Composite material of imitated glass reinforced plastic, its manufacture method and its application

A composite material and fiberglass technology, which is applied in the fields of furniture, plastic products, packaging materials, decorative materials, and building materials, can solve the problems of the weak point of hollow bricks, such as poor earthquake resistance, and achieve strong plasticity, long service life, and labor-saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

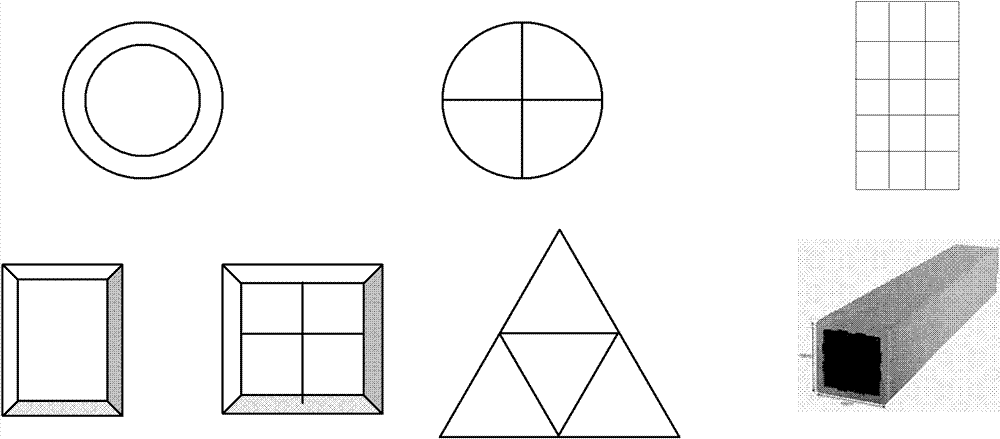

[0049] A method for manufacturing a composite material imitating glass fiber reinforced plastics and its application to light-weight walls, floor slabs, door panels, roofs, etc., comprising the following steps:

[0050] 1. Outer layer: active ground calcium carbonate powder (120-160 parts) → recycled plastic PET (60-90 parts) → glass fiber or basalt fiber (30-60 parts) → nano-carbon fiber powder (10-30 parts) →Nano anion powder (20-50 parts)→Nano titanium dioxide (20-50 parts)→Conductive mica powder (20-50 parts)→Silane coupling agent (10-30 parts)→Processing aid (30-60 parts) → Stabilizer (1-5 parts) → Stirring and drying → Start automatic electric control heating → Granulation → Special mold heating → Special equipment is extruded by melt blending (three-layer co-extrusion).

[0051] 2. Base layer: active light calcium carbonate powder (120-160 parts) → recycled plastic PVC (60-90 parts) → glass fiber (30-60 parts) → silane coupling agent (10-30 parts) → hair Foaming agent ...

Embodiment approach 2

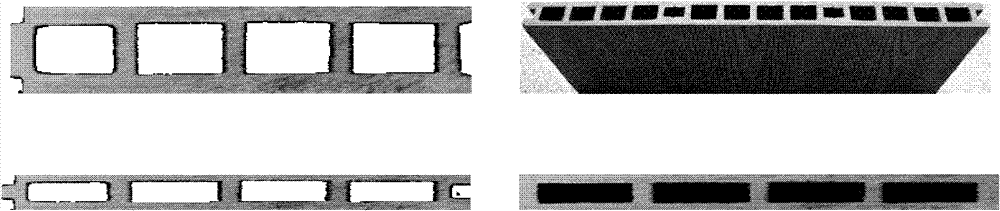

[0057] →A manufacturing method of imitating glass-steel composite material and its application to lightweight templates and hollow panels, comprising the following steps:

[0058] 1. Outer layer: active ground calcium carbonate powder (120-160 parts) → recycled plastic PET (60-90 parts) → PTFE (30-60 parts) → glass fiber or basalt fiber (30-60 parts) → Silane coupling agent (10-30 parts) → processing aid (30-60 parts) → stabilizer (1-5 parts) → stirring and drying → start automatic electric control heating → granulation → special mold heating → special equipment Melt blending (two-layer co-extrusion) extrusion molding.

[0059] 2. Base layer: active light calcium carbonate powder (120-160 parts) → recycled plastic PVC (60-90 parts) → glass fiber (30-60 parts) → silane coupling agent (10-30 parts) → hair Foaming agent (1-30 parts) → processing aid (30-60 parts) → stabilizer (1-5 parts) → stirring and drying → start automatic electric control heating → granulation → special mol...

Embodiment approach 3

[0064] A method for manufacturing imitation glass fiber reinforced plastic composite material and its application to various general-purpose plates, comprising the following steps:

[0065] 1. Outer layer: active ground calcium carbonate powder (120-160 parts) → recycled plastic PET (60-90 parts) → PTFE (30-60 parts) → glass fiber or basalt fiber (30-60 parts) → Nano-titanium dioxide (20-50 parts) → silane coupling agent (10-30 parts) → processing aid (30-60 parts) → stabilizer (1-5 parts) → stirring and drying → start automatic electric heating → manufacturing Granules → special mold heating → special equipment through melt blending (two-layer co-extrusion) extrusion molding.

[0066] 2. Base layer: active light calcium carbonate powder (120-160 parts) → recycled plastic PVC (60-90 parts) → glass fiber (30-60 parts) → silane coupling agent (10-30 parts) → hair Foaming agent (1-30 parts) → processing aid (30-60 parts) → stabilizer (1-5 parts) → stirring and drying → start aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com