Self-cleaning ceramic tile and preparation method thereof

A ceramic tile and self-cleaning technology, which is applied in the field of ceramic tiles, can solve the problems that the coating and the glaze layer do not bite each other, the glaze layer processing cost is high, and the thermal stability is not good enough to achieve low cost, improve self-cleaning ability, The effect of good self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

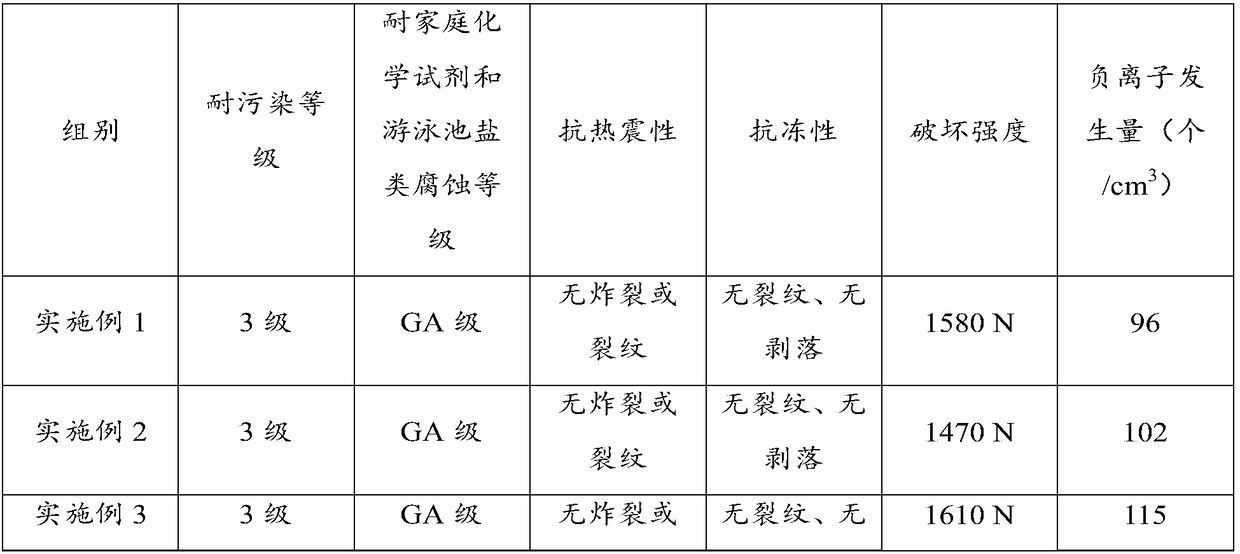

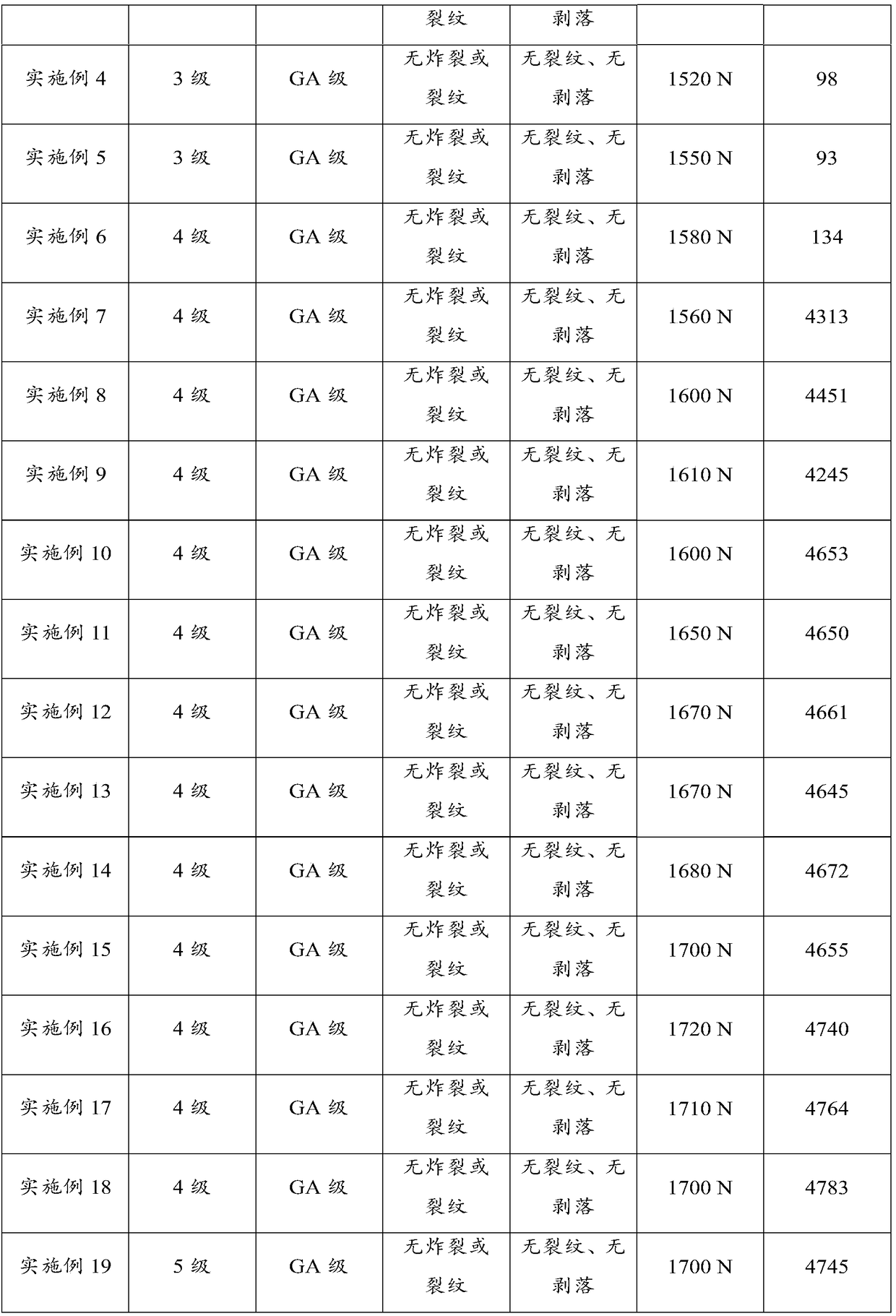

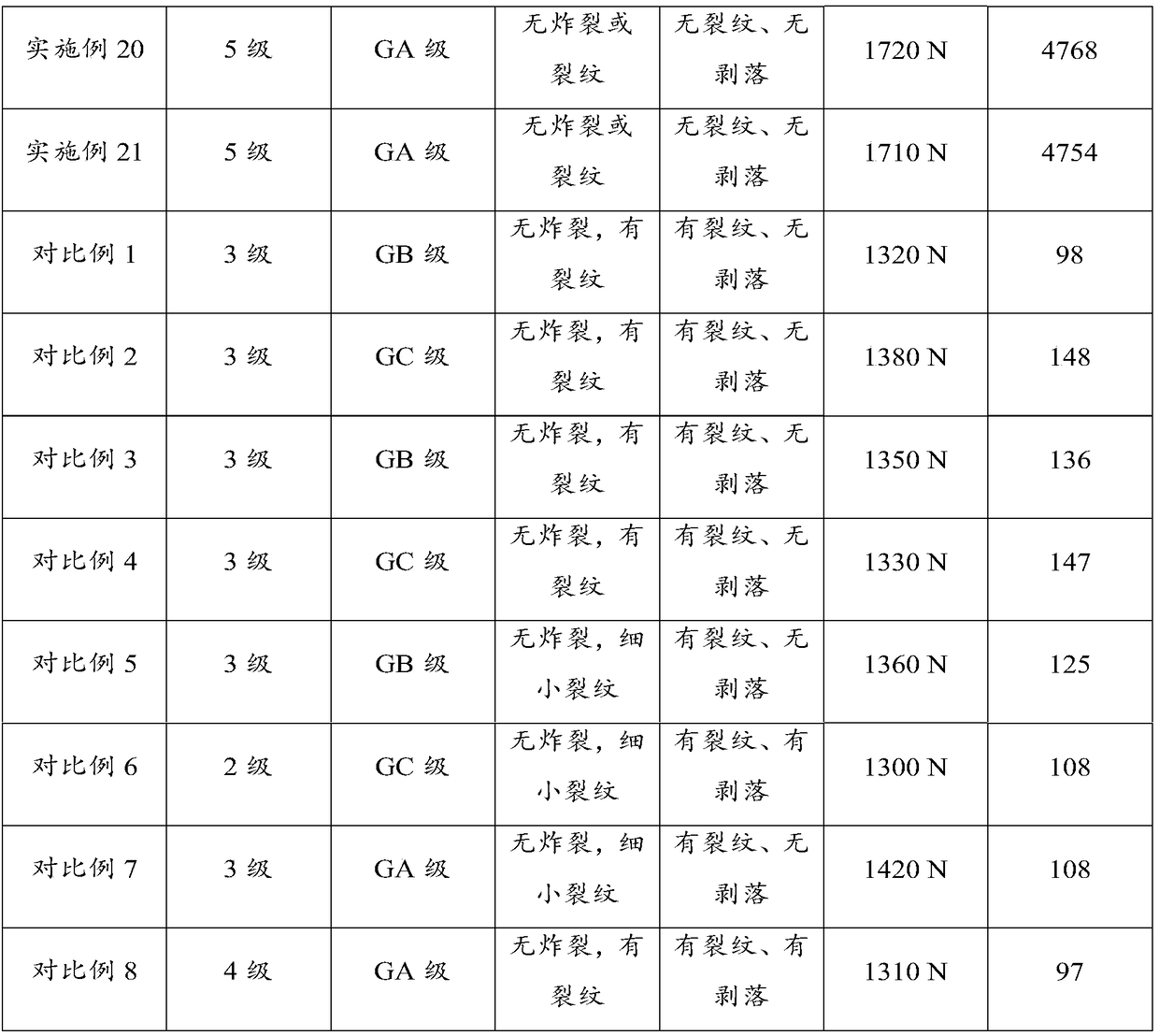

Examples

preparation example Construction

[0089] In a second aspect, in at least one embodiment, a method for preparing the above-mentioned self-cleaning ceramic tile is provided, comprising the following steps: (b) mixing the components of the cured film of the bottom layer of the formulation amount to obtain the bottom layer slurry → mixing the bottom layer Apply the slurry to the surface of the unglazed tile → dry → the bottom cured film; (c) mix the components of the formula amount of the surface cured film evenly to obtain the surface layer slurry → apply the surface layer slurry to the bottom cured film Surface→dry→surface cured film.

[0090] The above preparation method is scientific and simple, suitable for industrial production, and has low production cost. The prepared self-cleaning ceramic tile not only has good self-cleaning ability, but also has good chemical corrosion resistance, good weather resistance, good stability and low cost. It is suitable for building kitchens, bathrooms, and self-cleaning exte...

Embodiment 1

[0111] A self-cleaning ceramic tile, the ceramic tile is mainly composed of an unglazed tile and a bottom cured film and a surface cured film sequentially coated on the surface of the unglazed tile;

[0112] The bottom cured film is mainly composed of the following components by mass: 16 parts of epoxy acrylate resin, 18 parts of glycerol alkyd resin, 8 parts of 300 mesh quartz powder, 2 parts of 270 mesh α-alumina powder, hydroxy fluorosilicone oil 1.5 parts, 0.2 parts of polybutyl acrylate, 2 parts of chlorinated paraffin, 1.2 parts of emulsified silicone oil, 0.3 parts of dibutyl phthalate and 21 parts of propanol;

[0113] The surface cured film is mainly composed of the following components by mass: 2.0 parts of polyisobutylene, 0.4 parts of tetrabutyl titanate, 6 parts of zinc oxide, 1 part of sodium silicate nonahydrate, 35 parts of titanium dioxide, 35 parts of ethanol, 0.5 part of azobisisobutyronitrile, 1 part of sodium dodecylsulfonate, 4 parts of antimony-doped tin...

Embodiment 2

[0115] A self-cleaning ceramic tile, the ceramic tile is mainly composed of an unglazed tile and a bottom cured film and a surface cured film sequentially coated on the surface of the unglazed tile;

[0116] The bottom cured film is mainly composed of the following components in parts by mass: 26 parts of epoxy acrylate resin, 28 parts of glycerol alkyd resin, 18 parts of 325 mesh quartz powder, 12 parts of 300 mesh α-alumina powder, hydroxy fluorosilicone oil 4 parts, 2.3 parts of polybutyl acrylate, 7 parts of chlorinated paraffin, 2.1 parts of emulsified silicone oil, 2.3 parts of dibutyl phthalate and 31 parts of propanol;

[0117] The surface cured film is mainly composed of the following components by mass: 3.0 parts of polyisobutylene, 0.65 parts of tetrabutyl titanate, 10 parts of zinc oxide, 5 parts of polyacrylamide, 45 parts of titanium dioxide, 45 parts of ethanol, azo 1.5 parts of diisobutyronitrile, 3 parts of sodium dodecylsulfonate, 8 parts of antimony-doped ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com