Red phosphor for Eu-activated light emitting diode and preparation method thereof

A technology of red fluorescent powder and light-emitting diodes, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of harsh preparation conditions, high price, low color rendering index, etc., and achieve easy operation and industrial production, and the method is simple and easy , reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

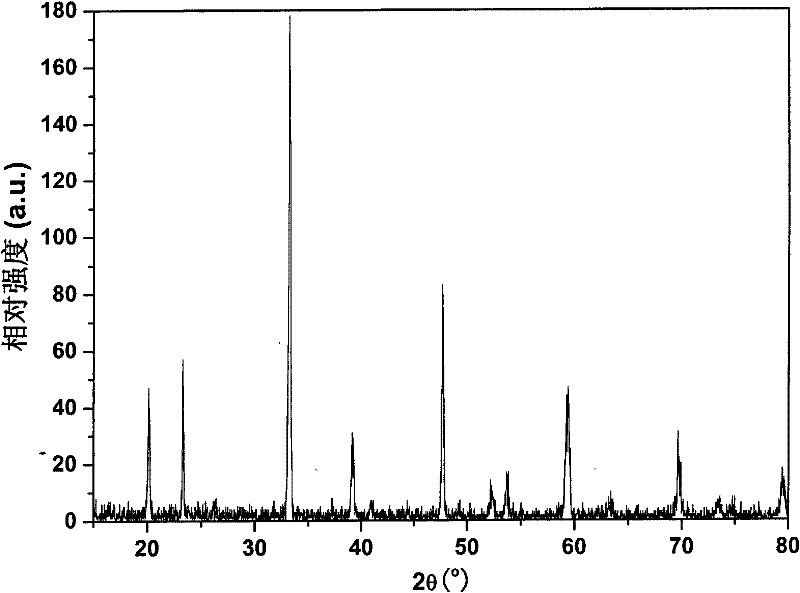

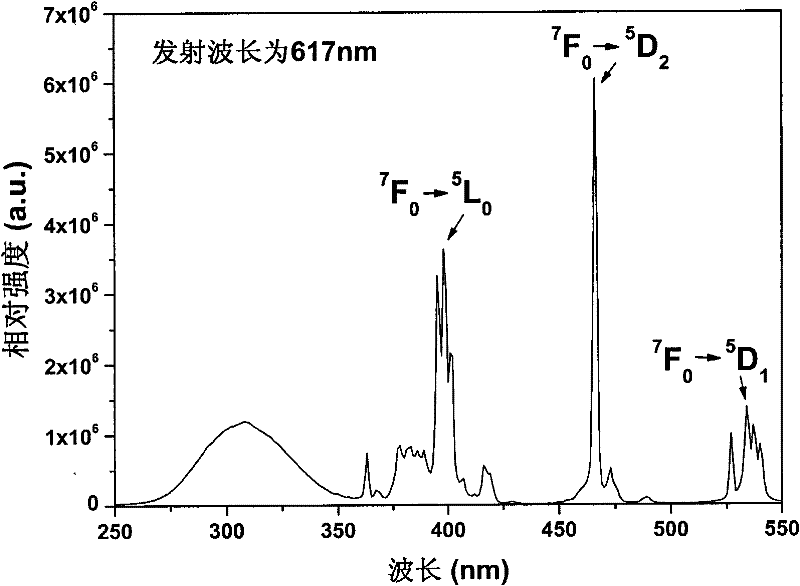

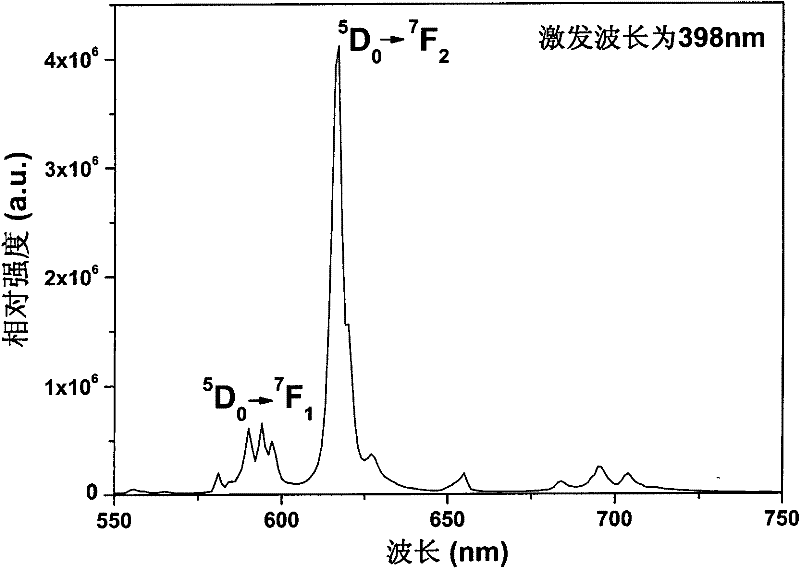

[0029] Weigh CaCO 3 (Analytical pure) 0.6301g, Al 2 o 3 (99.99%) 0.1672g, Nb 2 o 5 (99.99%) 0.4358g, Eu 2 o 3 (99.99%) 0.0462g, Li 2 CO 3 (99.99%) 0.02g, the above-mentioned raw materials are accurately weighed and mixed uniformly and then loaded into an alumina crucible and roasted in the air. The roasting temperature is 1400° C., and the holding time is 18 hours. After waiting for the temperature to drop to room temperature, the product obtained is taken out and Broken, the chemical composition obtained is (Eu 0.04 Ca 0.96 ) 2 AlNbO 6.04 of red phosphor. Its XRD pattern is shown in figure 1 , with Ca 2 AlNbO 6 The diffraction peaks of the XRD powder diffraction standard card (JCPDFNo.53-1283) completely match, indicating that the synthesized phosphor has no impurity phase, and the diffraction peak intensity is high and relatively sharp, indicating that the synthesized phosphor has good crystallinity. Its excitation spectrum see figure 2 , indicating that the...

Embodiment 2

[0031] Weigh CaCO 3 (Analytical pure) 0.6190g, Al 2 o 3 (99.99%) 0.1659g, Nb 2 o 5 (99.99%) 0.4326g, Eu 2 o 3 (99.99%) 0.0573g, Li 2 CO 3 (99.99%) 0.02g, the above-mentioned raw materials are accurately weighed and mixed uniformly and then loaded into an alumina crucible and roasted in the air. The roasting temperature is 1500 ° C, and the holding time is 18 hours. After waiting for the temperature to drop to room temperature, the product obtained is taken out and Broken, the chemical composition obtained is (Eu 0.05 Ca 0.95 ) 2 AlNbO 6.05 of red phosphor.

Embodiment 3

[0033] Weigh CaCO 3 (Analytical pure) 0.6528g, Al 2 o 3(99.99%) 0.1696g, Nb 2 o 5 (99.99%) 0.4423g, Eu 2 o 3 (99.99%) 0.0243g, Li 2 CO 3 (99.99%) 0.02g, the above-mentioned raw materials are accurately weighed and mixed uniformly and then loaded into an alumina crucible and roasted in the air. The roasting temperature is 1450° C., and the holding time is 18 hours. After waiting for the temperature to drop to room temperature, take out the product obtained and Broken, the chemical composition obtained is (Eu 0.02 Ca 0.98 ) 2 AlNbO 6.02 of red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com