Fluorescent glass sheet and preparation method thereof

A fluorescent glass and glass substrate technology, applied in the field of glass and glass preparation, can solve the problems of affecting the luminous efficiency of phosphor powder, loss of fluorescent characteristics of phosphor powder, large consumption of phosphor powder, etc., to improve the quality of LED packaging and meet the requirements of LED packaging Requirements, the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

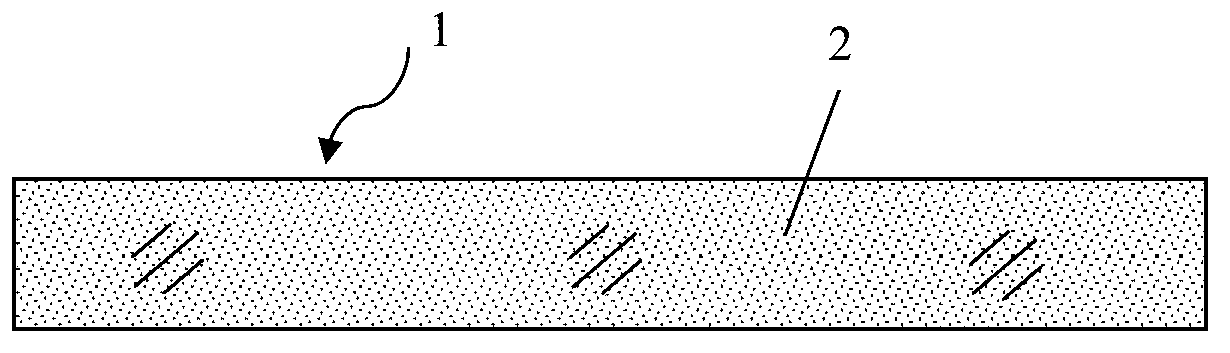

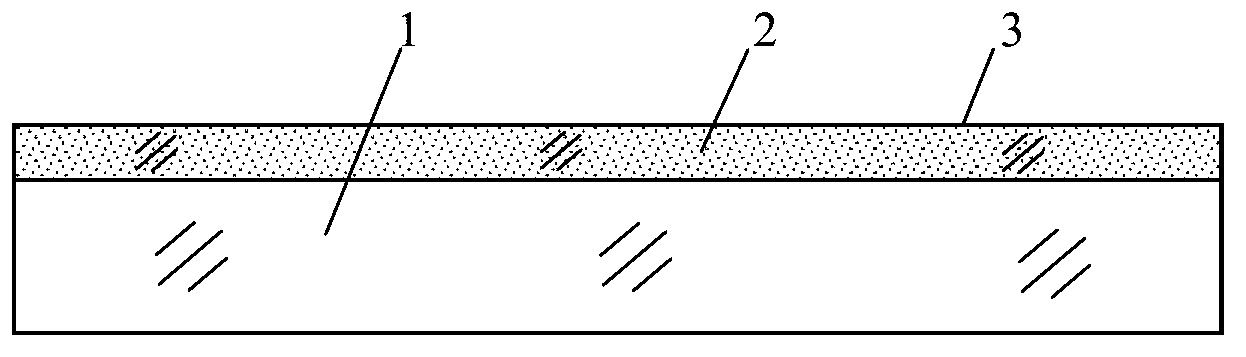

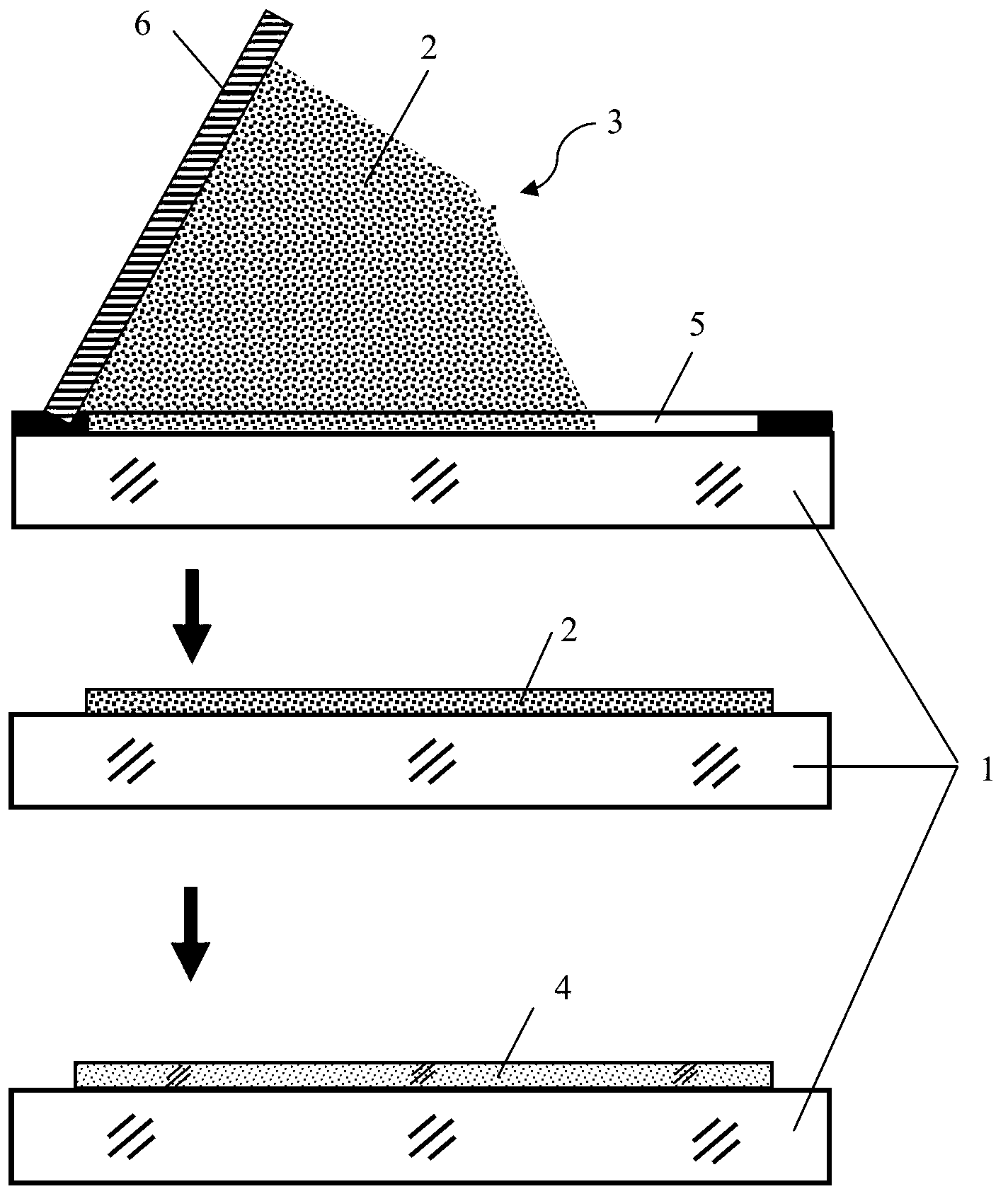

[0021] The preparation process of the fluorescent glass sheet includes the following steps:

[0022] 1) Select a glass substrate with a light transmittance> 80% and a refractive index of 1.4 to 1.6, and clean the surface of the glass substrate;

[0023] 2) Prepare phosphor-containing glass paste. The components of the glass paste include low-temperature glass powder, phosphor, reinforcing agent, binder, dispersant, etc. among them:

[0024] Low-temperature glass powder is borate glass, boroaluminate glass, etc., and its glass transition temperature is lower than 800℃;

[0025] The phosphor can be a single-color phosphor, or a multi-color phosphor or a mixture of multiple phosphors, and the content is 5%-50% of the weight of the glass powder;

[0026] The reinforcing agent is nano-zirconia, nano-alumina or nano-silica powder, and the content is 1%-5% of the weight of the glass powder;

[0027] The binder is terpineol, polyvinyl alcohol, carboxymethyl cellulose, etc., and the blending amo...

Embodiment 1

[0036] 1) Select a borosilicate glass sheet with a thickness of 2mm (model Pyrex 7740, glass transition temperature 821°C, refractive index 1.48, and light transmittance greater than 85%), ultrasonically clean with acetone solution, and dry for use;

[0037] 2) Weigh 60 grams of terpineol, add 1 gram of cellulose and 3 grams of nano zirconia powder, stir them into a mixed solution at 70°C, and then add 100 grams of low-temperature glass powder (the main component is PbO-B). 2 O 3 , The glass transition temperature is 650℃, the refractive index is 1.45) and 50 grams of commercially available Y 3 Al 5 O 12 :Ce 3+ Yellow phosphor (YAG), mixed and stirred in a ball mill for 60 minutes to prepare a homogeneous glass slurry;

[0038] 3) Using the spin coating process, a layer of glass paste with a thickness of 50um is uniformly coated on the surface of the glass substrate;

[0039] 4) Place the coated glass substrate in a high-temperature furnace, raise the temperature from room temperature...

Embodiment 2

[0042] 1) Choose a borosilicate glass sheet with a thickness of 3mm (glass transition temperature of 640°C, refractive index of 1.40, and light transmittance greater than 80%), ultrasonically clean with acetone solution, and dry for use;

[0043] 2) Weigh 80 grams of polyvinyl alcohol, add 3 grams of fish oil and 5 grams of nano-silica powder, stir to form a solution at 70 ℃ ultrasonically, and then add 100 grams of low-temperature glass powder (the main component is B 2 O 3 +Al 2 O 3 +Na 2 O, glass transition temperature of 450℃, refractive index of 1.40) and 5 grams of commercially available Y 3 Al 5 O 12 :Ce 3+ Yellow phosphor (YAG), mixed and stirred in a ball mill for 60 minutes to prepare a homogeneous glass slurry;

[0044] 3) Using a screen printing process to uniformly coat a layer of glass paste with a thickness of 500um on the surface of the glass substrate;

[0045] 4) Put the coated glass substrate in a high-temperature furnace, raise the temperature from room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com