Wing and blade structure using pultruded composites

a composite material and composite material technology, applied in the field of composite materials, can solve the problems of large performance gap, high bending stress of aircraft wing and blade structures, and low compression strength of carbon composite materials, so as to achieve high stress, increase compressive strength, and increase compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

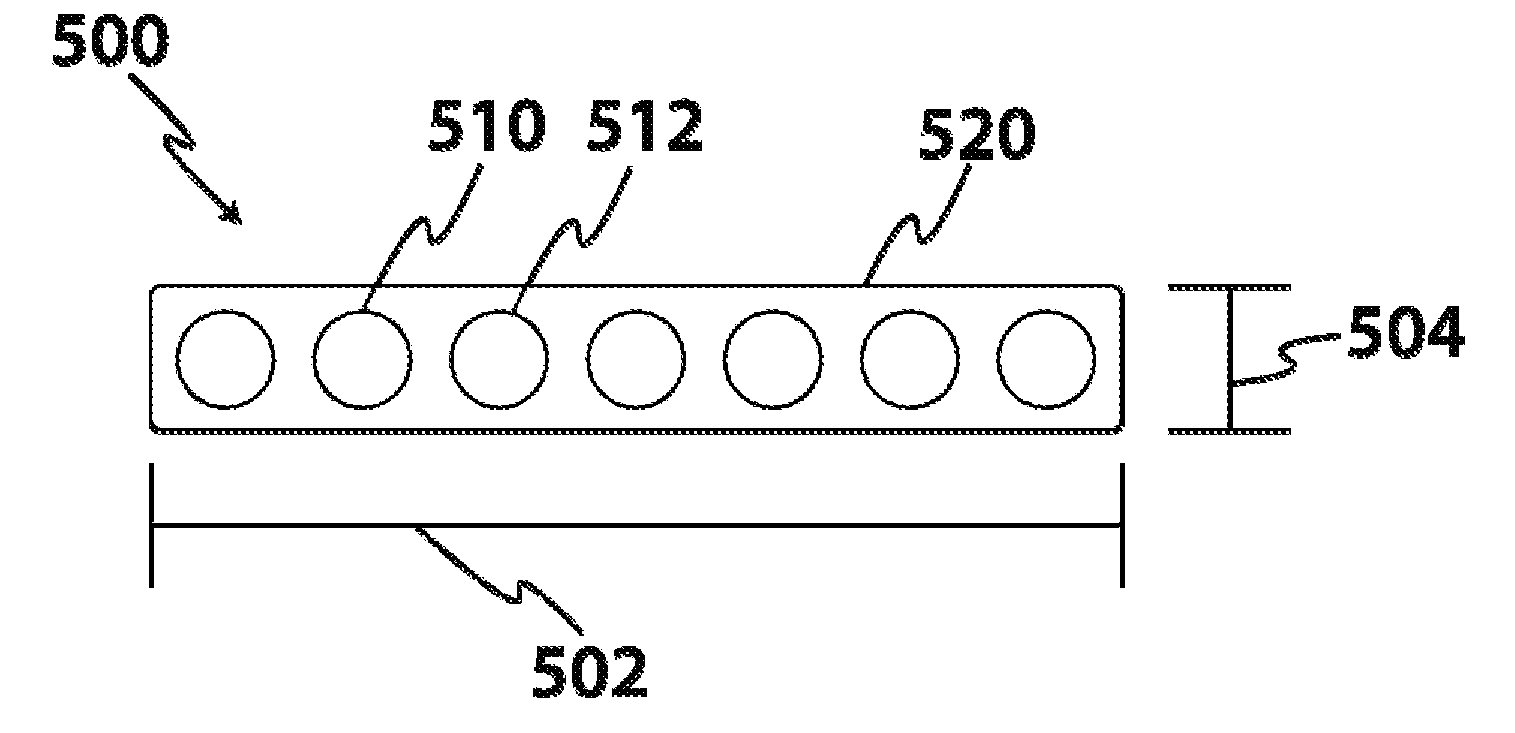

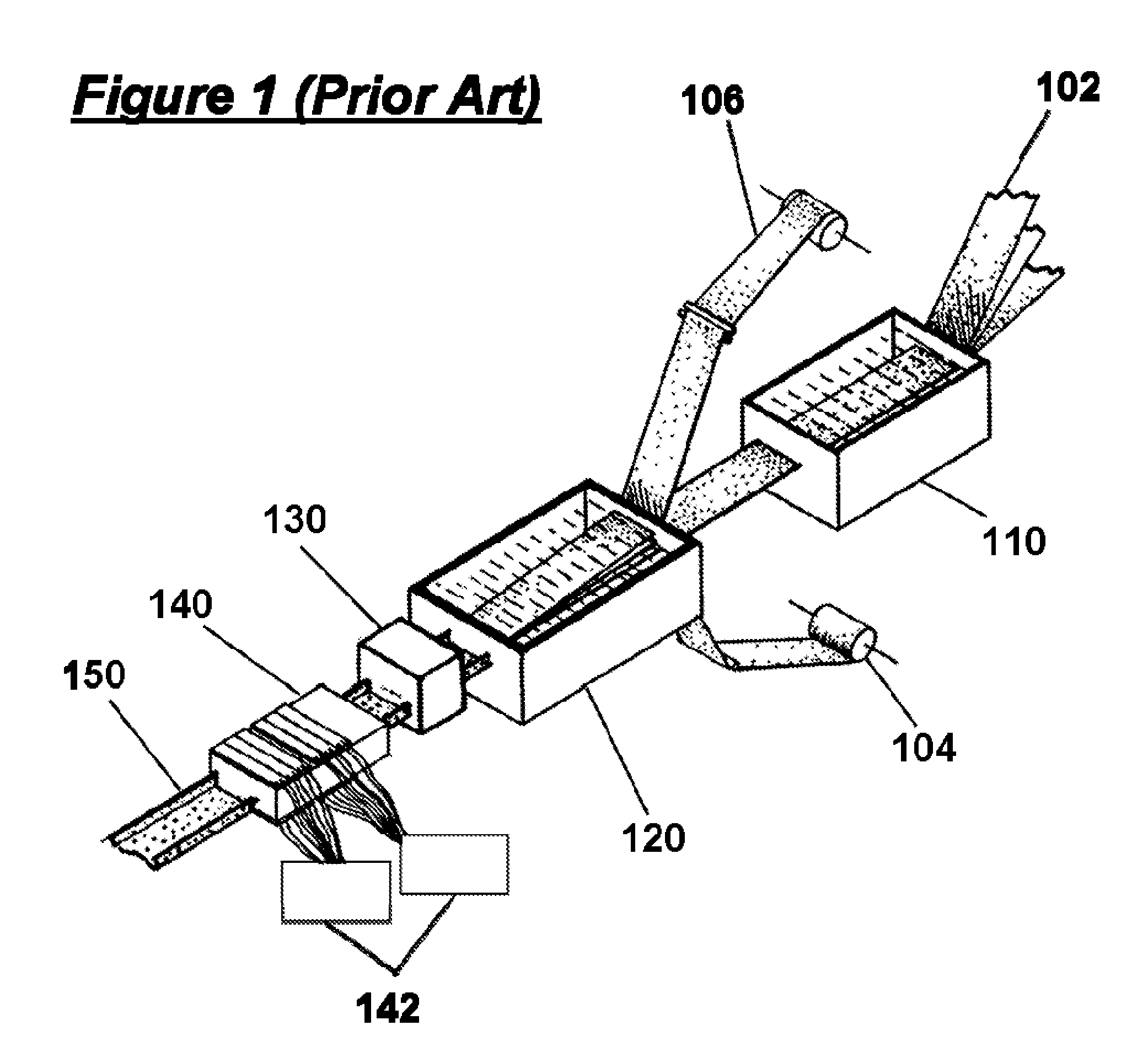

[0025]As shown in the drawing figures discussed below, pultruded fibers can be integrated into a highly-stressed tapered beam structure such as a structurally efficient aircraft wing, rotor blade, or propeller. Pre-cured pultruded material is advantageously laminated into a composite aircraft spar structure adding high compressive strength material to areas where it is most effective, thereby reducing aircraft weight and increasing structural capacity.

[0026]As used herein, “composite” means engineered materials comprising two or more constituent materials. Of special relevance is carbon composites, in which carbon fiber is embedded in a matrix or resin. Alternate composites are also contemplated, including those containing fiberglass, ceramics, and other elements. A layer of composite material could include a plurality of fibers positioned at an orientation with respect to the long axis of an object. A layer of composite material could also advantageously include pultruded fibers in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com