Gluing and slitting integrated device for corrugated paper production

A corrugated paper and gluing technology, which is applied to the surface coating liquid device, drying gas arrangement, coating, etc., can solve the problems of easy falling off, improper placement, and poor adhesion, so as to avoid the inconvenience of adjustment and improve Adhesive pressure, the effect of improving the adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

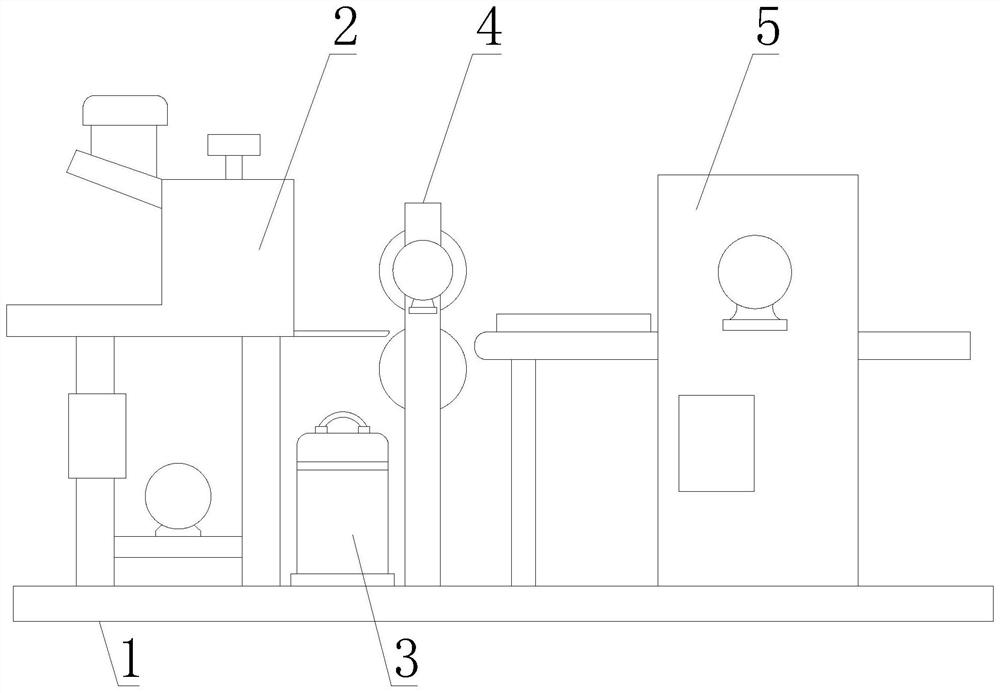

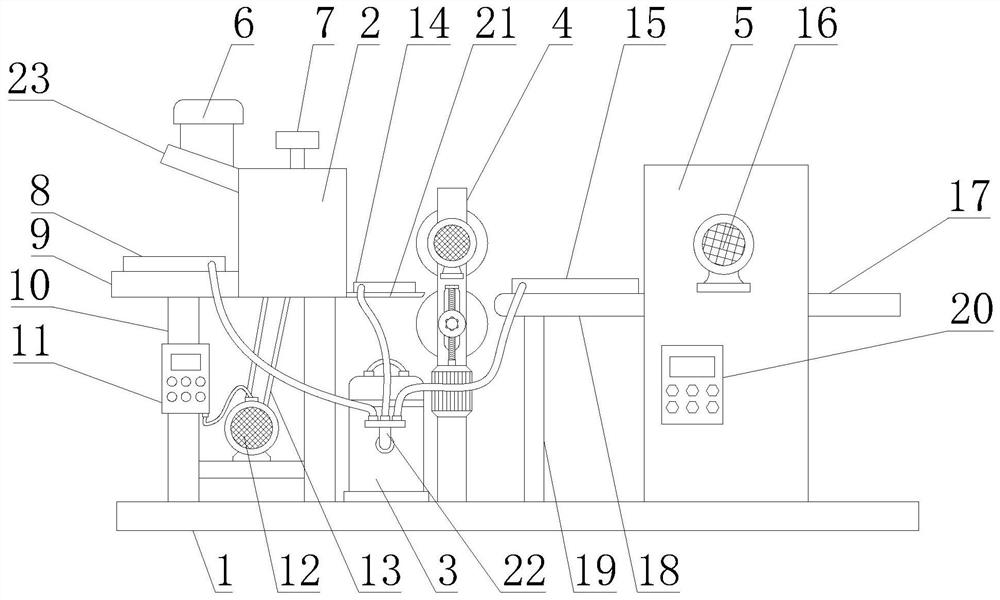

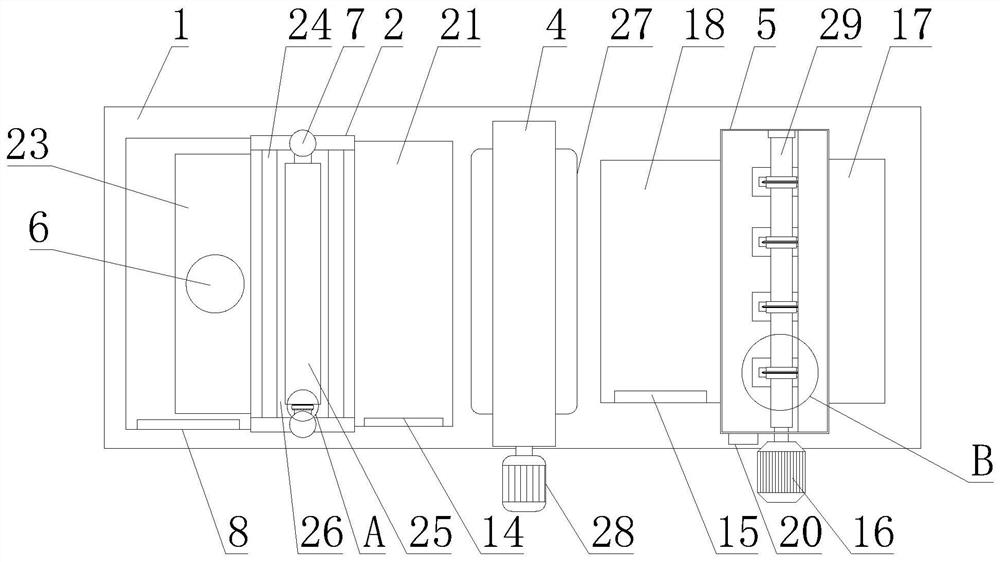

[0034] Such as Figure 1-Figure 8 As shown, the present invention provides a gluing and cutting integrated device for corrugated paper production, a base plate 1, a gluing frame 10 is fixedly installed on the left side of the top of the base plate 1, and a gluing machine is fixedly installed on the top of the gluing frame 10 2. The left side of the gluing machine 2 is fixedly installed with a gluing machine platform 9, the right side of the gluing machine 2 is fixedly installed with a gluing output plate 21, and the right side of the gluing frame 10 is provided with a dust removal box 3, the dust removal box The right side of 3 is provided with conveying roller frame 4, and the right side of conveying roller frame 4 is fixedly installed with slitting frame 19, and the top of slitting frame 19 is fixedly installed with splitter platform 18, and the right side of splitter platform 18 The side is provided with a splitter 5, the right side of the splitter 5 is provided with a spli...

Embodiment 2

[0039] Such as Figure 1-Figure 8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inner top of the dryer 6 is fixedly installed with a suspension seat, which is mainly used to fix the micro motor 31 through the suspension seat, and the bottom of the suspension seat is fixedly installed There is a micro motor 31, which is mainly used to dissipate the heat generated by the heating wire 34 through the micro motor 31 driving the fan blade 32. The bottom of the micro motor 31 is provided with a rotating shaft, and the fan blade 32 can be installed and driven by the rotating shaft. The outer wall of the rotating shaft A fan blade 32 is fixedly installed, a heater 30 is fixedly installed on the left side of the dryer 6, a heating wire 33 is fixedly connected to the right side of the heater 30, and one end of the heating wire 33 is fixedly connected to both ends of the heating wire 34, The bottom of the dryer 6 is fixedly equipped with ...

Embodiment 3

[0041] Such as Figure 1-Figure 8 Shown, on the basis of embodiment 1, embodiment 2, the present invention provides a kind of technical scheme: the top of dedusting box 3 is provided with box cover 37, by opening box cover 37 conveniently, cleaning internal dust, the inner side of box cover 37 The top is fixedly equipped with a dust collection bin 42, the inside top of the dust collection bin 42 is fixedly equipped with a vacuum cleaner 39, the right side of the dust collector 39 is fixedly connected with a dust suction pipe 40, and the bottom of the dust collection bin 42 is fixedly equipped with a filter screen 41, one end of the dust suction pipe 40 is fixedly connected above the filter screen 41, the bottom of the dust suction bin 42 is provided with a dust collection pipe, and the bottom of the dust collection pipe is provided with a sealing ring, which can seal the dust removal box 3 to prevent air leakage Cause dust removal efficiency to reduce, and the bottom of sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com