Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

A low-temperature glass solder and packaging method technology, which is applied in the direction of microstructure devices, optical waveguide coupling, and processing microstructure devices, can solve the problems of large thermal mismatch, poor packaging reliability, and large limitations, and achieve flatness The effect of low precision requirements, reduced packaging cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A low-temperature glass solder bonding packaging method based on wafer-level glass microcavities, comprising the following steps:

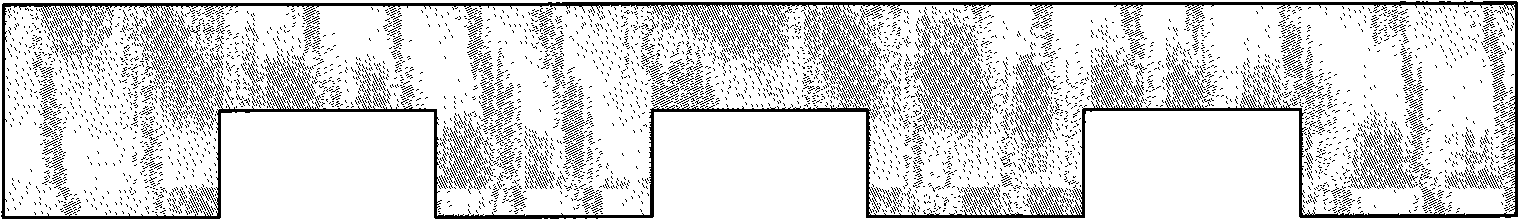

[0027] The first step is to use the screen printing process. The screen printing technology can use precision screen printing technology to coat the low-temperature glass solder on the package contact part of the Pyrex7740 glass substrate with a microcavity structure, and then apply the low-temperature glass solder Pre-baking, the pre-baking temperature is 350 ℃ ~ 450 ℃, usually slightly higher than the glass temperature of low temperature glass solder. The low-temperature glass solder is solidified and attached to the above-mentioned Pyrex7740 glass substrate with a microcavity structure. The low-temperature glass solder used here has a glass transition temperature of 330-500°C, such as 360°C, 375°C, 400°C, 430°C, At 470°C, the coefficient of thermal expansion is (20~50)×10 -7 / K glass solder (corresponding to the thermal expansion coeffi...

Embodiment 2

[0032]A low-temperature glass solder bonding packaging method based on a wafer-level glass microcavity, the steps of the packaging method are the same as in Example 1, but the glass microcavity is prepared by the following method:

[0033] In this embodiment, the preparation method of the microcavity structure on the Pyrex7740 glass substrate is as follows: the first step is to use silicon micromachining technology to manufacture a glass microcavity pattern structure on a double-sided polished silicon wafer; The wafer and the Pyrex7740 glass wafer of the same size are bonded under a pressure of less than 1Pa, so that the glass microcavity pattern structure is sealed into a vacuum cavity. The third step is to heat the above-mentioned bonded wafer under an atmospheric pressure to 810°C-890°C, such as 830°C, 850°C, 870°C, keep warm for 3-5 minutes, the time can be selected as 4 minutes, the pressure difference between the inside and outside of the cavity makes the softened glass f...

Embodiment 3

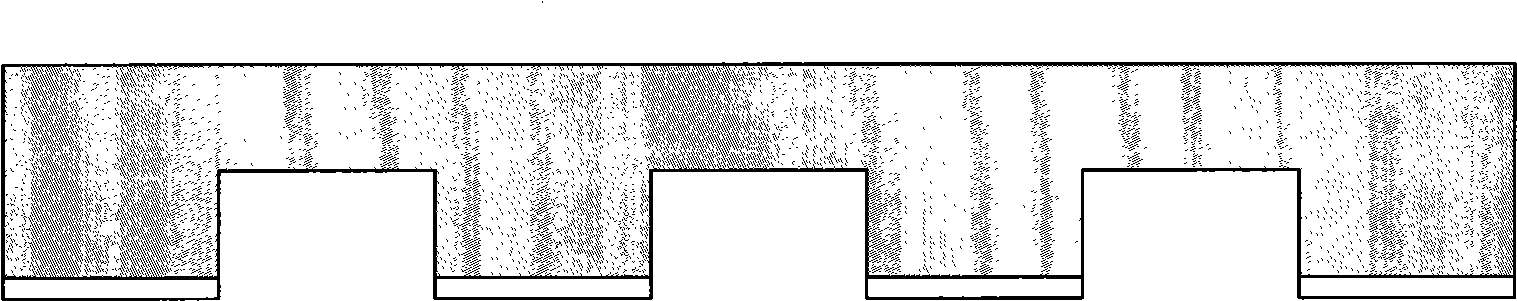

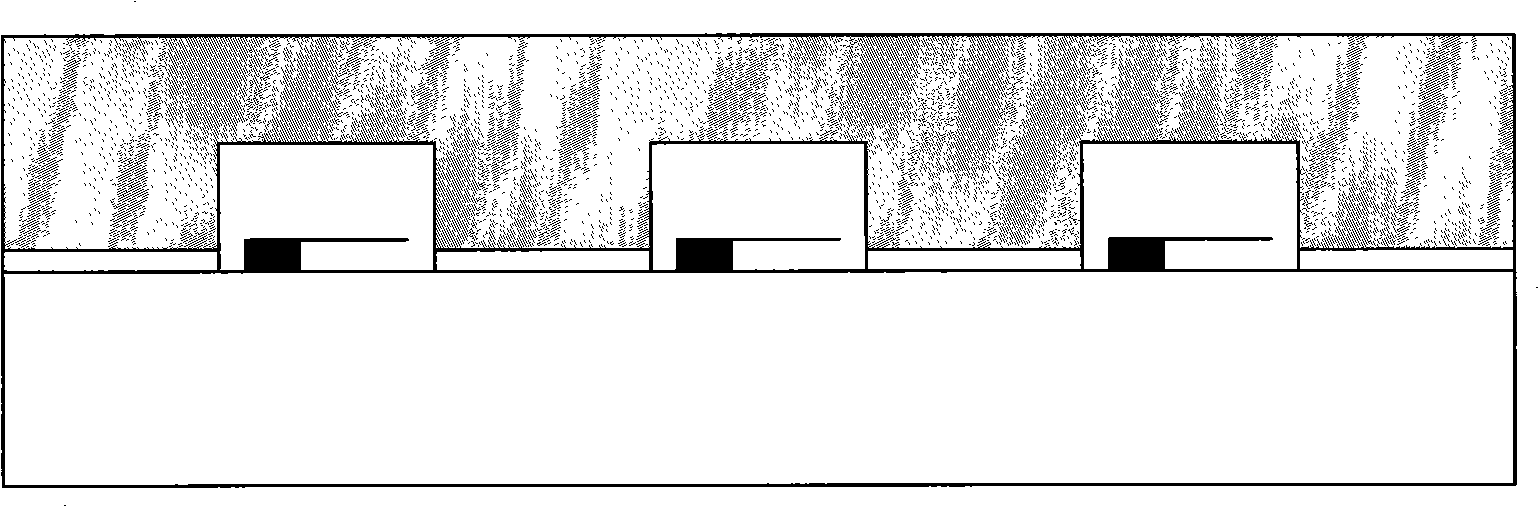

[0035] A method for low-temperature glass solder bonding packaging of a novel wafer-level glass microcavity, comprising the following steps:

[0036] In the first step, the low-temperature glass solder is coated on the bonding contact part of the Pyrex7740 glass substrate with a microcavity structure by using a screen printing process.

[0037] In the second step, pre-baking is carried out near the glass transition temperature Tg of the low-temperature glass solder to volatilize the organic solvent in the solder and at the same time make the solder adhere tightly to the glass substrate.

[0038] The third step is to align the Pyrex7740 glass packaging wafer coated and cured with low-temperature glass solder with the silicon substrate containing CMOS circuits or MEMS devices, so that the microcavity structure is facing the packaged part on the substrate.

[0039] The fourth step is to complete the alignment of the two bonded sheets, which are clamped by the fixture to apply pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com