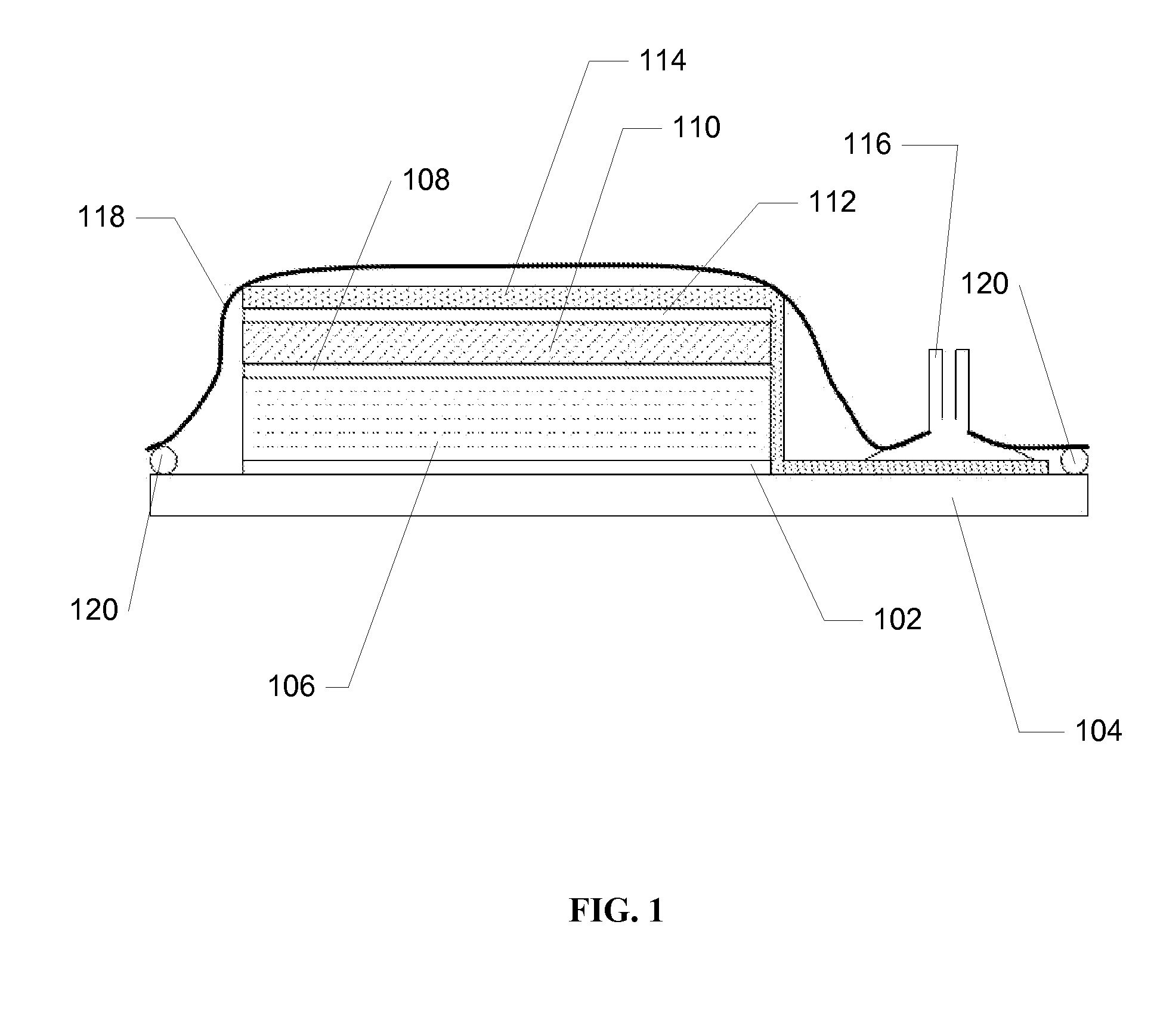

Electrical curing of composite structures

ActiveUS10285219B2Improve conductivityLayered productsHeater elementsElectric power systemEngineering

A composite structure cured by the process of: electrically coupling a first lead to a first portion of said composite structure; electrically coupling a second lead to a second portion of said composite structure; and using an electric power source to pass electric current through said composite structure from said first portion to said second portion, wherein passing said electric current through said composite structure causes the temperature of at least a portion of said composite structure increase to a predetermined temperature.

Owner:AURORA FLIGHT SCI CORP

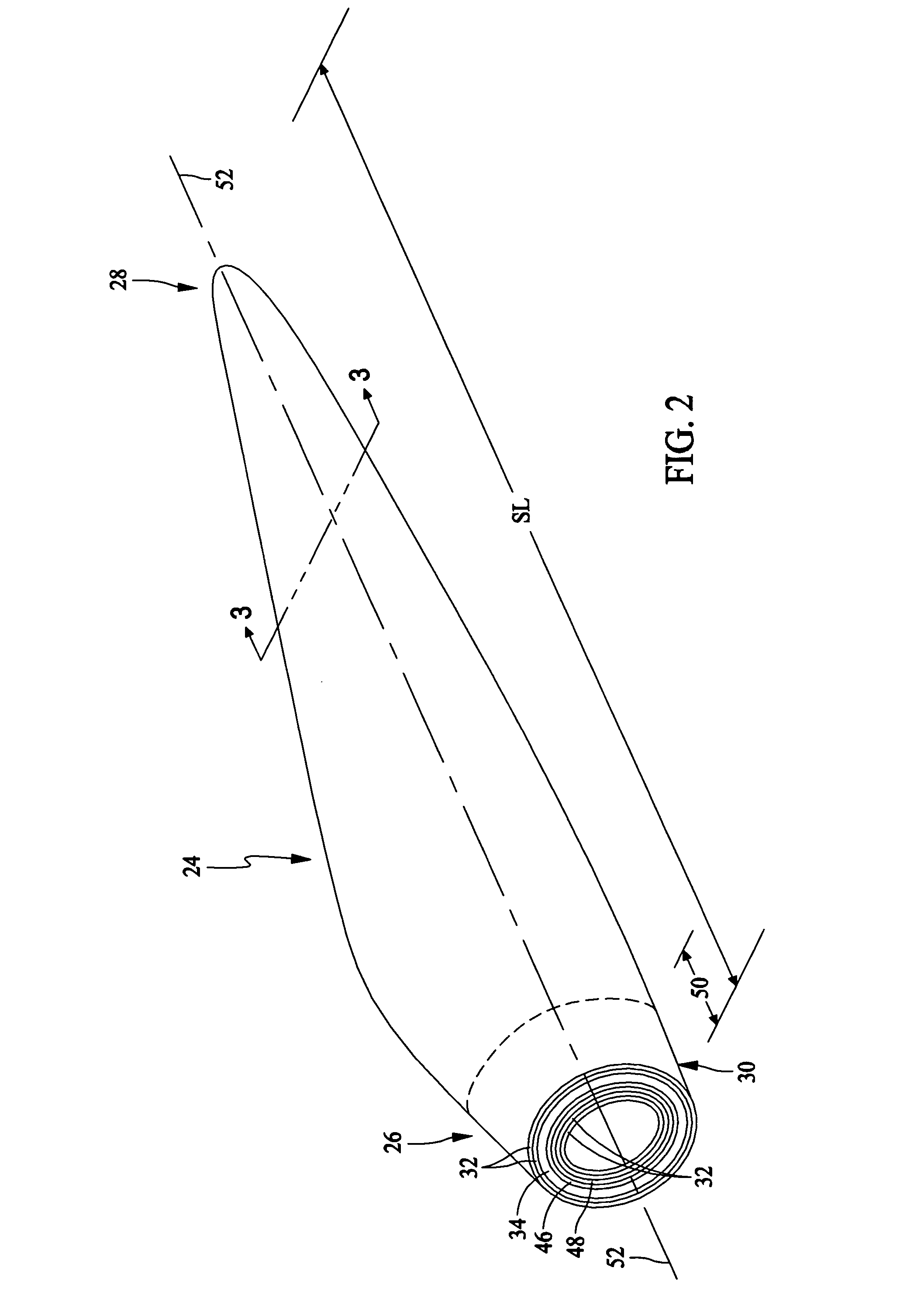

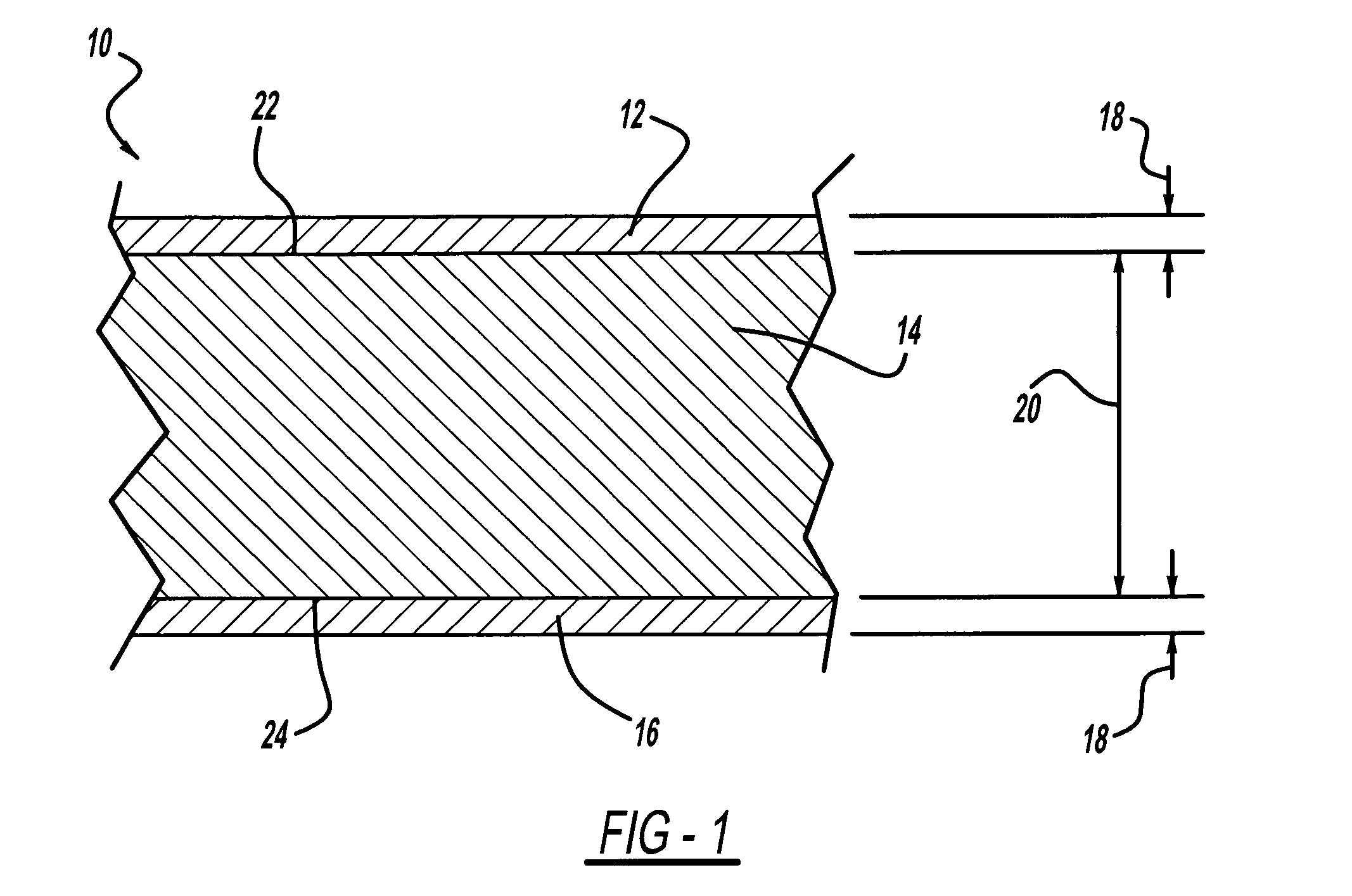

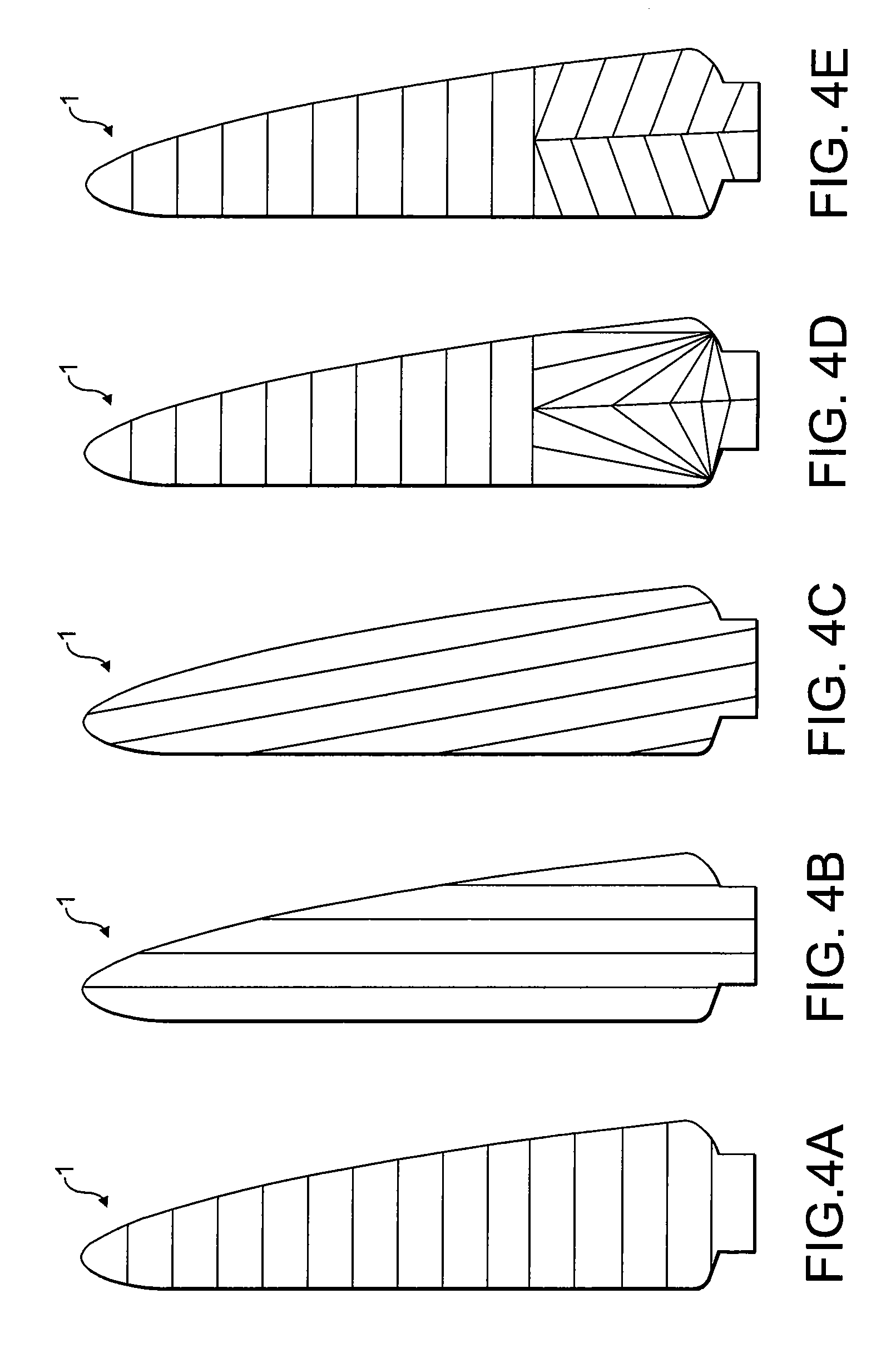

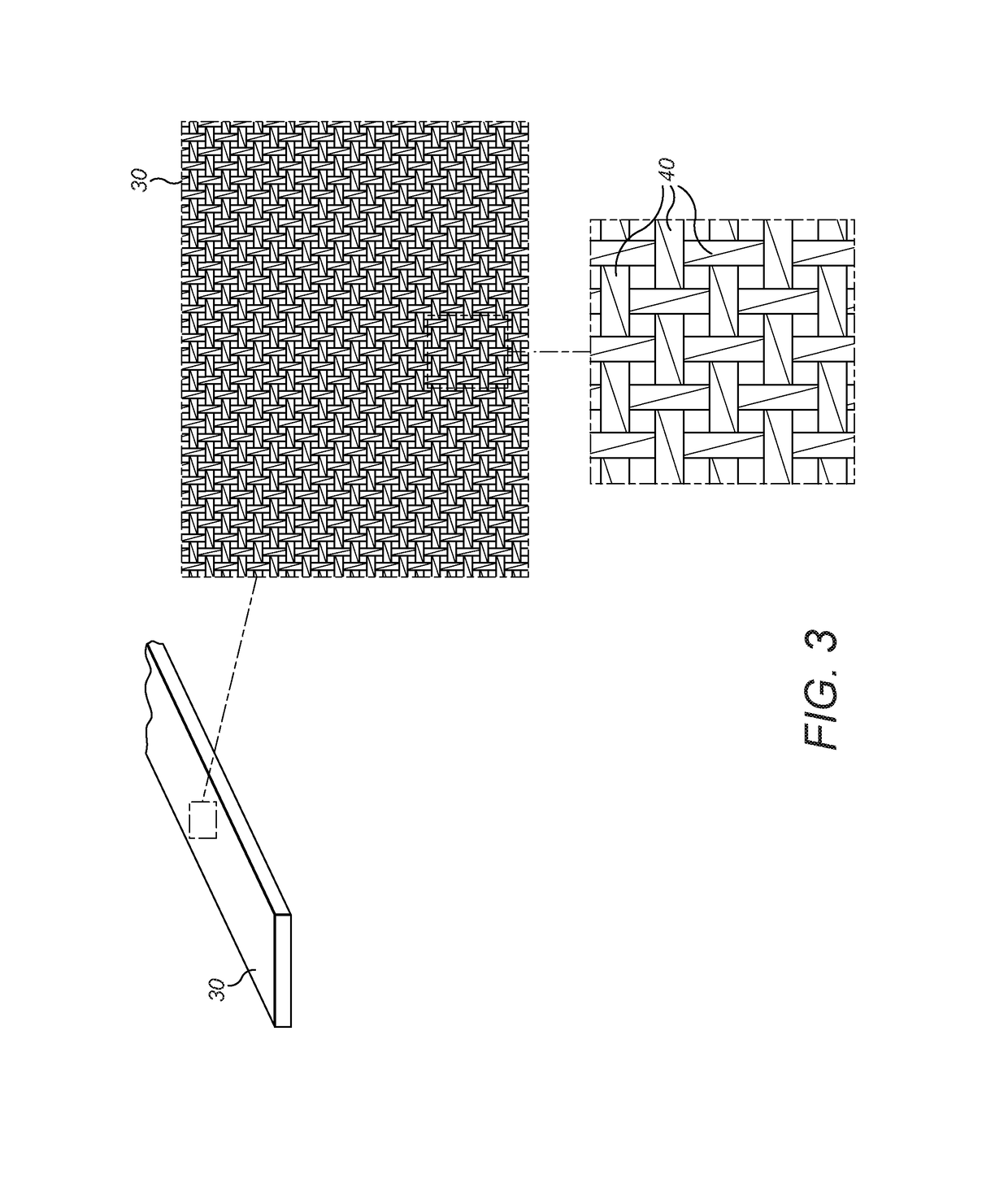

Wing and blade structure using pultruded composites

ActiveUS20090220747A1High compressive strengthIncrease pressureWingsVehicle componentsPropellerCompressive strength

Tapered layers of pre-cured composite material are integrated into a tapered, highly stressed laminate structure in order to provide improved compressive strength. The pre-cured composite material can advantageously be cured under tension as pultruded material, to further augment compressive strength. The thickness of composite layers can be tapered on their termination edges by mechanically abrading, chemical abrading, or other methods. Especially preferred embodiments include aircraft structural components such as wings, wing spars, wing skins, fuselage skins, rotor blades, propellers, and propeller blades. Preferred laminates can be constructed to have at least 6, 10, 30, 50, or 100 layers of material, and can have a maximum thickness of at least 0.15, 0.25, 0.5, 1.0, or 5.0 inches.

Owner:KAREM ABE

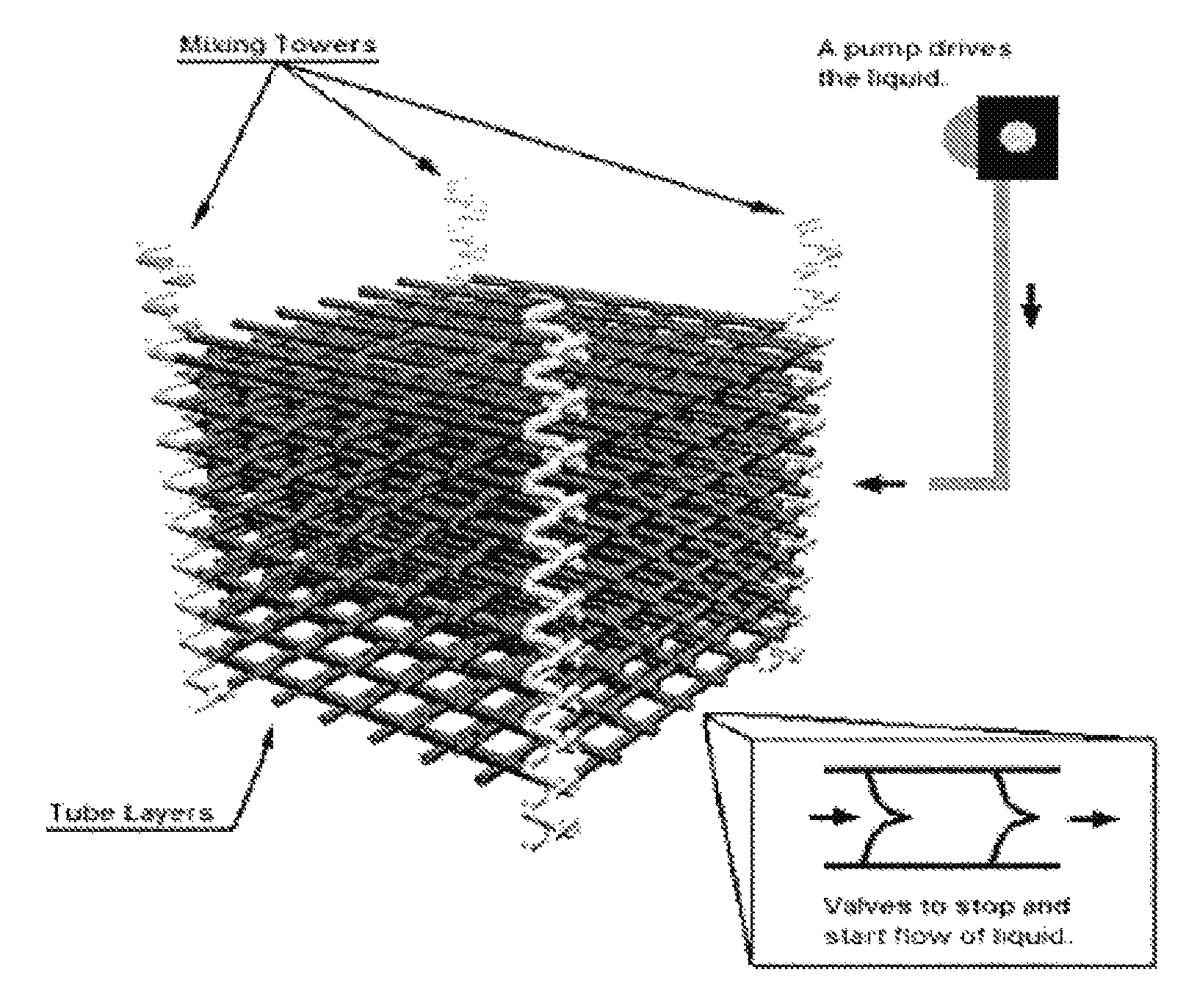

Multiple function, self-repairing composites with special adhesives

InactiveUS7811666B2Fast chemical reactionExtended shelf lifeLayered productsConstructions elementsFiberAdhesive

A system for self-repairing matrices such as concrete or cementitous matrices, polymeric matrices, and / or fibrous matrices, including laminates thereof. The system includes repair agents retained in and / or on vessels, such as hollow fibers, within the matrix. Upon impact, the vessel rupture, releasing the chemicals. For multi-layer laminates, the systems provides a total dynamic energetic circulation system that functions as an in situ fluidic system in at least one layer or area. The energy from the impact ruptures the vessels to release the chemical(s), and mixes the chemical(s) and pushes the chemical(s) and / or resulting compound through the matrix. The repair agents can withstand high temperatures, such as the heat of processing of many laminates, e.g., 250-350° F.

Owner:DRY CAROLYN

Sheet molding compound with cores

ActiveUS8992813B2Many layersStrength can be moreFinal product manufactureAnimal housingSheet moulding compoundEngineering

A component made of at least one thermoformable material, having a first layer made of a first material, a second layer made of a second material, and a third layer made of the first material. The three layers form a sheet, which is formed to various shapes, depending upon the part that is to be created. The sheet may be formed to produce the bumper of an automobile, a door panel for an automobile, a flotation device, such as a pontoon for a pontoon boat, or the like. The first and third layers are SMC, and the second layer, or “core,” is disposed between the first and third layers, allowing the strength of the first and third layers to be used more efficiently, compared to a sheet having only the first and third layers, and no core.

Owner:MAGNA INTERNATIONAL INC

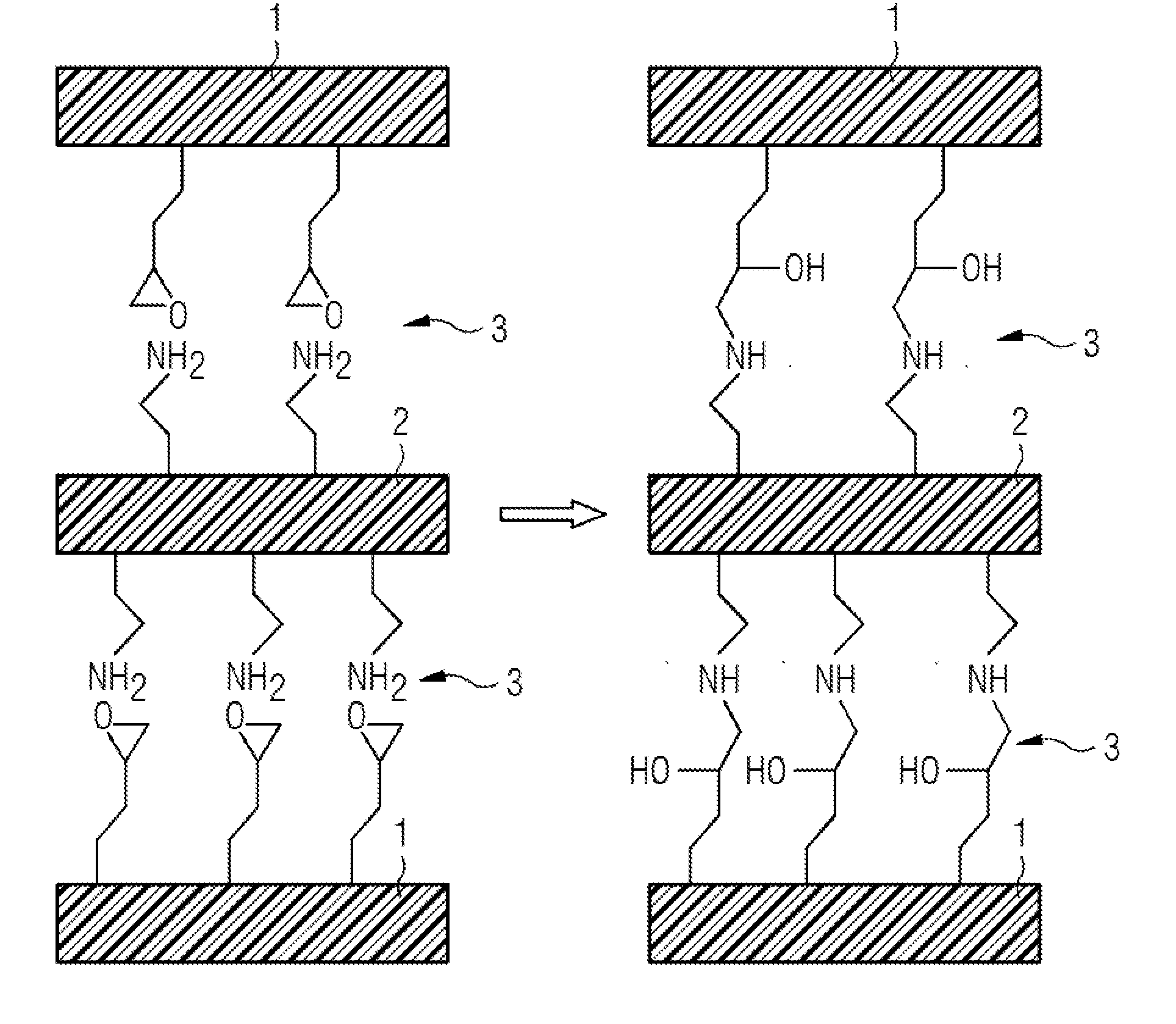

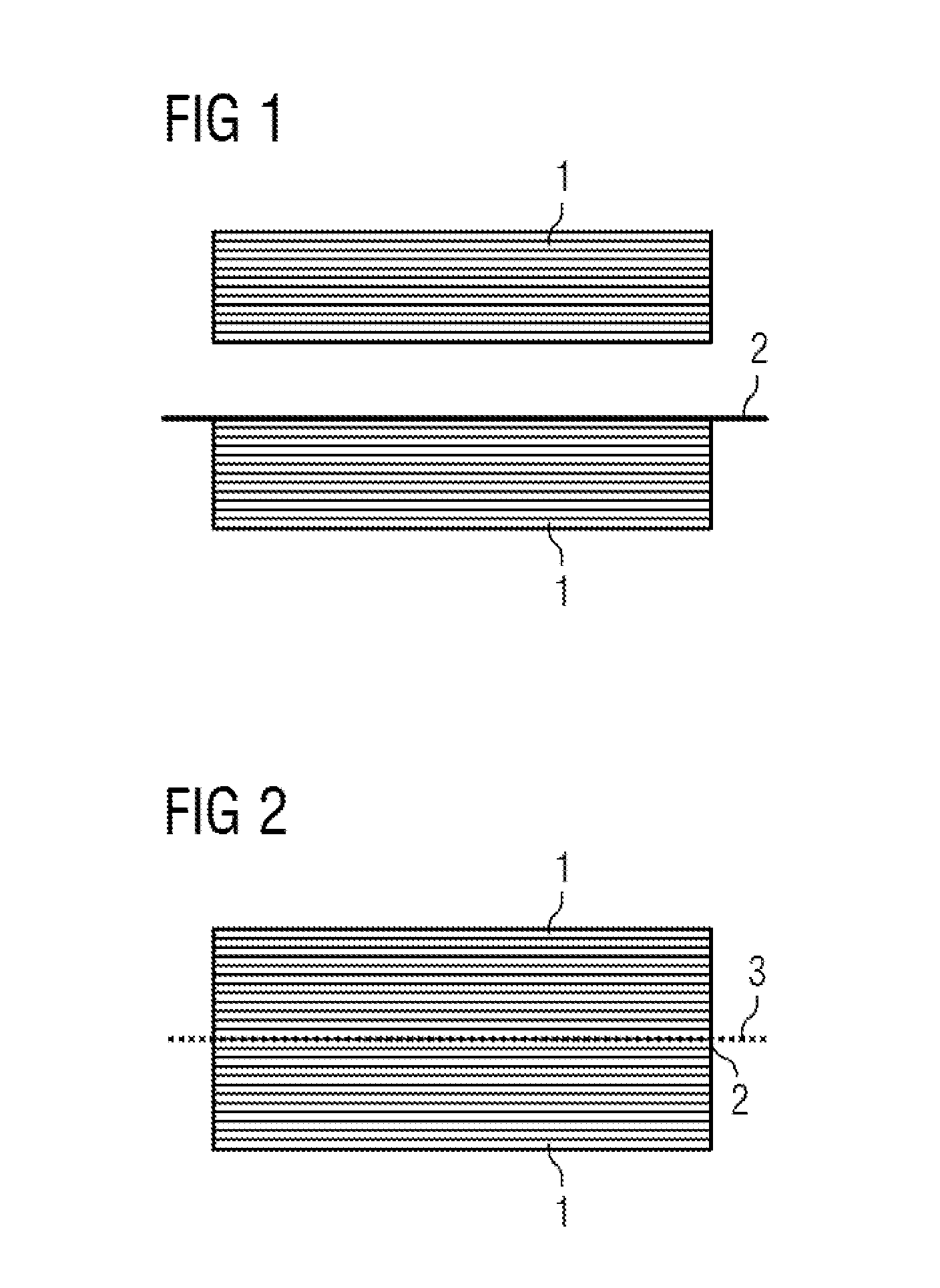

Composite structure

ActiveUS20140295187A1Improve mechanical propertiesOvercome disadvantagesSynthetic resin layered productsMachines/enginesEthylene oxideCarboxylic acid

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

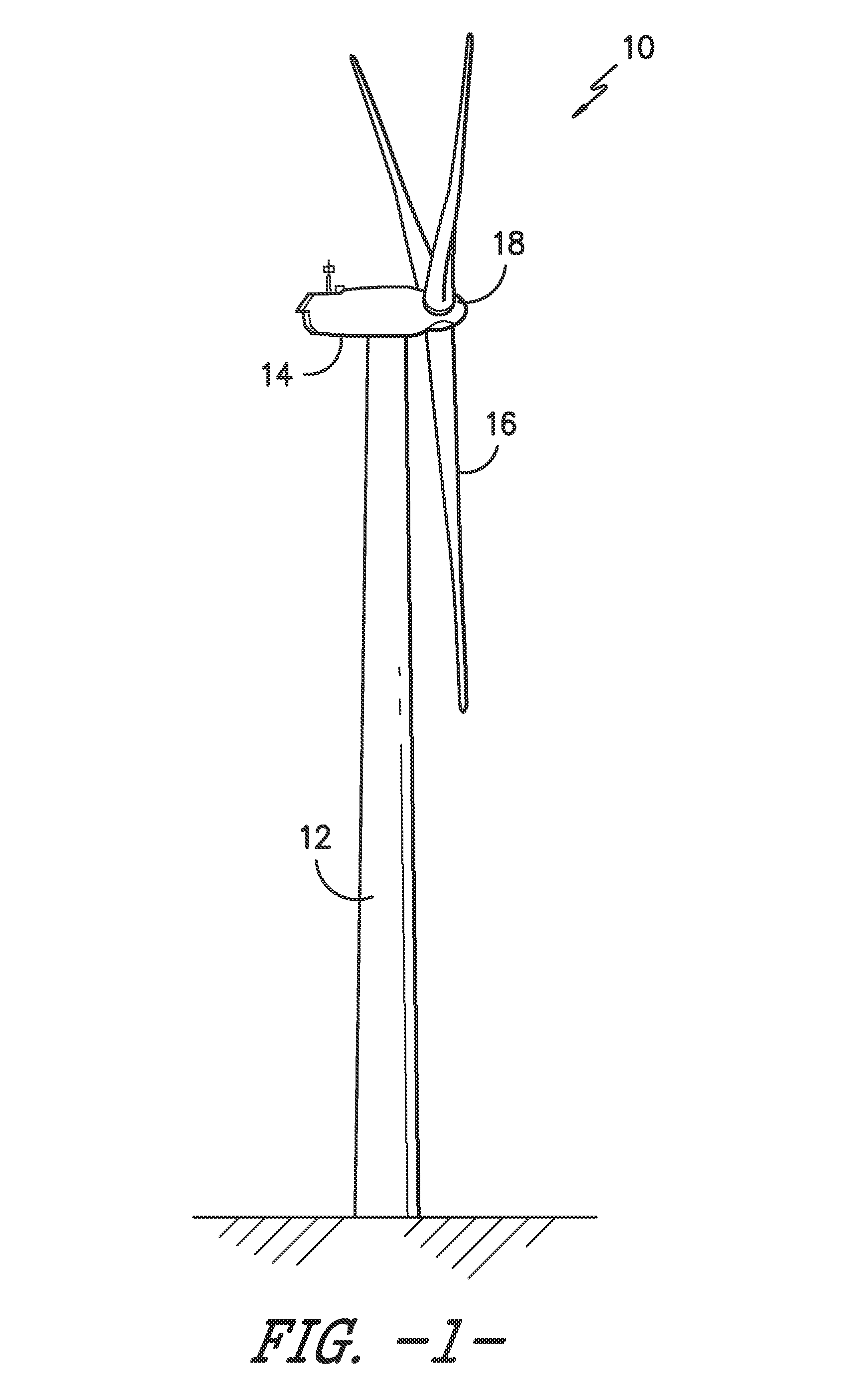

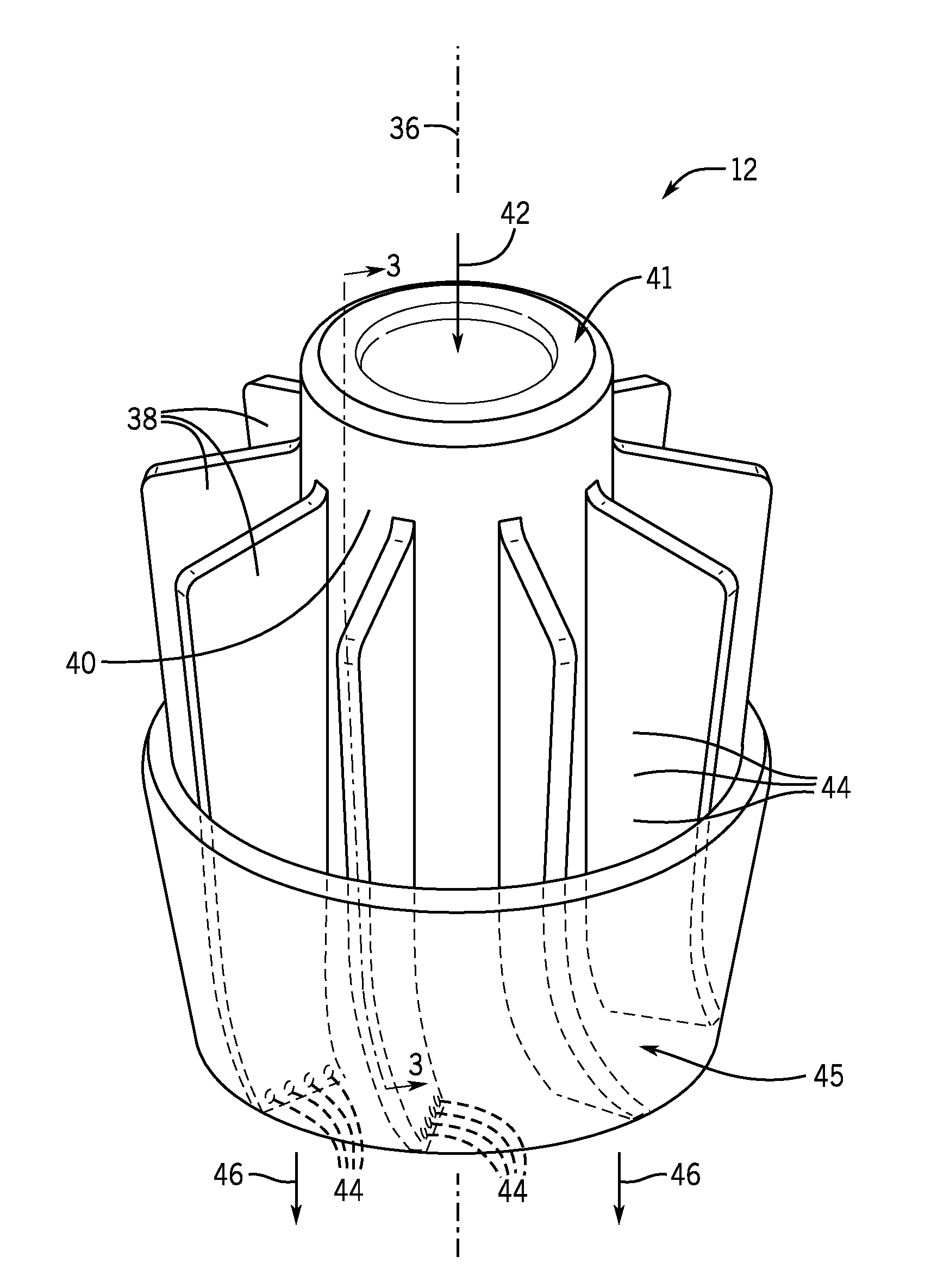

Methods of making wind turbine rotor blades

A method of manufacturing a root portion of a wind turbine blade includes, in an exemplary embodiment, providing an outer layer of reinforcing fibers including at least two woven mats of reinforcing fibers, providing an inner layer of reinforcing fibers including at least two woven mats of reinforcing fibers, and positioning at least two bands of reinforcing fibers between the inner and outer layers, with each band of reinforcing fibers including at least two woven mats of reinforcing fibers. The method further includes positioning a mat of randomly arranged reinforcing fibers between each pair of adjacent bands of reinforcing fibers, introducing a polymeric resin into the root potion of the wind turbine blade, infusing the resin through the outer layer, the inner layer, each band of reinforcing fibers, and each mat of random reinforcing fibers, and curing the resin to form the root portion of the wind turbine blade.

Owner:GENERAL ELECTRIC CO

Composite Articles Comprising Protective Sheets and Related Methods

Methods of the invention include those for applying protective sheets to composite articles. According to these methods and resulting composite articles, a protective sheet is applied to at least a portion of an exterior surface formed from a composite material and where protection is desired. At least one exterior surface of the composite article to be protected can be integrally formed in the presence of the protective sheet. Improved bonding of the protective sheet to the composite article and improved processing efficiency are advantageously achieved according to the invention.

Owner:PPG ADVANCED SURFACE TECH LLC

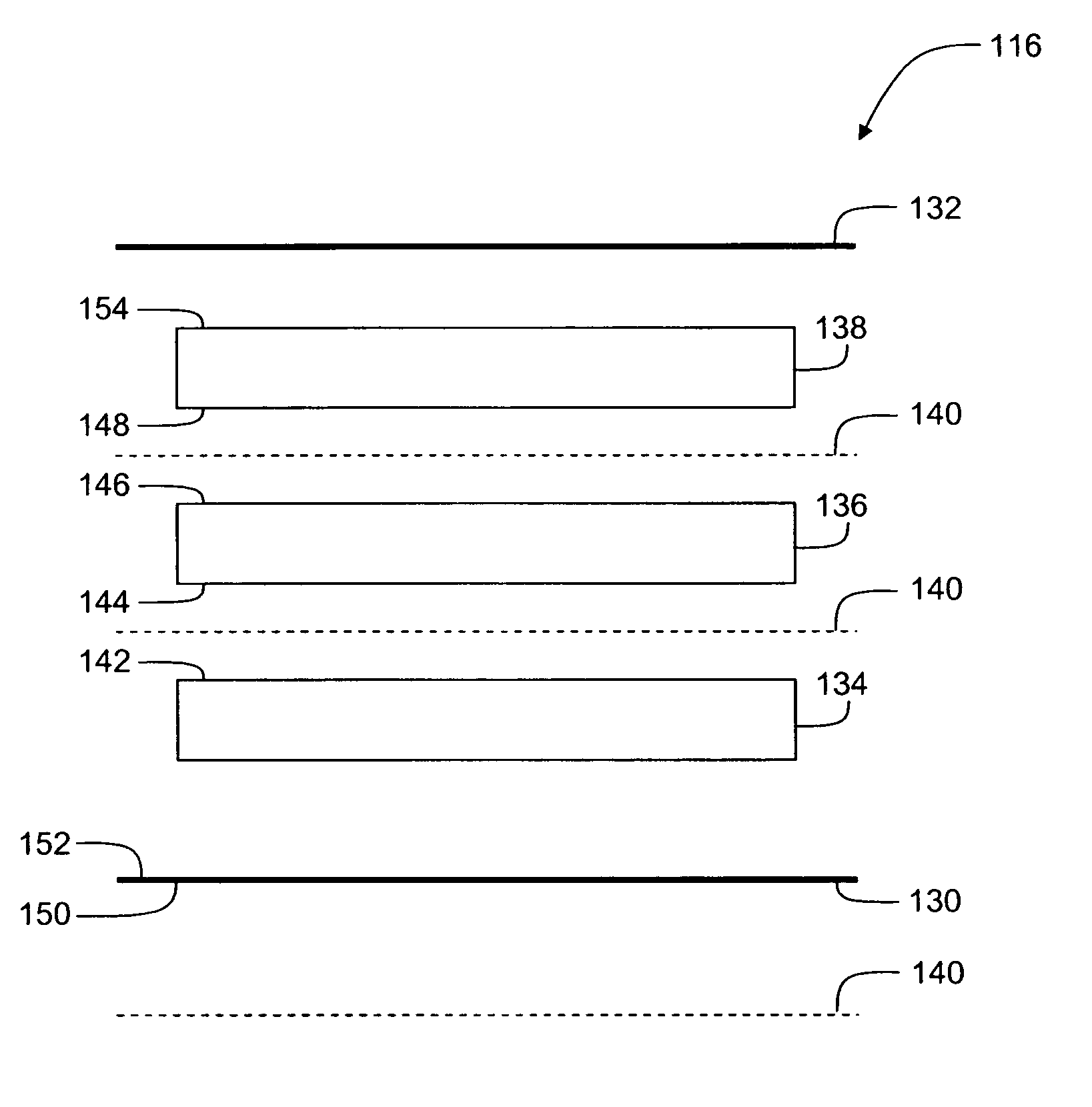

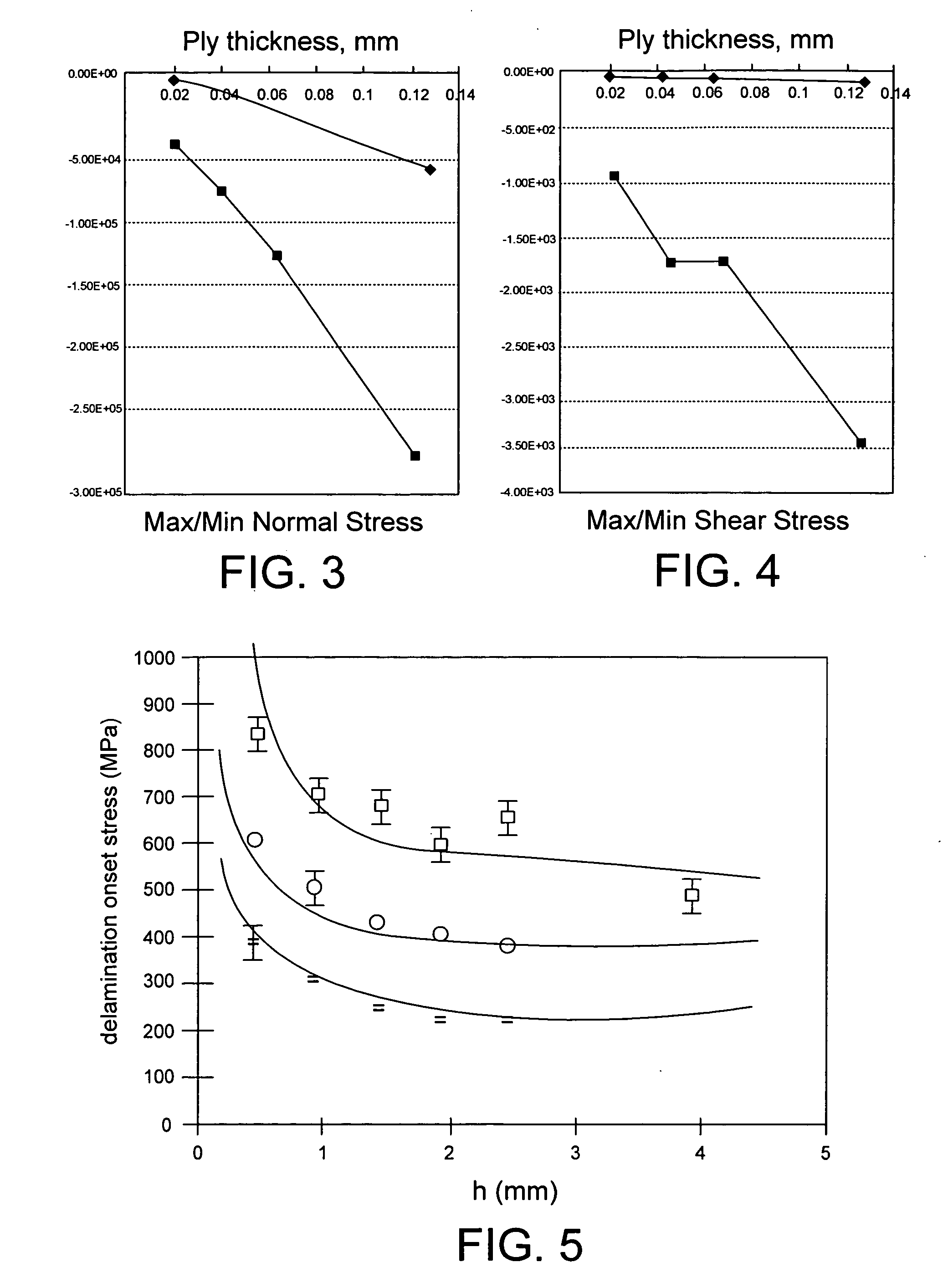

Thin ply laminates

InactiveUS20060093802A1High resistance to delaminationLight weightMechanical working/deformationConstructions elementsAdhesiveFibrous composites

Fiber composite materials using thin plies with a thickness of less than 0.08 mm provide improved delamination resistance and thinner minimum gauge for laminates. Thin plies may be hybridized with conventional plies, interlaced for strength, and used with adhesives as reinforcement in bonding.

Owner:ITOCHU CO LTD +3

Wind turbine blade

InactiveUS20090246033A1Increase flexibilityEfficient use ofPropellersFinal product manufactureTurbine bladeGelcoat

There is provided a wind turbine blade at least 50% of the surface of which is covered with a self-adhesive thermoplastic film. By applying a self-adhesive thermoplastic film to the blade, the need for a gelcoat or the paint is eliminated. It is estimated that the thermoplastic film will take a similar time to apply as the gelcoat and / or paint. However, it does not require any further treatment once it has been applied thereby reducing significantly the work involved in finishing the blade. Also, the thickness of the film is precisely controlled in advance of its application to the blade ensuring that a surface with a uniform thickness is produced.

Owner:BLADE DYNAMICS LTD

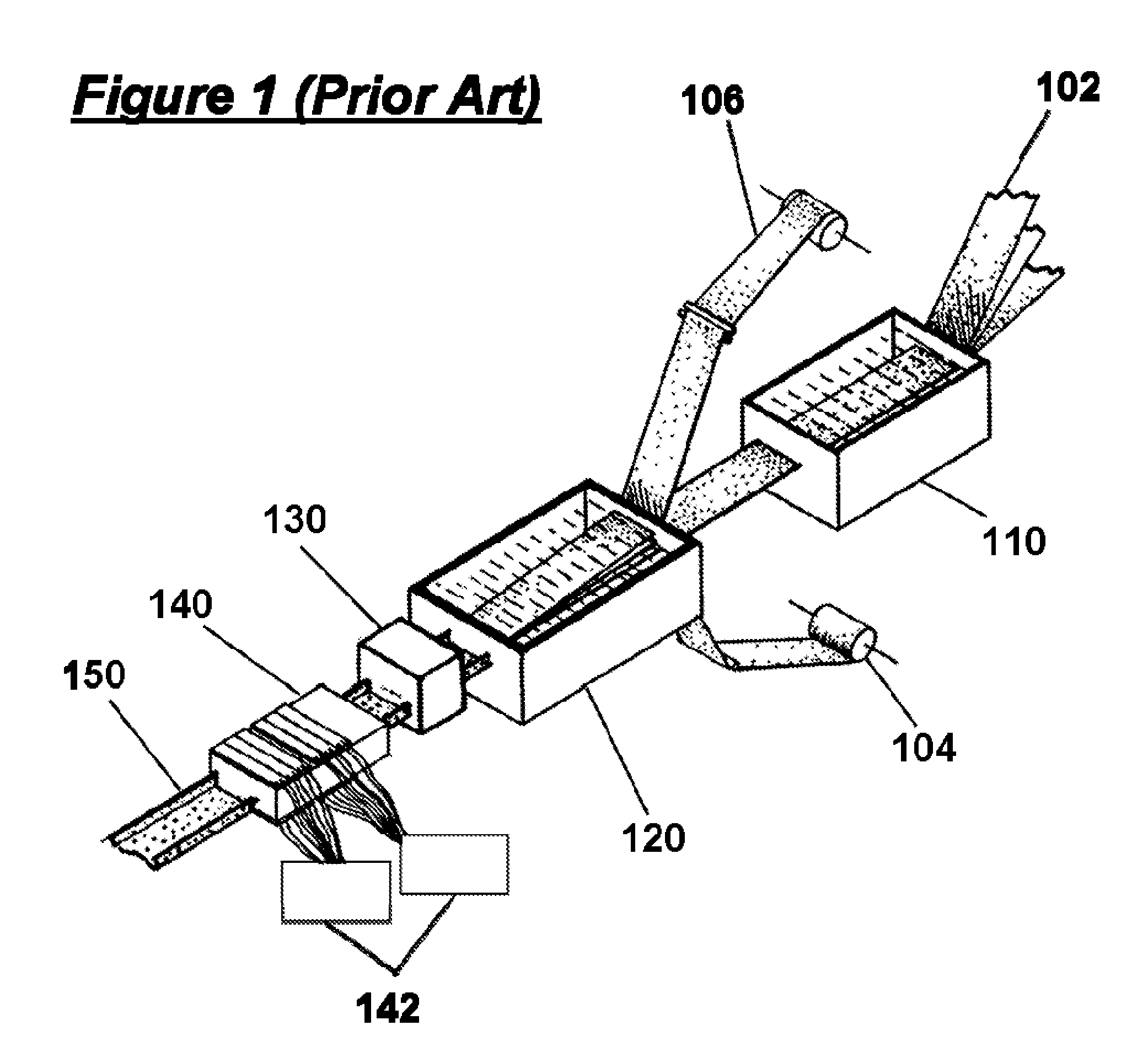

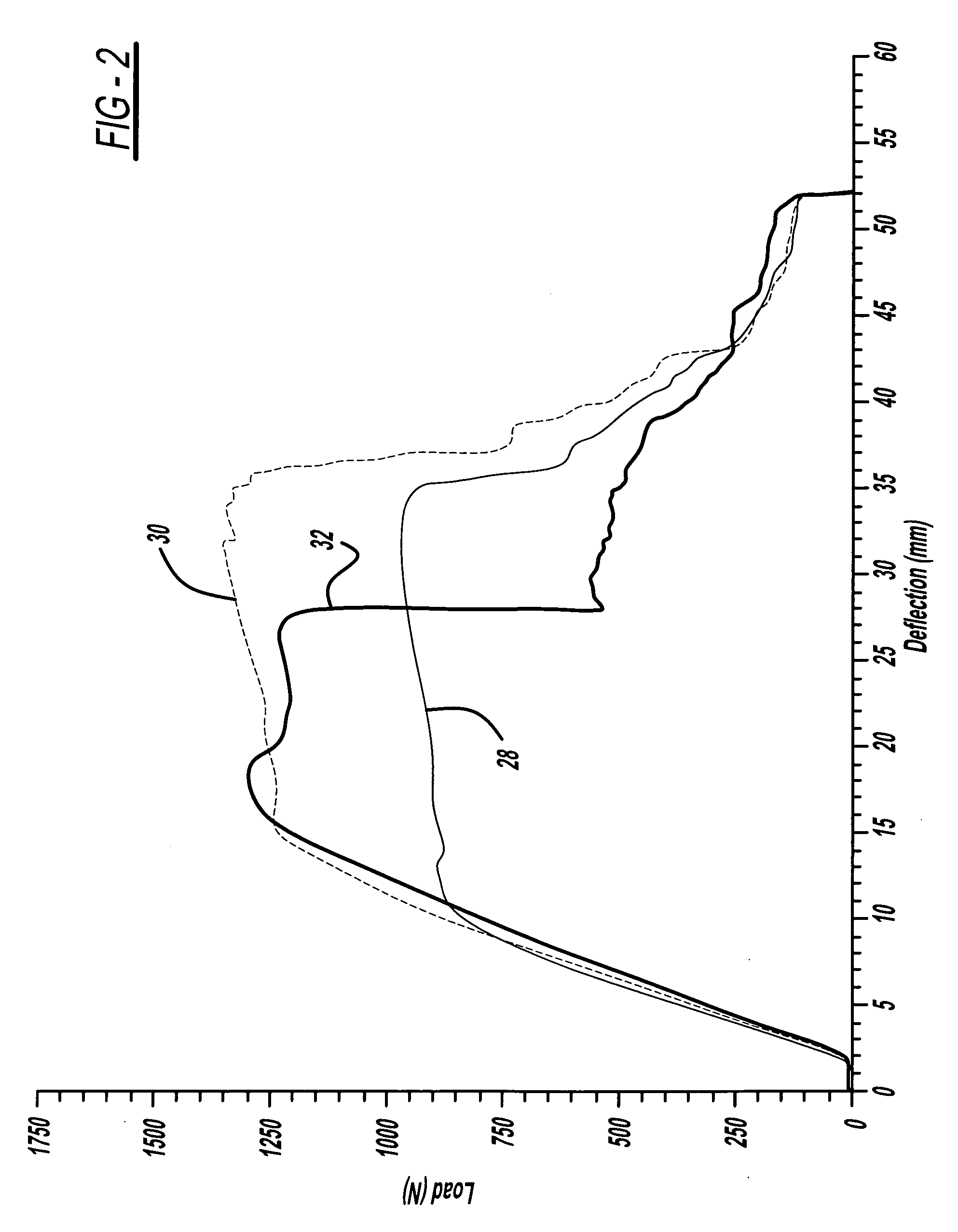

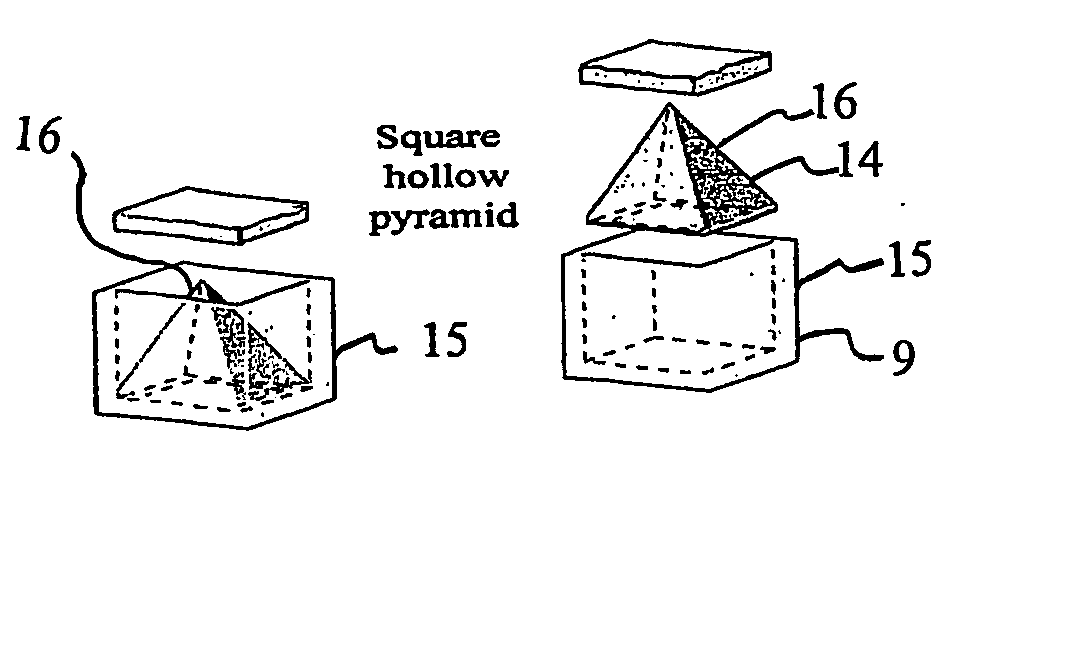

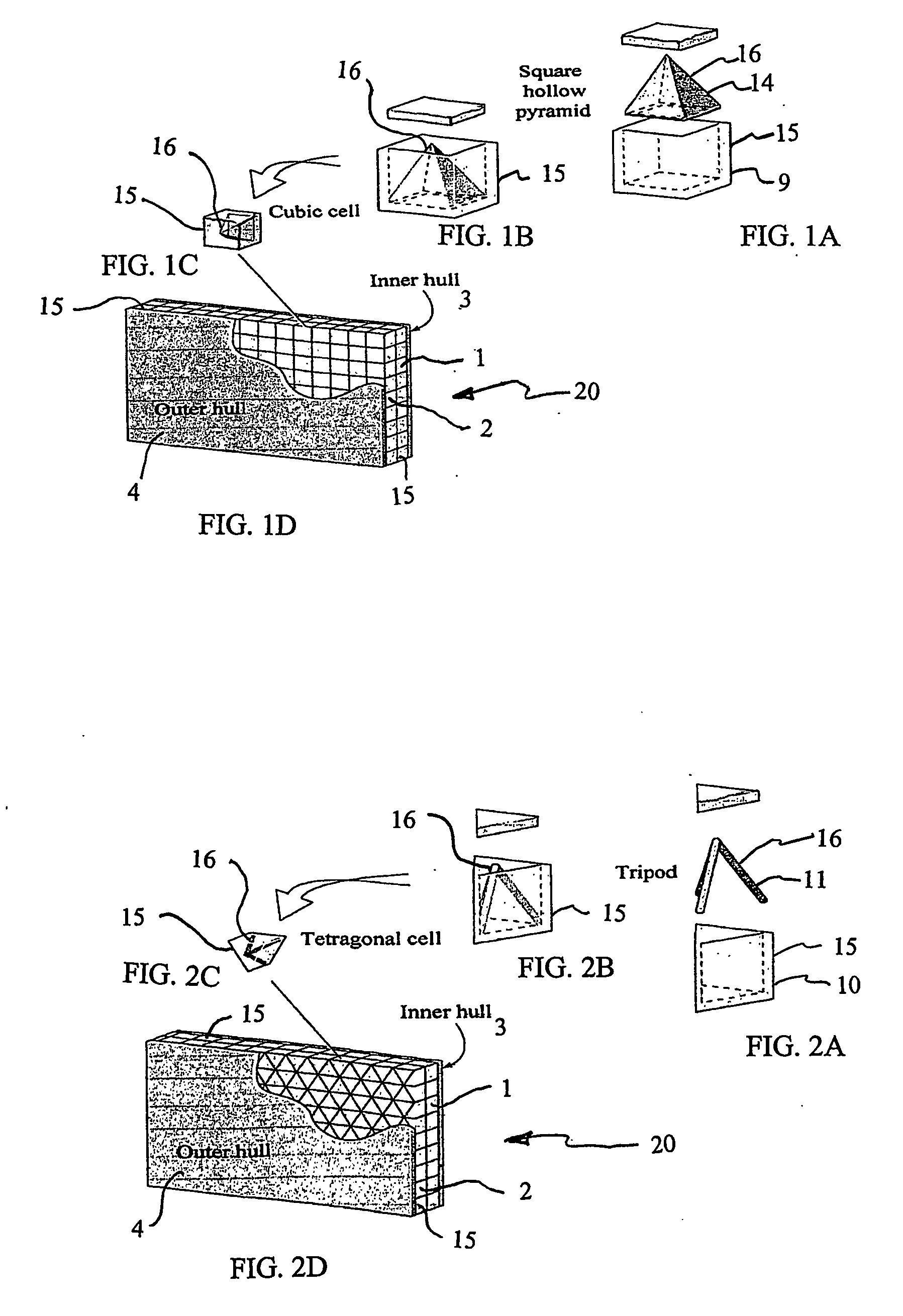

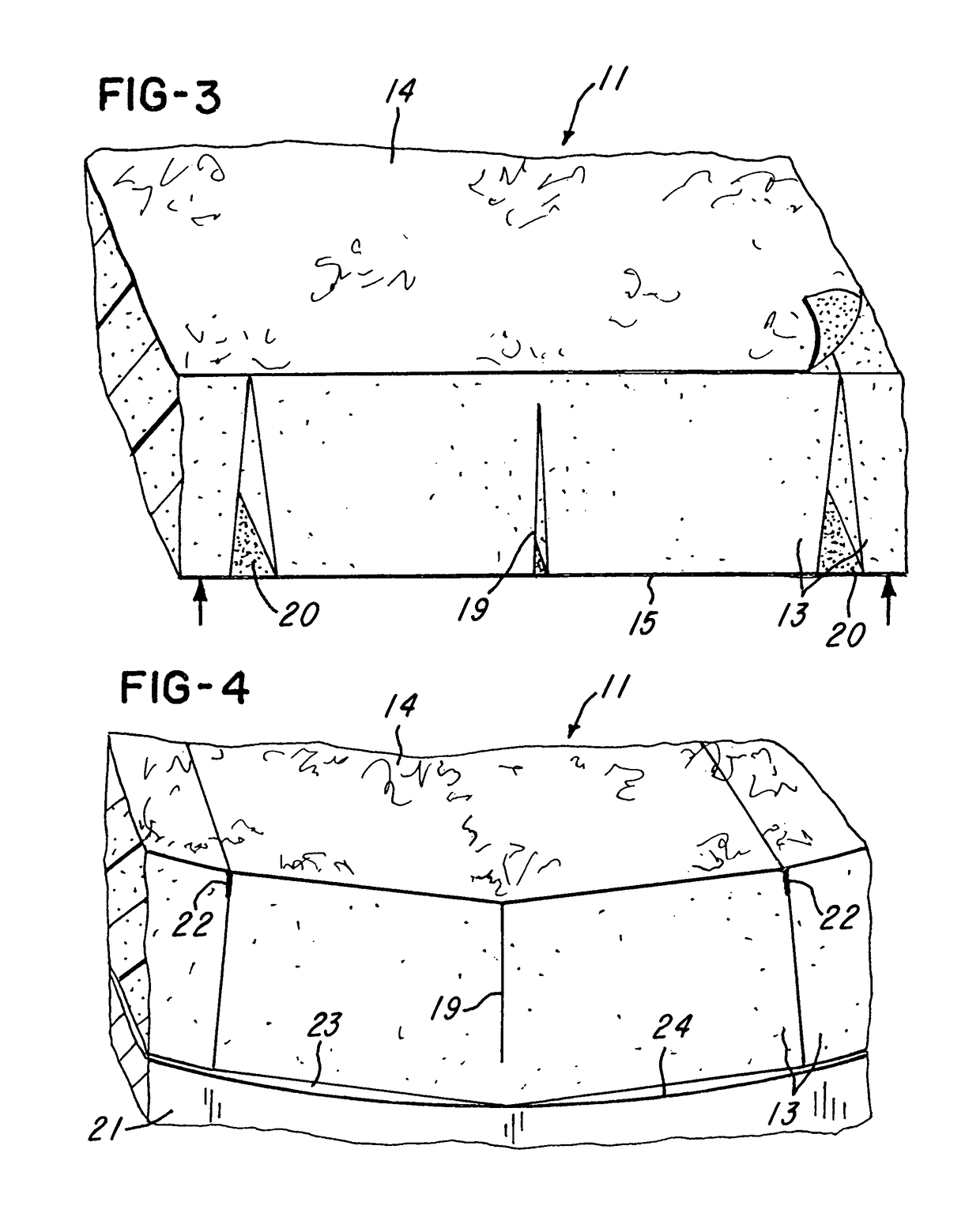

Method for manufacture of cellular materials and structures for blast and impact mitigation and resulting structure

Provided is the utilization of face panels (20) containing core materials (16) topologically structured at small scale, relative to a system (e.g. ship hull) that utilize them. They are optimized Lo absorb or reflect the energy subject to their while also possessing the ability to efficiently support high structural loads. It is entirely compatible with double-hull ship design concepts, because the volume between the hulls is used to locate the energy absorbing material substructures. The approach can be generalized to provide protection from impacts of low, intermediate or high intensity. The technology to design such structures requires materials selection and cell topology designs coupled with and techniques for the affordable manufacturing of structures that must he able to sustain severe dynamic deformations. It requires a coupling of effects occurring and phenomena that occur at the materials and structural levels.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

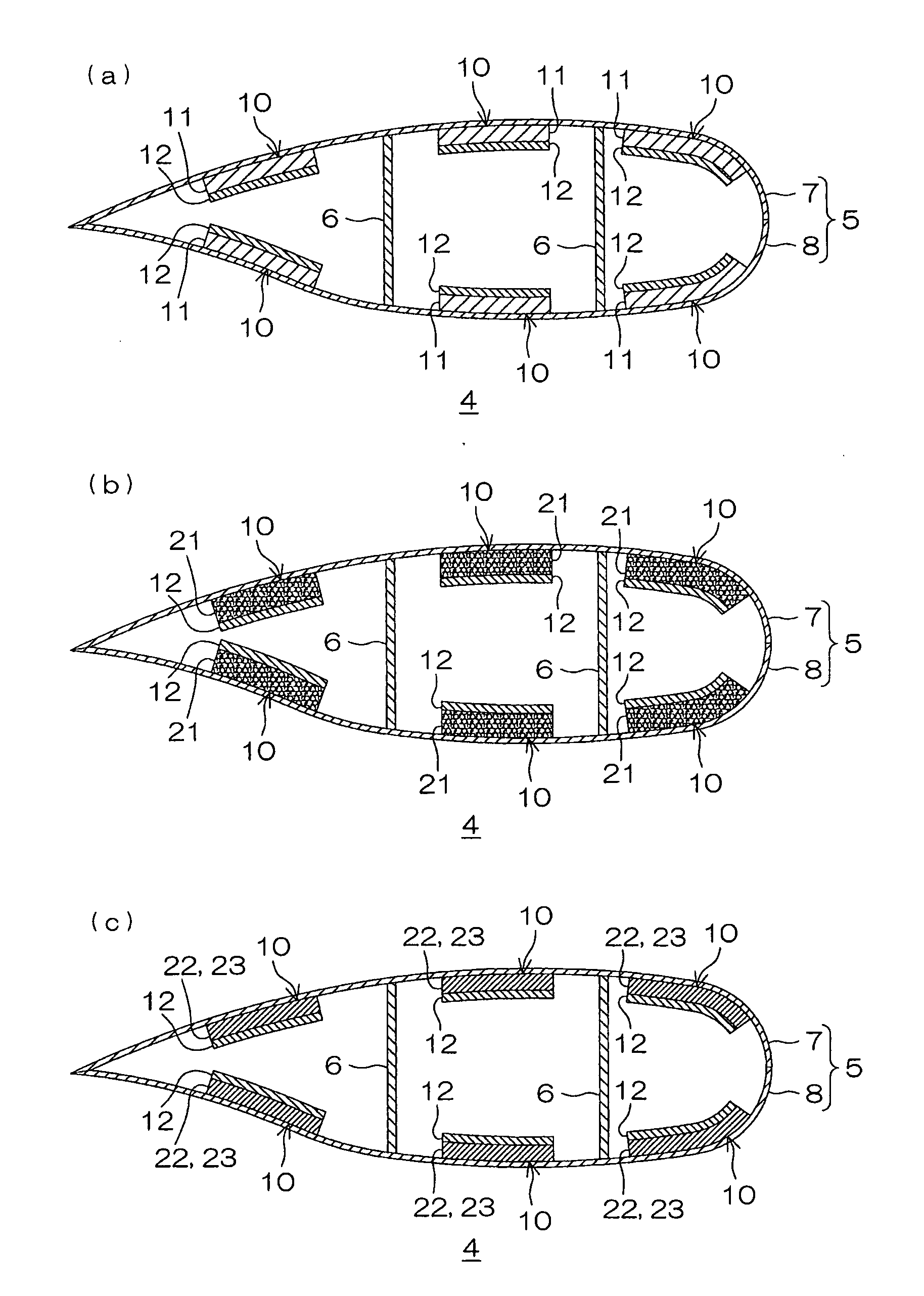

Reinforcing sheet for wind power generator blades, reinforcing structure of wind power generator blade, wind power generator, method for reinforcing the wind power generator blade

InactiveUS20110031758A1Easily and sufficiently reinforceRigidity can be easily and reliablyPropellersReaction enginesWind forceElectric generator

Owner:NITTO DENKO CORP

Modified ply drops for composite laminate materials

Owner:GENERAL ELECTRIC CO

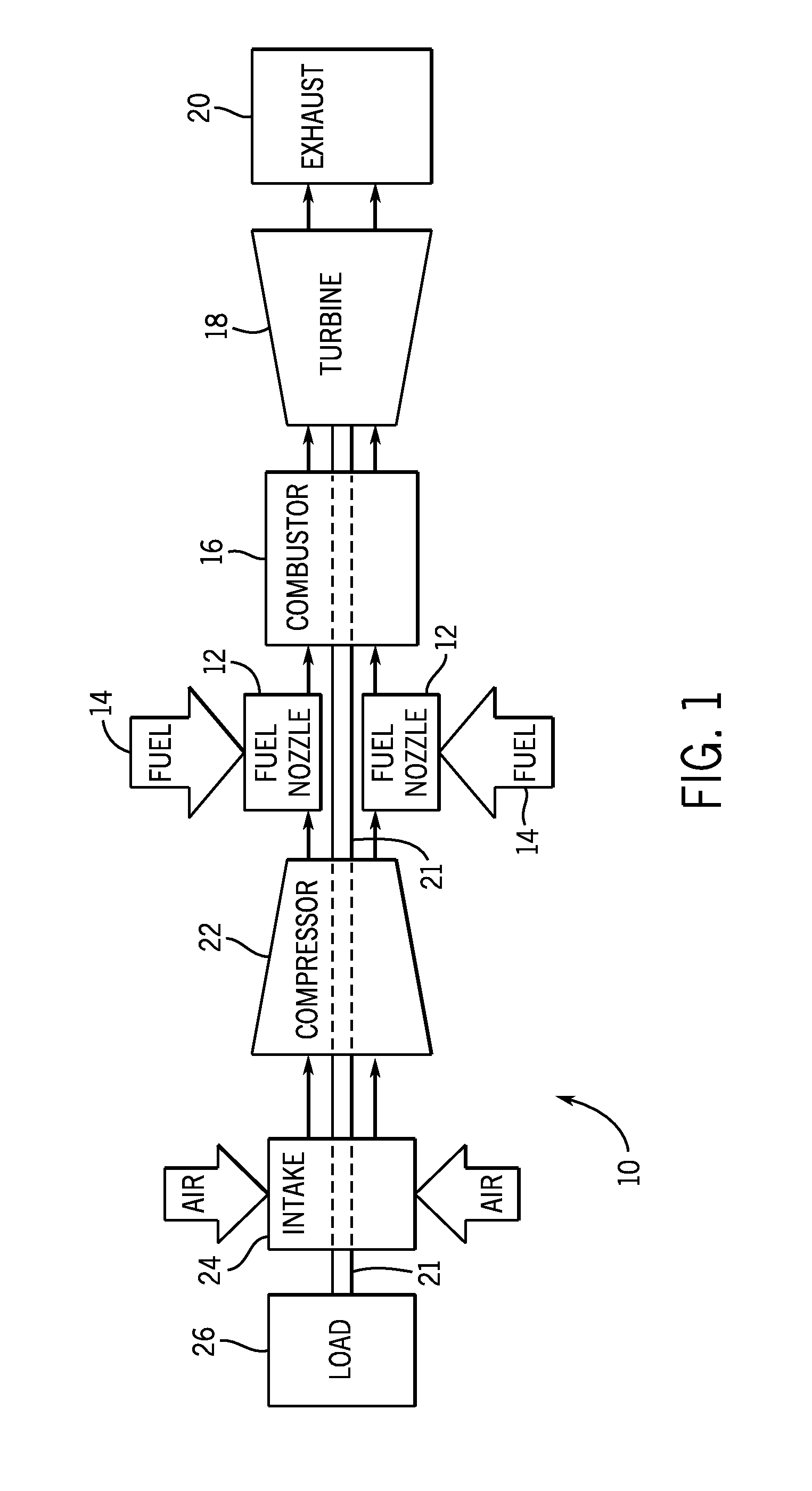

Shaped composite ply layups and methods for shaping composite ply layups

Ply layups and methods for forming composite components are provided. For example, a method for forming a composite component comprises laying up a plurality of composite plies to form a composite ply layup; partially processing the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing the green state layup and the one or more sub-assemblies to form the composite component. In an exemplary embodiment, the composite component is a turbine nozzle airfoil. Another exemplary method comprises laying up a plurality of composite plies to form a composite ply layup; compacting the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing the green state layup and the one or more sub-assemblies to form the composite component.

Owner:GENERAL ELECTRIC CO

Prepreg and carbon fiber reinforced composite materials

ActiveUS7931958B2Improve conductivityIncrease resistanceCarbon fibresSynthetic resin layered productsFiberCarbon fiber reinforced composite

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

Articles Comprising Protective Sheets and Related Methods

ActiveUS20100068446A1Promote formationEliminate process stepsSynthetic resin layered productsRecord information storageEngineering

Methods of the invention include those for applying protective sheets to articles. According to these methods and resulting articles, a protective sheet is applied to at least a portion of an exterior surface where protection is desired on an article. At least one portion of at least one exterior surface of the article to be protected can be integrally formed in the presence of the protective sheet. Improved bonding of the protective sheet to the article and improved processing efficiency are advantageously achieved according to the invention.

Owner:PPG ADVANCED SURFACE TECH LLC

Composite cores and panels

Owner:METYX USA INC

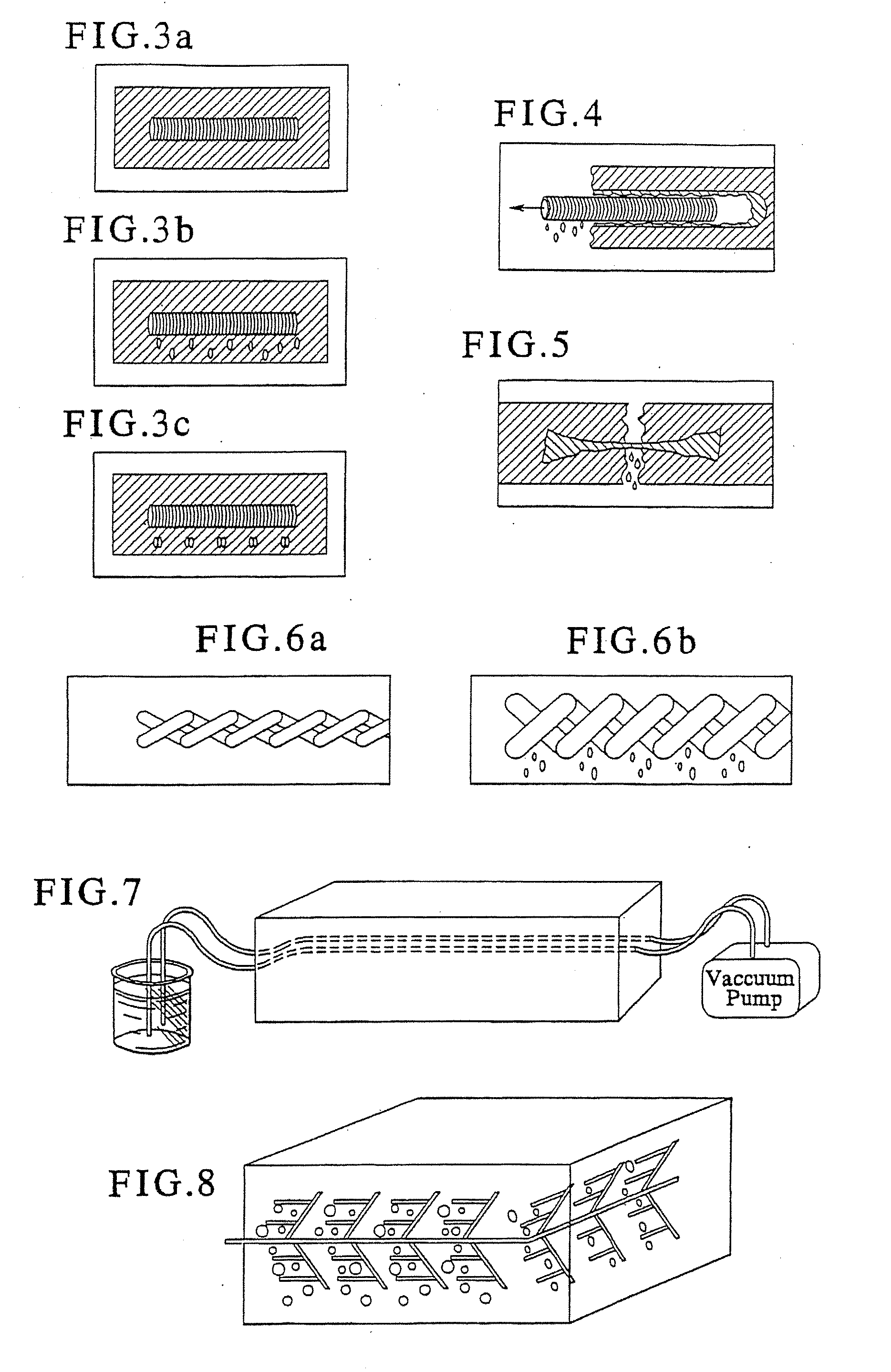

Self-repairing, reinforced matrix materials

InactiveUS20060169180A1Long-term durabilityIncreased durabilityMaterial nanotechnologyAuxillary shaping apparatusMaterials sciencePolymer

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN M

Cellular structures with fourteen-cornered cells

ActiveUS20180057060A1Reduce distanceImprove energy absorptionDomestic upholsteryUnderstructuresEngineeringCell structure

A cellular structure may include a plurality of cells each cell of the plurality of cells having a fourteen-cornered cross section. The fourteen-cornered cross section may include fourteen sides and fourteen corners. Each cell may include a plurality of longitudinal walls extending between a top and a bottom of the cell, the longitudinal walls intersecting to create corners of the cell.

Owner:FORD GLOBAL TECH LLC

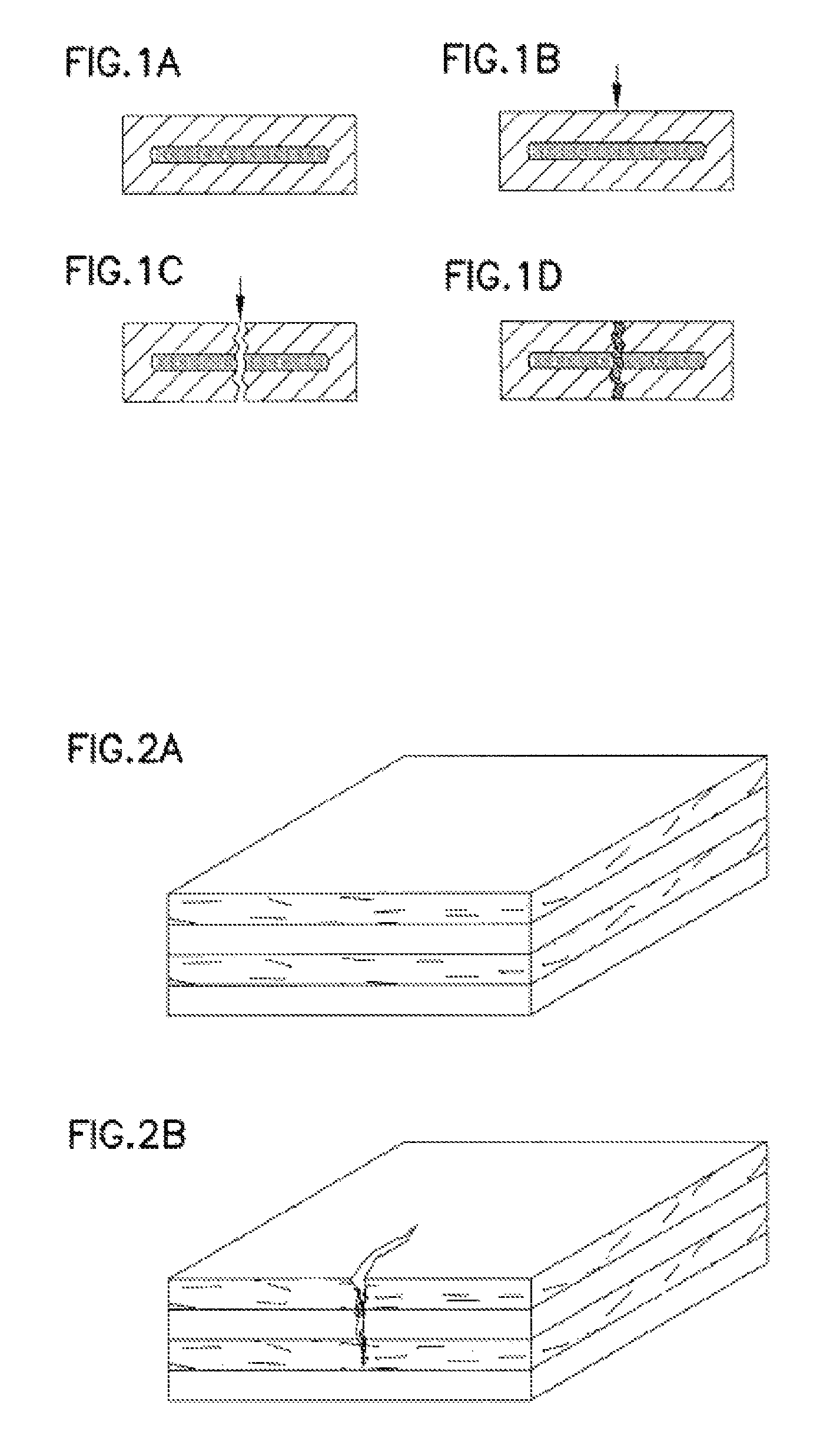

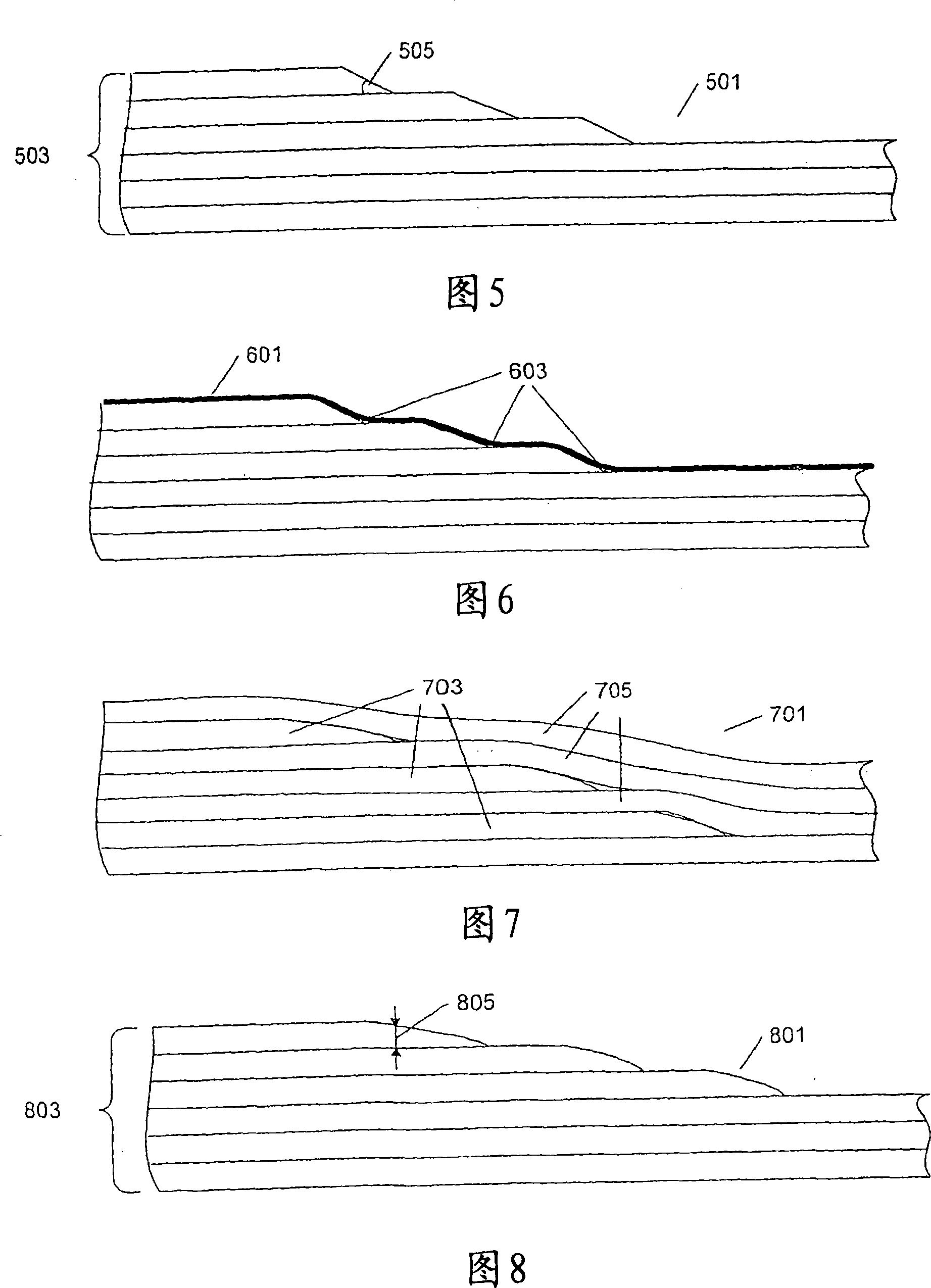

A method of cutting off laminate layers, eg a glass-fibre or carbon-fibre laminate layer in the blade of a wind turbine

The invention relates to a method of cutting off laminate layers for use in a fibre-reinforced laminate object (701) comprising a number of combined laminate layers (703) wherein, along a section of the at least one rim of the laminate layer, a tapering cut is performed through the thickness of the laminate layer, whereby the thickness of the laminate layer is reduced. Since not only the number of laminate layers, but also the thickness of the individual laminate layers are reduced, a laminate layer is accomplished that can be used in a laminate object, by which both the issues of areas rich in resin, air pockets and the risk of delamination are reduced. The invention also relates to a laminate layer for use in a fibre-reinforced laminate object comprising a number of combined laminate layers and a fiber - reinforced laminate object in the form of the blade of a wind turbine, wherein the blade of the wind turbine comprises a number of combined laminate layers.

Owner:LM GLASSFIBER

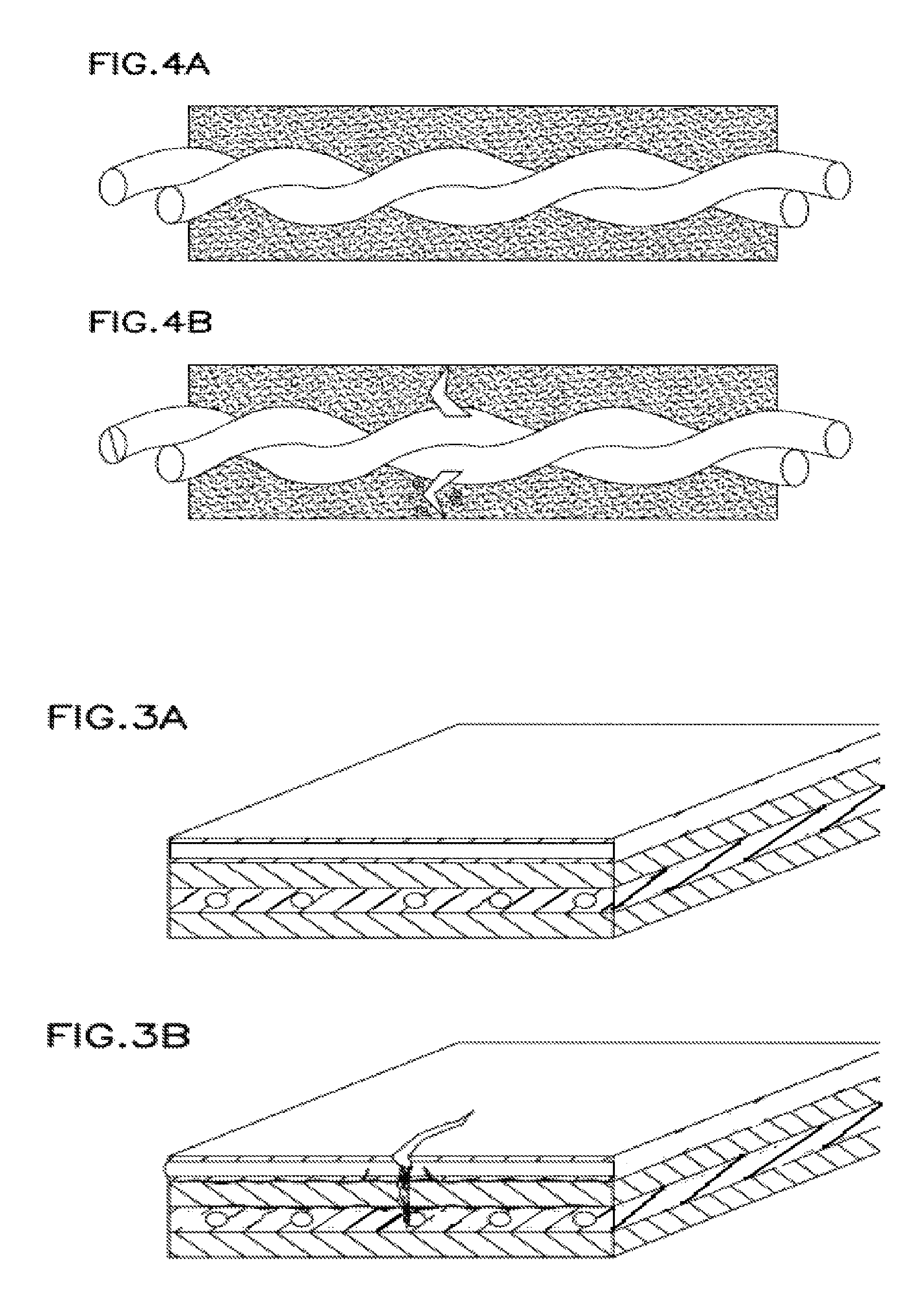

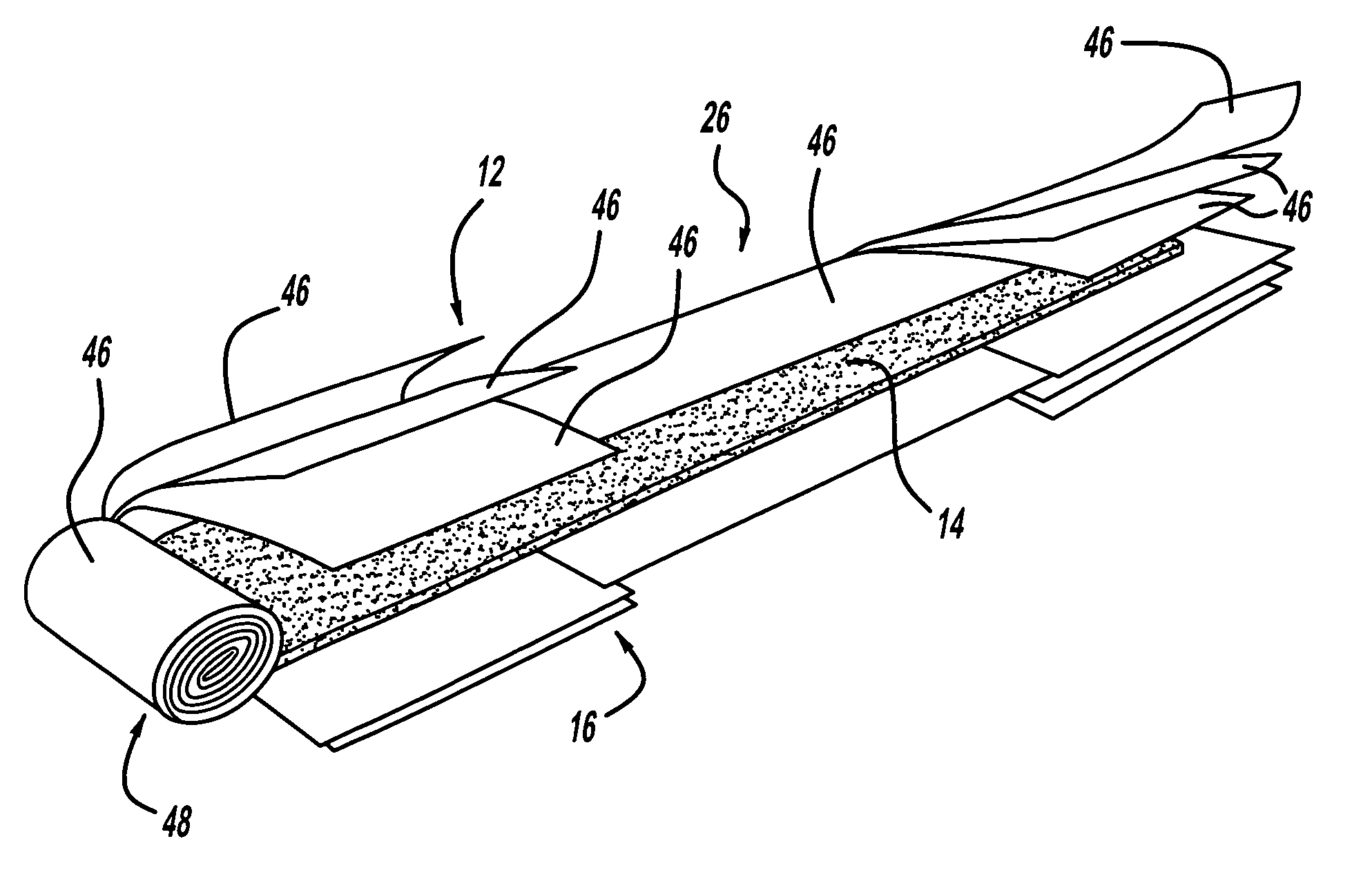

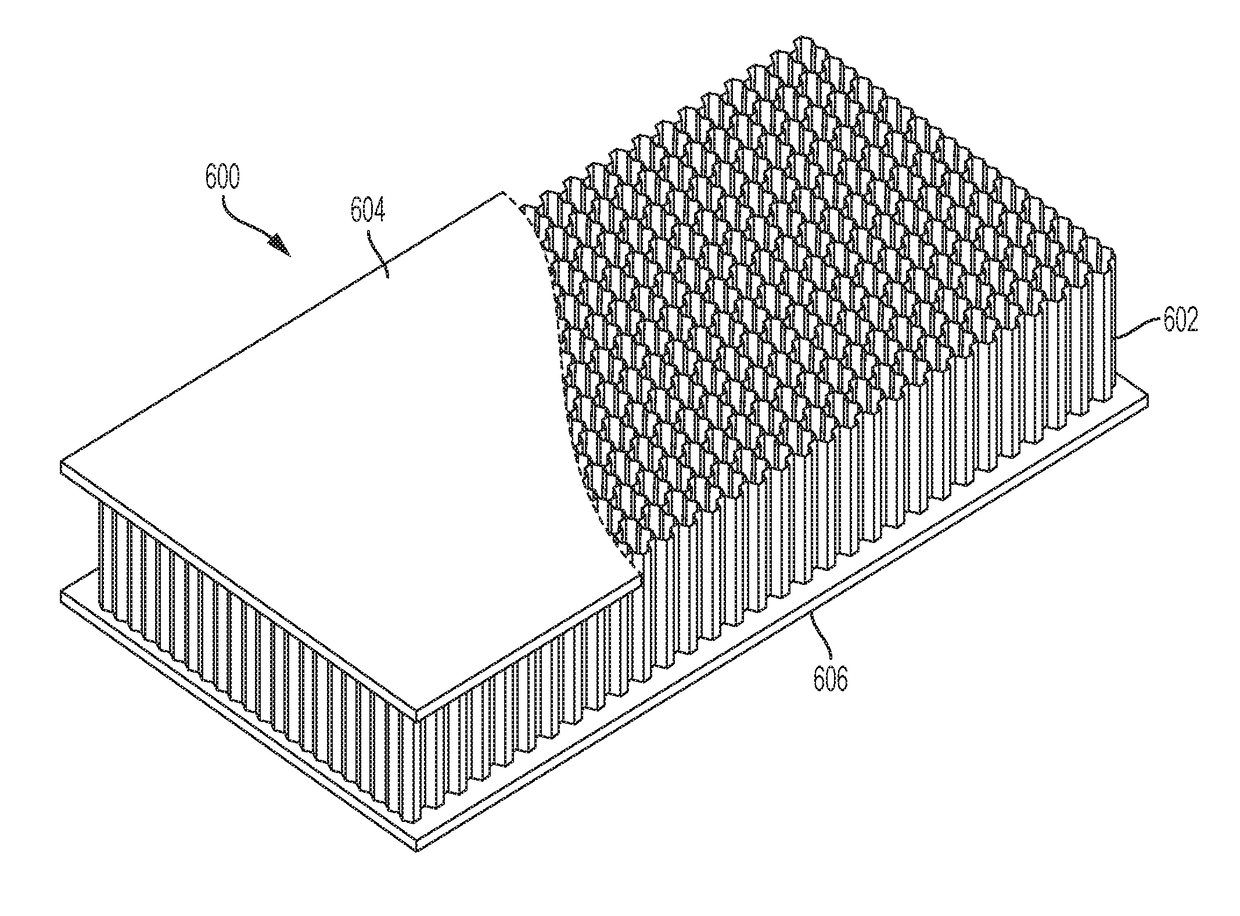

Improvements relating to reinforcing structures for wind turbine blades

ActiveUS20170218918A1Easy to controlReduce riskSynthetic resin layered productsReaction enginesYarnTurbine blade

A wind turbine blade including an elongate reinforcing structure, the reinforcing structure comprising a plurality of strips of fibre-reinforced polymer arranged into a stack structure, and at least one adjacent pair of the plurality of strips including an infusion promoting layer, wherein the infusion promoting layer is a fabric comprising a plurality of twisted yarns. The invention is also expressed as a method of assembling a wind turbine blade.

Owner:VESTAS WIND SYST AS

Self-Repairing, Reinforced Matrix Materials

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN

Methods for manufacturing a spar cap for a wind turbine rotor blade

InactiveUS20160146185A1Reduce stress concentration effectsEngine manufactureFinal product manufactureFiber bundleEngineering

Owner:GENERAL ELECTRIC CO

System having layered structure and method of making the same

A system includes a layered structure. The layered structure includes first and second coalesced layers and an intermediate layer disposed between the first and second coalesced layers. The first and second coalesced layers have a higher degree of coalescence than the intermediate layer.

Owner:GENERAL ELECTRIC CO

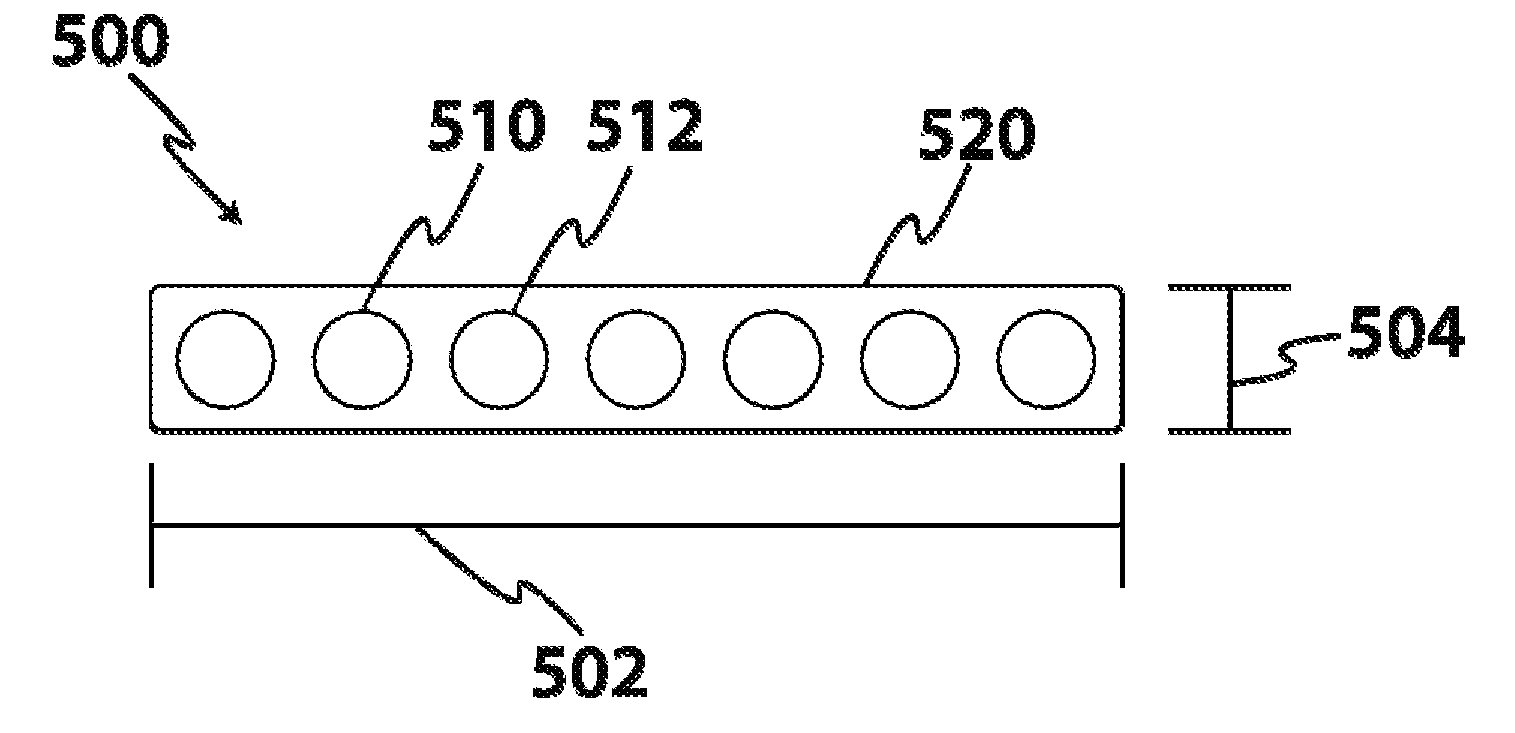

Fiber reinforced core panel

A fiber reinforced core panel having a first side and an opposing second side. The core panel contains a series of adjacent low density strips having at least three faces. The major face of each strip is disposed within the first or second side of the core panel and the major face of each strip is disposed within an opposite face of the core panel than the major face of the adjacent strips. The core panel also contains a continuous fibrous reinforcement sheet which is threaded through the low density strips such that the fibrous reinforcement sheet is disposed between adjacent strips and adjacent to the major faces of the low density strips. The reinforcement sheet forms at least about sixty five percent of the surface area of the first side and at least about sixty five percent of the surface area of the second side of the core panel.

Owner:MILLIKEN & CO

Wind turbine blades and method of manufacturing the same

ActiveUS20150316027A1Efficiently formedHigh bonding strengthLayered productsFinal product manufactureEdge surfaceTurbine blade

Method of making a spar cap (146) for a wind turbine blade, the method comprising: (a) providing a plurality of elongate pultruded fibrous composite strips (100), each strip being of substantially constant cross section defined by first and second mutually opposed and longitudinally extending sides (102. 104) and by first and second longitudinal edges (110, 112), the first and second sides comprising, respectively, first and second planar abutment surfaces (118), the strip being of substantially uniform thickness between the first and second abutment surfaces, a first edge region (120) of the strip comprising a first edge of the strip being of relatively reduced thickness, the first side of the strip comprising an edge surface (122) adjacent the first abutment surface in the first edge region of the strip, and the strip having a first peel ply layer (114) at least partially covering the first abutment surface and at least partially covering the edge surface; (b) removing the first peel ply layers from the respective strips; (c) stacking the strips in a mould such that the first abutment surface of each strip abuts an abutment surface of an adjacent strip in the stack to define an interface region (142) between the strips, and such that a clearance region (144) is defined between the first edge region of each strip and an edge region of an adjacent strip in the stack; (d) supplying resin to the respective clearance regions and causing the resin to infiltrate into the interface regions between adjacent strips; and (e) curing the resin to bond the strips together.

Owner:VESTAS WIND SYST AS

Methods of making wind turbine rotor blades

A method of manufacturing a root portion of a wind turbine blade includes, in an exemplary embodiment, providing an outer layer of reinforcing fibers including at least two woven mats of reinforcing fibers, providing an inner layer of reinforcing fibers including at least two woven mats of reinforcing fibers, and positioning at least two bands of reinforcing fibers between the inner and outer layers, with each band of reinforcing fibers including at least two woven mats of reinforcing fibers. The method further includes positioning a mat of randomly arranged reinforcing fibers between each pair of adjacent bands of reinforcing fibers, introducing a polymeric resin into the root potion of the wind turbine blade, infusing the resin through the outer layer, the inner layer, each band of reinforcing fibers, and each mat of random reinforcing fibers, and curing the resin to form the root portion of the wind turbine blade.

Owner:GENERAL ELECTRIC CO

Self-Repairing, Reinforced Matrix Materials

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com