Integrally gummed electronic circuit module for electronic detonator and process method thereof

An electronic circuit and electronic detonator technology, applied in the field of new detonating equipment, can solve the problems of irregular packaged products, low efficiency, inability to achieve static resistance, alternating current, direct current mechanical shock and other problems, and achieve high production efficiency and use. Convenience and the effect of improving the anti-high frequency oscillation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The following embodiments mainly take a group of 20 rounds with high production efficiency and easy operation and use as an example to describe in detail, and other numbers change accordingly. The innovation of the present invention is not limited to the specific values exemplified in the embodiments.

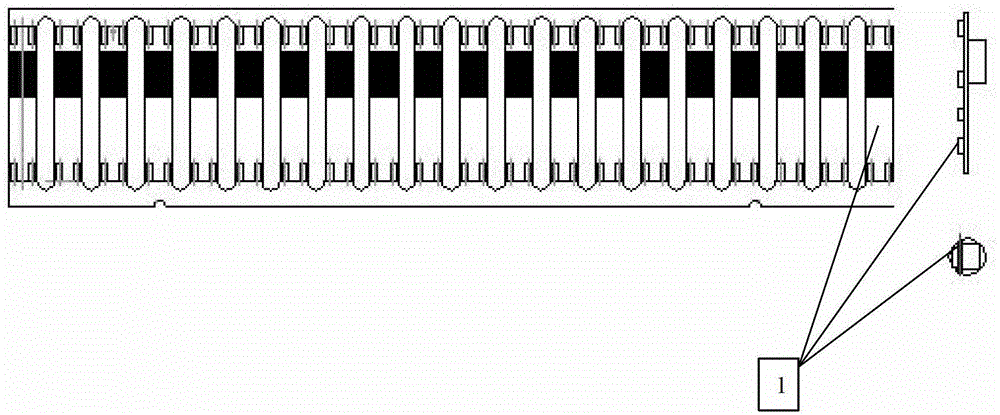

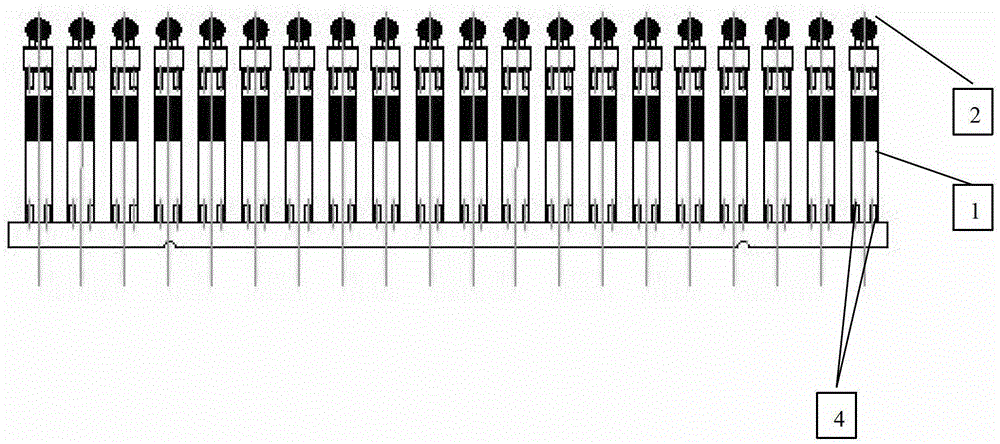

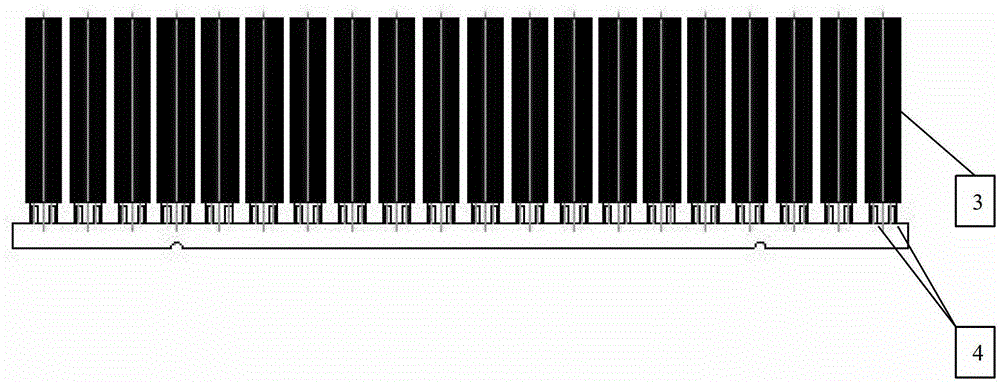

[0027] An electronic circuit module for an integral glue-sealed electronic detonator, which is composed of a dedicated electronic circuit module for electronic detonators (1), an electric ignition powder (2), a cured sealant (3), and a leg wire welding piece (4). Assembly and production of electronic detonators. The specific identification is shown in the description of the accompanying drawings.

[0028] figure 1 It is the arrangement mode of the electronic circuit module dedicated to the electronic detonator shown in the present invention, and the size of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com