High-strength steel for 750 to 880 MPa-level vehicles and production method thereof

A production method, 880mpa technology, applied in the field of vehicle steel production, to achieve the effect of improving strength level, good low temperature impact toughness and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

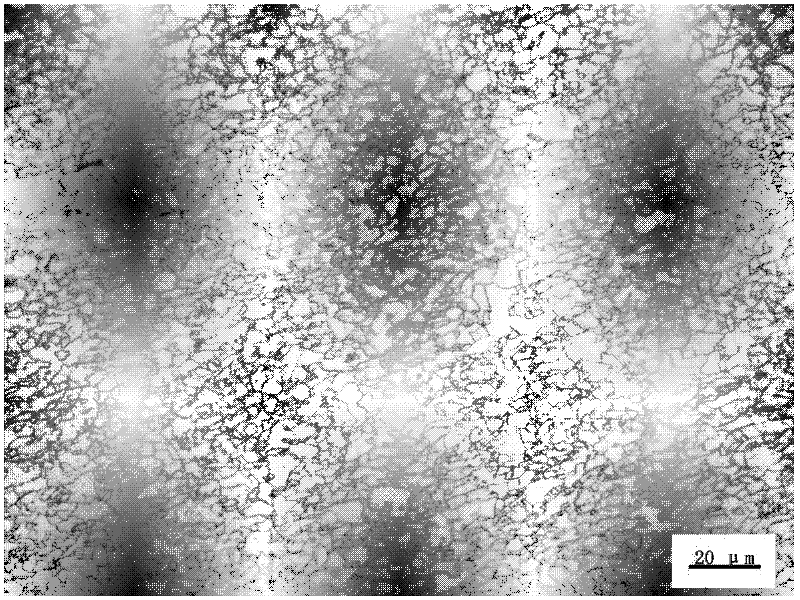

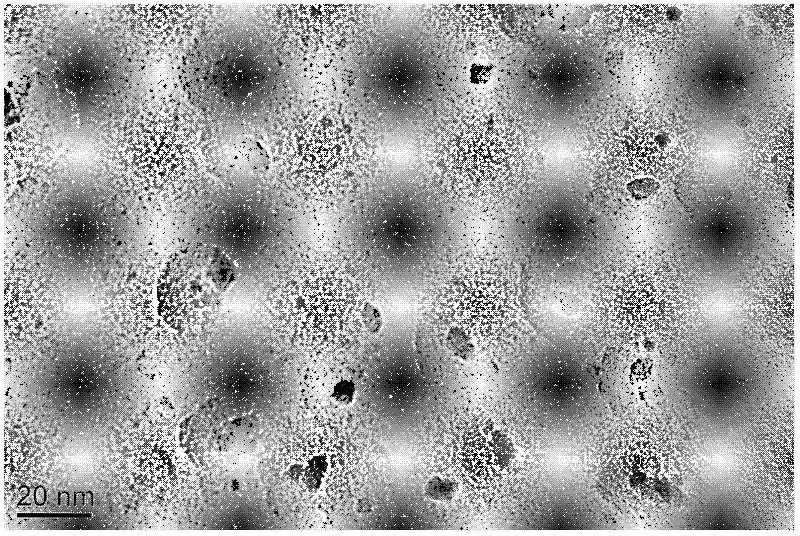

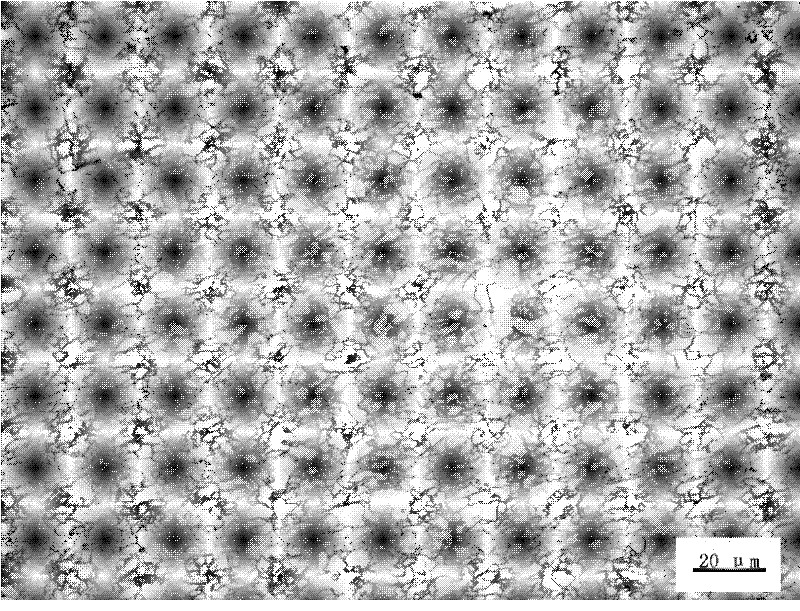

Image

Examples

Embodiment 1

[0040] The molten steel smelted in a 220-ton converter and refined outside the furnace is continuously cast into a slab, and its weight percentage is C: 0.077%, Si: 0.20%, Mn: 1.50%, P: 0.012%, S: 0.003%, Al: 0.041%, Nb: 0.047%, Ti: 0.10%, N: 0.004%, and the rest are Fe and unavoidable impurities. The thickness of the slab is 230mm.

[0041] Rolling is carried out in the 2250 hot continuous rolling production line, the heating temperature is 1200°C, the finish rolling entrance temperature is 1000°C, the thickness of the intermediate billet is 54mm, the final rolling temperature is 820°C, the target thickness is 10mm, after rolling, it is cooled to The target coiling temperature is 590°C, and air-cooled to room temperature after coiling.

[0042] The yield strength Rel of the high-strength steel produced according to the above method is 745MPa, the tensile strength is 820MPa, the elongation is 20%, the cold bending D=2a has no cracks on the surface, the impact energy at -20°C ...

Embodiment 2

[0044] The molten steel smelted in a 220-ton converter and refined outside the furnace was continuously cast into a slab, and its weight percentage was the same as in Example 1. The thickness of the slab is 230mm.

[0045] Rolling is carried out in the 2250 hot continuous rolling production line, the heating temperature is 1220°C, the finish rolling entrance temperature is 1020°C, the thickness of the intermediate billet is 42mm, the final rolling temperature is 830°C, the target thickness is 8mm, after rolling, it is cooled to The target coiling temperature is 580°C, and air-cooled to room temperature after coiling.

[0046] The yield strength Rel of the high-strength steel produced according to the above method is 735MPa, the tensile strength is 800MPa, the elongation is 19%, the cold bending D=2a has no cracks on the surface, the impact energy at -20°C is 64J, and the impact energy at -40°C is 51J (impact test The sample size is 5mm×10mm×55mm).

Embodiment 3

[0048] The molten steel smelted in a 220-ton converter and refined outside the furnace was continuously cast into a slab, and its weight percentage was the same as in Example 1. The thickness of the slab is 230mm.

[0049] Rolling is carried out in the 2250 hot continuous rolling production line, the heating temperature is 1250°C, the finish rolling entrance temperature is 1060°C, the thickness of the intermediate billet is 34mm, the final rolling temperature is 850°C, the target thickness is 4mm, and after rolling, it is cooled to The target coiling temperature is 570°C. After coiling, the steel coil enters the slow cooling pit, and the temperature is lower than 150°C, leaving the pit to be air-cooled to room temperature.

[0050] The yield strength Rel of the high-strength steel produced according to the above method is 750MPa, the tensile strength is 805MPa, the elongation is 20.5%, and there is no crack on the surface of the cold-formed D=2a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| -20°c impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com