High-heat-conductivity epoxy resin electronic binding glue

A technology of epoxy resin and bonding glue, which is applied in the field of bonding glue, can solve the problems of affecting mechanical properties, improving thermal conductivity limited, low thermal conductivity, etc., to reduce volume shrinkage, reduce thermal expansion coefficient, and high thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

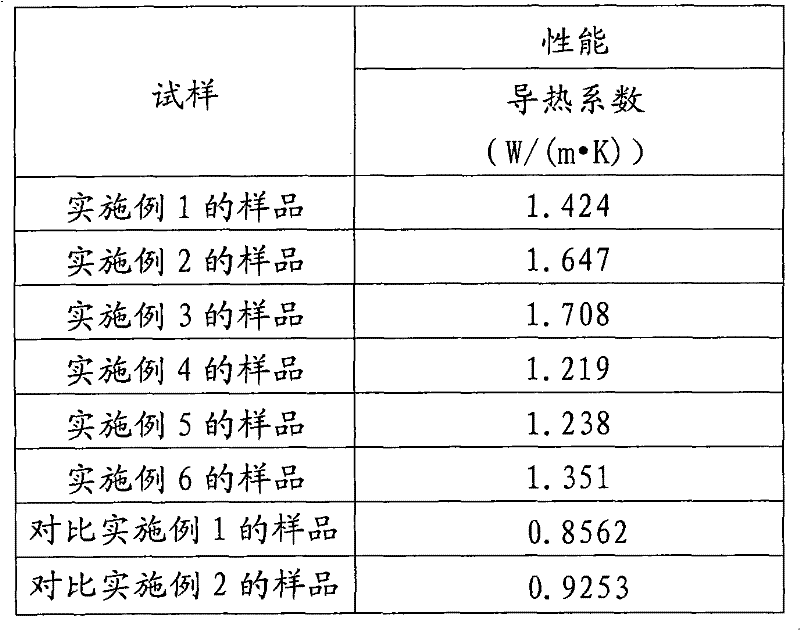

Embodiment 1

[0036] 70 parts of spherical alumina powder (domestic average particle size is 40 μm), 15 parts of bisphenol A epoxy resin, 5 parts of bisphenol F epoxy resin, 3.3 parts of allyl glycidyl ether, hydroxyl-terminated liquid nitrile rubber 5 parts, 0.5 parts of phenyltrimethoxysilane, 1.0 parts of fumed silica Aerosil R202, stirred evenly at room temperature to prepare component A; polyamide 300 and polyetheramine D-400 amine with a weight ratio of 1:1 kind of curing agent. Mix component A and amine curing agent in a weight ratio of 100:12, stir evenly at room temperature, cure the mixture at 25°C for 24 hours, and measure the thermal conductivity of the cured product.

Embodiment 2

[0038] 75 parts of spherical alumina powder (domestic average particle size is 40 μm), 14 parts of bisphenol A epoxy resin, 3 parts of bisphenol F epoxy resin, 3 parts of n-butyl glycidyl ether, hydroxyl-terminated liquid nitrile rubber 3.7 parts, 0.3 parts of phenyltrimethoxysilane, 0.8 parts of fumed silica Aerosil R2020, 0.2 parts of carbon black, and stir evenly at room temperature to obtain component A; weight of polyamide 651 and polyetheramine D-400 Amine curing agent with a ratio of 1:1. Mix component A and amine curing agent in a weight ratio of 100:9.8, stir evenly at room temperature, cure the mixture at 25°C for 36 hours, and measure the thermal conductivity of the cured product.

Embodiment 3

[0040] 80 parts of spherical alumina powder (domestic average particle size is 40 μm), 11 parts of bisphenol A epoxy resin, 3 parts of bisphenol F epoxy resin, 2.2 parts of phenyl glycidyl ether, 3 parts of hydroxyl-terminated liquid nitrile rubber 0.2 parts, 0.2 parts of γ-(glycidoxy) propyl trimethoxysilane, 0.4 parts of fumed silica AerosilR2020, 0.2 parts of carbon black, stir well at room temperature to obtain component A; D-400 Amine curing agent. Component A and amine curing agent were mixed in a weight ratio of 100:7.7, stirred evenly at room temperature, the mixture was cured at 25°C for 48 hours, and the thermal conductivity of the cured product was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com