Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Good light aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meteorologic balloon and production method thereof

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Illumination aging resisting polycarbonate/styryl resin composition and preparing method thereof

ActiveCN101210105AImprove anti-separation performanceGood light aging resistanceMolecular sievePolycarbonate

The invention discloses a polycarbonate / styryl resin composition which has light fastness and aging resistance and a preparation method thereof. The components and mixture ratio (weight proportion) of the composition are that: 50 percent-80 percent of polycarbonate, 10 percent-50 percent of styryl resin, 0.1-5 percent of molecular sieve, 0.1-1.0 percent of antioxidant 168, 0.1-1.0 percent of antioxidant 245, 0.1-2.0 percent of ultraviolet absorber, 0.1-2.0 percent of free radical quencher, etc. The resin composition prepared by the technical proposal of the invention can not only improve the anti-precipitation efficiency of light stabilizer in a composite material system to lead the prepared polycarbonate / styryl resin composition has better light fastness and aging resistance performance, but also has the advantage that all the physical mechanical performances and thermodynamic property of the material are basically not affected; furthermore, the method presented for improving the light fastness and aging resistance of polycarbonate / styryl resin composition has simple preparation technique and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

Polypropylene composite material with excellent illumination aging resisting performance and preparing method thereof

InactiveCN101210088AGood light aging resistanceImprove anti-separation performanceMolecular sievePolypropylene composites

The invention discloses a polypropylene composite material that has excellent light and aging resistant performance and a preparation method thereof. The polypropylene composite material that has excellent light and aging resistant performance consists of raw materials comprising 55 to 95wt percent of polypropylene, 0 to 40wt percent of inorganic filler, 0 to 20wt percent of toughener POE, 0.1 to 5wt percent of molecular sieve activator powder, 0.1 to 1wt percent of main chemical inhibitor, 0.1 to 1wt percent of secondary chemical inhibitor, 0.1 to 2wt percent of light stabilizer agent and 0 to 5.0wt percent of other additives. By adding powder molecular sieve into basic formulation of the polypropylene composite material, the dispersibility of the light stabilizer agent in the polypropylene composite material is effectively improved, thus improving the light and aging resistant performance of the polypropylene composite material.

Owner:SHANGHAI PRET COMPOSITES

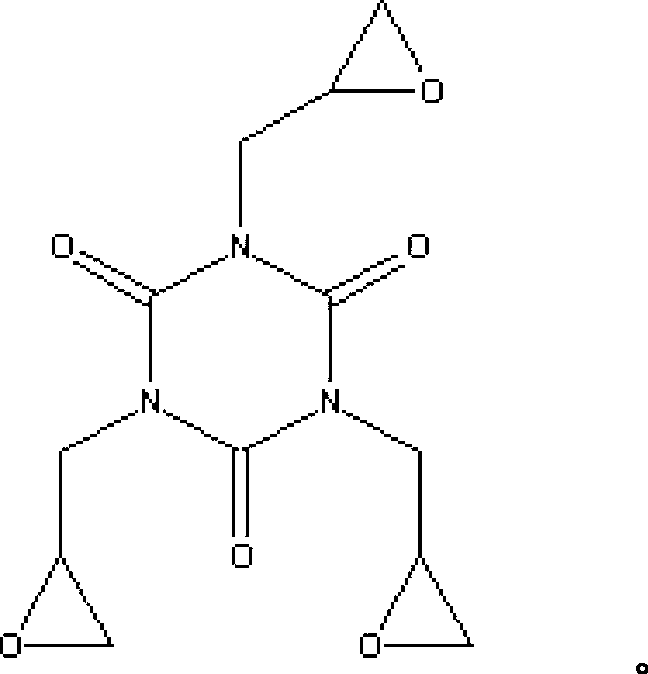

Photosensitive solder resist composite, application thereof and printed circuit board (PCB) containing same

ActiveCN102944977AImprove heat resistanceHigh hardnessPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationResistEpoxy

The invention relates to a photosensitive solder resist composite. The photosensitive solder resist composite comprises (A) 100 parts by weight of alkali-soluble photosensitive resin with a triazine ring structure in molecule and the following components in parts by weight based on the 100 parts by weight of alkali-soluble photosensitive resin: (B) 5 to 70 parts of epoxy resin free of aromatic rings in molecule, (C) 1 to 30 parts of photoinitiator containing at least one type of acylphosphine oxide photoinitiators, (D) 30 to 200 parts of titanium dioxide, and (E) 3 to 100 parts of organic solvent and / or 50 parts or less of photopolymerizable monomer as diluent. The photosensitive solder resist composite provided by the invention has excellent thermal resistance, hardness and photoaging resistance. In addition, the invention also relates to the application of the photosensitive solder resist composite in a PCB, and the PCB containing the solder resist composite.

Owner:惠州市容大感光科技有限公司

Super thermal-insulation heat-preservation coating containing nanometer LaB6 powder and preparation method of coating

InactiveCN104629582AHigh transparencyReduce aging speedEpoxy resin coatingsThermal insulationUltraviolet

The invention discloses a super thermal-insulation heat-preservation coating containing nanometer LaB6 powder. The coating is prepared from the following raw materials in parts by weight: 34-38 parts of ethyl orthosilicate, a proper amount of ethanol, a proper amount of deionized water, 3-3.5 parts of trimethylchlorosilane, 0.6-0.8 part of sodium di(2-ethyl-hexyl)sulfosuccinate, 0.08-0.12 part of a silane coupling agent kh-550, 1-1.5 parts of nanometer LaB6 powder, 70-75 parts of an E-12 epoxy resin, 9-12 parts of ethylene glycol diglycidyl ether and 7-7.5 parts of triethanolamine. The nanometer LaB6 powder is combined with silica aerogel, so that the aerogel has the function of filtering the ultraviolet and near-infrared rays, the transparency of the coating is improved, and the aging speed of the aerogel is retarded. The coating disclosed by the invention is good in thermal insulation performance and high in light aging resistance and can be used for places with strong illumination.

Owner:WUHU BAOYI AMUSEMENT EQUIP

UV-LED curing modified acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN110396370AImprove cohesionGood adhesionOrganic non-macromolecular adhesiveTemperature resistanceHigh heat

The invention relates to the technical field of pressure-sensitive adhesives, in particular to a UV-LED curing modified acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive comprises the following components in percentage by mass: 20%-60% of acrylate monomer diluent, 1%-4% of photoinitiator and 36%-79% of modified acrylate pressure-sensitive prepolymer, wherein the modified acrylate pressure-sensitive prepolymer is prepared by polymerizing various acrylate monomers terminated by hydrogenated rosin glyceride, hydrogenated rosin glyceride tackifying resin is introduced into a molecular chain of the modified acrylate pressure-sensitive prepolymer to obtain the acrylate pressure-sensitive adhesive with a self-tackifying effect, and the initialadhesion and peel strength of the acrylate pressure-sensitive adhesive are obviously improved; the pressure-sensitive adhesive prepared from the prepolymer has good light aging resistance and high temperature resistance, can be used for preparing an optical pressure-sensitive adhesive with the light transmittance of more than 90%, and satisfies the use requirements of electronic products on the optical pressure-sensitive adhesive. No water or organic solvent participates in the whole production process of the pressure-sensitive adhesive, and the purposes of low energy consumption, safety and environmental protection are achieved.

Owner:JINAN NORTH TAIHE NEW MATERIAL

Light aging resistant ABS (acrylonitrile butadiene styrene) plastic used for inside decorations of automobile and preparation method thereof

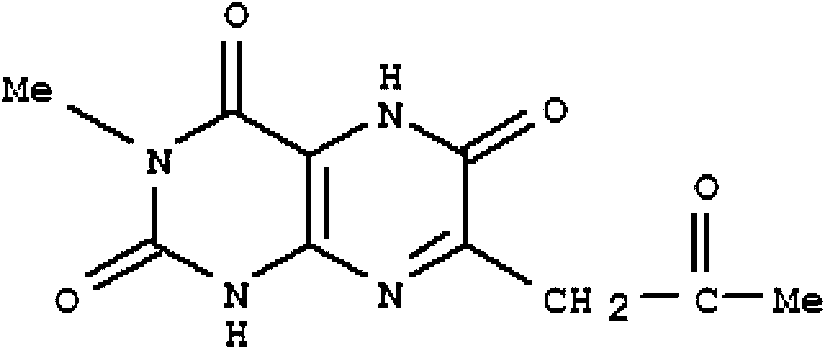

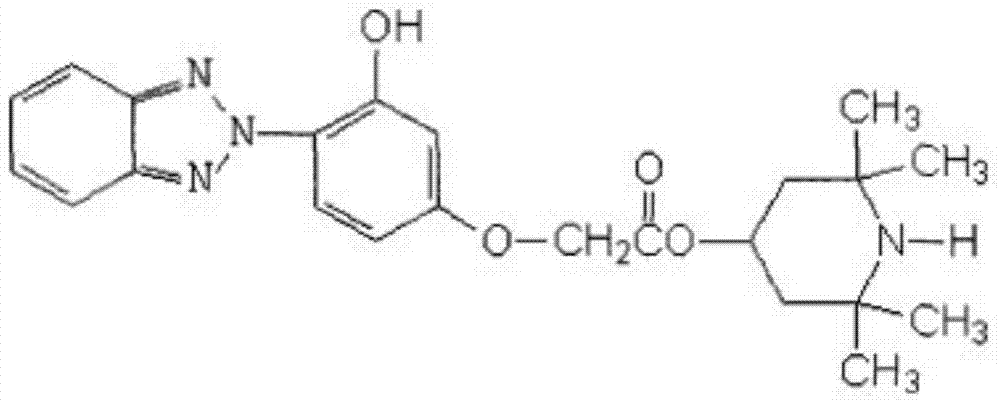

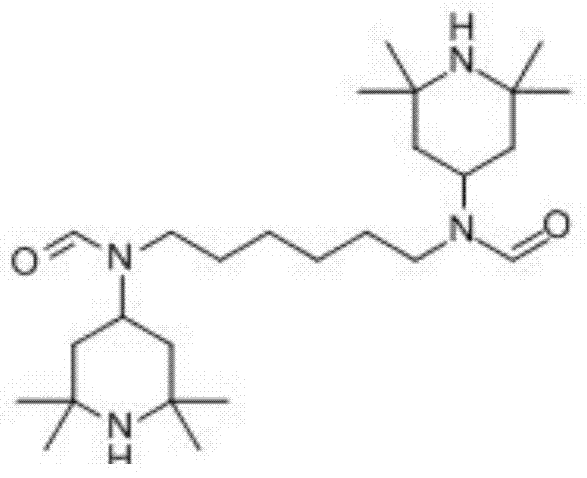

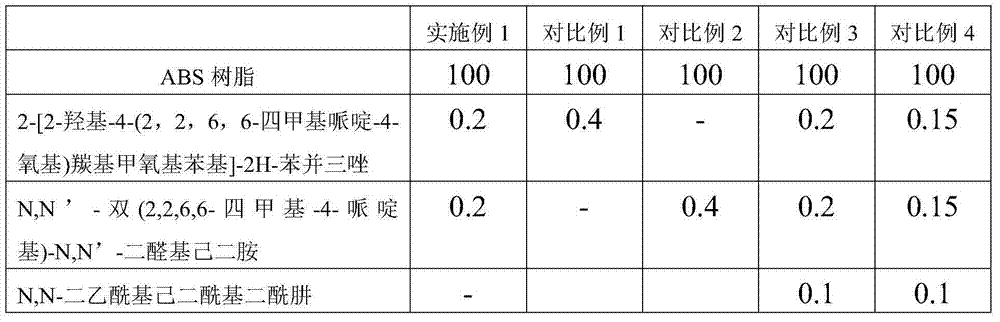

The invention discloses light aging resistant ABS (acrylonitrile butadiene styrene) plastic used for inside decorations of an automobile and a preparation method thereof. The light aging resistant ABS plastic used for the inside decorations of the automobile comprises the following components in part by weight: 100 parts of ABS resin and 0.2-0.8 part of composite light stabilizer, wherein the composite light stabilizer comprises the components in part by weight as follows: 30-50 parts of C23H27N4O3, 20-40 parts of C26H50N4O2 and 5-15 parts of C10H10N4O4. The light aging resistant ABS plastic has better light aging resistance and comprehensive performance, is simple in preparation process and low in cost, can be easily processed into parts with various shapes by adopting the injection molding process, and is particularly and suitably molded into various inside decorations of the automobile.

Owner:常州市信合久复合材料科技有限公司

PET fiber microfiber fabric and manufacturing process thereof

The invention relates to a PET fiber microfiber fabric and a manufacturing process thereof, and belongs to the technical field of fabric manufacture. The PET fiber microfiber fabric comprises, from top to bottom in sequence, upper mesh cloth, PET fiber ultrafine short-fiber non-woven fabric, and lower mesh cloth, wherein both the upper and lower mesh cloth are made from high-strength FDY filaments with 2000-4000 twists and 75-100 D / 48 F, and the PET fiber ultrafine short-fiber non-woven fabric is made from PET fiber ultrafine short fibers with the filament number being 0.15-0.25 dtex. The PET fiber microfiber fabric has skin feeling and downy feeling close to the real skin, and the manufacturing process is short in whole process, low in energy consumption and high in production efficiency.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Polypropylene material and preparation method thereof

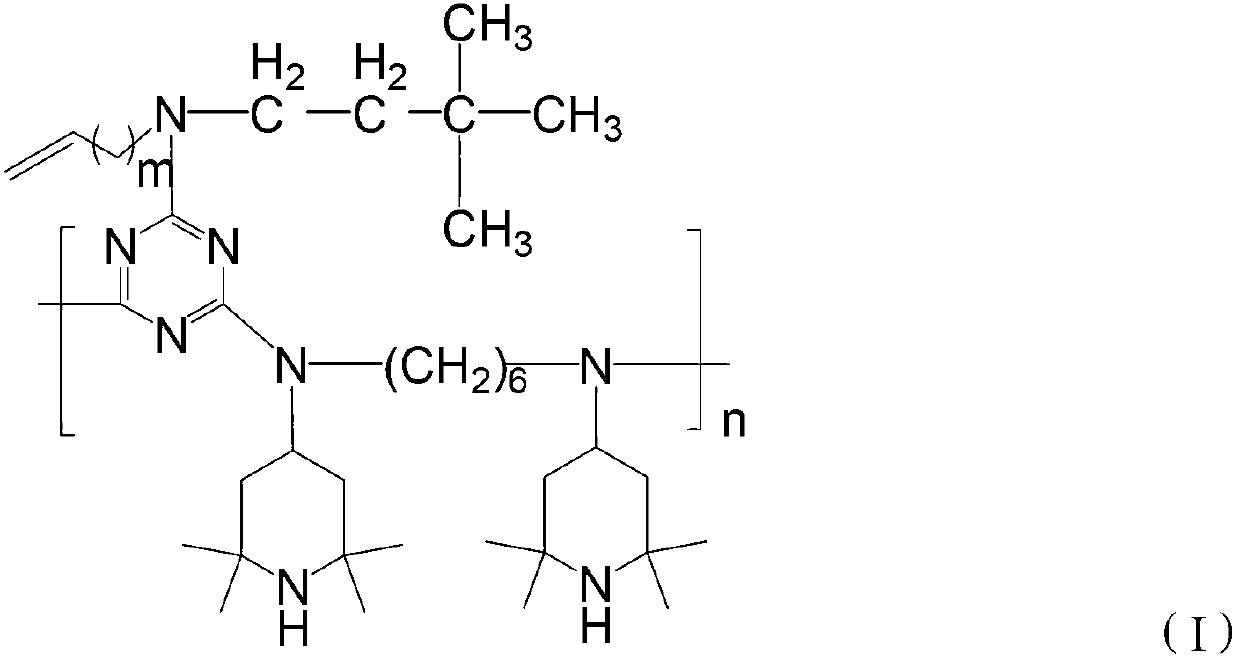

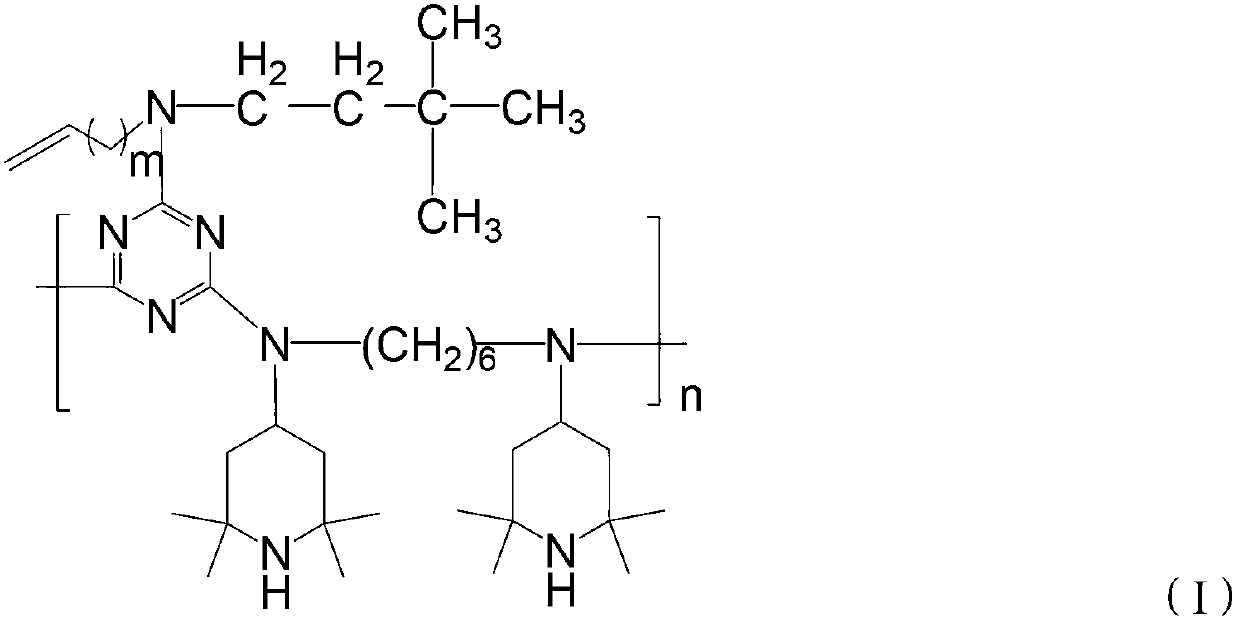

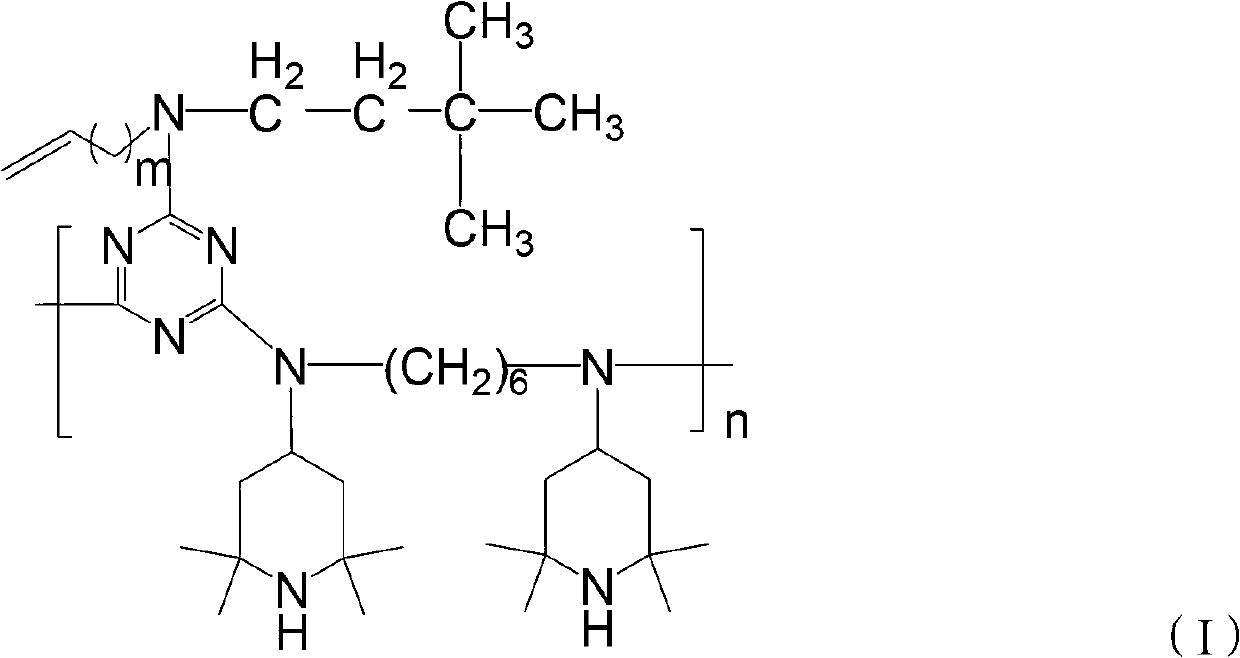

The invention provides a polypropylene material and a preparation method for the polypropylene material. The polypropylene material is prepared in parts in weight: mixing 100 parts of polypropylene resin, 30-80 parts of flexibilizer, 2-4 parts of ethylene based multifunctional group monomer, 1.5-2.5 parts of hindered amine compound of a structure in a formula (I) and 0.15-0.25 parts of antioxygen, extruding, prilling and irradiating. Compared with a modified mode of mixing a light stabilizer and the polypropylene material in the prior art, the polypropylene material uses a modified mode that the hindered amine compound of the structure in the formula (I) serves as the light stabilizer to be mixed with the polypropylene material for irradiation. Firstly, the hindered amine compound contains end alkenyl groups with an unsaturated bond, and the hindered amine compound can be grafted on a macromolecule chain, so that the light stabilizer is not easy to move to a surface of the material; and secondly, modification is carried out by using irradiation, so that the material can form a three-dimensional space grid structure through crosslinking to limit movement of a molecular chain at the high temperature so as to improve heat-resistant property of the material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

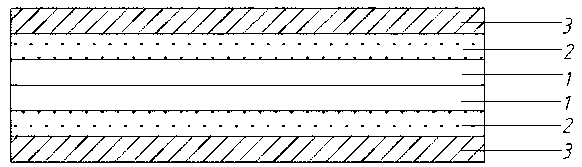

Film coated metal plate with high corrosion resistance, and manufacturing process thereof

InactiveCN109263204ACorrosion resistanceImpact resistantRoof covering using slabs/sheetsConstruction materialSurface layerHigh volume manufacturing

The invention discloses a film coated metal plate with high corrosion resistance, and a manufacturing process thereof. The film coated metal plate comprises a first corrosion-resistant film layer, a first adhesive layer, a base plate layer, a second adhesive layer and a second corrosion-resistant film layer, wherein the first corrosion-resistant film layer, the first adhesive layer, the base platelayer, the second adhesive layer and the second corrosion-resistant film layer are sequentially arranged from top to bottom, the first corrosion-resistant film layer and the second corrosion-resistant film layer respectively comprise a surface layer, a function layer and an adhesion layer, and the surface layer, the function layer and the adhesion layer are sequentially arranged from top to bottom. The manufacturing process comprises: (1) unwinding; (2) adhesive adding; (3) drying; (4) compounding; and (5) winding. According to the present invention, the film coated metal plate has advantagesof impact resistance, hot water resistance, salt spray resistance, wear resistance, stain resistance, corrosion resistance, light aging resistance, acid resistance, alkali resistance, oil resistance,good flexibility and corrosion resistance, such that the film coated metal plate has long service life; and the process method is simple, and is suitable for mass production.

Owner:ZHEJIANG GREEN NEW MATERIALS

High-thermal-conductivity cured coating for aluminum-magnesium alloy back plate of LED lamp and preparation method thereof

InactiveCN111647297AImprove cooling effectGuaranteed cooling effectLighting heating/cooling arrangementsCoatingsCoated surfaceFiber

The invention discloses a high-thermal-conductivity cured coating for an aluminum-magnesium alloy back plate of an LED lamp and a preparation method thereof and belongs to the field of coatings for luminescent materials. The heat conduction monomers can be doped in the coating in a large range to improve the heat dissipation effect of the coating; heat collection microspheres are embedded in the surface of the coating; meanwhile, special dispersed heat-conducting carbon fibers are directionally connected by utilizing a magnetic attraction effect; on one hand, the coating is assisted in efficient heat dissipation; the heat exchange area with the external environment is enlarged; on the other hand, the effect of accumulating heat can be achieved in a high-heat state; accumulated heat causedby insufficient heat dissipation is temporarily guided and stored in the heat collection microspheres; the heat storage capacity of the coating is utilized to make up for insufficient heat dissipationof the coating, the contact surface of the coating and the back plate is kept at a lower temperature all the time, and the heat dissipation time difference is creatively utilized to greatly improve the heat dissipation efficiency of the whole coating on the back plate, so that the heat dissipation effect of the LED lamp is effectively guaranteed.

Owner:东莞市全印铼实业有限公司

Preparation method of epoxy resin cyanate ester resin composite material

The invention relates to the field of a macromolecular material, in particular to a preparation method of an epoxy resin cyanate ester resin composite material. The preparation method comprises the following steps: stirring 80 to 150 parts by weight of epoxy resin and 1 to 30 parts by weight of a toughening agent at 50 to 200 DEG C, dissolving and dispersing uniformly, cooling to 70 to 150 DEG C,adding 0.1 to 10 parts by weight of an antioxidant and 0.1 to 20 parts by weight of an ultraviolet absorbent, dissolving and dispersing uniformly, cooling to 70 to 150 DEG C, adding 1 to 50 parts by weight of cyanate ester resin and 0.1 to 10 parts by weight of a coupling agent, dispersing uniformly to obtain a resin composition, performing coating process and fiber composite process on the resincomposition, and curing to obtain the epoxy resin cyanate ester resin composite material.

Owner:WEIHAI GUANGWEI COMPOSITES

High weathering resin tile and manufacturing process thereof

InactiveCN109291582AImprove flame retardant performanceGood weather resistanceSynthetic resin layered productsMacromolecular adhesive additivesMasterbatchSurface layer

The invention discloses a high weather resistant resin tile and a manufacturing process thereof. The high weathering resin tile comprises a surface layer, a bonding layer and a substrate. The surfacelayer is composed of the following components in parts by weight: PVDF, modified PMMA resin, an ultraviolet absorbent, mineral pigment or color masterbatch, an auxiliary agent A, and other fluorine materials. The bonding layer consists of the following components by weight: the modified PMMA, the PVDF, and the mineral pigment or color masterbatch. The substrate consists of the following componentsby weight: PVC SG-5, modified PMMA, an auxiliary agent B, and mineral pigment or color masterbatch. The high weathering resin tile of the invention can resist acid-base solution with pH of 1-14, hashigh flame retardancy, good weather resistance, excellent weather resistance, light aging resistance, strong chemical resistance and strong solvent resistance, is widely used in outdoor buildings, andhas life span of 20 years or above; and the manufacturing process is simple in process, low in cost and easy for mass production.

Owner:ZHEJIANG GREEN NEW MATERIALS

Dendritic high-temperature-resistant polyurethane resin prepolymer and preparation method thereof

InactiveCN104650312AUnique high temperature resistanceImprove high temperature resistancePolymer scienceSolid content

The invention discloses a dendritic high-temperature-resistant polyurethane resin prepolymer and a preparation method thereof. The preparation method is characterized by comprising the following steps: dissolving isocyanate in a first solvent, dropping a mixture of a dendritic molecular polymer and a second solvent at a weight ratio of 1:1, reacting at 20-60 DEG C for 1-5 h after dropping, and adjusting the solid content to be 50% by using a third solvent so as to prepare the dendritic polyurethane resin prepolymer, the NCO content of which is 1-7.5%. Because the dendritic high-temperature-resistant polyurethane resin prepolymer prepared by the invention has a dendritic three-dimensional spherical structure, the temperature tolerance of a prepared polyurethane product is greatly increased; and the dendritic high-temperature-resistant polyurethane resin prepolymer can be widely applied in the field of packaging of high-temperature-resistant synthetic leathers, coatings and electronics, and has important significance for promoting technological innovation of novel polyurethane materials.

Owner:烟台万华合成革集团华海聚氨酯有限公司 +1

PVC release film

The invention provides a PVC release film. The PVC release film comprises a thin film layer which comprises the following raw materials by weight: PVC, TPX, PP, 2-ethyl methacrylate, nano-barium sulfate, polyether imide, phenolic resin, polyarylester, carbon fiber, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a light stabilizer, a defoamer and a thickener. The PVC release film has a smooth and clean surface and good peel strength and tensile strength; secondly, the PVC release film has good heat stability and heat shrinkage rate, is capable of resisting light aging and can be repeatedly used; and the PVC release film has relatively balanced comprehensive performance and extremely good water resistance, solvent resistance, chemical resistance, corrosion resistance, temperature resistance, weather resistance and adhesiveness. Besides, the PVC release film provided by the invention is environmentally friendly and nontoxic, a synthetic method is simple, the operation is simple and convenient, conditions are mild, and the synthetic method is applicable to industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

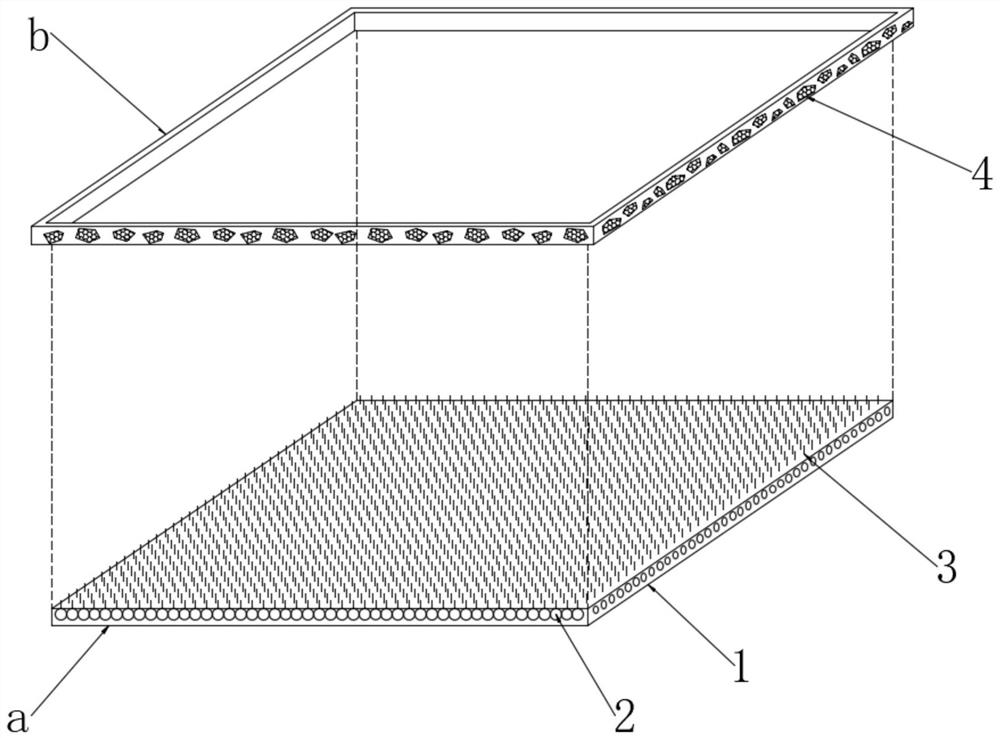

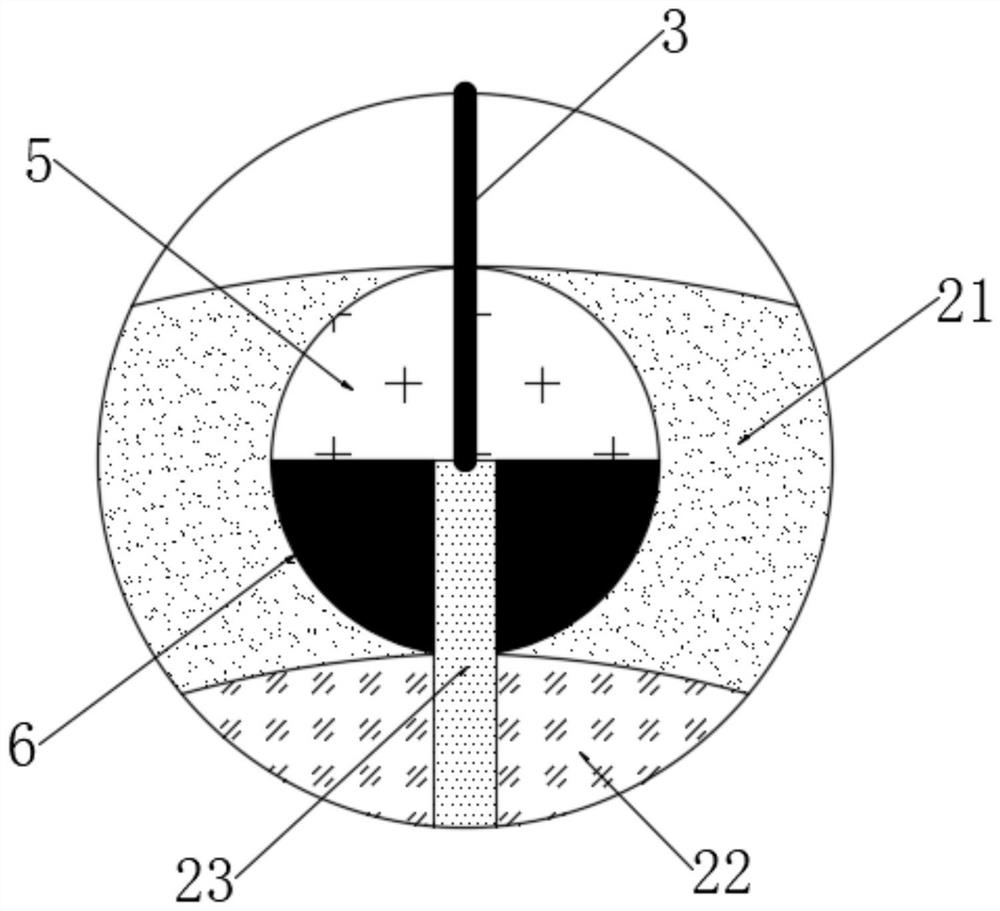

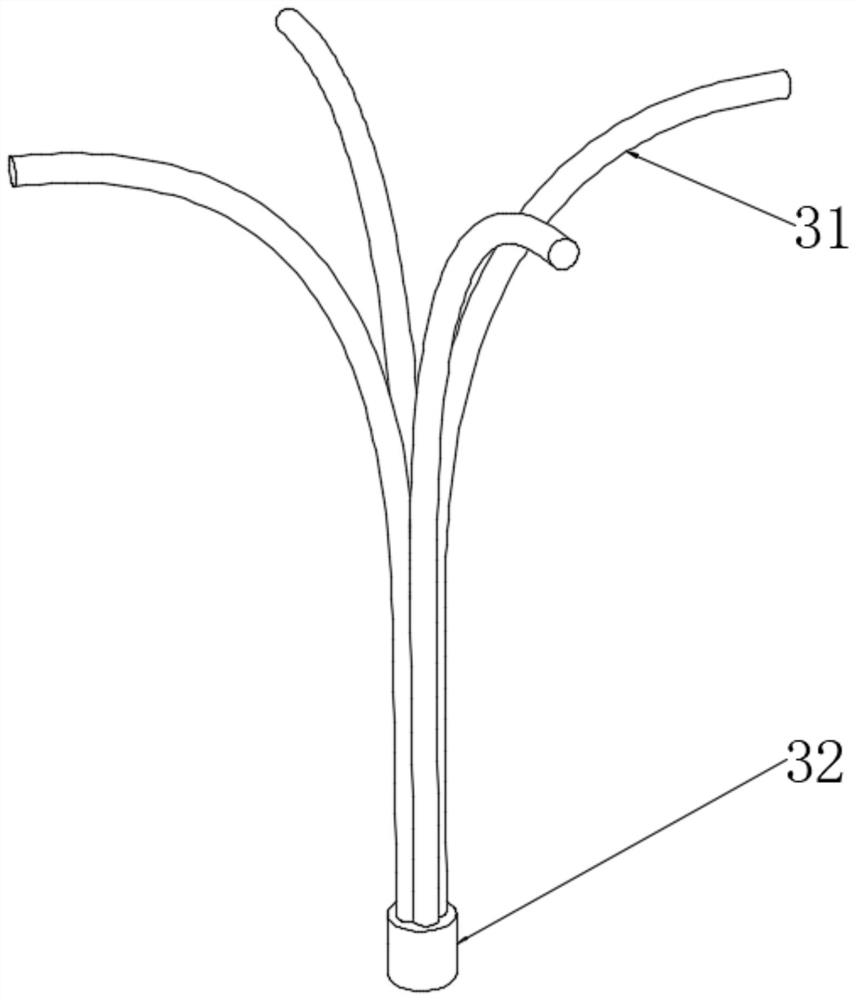

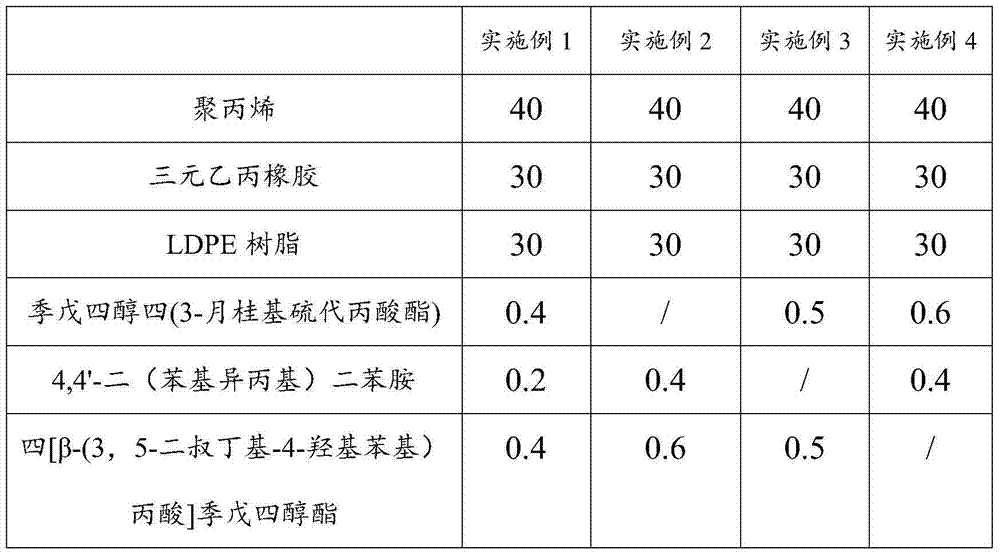

Plastic for automobile inner ornaments and preparation method thereof

ActiveCN103937112AImprove anti-yellowing effectGood light aging resistanceLow-density polyethyleneEthylene-propylene-diene-monomer

The invention discloses a plastic for automobile inner ornaments and a preparation method thereof. The plastic for automobile inner ornaments comprises the following components in parts by weight: 30-50 parts of polypropylene, 20-40 parts of ethylene propylene diene monomer, 20-40 parts of LDPE (low-density polyethylene) resin and 0.5-1.5 parts of anti-yellowing agent. The preparation method comprises the following steps: proportionally weighing the raw materials, uniformly mixing, melting and compounding, and extruding and granulating. The plastic for automobile inner ornaments has favorable light aging resistance, and can be made into cockpit outer lateral side plates, small covers, lateral side plate inner plates, inner lateral side plate plastic parts, passenger seat outer lateral side plates, door plate armrest frameworks, door insertion plate frameworks, door insertion plates and other automobile inner ornaments by an injection molding technique.

Owner:SHANDONG HANSHI AUTOMOTIVE COMPONENTS

TPX (methyl pentene copolymer) release film

The invention provides a TPX (methyl pentene copolymer) release film. The TPX release film comprises a thin film layer; the thin film layer is prepared from the following raw materials in parts by weight: TPX, PC (Polycarbonate), 2-ethyl methacrylate, polyurethane, polyimide, polyetheretherketone fibers, carbon fibers, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a light stabilizer, a de-foaming agent and a thickener; the TPX release film has a flat and smooth surface and has good peeling strength and tensile strength; secondly, the TPX release film has good thermal stability and thermal shrinkage rate, can resist light aging and can be repeatedly used for a plurality of times; furthermore, the TPX release film provided by the invention is environment-friendly and has no toxin; a synthesis method is simple, is simple and convenient to operate, has moderate conditions and is suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

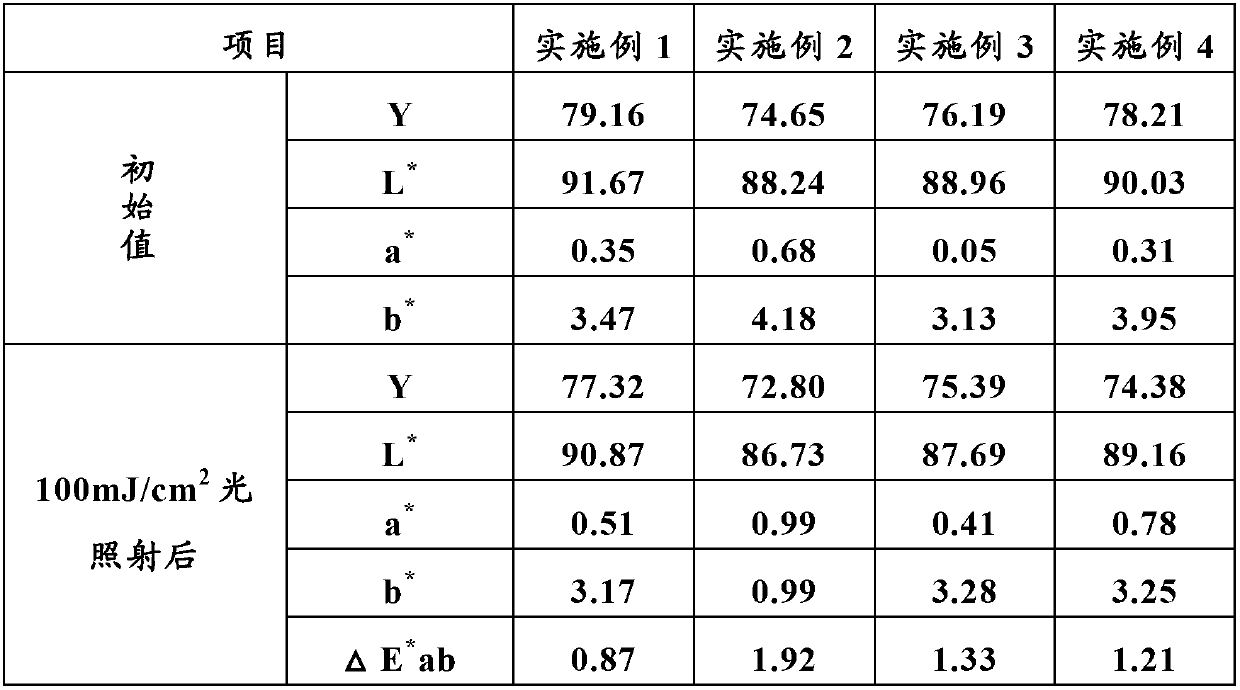

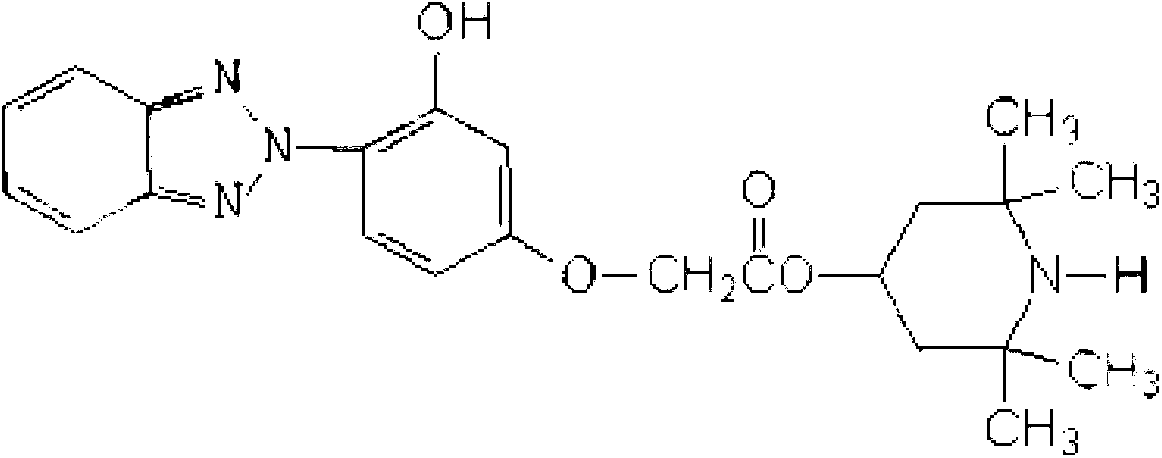

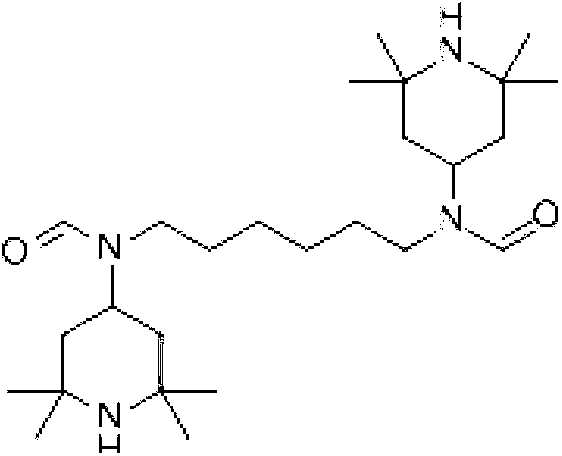

Illumination aging-resistant ABS plastic and preparation method thereof

The invention discloses an illumination aging-resistant ABS plastic and a preparation method thereof. The illumination aging-resistant ABS plastic is prepared from the following components in parts by weight: 100 parts of ABS resin and 0.3-0.5 part of composite light stabilizer; and the composite light stabilizer is prepared from the following components in parts by weight: 40-60 parts of 2-[2-hydroxy-4-(2,2,6,6-tetramethylpiperidine)-4-oxy]carbonylmethoxyphenyl]-2H-benzotriazole and 40-60 parts of N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-N,N'-dialdehyde hexamethylenediamine. The illumination aging-resistant ABS plastic is excellent in illumination aging resistance, and the preparation process is simple, the product cost is low, and the comprehensive properties of the product are excellent. The illumination aging-resistant ABS plastic can be easily processed into parts in various shapes by use of an injection molding process, and especially can be molded into various automobile interior trim parts.

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

Special filler for ultraviolet-resistant capacitor films and preparation method thereof

The invention relates to a special filler for ultraviolet-resistant capacitor films, which is prepared from the following raw materials in parts by weight: 4-6 parts of calcium hydroxide, 3-5 parts of magnesium oxide, 0.4-0.7 part of palm wax, 1-2 parts of aluminum dihydrogen phosphate, 0.1-0.2 part of sodium dodecyl benzene sulfonate, 0.2-0.4 part of stearic acid, 6-8 parts of titanium dioxide, 2-3 parts of silicon dioxide, 0.3-0.4 part of aluminum isopropoxide, 60-65 parts of clay, a right amount of 4-6% hydrochloric acid, a right amount of water and 15-20 parts of assistant. The titanium dioxide and silicon dioxide added to the filler can enhance the ultraviolet resistance of the film, so that the filler has favorable reinforcing action and can greatly enhance the light aging resistance, tearing strength and impact strength of the polypropylene film; by using the clay, the cost is lowered; and the assistant can enhance the dispersity and reinforcing performance of the filler and also enhance the strength and impact resistance of the film.

Owner:ANHUI JIANGWEI PRECISION IND

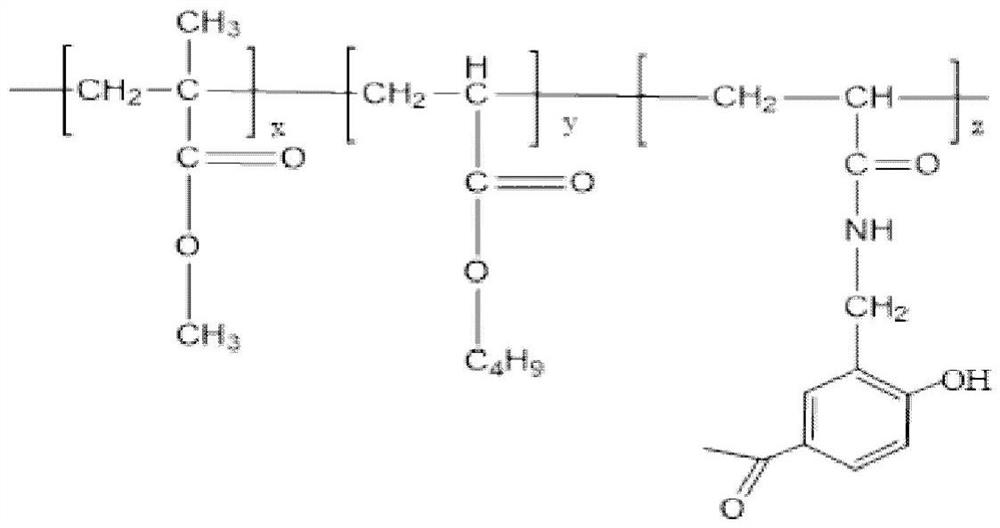

Polymerized ultraviolet absorbent, acrylic resin, and preparation method of modified epoxy coating

PendingCN111646918ASimple preparation processGood light aging resistanceOrganic compound preparationCarboxylic acid amides preparationUv absorbanceOrganosolv

The invention provides a polymerization type ultraviolet absorbent. A preparation method comprises the following steps: mixing 4-hydroxybenzophenone, N-hydroxymethyl acrylamide and an organic solventand carrying out a constant-temperature water bath reaction; and performing column chromatography purification to obtain the polymerized ultraviolet absorbent. The polymerized ultraviolet absorbent comprises 3-acrylamidemethyl-4-hydroxybenzophenone with a carbon-carbon double bond functional group. The preparation process is simple, and the ultraviolet absorbent can be used for graft polymerization; in addition, the invention further provides application of the polymerization type ultraviolet absorbent to synthesis of acrylic resin through a chemical grafting method, and relates to a modifiedepoxy coating which is obtained by compounding improved high-weather-resistance acrylic resin and epoxy resin according to a certain proportion and has corrosion resistance and aging resistance.

Owner:QINGDAO AIR NEW MATERIALS

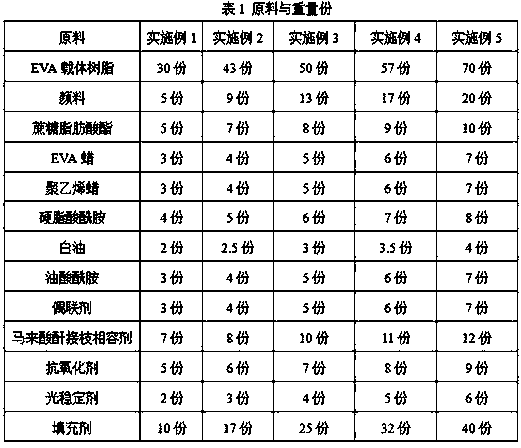

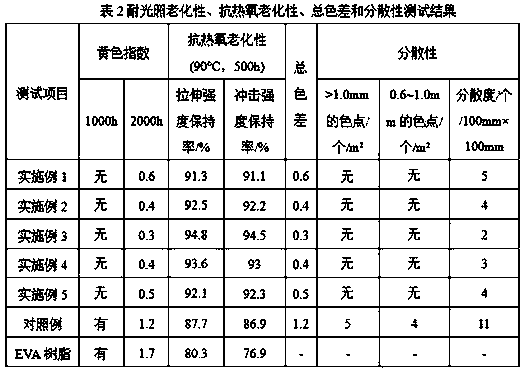

High dyeability EVA color master batch special for shoes and preparation method thereof

The invention provides a high dyeability EVA color master batch special for shoes. The high dyeability EVA color master batch comprises, by weight, 30-70 parts of an EVA carrier resin, 5-20 parts of apigment, 5-10 parts of sucrose fatty acid ester, 3-7 parts of EVA wax, 3-7 parts of polyethylene wax, 4-8 parts of octadecanamide, 2-4 parts of white oil, 3-7 parts of oleamide, 3-7 parts of a coupling agent, 7-12 parts of a maleic anhydride graft compatilizer, 5-9 parts of an antioxidant, 2-6 parts of a light stabilizer and 10-40 parts of a filler. The high dyeability EVA color master batch special for shoes is prepared from the above raw materials through processes, has the advantages of no flow pattern, no color point, small color difference, good light aging resistance, strong resistanceto thermo-oxidative aging and good dispersibility and solves the existing EVA master batch problems of uneven color and large color difference in coloring.

Owner:JINJIANG XINBANG NEW MATERIAL TECH

High-temperature-resistant adhesion-resistant release film

The invention provides a high-temperature-resistant adhesion-resistant release film which comprises a thin film layer. The thin film layer comprises the following raw materials in parts by weight: TPX, PP (polypropylene), ethyl 2-methacrylate, polyurethane, polyarylester, glass fibers, carbon fibers, organic montmorillonite, ethanediol, a silane coupling agent, an antioxidant, a light stabilizer, a defoaming agent and a thickener. The high-temperature-resistant adhesion-resistant release film has the advantages of smooth surface, favorable peel strength, favorable tensile strength, favorable filling property and favorable separability. The high-temperature-resistant adhesion-resistant release film has favorable temperature resistance and heat shrinkage rate, can resist photoaging, and can be used repeatedly. Besides, the high-temperature-resistant adhesion-resistant release film provided by the invention is environment-friendly and nontoxic. The synthesis method is simple, is convenient to operate and mild in conditions, and is suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Photodiffusion release film

The invention provides a photodiffusion release film. The photodiffusion release film comprises a film layer, wherein the film layer contains the following raw materials in parts by weight: TPX, PC, PFA, PBT, nano barium sulfate, nano-silica, polyetherimide, phenol-formaldehyde resin, polyurethane, polyimide, 2-ethyl methacrylate, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a photostabilizer, an antifoamer and a thickener. The photodiffusion release film has an excellent optical diffusion effect and has good peeling strength and tensile strength; secondly, the photodiffusion release film is flat and smooth in surface, has good thermal stability and thermal shrinkage ratio, can resist photoaging and can be reused repeatedly; in addition, the photodiffusion release film provided by the invention is environmentally friendly and non-toxic, the synthesis method is simple, is simple and convenient in operation and moderate in condition and is applicable to industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Environment-friendly and flame retardant elastic ground paving material and preparation method thereof

The invention discloses an environment-friendly and flame retardant elastic ground paving material. The paving material comprises the following raw materials by weight: 70-90 parts of ABS resin, 10-14 parts of a compound flame retardant, 2-4 parts of organobentonite, 5-7 parts of white carbon black, 8-10 parts of fiber filler, 4-6 parts of a coupling agent, 2-4 parts of a lubricant, 7-9 parts of a processing aid, 1-3 parts of wollastonite, and 5-9 parts of a weather-proof anti-aging agent. The ground paving material provided by the invention has good impact resistance, aging resistance and flame retardant properties, strong anti-wear ability, and excellent compression resilience, and additionally has anti-static and fouling resistant properties. Also the preparation method provided by the invention has the advantages of safe and reliable raw materials, no harm to the environment and easily available raw materials, low cost, concise process, easy operation and realization of industrial production, and has high practical value and good application prospect.

Owner:滁州恒盛农业科技有限公司

PET (polyester) release film

The invention provides a PET release film, comprising a film layer, and the film layer includes the following raw materials by weight: PET, PC, 2-ethyl methacrylate, polyurethane, polyimide, natural latex, stearic acid Calcium, ethylene glycol, silane coupling agent, antioxidant, light stabilizer, defoamer and thickener; the PET release film has a smooth surface and good peel strength and tensile strength; The PET release film described has good thermal stability and thermal shrinkage rate, is resistant to light aging and can be used repeatedly; in addition, the PET release film provided by the present invention is environmentally friendly and non-toxic, has a simple synthesis method, and is easy to operate. The conditions are mild and suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

A preparing method of a cyanate resin composite

The invention relates to the field of polymer materials and particularly relates to a preparing method of a cyanate resin composite. The method is characterized by comprising steps of stirring 50-100 parts by weight of cyanate resin and 1-30 parts by weight of a flexibilizer at 50-200 DEG C, after uniform melting and dispersion, cooling the mixture to 70-150 DGE C, adding 0.1-10 parts of an antioxidant and 0.1-20 parts of an ultraviolet absorber, cooling the mixture to 70-150 DGE C after uniform melting and dispersion, then adding 0.1-10 parts of a coupling agent and 0.1-10 parts of a thixotropic agent, fully dispersing the mixture to obtain a cyanate resin composition resistant to illumination aging, and subjecting the resin composition to a coating step, a fiber compositing step and curing to obtain the composite resistant to illumination aging. The prepared composite has better illumination aging resistance and good manufacturability, and can be subjected to film coating and composite processes to prepare prepregs. A preparing process is simple and the production cost is low.

Owner:WEIHAI GUANGWEI COMPOSITES

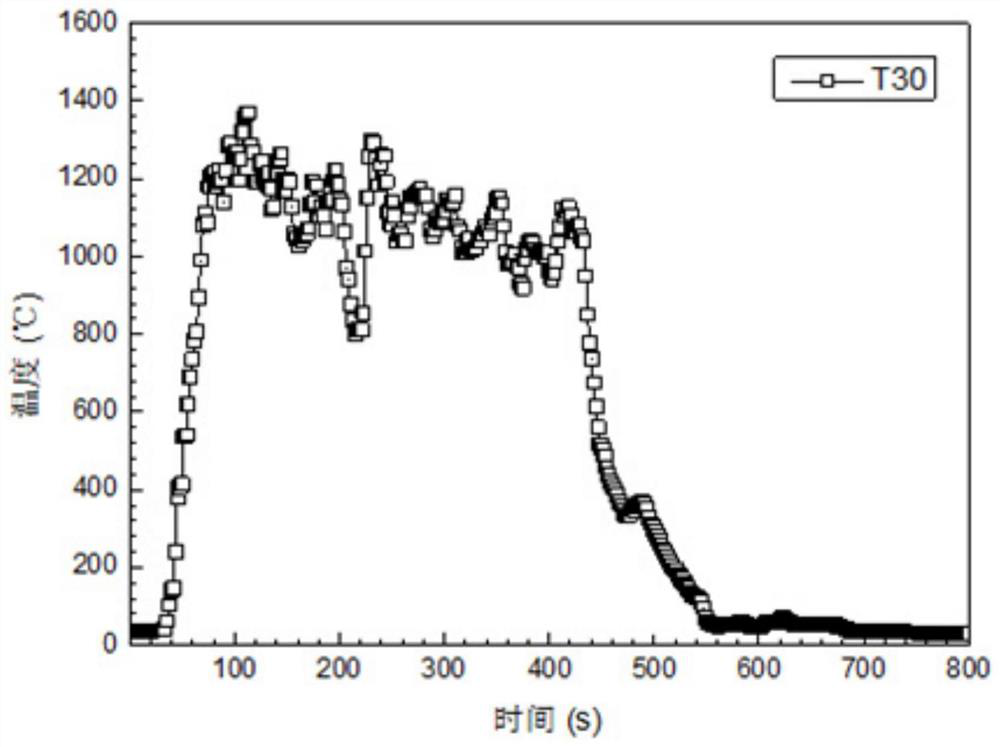

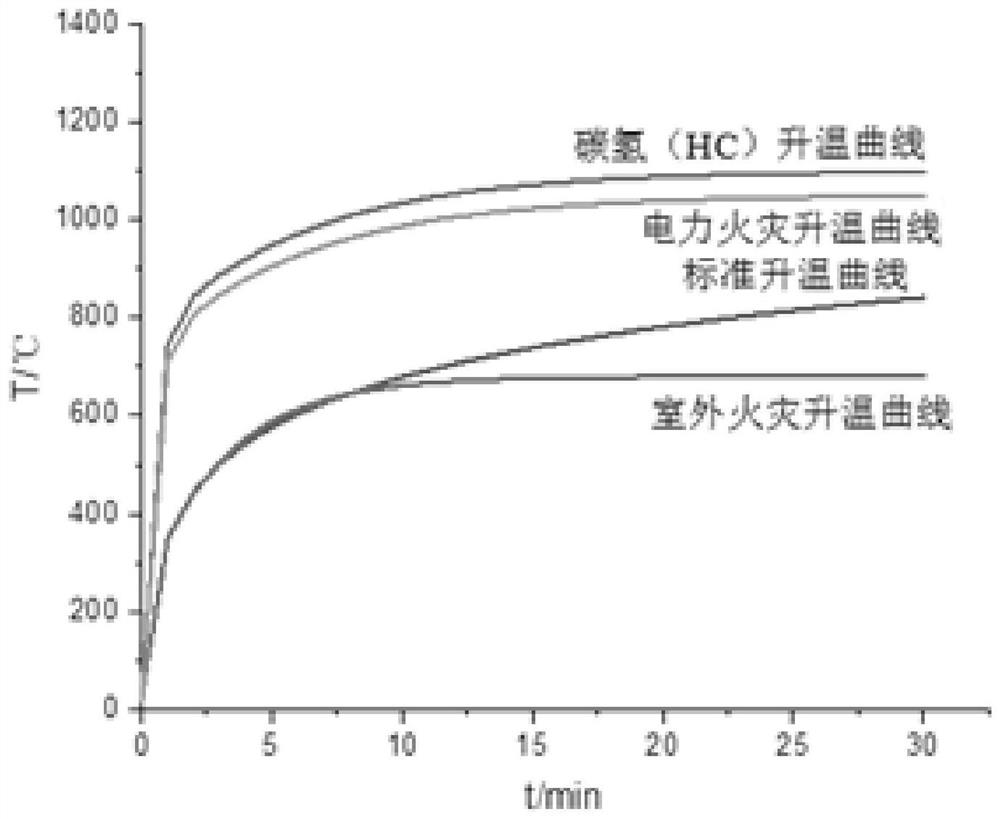

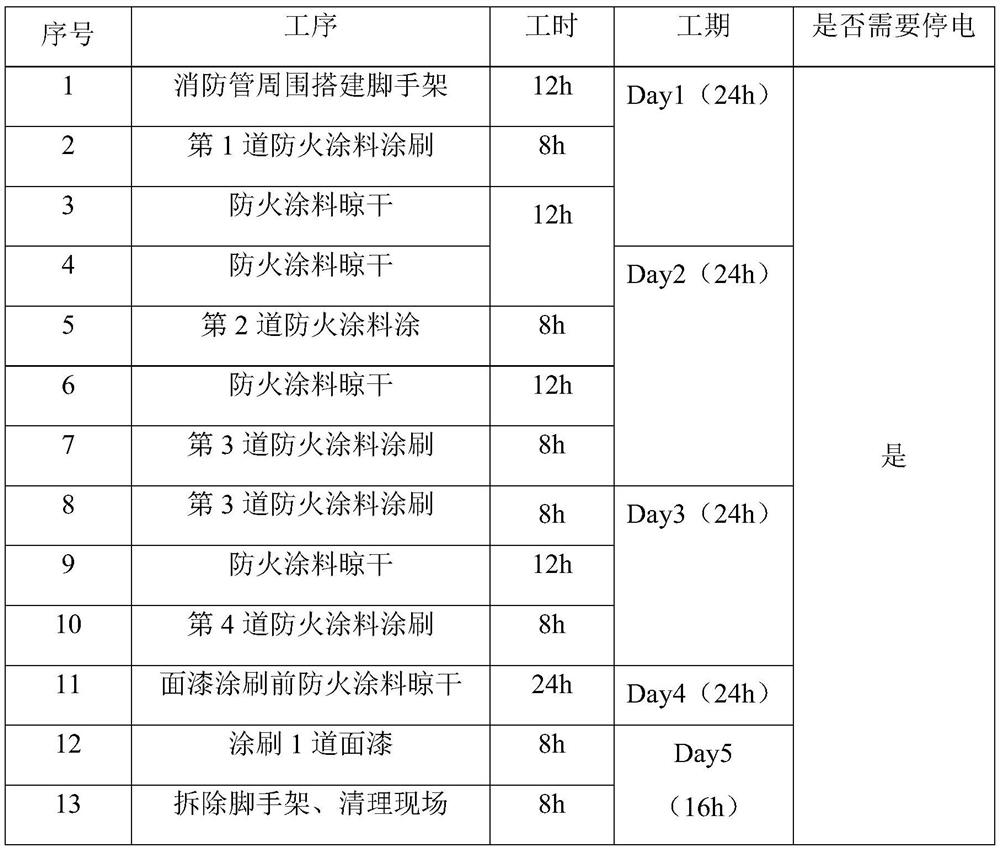

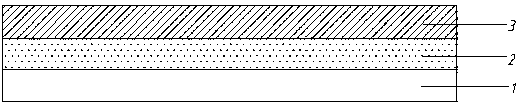

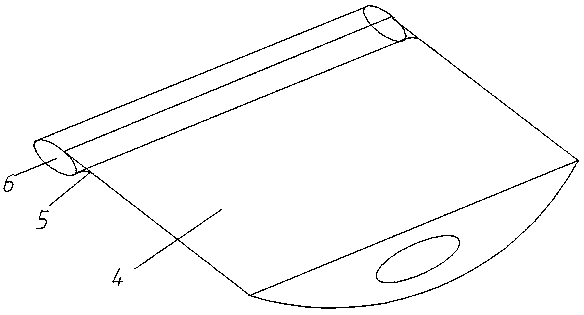

Anti-aging polyurethane flame-retardant paint for electric fire-fighting equipment as well as preparation method and application of anti-aging polyurethane flame-retardant paint

PendingCN114686095AReduce consumptionImprove availabilityFireproof paintsPolyurea/polyurethane coatingsPolymer scienceFoaming agent

The invention discloses anti-aging polyurethane flame-retardant paint for electric fire-fighting equipment, and relates to the technical field of fire prevention and flame retardance. The flame-retardant polyurethane composite material is prepared from the following raw materials in parts by weight: 100 parts of polyurethane resin, 20-100 parts of a flame retardant, 10-60 parts of a charring agent, 20-80 parts of a foaming agent, 0.05-5 parts of a wetting agent, 0.5-5 parts of a defoaming agent, 0.5-10 parts of a dispersing agent, 0.5-10 parts of an anti-settling agent, 1-70 parts of pigment and filler, 0.01-3 parts of a flatting agent, 1-100 parts of a diluent, 10-100 parts of a curing agent and 1-20 parts of a light stabilizer. The invention also provides a preparation method and application of the polyurethane flame-retardant paint. The light-aging-resistant polyurethane flame-retardant paint has the beneficial effects that the problems that polyurethane paint is extremely easy to burn and is easy to age by light are solved, and the light-aging-resistant polyurethane flame-retardant paint has the properties of high adhesive force, good water resistance, strong weather resistance and the like while solving the fireproof problem, and can meet the fireproof requirements of fire-fighting pipelines of power equipment.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

PVC leather and manufacturing method and application thereof

ActiveCN108998987ASmall smellHigh mechanical strengthRoad vehiclesTextiles and paperMolten stateSurface layer

The invention discloses PVC leather and a manufacturing method and application thereof. The PVC leather comprises base fabric layers, a foam layer and a surface layer from inside to outside. The surface layer has a melting temperature higher than the melting temperature of the foam layer. The foam layer in the molten state can penetrate the base fabric layer. When used to make a car curtain, the PVC leather bypasses a reel of the curtain. The foam layer is in the molten state and the surface layer is not molten in the high-frequency heat sealing. Under the pressure, the molten foam layer penetrates the base fabric layer and enters the gap between the two base fabric layers and the layers are molten into a whole without a binder so that the PVC leather is environmentally friendly and has good adhesion effects and mechanical strength.

Owner:四川金路高新材料有限公司

Heat-conducting weather-resistant anti-radiation protective film for display screen and preparation method of protective film

InactiveCN108285617AImprove radiation protection performanceGood weather resistanceEpoxyHeat conducting

The invention discloses a heat-conducting weather-resistant anti-radiation protective film for a display screen and a preparation method of the protective film. The protective film comprises, by weight, 20-30 parts of epoxy resin, 10-14 parts of polyurethane resin, 4-6 parts of modified silicon dioxide, 10-16 parts of methyl methacrylate, 10-12 parts of poly-ethyl silicate, 4-6 parts of ethyl acrylate, 8-10 parts of anti-radiation additives, 5-7 parts of nano additive, 10-16 parts of acid ester mixture, 4-6 parts of flame-retardant additive, 5-7 parts of processing aid and 2-3 parts of coupling agent. The protective film is excellent in mechanical property, glossiness, light transmittance and heat shrinkage performance, good in scratch resistance, uniform in heat dissipation, capable of preventing radiation and excellent in weather resistance, and has certain fireproof and flame-retardant performance. The preparation method is safe and reliable in raw material component, harmless to human bodies and environments, low in cost, simple in process, easy to operate, capable of achieving industrial production, high in practical value and good in application prospect, and the raw materials are easy to obtain.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Insulating release film

InactiveCN106147148AFlat surfaceImprove thermal stabilityPlastic/resin/waxes insulatorsEpoxyPolyester

The invention provides an insulating release film which comprises a thin film layer. The thin film layer is prepared from materials including PET (polyester), PC (propylene carbonate), OPP (o phenylphenol), PBT (polybutylece terephthalate), polyetherimide, phenolic resin, epoxy resin, polyurethane, polymide, talcum powder, 2-ethyl methacrylate, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxygen, a light stabilizer, a defoamer and a thickener. The insulating release film is good in insulating performance, peeling strength and tensile strength, smooth and clean in surface, good in heat stability and heat shrinkage, resistant to light aging and reusable; besides, the insulating release film is environment friendly and non-toxic, simple in synthetic method, convenient in operation, moderate in condition and suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com