High-speed handling robot system for photovoltaic panels

A technology for handling robots and panels, which is applied in the direction of photovoltaic power generation, conveyors, conveyor objects, etc., can solve problems such as sticking, falling of the second photovoltaic panel, and slow handling, so as to avoid broken and hidden cracks and achieve high-speed The effect of handling and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

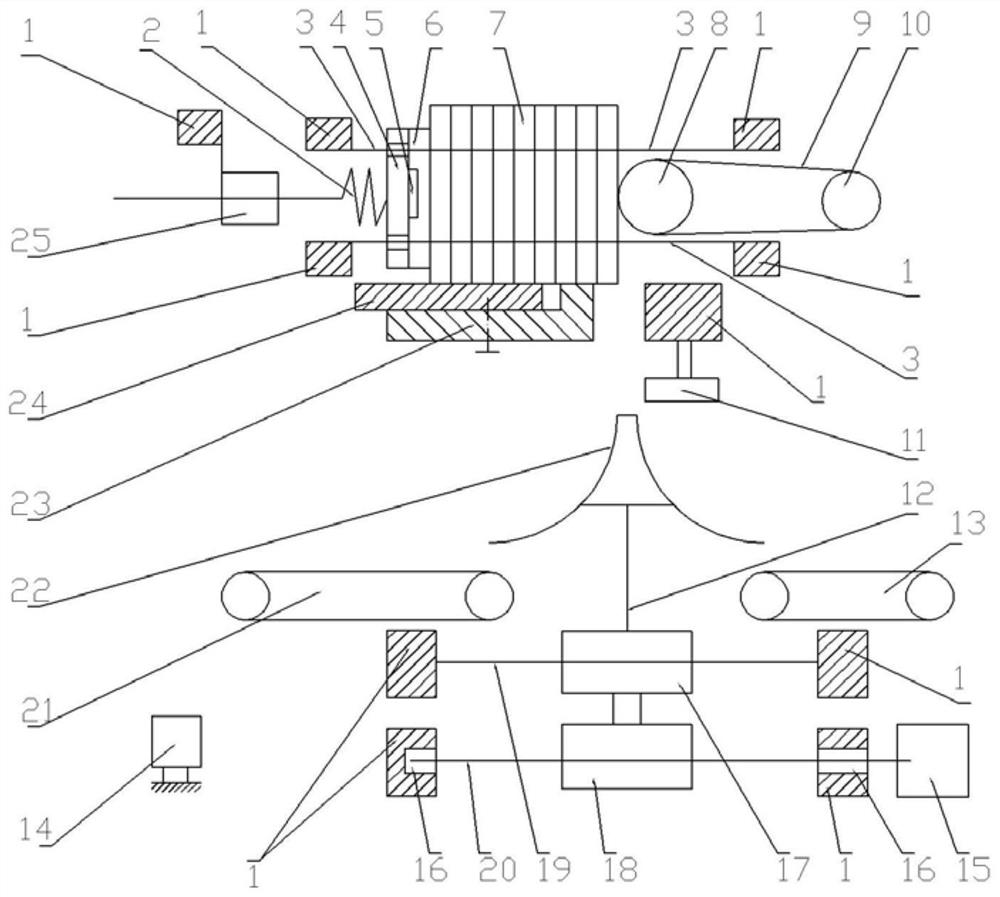

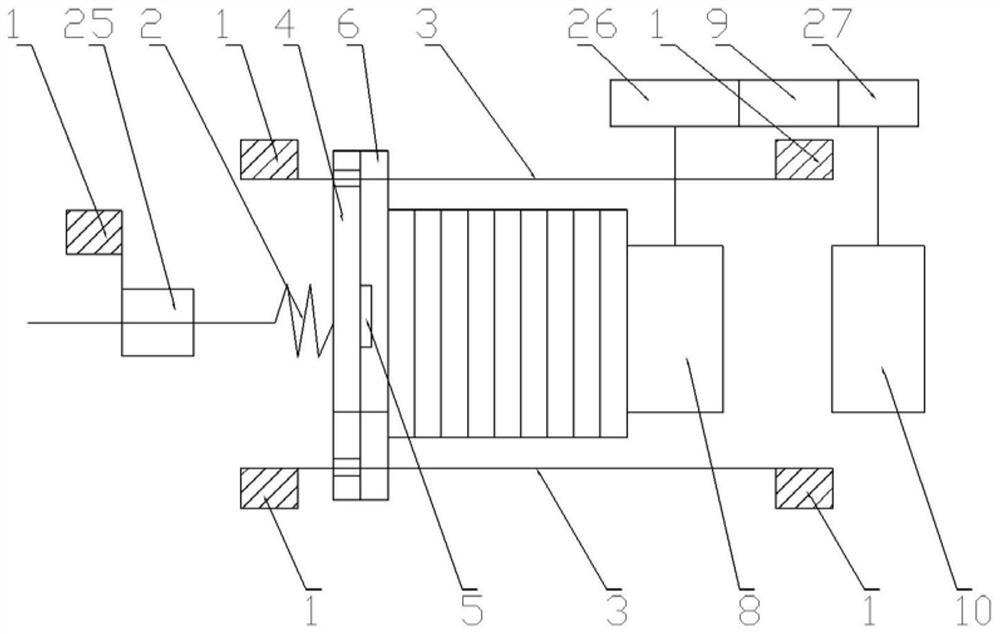

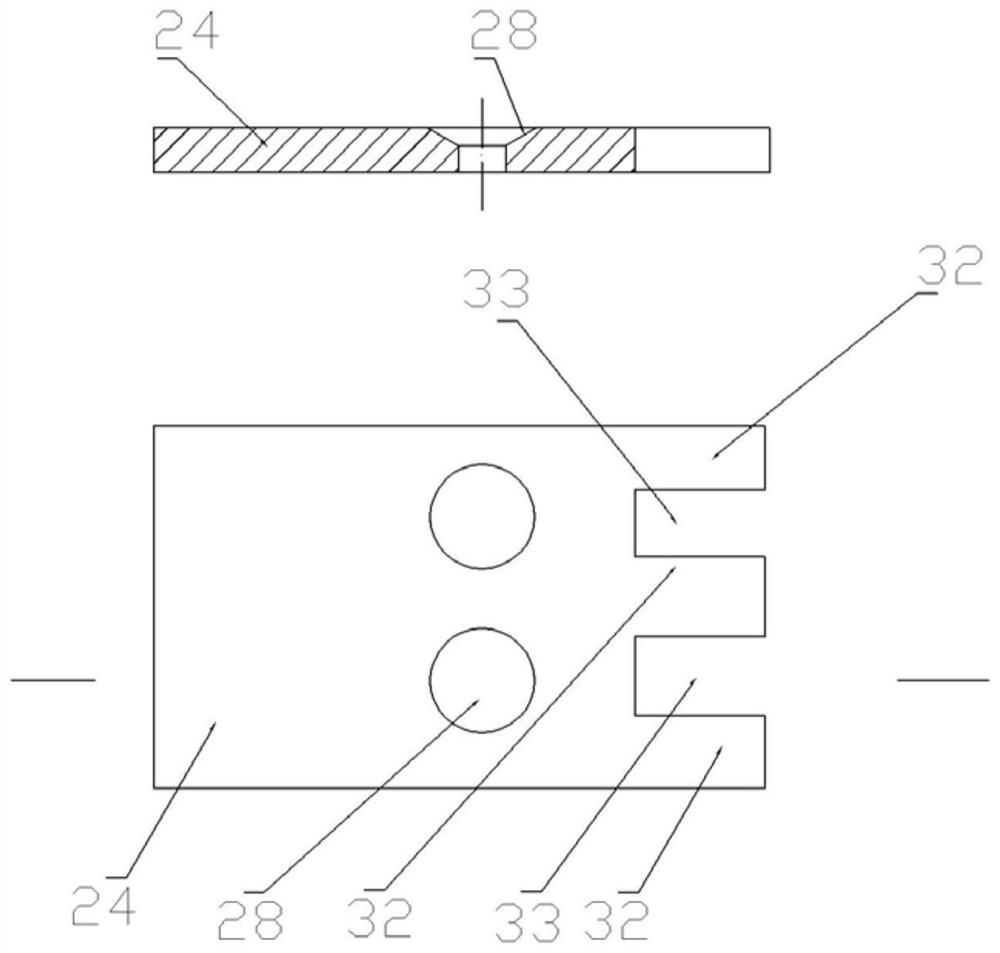

[0031] as above Figure 1 to Figure 5 As shown, a high-speed handling robot system for photovoltaic panels is prepared, wherein the preset height is set according to the thickness of photovoltaic panels 7 of different specifications, the edge of the “L”-shaped adjusting plate protruding teeth 35 is provided with chamfers, and the “herringbone”-shaped guide 22 Set as two 90° arcs, the tangent of the uppermost end of the guide rail of the "herringbone"-shaped guide 22 is in a vertical position, there are two "U"-shaped holes 29 and two countersunk holes 28 .

[0032] In the following, the handling of the photovoltaic panel 7 will be taken as an example.

[0033] The first step, manual batch feeding

[0034] Manually place the stack of photovoltaic panels 7 on the bottom plate 24 vertically, between the rubber pad 6 and the friction wheel 8 in the left and right directions, and between the front and rear rows of light bars 3 in the front and rear directions. Due to the elasticit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com