Wafer expander with high expansion uniformity

A crystal expansion machine and blue film technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of multi-machine resolution and positioning time, unequal distance, process occupation of measurement and sorting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

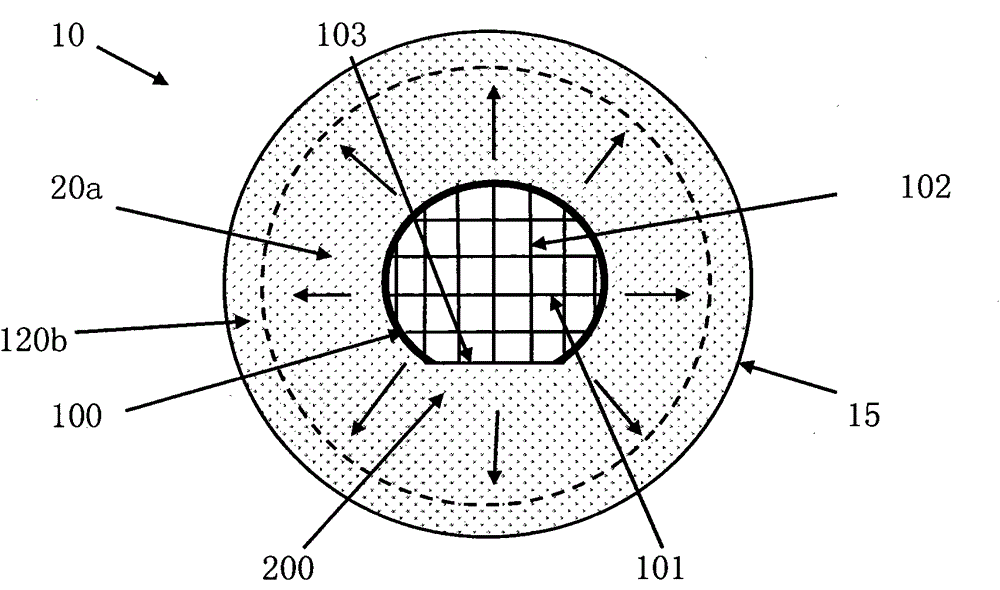

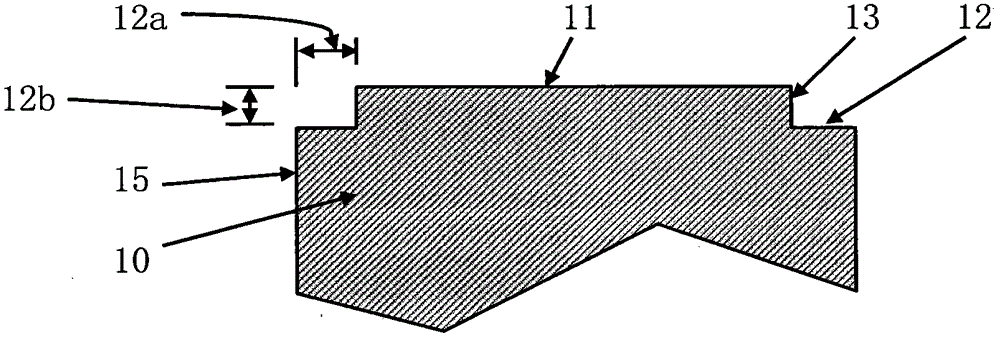

[0085] An implementation example: Figure 6a The display expander and Figure 1a The traditional crystal expander shown is similar: the difference is: Figure 6a The crystal expanding machine comprises the annex 60 ( Figure 6k and Figure 6n ). The blue membrane contact surface 63 on the top of the attachment 60 is on the same plane as the blue membrane contact surface 11 of the top membrane structure 10 . A through hole 62 a is formed in the center of the attachment 60 , and the diameter of the through hole 62 a matches the diameter of the top membrane structure 10 , so that the attachment 60 can be fixed on the top of the top membrane structure 10 .

[0086] An implementation example: Figure 6a The display expander and Figure 4a The expanders shown are similar: the differences are: (1) Figure 6a The periphery 15 of the crystal expansion ring supporting surface 12 can also be circular; (2) Figure 6a The expansion machine includes accessories 60 (such as Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com