Process for preparing low-temperature wafer-level mini-sized gas container

A wafer-level, gas-based technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as the difficulty of making chip-level atomic clocks, achieve reduced residual thermal stress, low processing costs, and prevent element loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

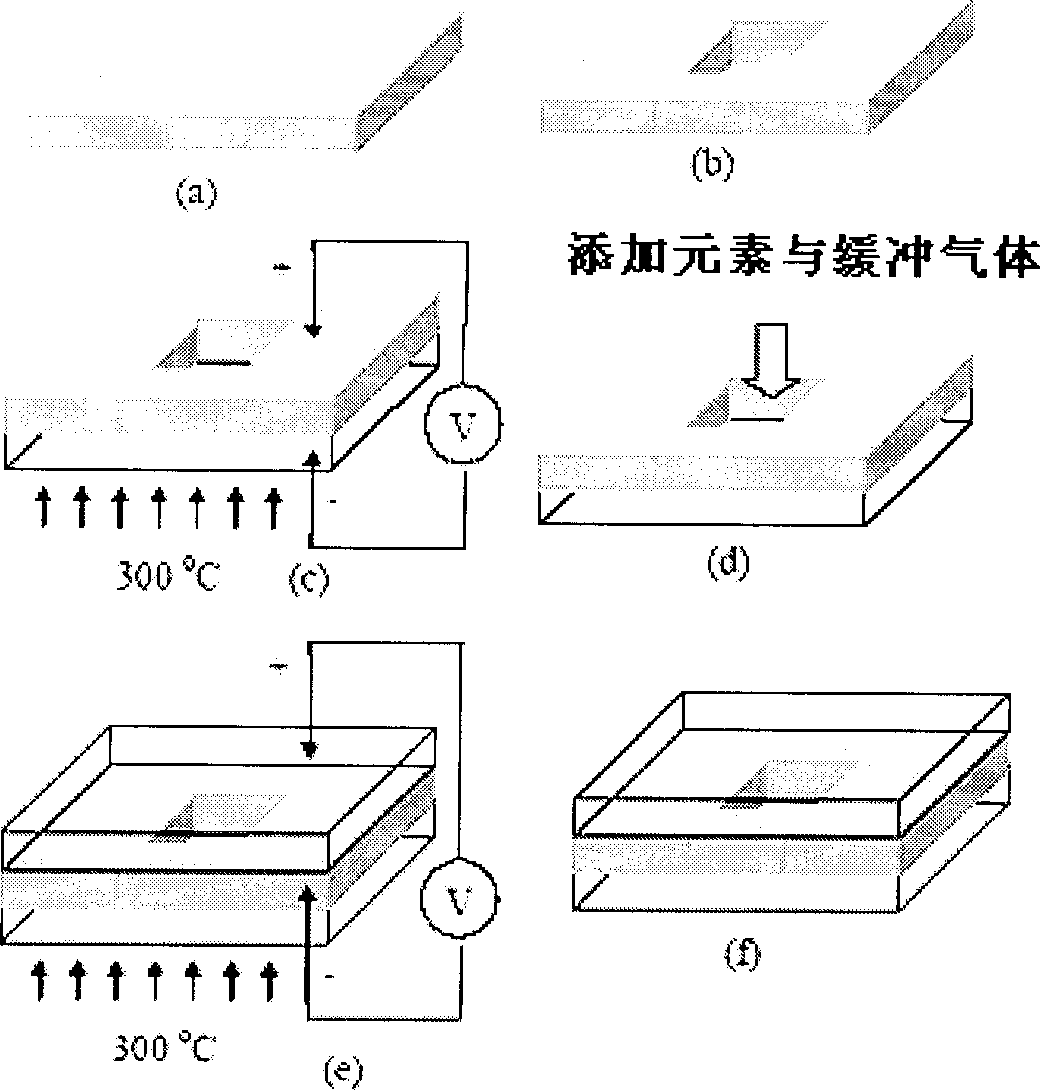

[0097] The chip-level atomic clock gas box is fabricated by wet etching silicon material, and the specific process is as follows Figure 4 , as shown in 5. The process steps are as follows:

[0098] (1) Select a semiconductor material such as silicon wafer 1 (ordinary N-type (100) double-polished silicon wafer, thickness 420±15 μm, resistivity 3-8 (Ω cm)), and oxidize to obtain the top mask silicon dioxide 2 and underlying silica 3, such as Figure 4 (b);

[0099] (2) Coat photoresist 4 (in this experiment, adopt the trade mark 1912 photoresist of Shipley Company), after curing, protect the top mask silicon dioxide 2, remove the bottom layer silicon dioxide 3 in BOE etching solution, as Figure 4 (d);

[0100] (3) After removing the cured photoresist, apply photoresist 4 again and pattern exposure and development to obtain the following: Figure 4 (e) structure;

[0101] (4) corrode top layer mask silicon dioxide 2 in BOE etching solution, open etching window for it, rem...

Embodiment 2

[0110] The chip-level atomic clock gas box is made by dry etching silicon material, and the specific process is as follows Figure 4 , as shown in 5. The process steps are as follows:

[0111] (1) Select a semiconductor material such as silicon wafer 1 (ordinary N-type (100) double-polished silicon wafer, thickness 420±15 μm, resistivity 3-8 (Ω cm)), apply photoresist 4 and pattern exposure, developed, obtained as Figure 4 (k) structure;

[0112] (2) Under the patterned mask of photoresist, the Figure 4 (k) The structure is etched by dry reactive particle to obtain as Figure 4 (1) structure;

[0113] (3) Carry out anodic bonding of silicon wafer 1 and Pyrex7740 glass 5 under normal standard process (temperature 380°C, voltage ±800V), such as Figure 4 (m) cavity structure;

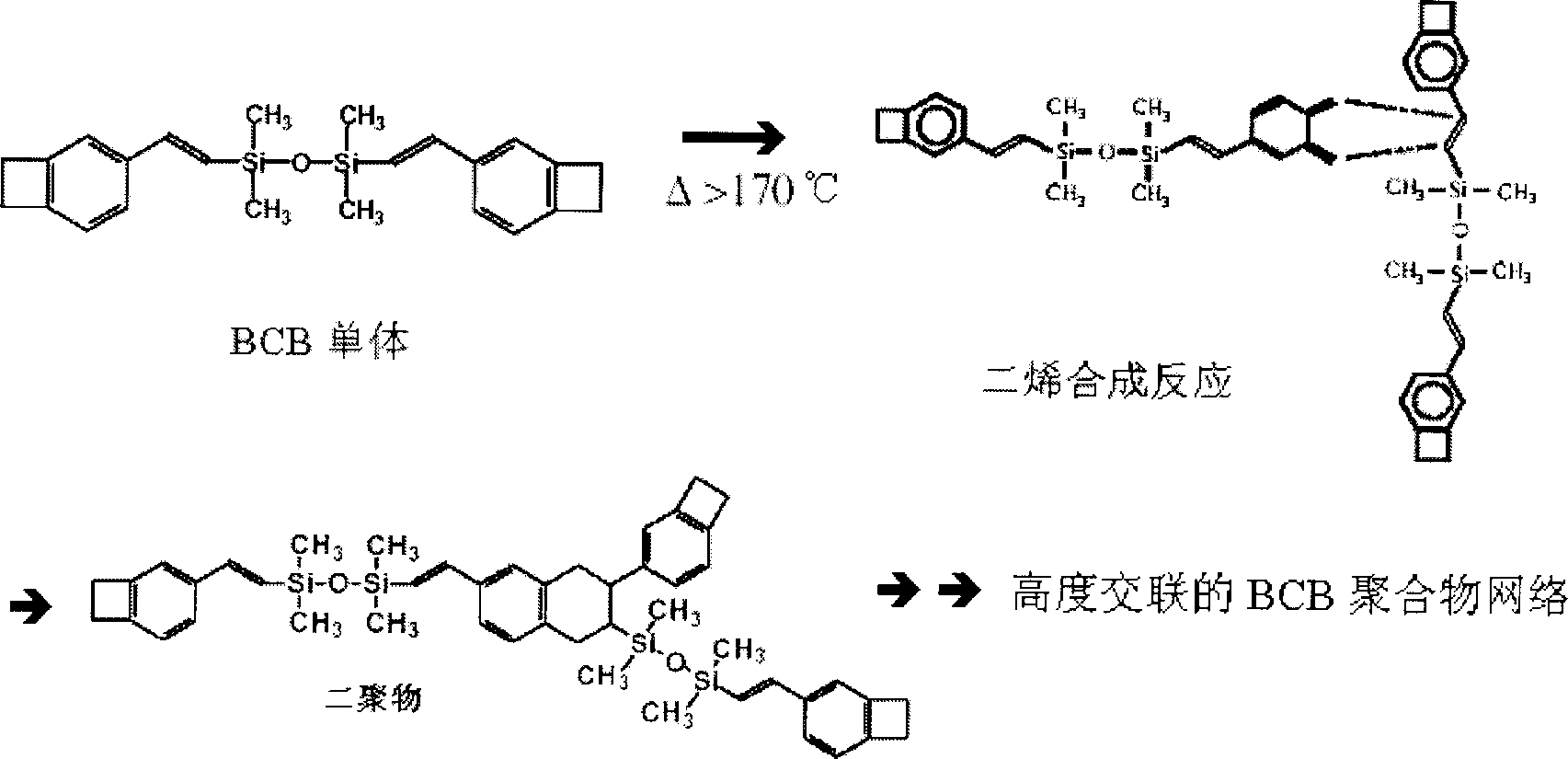

[0114] (4) In Pyrex (Pyrex) 7740 glass 5 or as Figure 4 (m) spin-coating or spraying BCB glue 6 on the top surface of the cavity structure, the concrete coating process parameters are with refe...

Embodiment 3

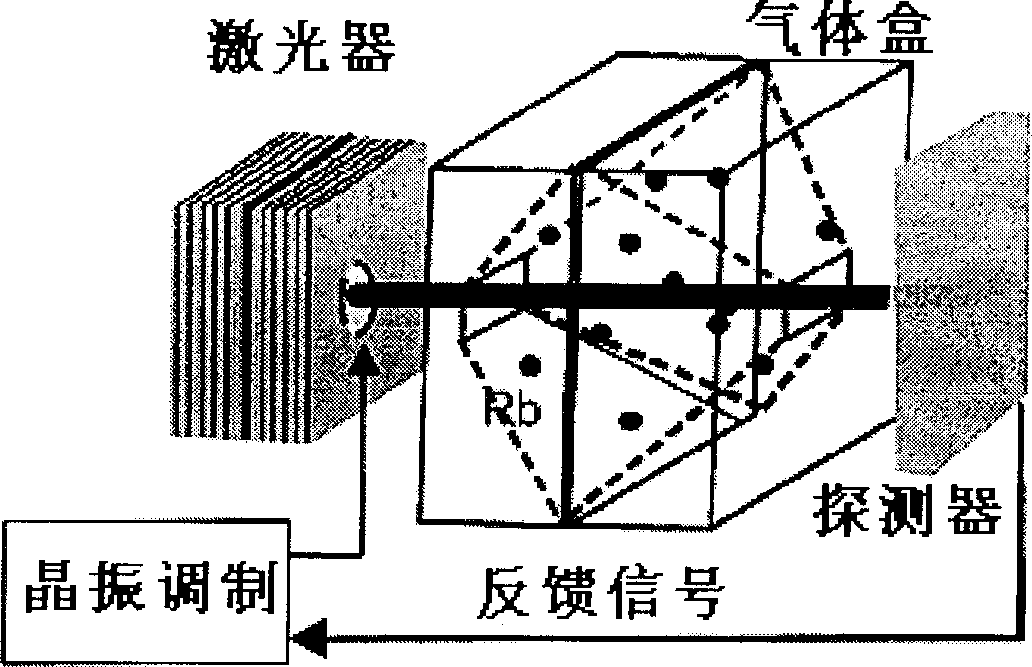

[0119] The high-precision magnetic field sensor gas box is made of wet-etched silicon material. The structure of the high-precision magnetic field sensor based on atomic energy level transition is as follows: Figure 12 As shown, it includes a semiconductor vertical cavity emitting laser 9 , an optical adjustment and collimation system 10 , an Rb element vapor cavity 11 , and a photodetector 12 . The manufacturing process steps of its core component—the Rb element steam chamber 11 are as follows:

[0120] (1) Select a semiconductor material such as a silicon wafer 1 (ordinary N-type (100) double-polished silicon wafer, thickness 420±15 μm, resistivity 3-8 (Ω cm)), and oxidize to obtain the top layer mask silicon dioxide 2 and underlying silica 3, such as Figure 4 (b);

[0121] (2) Coat photoresist 4 (in this experiment, adopt the trade mark 1912 photoresist of Shipley Company), after curing, protect the top mask silicon dioxide 2, remove the bottom layer silicon dioxide 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com