High-thermal-conductivity cured coating for aluminum-magnesium alloy back plate of LED lamp and preparation method thereof

A technology of aluminum-magnesium alloy and LED lights, which is applied in coatings, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve problems such as burnout, easy failure, and heat resistance, so as to ensure heat dissipation and improve heat dissipation Efficiency and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

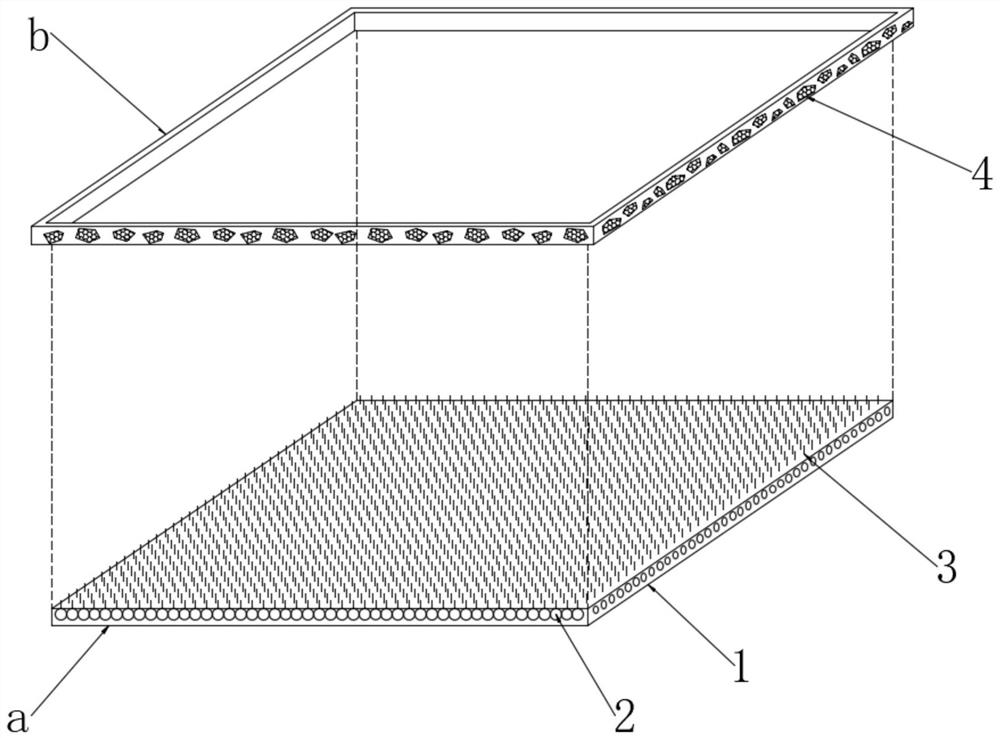

[0044] see figure 1 , a high thermal conductivity cured coating for an aluminum-magnesium alloy backplane of an LED lamp and a preparation method thereof, comprising a varnish component, a color ink component and a heat dissipation component, the varnish component comprising 15 parts of acrylate, 5 parts of grease, and 10 parts of urea-formaldehyde resin 5 parts, 5 parts of silicon alkyd resin and 1 part of nano-titanium dioxide, the color ink components include 0.2 parts of dispersant, 0.1 parts of leveling agent and 3 parts of carbon powder, and the heat dissipation components include 8 parts of heat-conducting monomer, 25 parts of heat-collecting microspheres and 32 parts of thermally conductive carbon fiber.

[0045] The dispersant in the color ink composition is an ionic dispersant or a polymer dispersant, and the leveling agent is a silicone leveling agent, an acrylic leveling agent or a fluorocarbon leveling agent.

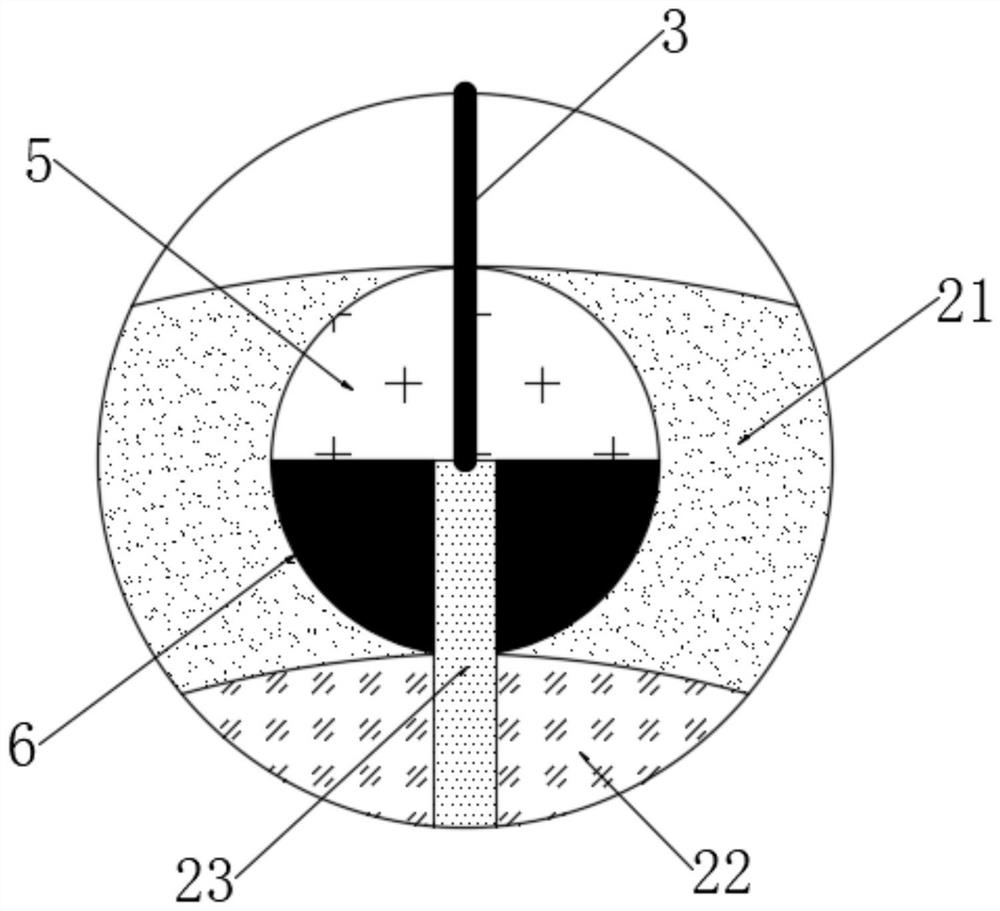

[0046] The thermal conductor in the heat dissipation...

Embodiment 2

[0059] see figure 1 , a high thermal conductivity cured coating for an aluminum-magnesium alloy backplane of an LED lamp and a preparation method thereof, comprising a varnish component, a color ink component and a heat dissipation component, and the varnish component includes 18 parts of acrylate, 6 parts of grease, and 12 parts of urea-formaldehyde resin 6 parts, 6 parts of silicon alkyd resin and 3 parts of nano-titanium dioxide. The color ink components include 0.6 parts of dispersant, 0.3 parts of leveling agent and 4 parts of carbon powder. The heat dissipation components include 10 parts of heat conducting monomer, 28 parts of heat collecting microspheres and 33 parts of thermally conductive carbon fiber.

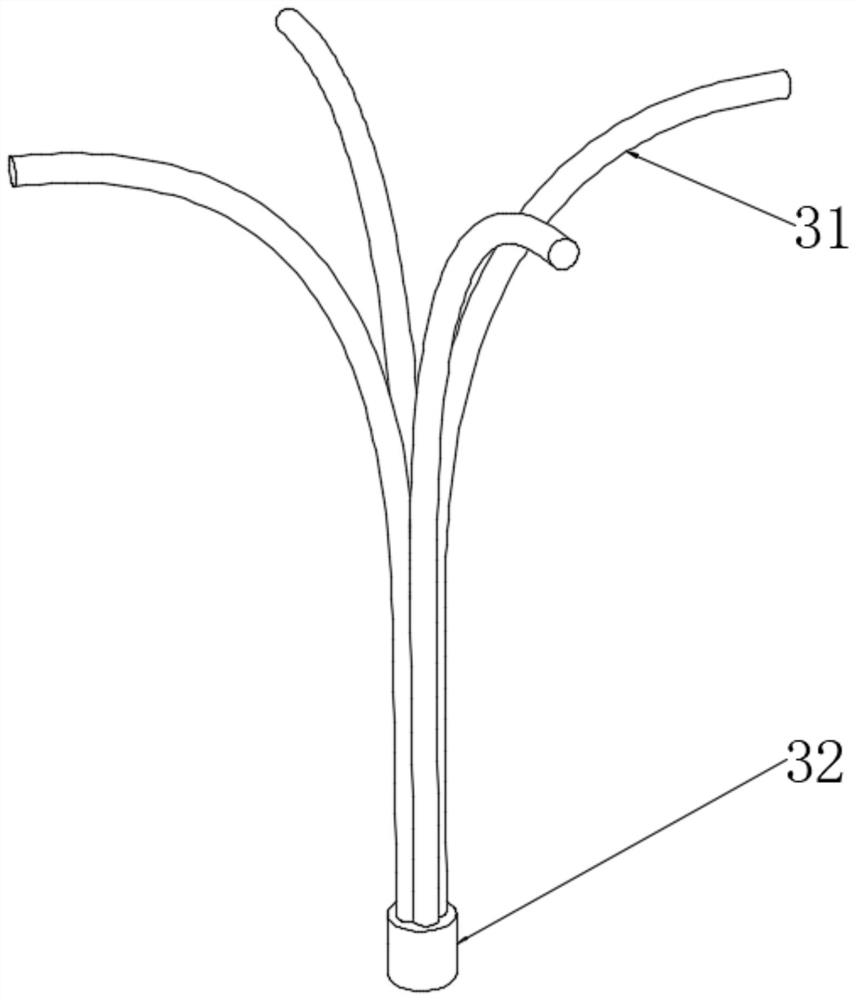

[0060] see Figure 5 A method for preparing a high thermal conductivity cured coating for an aluminum-magnesium alloy backplane of an LED lamp, comprising the following steps:

[0061] S1. Raw material preparation: prepare the corresponding varnish components, colo...

Embodiment 3

[0068] see figure 1 , a high thermal conductivity cured coating for an aluminum-magnesium alloy backplane of an LED lamp and a preparation method thereof, comprising a varnish component, a color ink component and a heat dissipation component, the varnish component including 20 parts of acrylate, 7 parts of grease, and 15 parts of urea-formaldehyde resin 1 part, 8 parts of silicon alkyd resin and 5 parts of nano-titanium dioxide, the color ink components include 1 part of dispersant, 0.5 parts of leveling agent and 5 parts of carbon powder, and the heat dissipation components include 12 parts of heat-conducting monomer, 210 parts of heat-collecting microspheres and 34 parts of thermally conductive carbon fiber.

[0069] see Figure 5 A method for preparing a high thermal conductivity cured coating for an aluminum-magnesium alloy backplane of an LED lamp, comprising the following steps:

[0070] S1. Raw material preparation: prepare the corresponding varnish components, color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com