Current regulation diode chip and manufacturing method thereof

A technology of current regulation and diodes, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of small anode area, short circuit, and inability to achieve low-cost packaging, and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached figure 2 to attach Figure 9 Embodiments of the present invention are further described in detail.

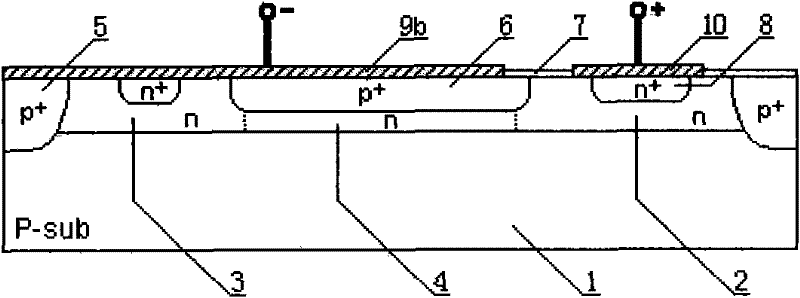

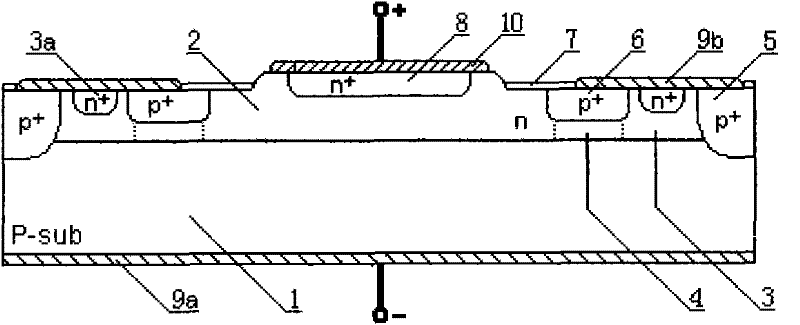

[0024] The present invention is a current regulating diode chip, which includes a substrate layer 1 and an epitaxial layer 1a covering it, and selects an applicable special-shaped epitaxial wafer according to the parameter requirements of the CRD and the height of the mesa. In this embodiment, the epitaxial layer 1a It is N-type, and the substrate layer 1 is highly doped P-type.

[0025] A drain region 2 is formed on the epitaxial layer 1a, and the surface of the drain region 2 is further provided with a first ohmic contact diffusion layer 8 and a first metal layer 10 covering the first ohmic contact diffusion layer 8 .

[0026] The drain region 2 is in the shape of a mesa, and its height is greater than 2 microns. The mesa shape is etched on the epitaxial layer by the method of silicon homogeneous etching or anisotropic etching. The function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com