Oxygen enrichment intensifying roasting method of nonferrous metal mineral resource

A technology for mineral resources and non-ferrous metals, applied in the field of oxygen-enriched intensified roasting of non-ferrous metal mineral resources, can solve the problems of low fuel utilization efficiency, limited reaction efficiency, and large negative impact on the environment, so as to improve and reduce combustion efficiency and combustion degree. Carbon black loading rate, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

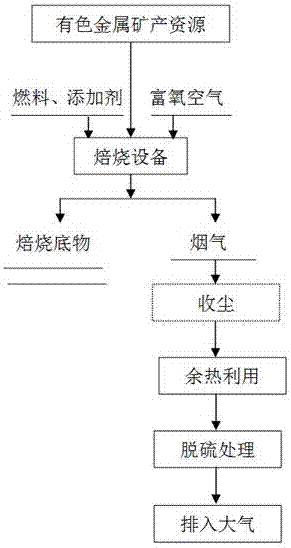

[0018] Such as figure 1 As shown, the non-ferrous metal mineral resources oxygen-enriched intensified roasting method, its specific steps are as follows:

[0019] First, the non-ferrous metal mineral resources (zinc oxide concentrate, zinc content is 42wt%) and fuel (anthracite) are crushed to control the particle size of 40-200 mesh > 90%, and then according to the mass ratio of non-ferrous metal mineral resources and fuel to 3: 1 Mix evenly, put the mixed material into a 20×2.5m rotary kiln, first blow oxygen-enriched air into the kiln body through a spray gun (Oxygen-enriched O 2 concentration is 30vol%), ignited in an oxygen-enriched environment for oxygen-enriched intensified roasting, during the process of oxygen-enriched intensified roasting, the composition of the roasted gas phase is monitored, and the oxygen-enriched concentration is adjusted in real time. The COvol% in the gas is 85%, and the O in the oxygen-enriched is controlled 2 vol% is 70%, and the oxygen-enr...

Embodiment 2

[0021] Such as figure 1 As shown, the non-ferrous metal mineral resources oxygen-enriched intensified roasting method, its specific steps are as follows:

[0022] First, the non-ferrous metal mineral resources (tin concentrate, tin content of 28wt%) and fuel (anthracite) are crushed to control the particle size of 40-200 mesh > 85%, and then according to the mass ratio of non-ferrous metal mineral resources and fuel to 3.2:1 Mix evenly, put the mixed material into a 20×2.5m rotary kiln, first blow oxygen-enriched air into the kiln body through a spray gun (Oxygen-enriched O 2 concentration is 25vol%), ignite in an oxygen-enriched environment for oxygen-enriched enhanced roasting, monitor the composition of the roasted gas phase during the oxygen-enriched enhanced roasting process, and adjust the oxygen-enriched concentration in real time. The COvol% in the gas is 80%, and the O in the oxygen-enriched is controlled 2 vol% is 50%, and the oxygen-enriched air flow rate is contr...

Embodiment 3

[0024] Such as figure 1 As shown, the non-ferrous metal mineral resources oxygen-enriched intensified roasting method, its specific steps are as follows:

[0025] First, the non-ferrous metal mineral resources (zinc oxide concentrate, zinc content is 45wt%) and fuel (anthracite) are crushed to control the particle size of 40-200 mesh > 80%, and then according to the mass ratio of non-ferrous metal mineral resources and fuel to 2.8: 1 Mix evenly, put the mixed material into the fluidized bed, first blow oxygen-enriched air into the kiln body through the spray gun (Oxygen-enriched O 2 concentration is 30vol%), ignited in an oxygen-enriched environment for oxygen-enriched intensified roasting, during the process of oxygen-enriched intensified roasting, the composition of the roasted gas phase is monitored, and the oxygen-enriched concentration is adjusted in real time. The COvol% in the gas is 88%, and the O in the oxygen-enriched is controlled 2 vol% is 90%, and the oxygen-enr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com