Plastic basin edge trimmer

A technology of trimming machine and plastic, applied in the field of automation equipment, can solve the problems of high production cost, burr, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

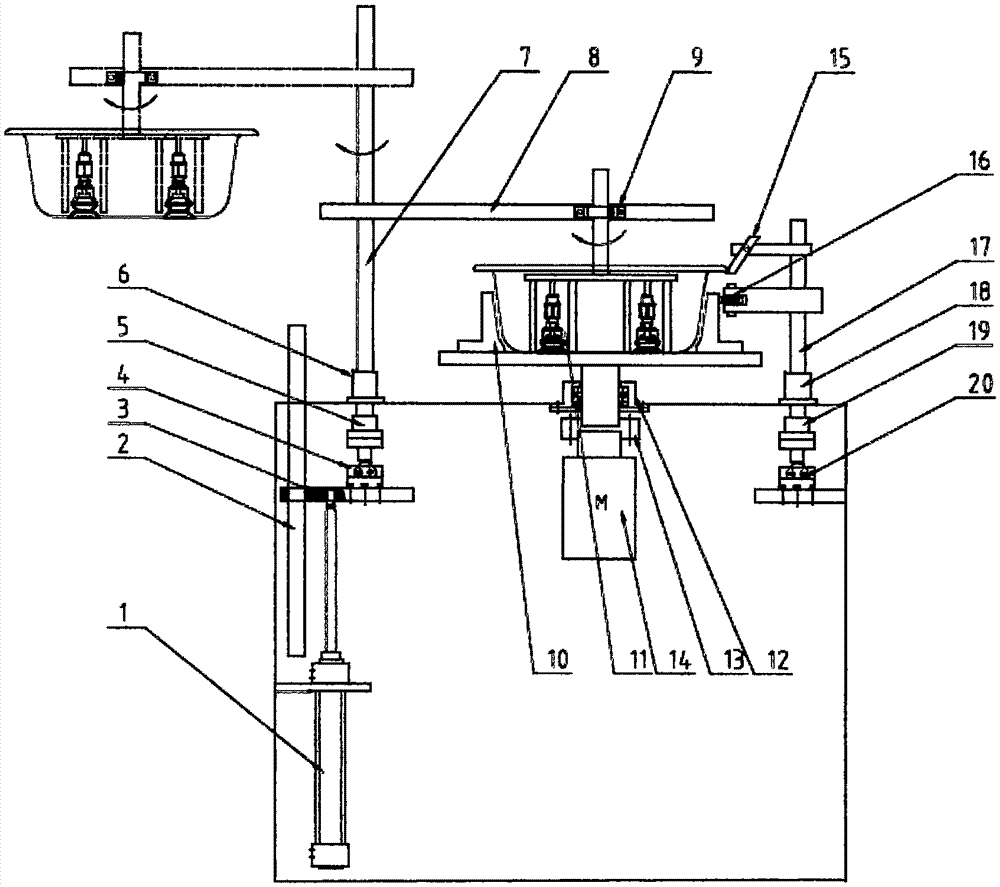

[0019] Below in conjunction with accompanying drawing 1, the implementation mode of the plastic basin trimming machine of the present invention will be further described in detail.

[0020] As shown in Fig. 1, the present invention provides a plastic basin edge trimmer, comprising a frame, a main arm cylinder 1, a positioning guide rod 2, a main arm connecting plate 3, a main arm corner cylinder 4, a main arm connecting block 5, Up and down main arm guide sleeve 6, up and down main arm 7, fetching cross arm 8, bearing 9, plastic basin positioning fixture and rotating disk 10, suction cup and pressing block 11, rotating disk bearing and fixing frame 12, connecting motor and Turntable transmission shaft 13, rotating motor 14, tool 15, conformal guide arm 16, tool driving rod 17, tool driving rod guide sleeve 18, tool driving rod and corner cylinder connector 19, tool corner cylinder 20.

[0021] The main arm cylinder 1 is vertically installed on the frame through the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com