Resin composition for base material of photovoltaic backboard and preparation method of photovoltaic backboard

A technology of resin composition and photovoltaic backplane, applied in the field of solar photovoltaic backplane, can solve the problems of inability to meet the transparent conditions, increase the load-bearing capacity of buildings, low strength and brittleness, etc., so as to maintain power generation efficiency and low load-bearing capacity of buildings. , Good water vapor barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

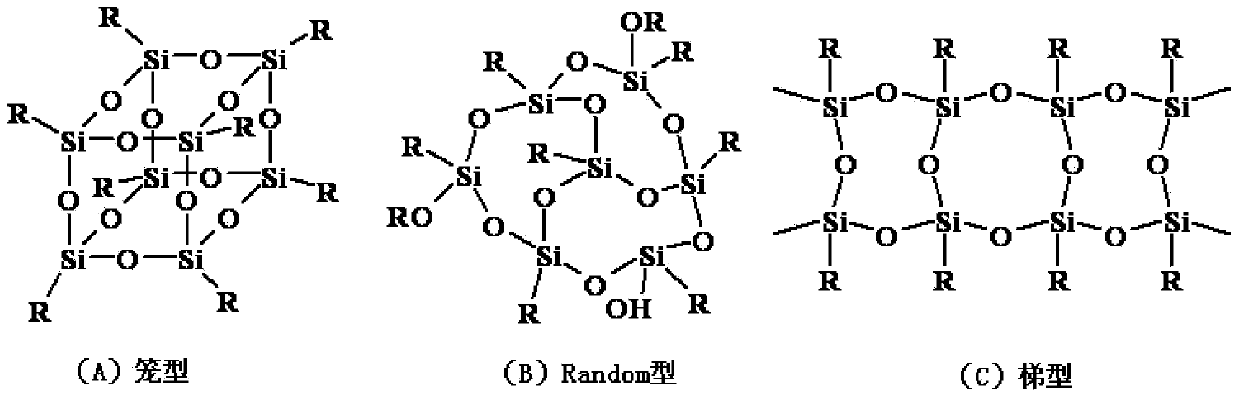

Method used

Image

Examples

Embodiment 1

[0023] A resin composition for a matrix material of a photovoltaic backplane, comprising the following components in parts by weight: 40 parts of polysilsesquioxane (Arakawa Chemical Industry Co., Ltd., trade name: Composelan SQ101), bisphenol A type 60 parts of epoxy resin (Hexion, trade name: EPIKOTE Resin1001), 5 parts of curing agent 4,4-diaminodiphenylsulfone (4,4-DDS), 1-nitrile ethyl-2-ethyl-4-methyl 0.1 part of imidazole (2E4MZ-CN);

[0024] The method for preparing a photovoltaic backboard with the above resin composition comprises the steps of:

[0025] (1) Weigh the components according to the formula, and add them into organic solvents such as ethylene glycol dimethyl ether, toluene or butanone to prepare a resin composition with a solid content of 40%;

[0026] (2) Put the resin composition in the glue tank, soak the 1080 glass fiber cloth into the glue tank, soak the resin composition, send it to the oven for drying, the drying temperature is 80-160°C, dry the s...

Embodiment 2

[0030] A resin composition for a matrix material of a photovoltaic backplane, comprising the following components in parts by weight: 45 parts of polysilsesquioxane (Arakawa Chemical Industry Co., Ltd., trade name: Composelan SQ102-1), bisphenol 35 parts of A-type epoxy resin (Dalian Qihua Chemical Co., Ltd., trade name: DYD-128), 20 parts of bisphenol F-type epoxy resin (Dainippon Ink Chemical Industry Co., Ltd., trade name: Epiclon830), curing agent 3 , 6 parts of 3-diaminodiphenylsulfone (3,3-DDS), 0.2 parts of 2-ethyl-4-methylimidazole (2E4MZ);

[0031] The method for preparing a photovoltaic backboard with the above resin composition comprises the steps of:

[0032] (1) Weigh the components according to the formula, and add them into organic solvents such as ethylene glycol dimethyl ether, toluene or butanone to prepare a resin composition with a solid content of 40%;

[0033] (2) Put the resin composition in the glue tank, soak 106 glass fiber cloth into the glue tank, ...

Embodiment 3

[0037] A resin composition for a matrix material of a photovoltaic backplane, comprising the following components in parts by weight: 50 parts of polysilsesquioxane (Arakawa Chemical Industry Co., Ltd., trade name: Composelan SQ105), bisphenol A type 30 parts of epoxy resin (Dalian Qihua Chemical Co., Ltd., trade name: DYD-128), 20 parts of biphenyl epoxy resin (Nippon Kayaku Co., Ltd., trade name: NC-3000), curing agent 3,3- 4 parts of diaminodiphenylsulfone (3,3-DDS), 0.2 parts of 1-nitrile ethyl-2-ethyl-4-methylimidazole (2E4MZ-CN);

[0038] The method for preparing a photovoltaic backboard with the above resin composition comprises the steps of:

[0039] (1) Weigh the components according to the formula, and add them into organic solvents such as ethylene glycol dimethyl ether, toluene or butanone to prepare a resin composition with a solid content of 40%;

[0040] (2) Put the resin composition in the glue tank, soak the 2116 glass fiber cloth into the glue tank, soak the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com