One-component polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof, one-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor durability of hydrophobic effect, low glass transition temperature, easy precipitation, etc. Good color and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

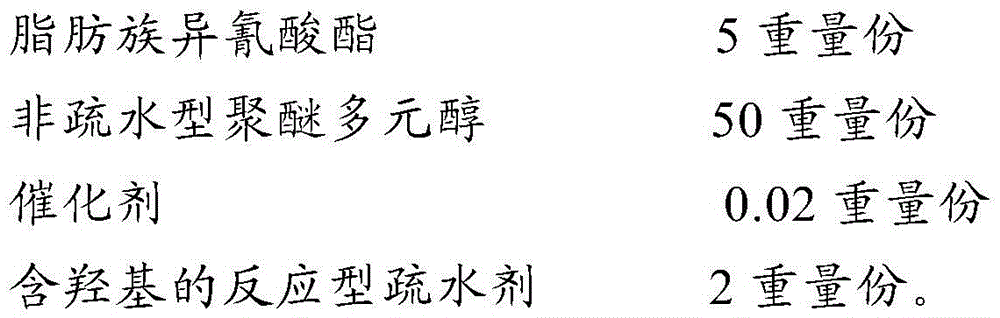

[0034] This embodiment provides a one-component polyurethane waterproof coating. The raw material formula for preparing the one-component polyurethane waterproof coating includes: aliphatic isocyanate, non-hydrophobic polyether polyol, catalyst, and reactive hydrophobic agent containing hydroxyl.

[0035] This embodiment provides a method for preparing a one-component polyurethane waterproof coating, and the following steps are carried out according to the above-mentioned raw material formula:

[0036] (1) Mix non-hydrophobic polyether polyol and reactive hydrophobic agent containing hydroxyl group, stir and heat up to 100°C, and dehydrate under vacuum -0.01MPa for 2.3 hours;

[0037] (2) Lower the temperature to 70°C, add aliphatic isocyanate, and react for 4.5 hours;

[0038] (3) Cool down to 35°C, add catalyst, stir for 1.8 hours, cool down to 38°C, fill with inert gas for protection, and discharge to obtain one-component polyurethane waterproof coating.

[0039] The hydro...

Embodiment 2

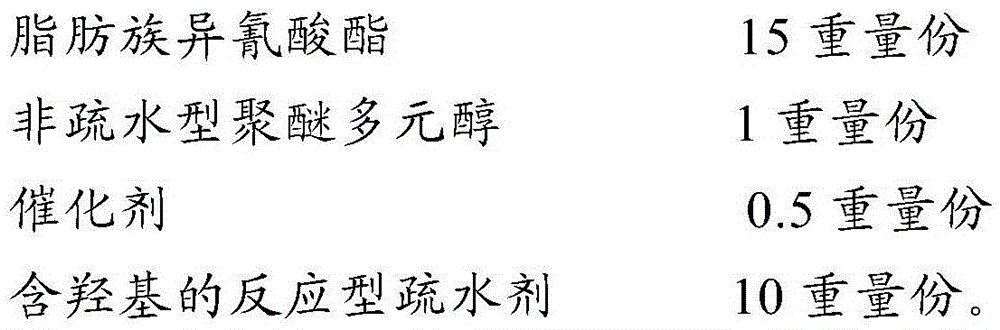

[0041] This embodiment provides a kind of one-component polyurethane waterproof coating, and the raw material formula for preparing this one-component polyurethane waterproof coating includes:

[0042]

[0043] The aliphatic isocyanate is hexamethylene diisocyanate and isophorone diisocyanate (weight ratio is 2:1), the non-hydrophobic polyether polyol is polyether glycol, and the latent curing agent is The imine type latent curing agent, the reactive hydrophobic agent containing hydroxyl group is triethoxysilanol.

[0044] This embodiment provides a method for preparing a one-component polyurethane waterproof coating, and the following steps are carried out according to the above-mentioned raw material formula:

[0045] (1) Mix non-hydrophobic polyether polyol and reactive hydrophobic agent containing hydroxyl group, stir and heat up to 120°C, and dehydrate under vacuum -0.01MPa for 3 hours;

[0046] (2) Lower the temperature to 60°C, add aliphatic isocyanate, and react fo...

Embodiment 3

[0050] This embodiment provides a kind of one-component polyurethane waterproof coating, and the raw material formula for preparing this one-component polyurethane waterproof coating includes:

[0051]

[0052] The aliphatic isocyanate is dicyclohexylmethane diisocyanate, the non-hydrophobic polyether polyol is polyether triol, the latent curing agent is an oxazolidine type latent curing agent, and the hydroxyl-containing reactive type The hydrophobic agent is triethoxysilanol and silicon-containing polyether polyol.

[0053] This embodiment provides a method for preparing a one-component polyurethane waterproof coating, and the following steps are carried out according to the above-mentioned raw material formula:

[0054] (1) Mix non-hydrophobic polyether polyol and reactive hydrophobic agent containing hydroxyl group, stir and heat up to 110°C, and dehydrate under vacuum -0.01MPa for 2 hours;

[0055] (2) Lower the temperature to 100°C, add aliphatic isocyanate, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com